Preparation method of pollution-free high-whiteness palm silk paper pulp and application of paper pulp in paper product

A technology with high whiteness and palm silk, which is applied in pulp beating/refining methods, pulp bleaching, washing/replacing pulp treatment liquid, etc., can solve the problems of non-chlorine-free bleaching, increase farmers' income, and solve fiber problems. The effect of resource shortage and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described in detail below through specific examples. It should be noted that this embodiment is illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0069] A kind of preparation method of pollution-free high brightness palm fiber pulp, the steps are:

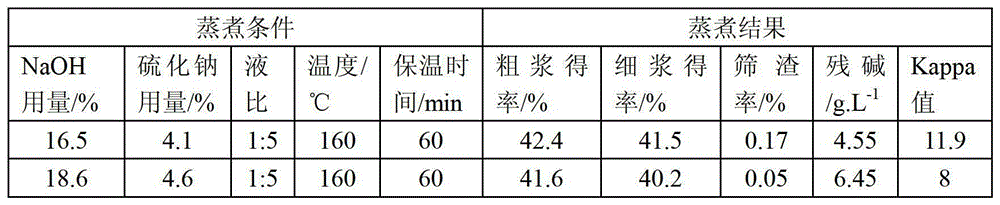

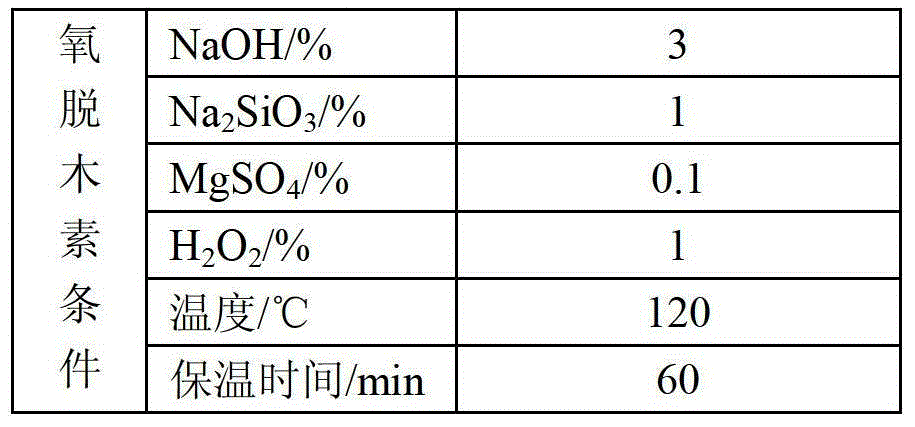

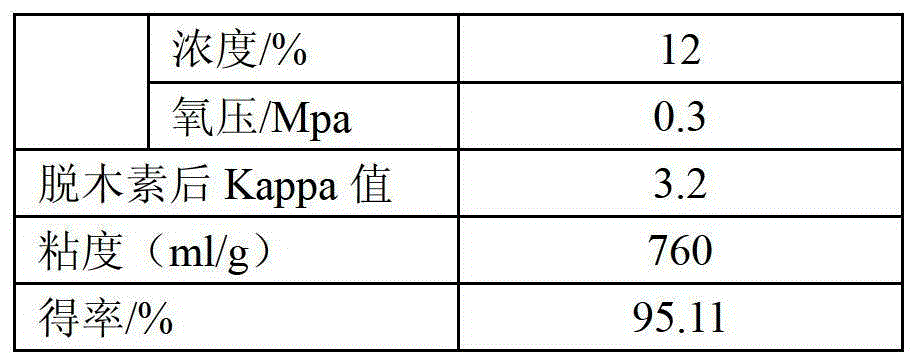

[0070] (1) Remove dust, debris and impurities in the laboratory, put the palm silk into an electric heating rotary cooking pot with a volume of 15 liters, and cook according to the process conditions in Table 1 by using the sulfate method of caustic soda and sodium sulfide.

[0071] ⑵ After cooking, squeeze out the black liquor, analyze and measure the residual alkali in the black liquor and the physical and chemical properties of the black liquor. Wash the pulp after cooking, and measure the brown stock yield.

[0072] The pulp was screened with a laboratory flat screen (screen slot 0.25 mm), and the fine pulp yield, reject rate and pulp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com