Multistage double effect distillation seawater desalination technology with heating seawater by solar energy

A solar energy, heating technology, applied in seawater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as large fuel consumption or power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

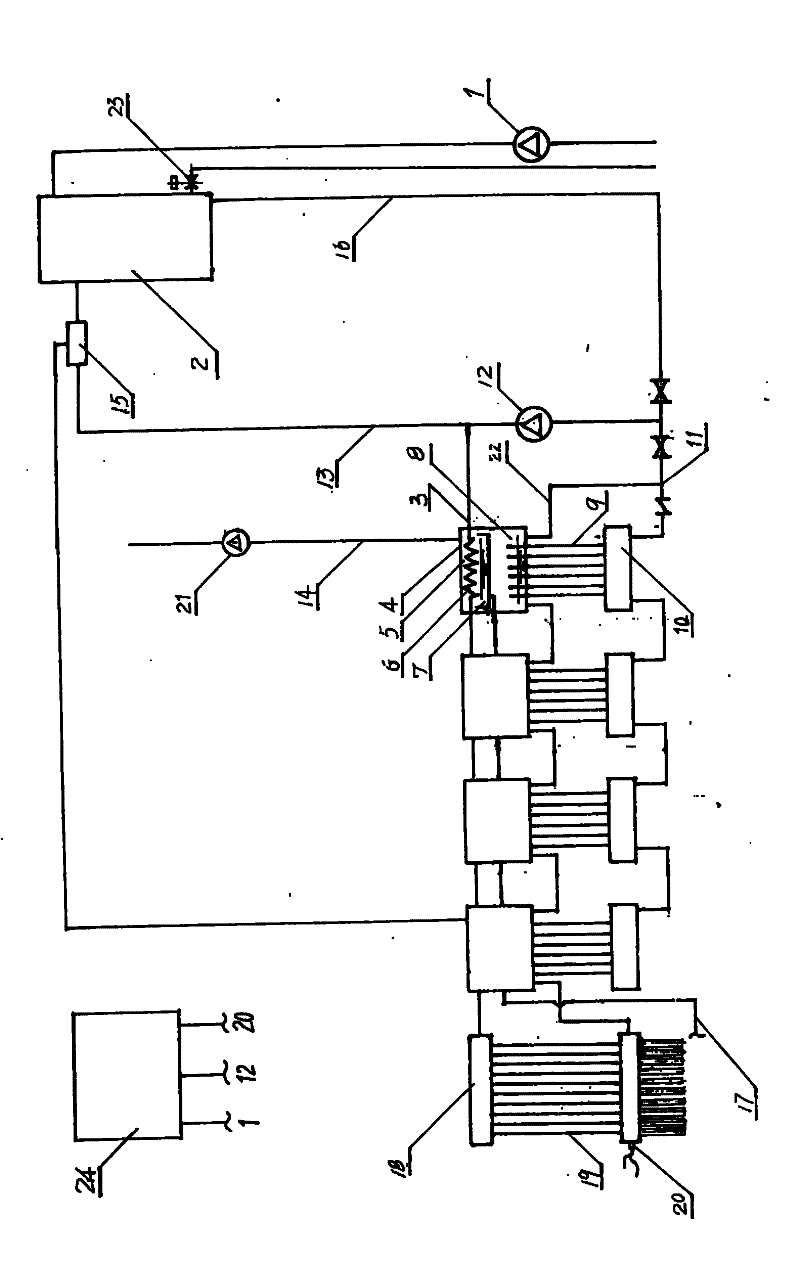

[0023] figure 1 It is a system diagram of the present invention, and it is a specific embodiment of the process. The process is as follows: seawater is transported to the high-level water tank (2) through the seawater pump (1), and the seawater in the high-level water tank (2) is transferred by the circulation pump (12). Water is supplied to the system through the water supply pipe (16) and the condenser water inlet pipe (3), and the seawater is heated to a certain temperature after absorbing the steam latent heat in the double-effect evaporators (4) at all levels through the condensers (6) of the system at all levels, and then Enter the solar fast heater (18), enter in the evaporation chamber (8) of the double-effect evaporator (4) after being heated to the design temperature again through the solar heating tube (19), because the pressure in the evaporation chamber (8) passes through the vacuum pump ( 21) and the exhaust pipe (14) are controlled below the saturated vapor pres...

Embodiment 2

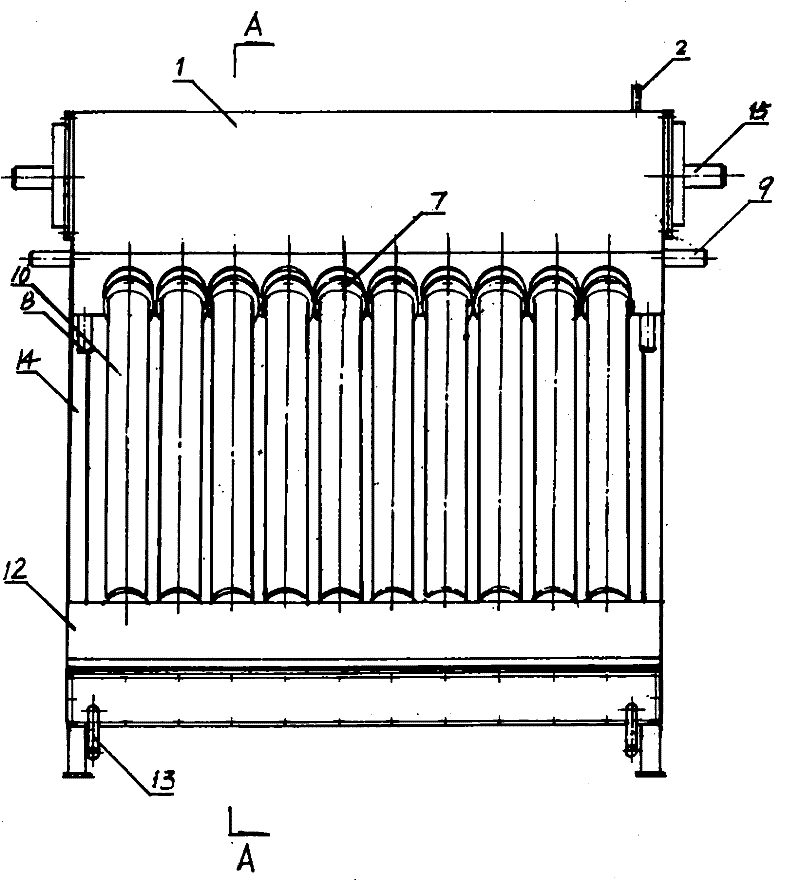

[0025] Figure 2 to Figure 5 is the system figure 1The structural diagram of the middle double-effect evaporator (4) is a specific embodiment of the present invention, and its technological process is: seawater enters from the condenser water inlet pipe (15) under the effect of the circulating pump, and the condenser (3) After internally absorbing the latent heat of steam in the evaporation chamber (16), it enters the next-stage double-effect evaporator through the water outlet pipe at the other end of the condenser (3). After the multi-stage double-effect evaporator absorbs latent heat, it enters the solar rapid heater to continue heating. The hot seawater heated to the design temperature enters the evaporation chamber (16) through the double-effect evaporator water inlet pipe (8). The pressure of the seawater is controlled below the saturated vapor pressure corresponding to the temperature of the hot seawater. After the hot seawater enters the evaporation chamber (16), it b...

Embodiment 3

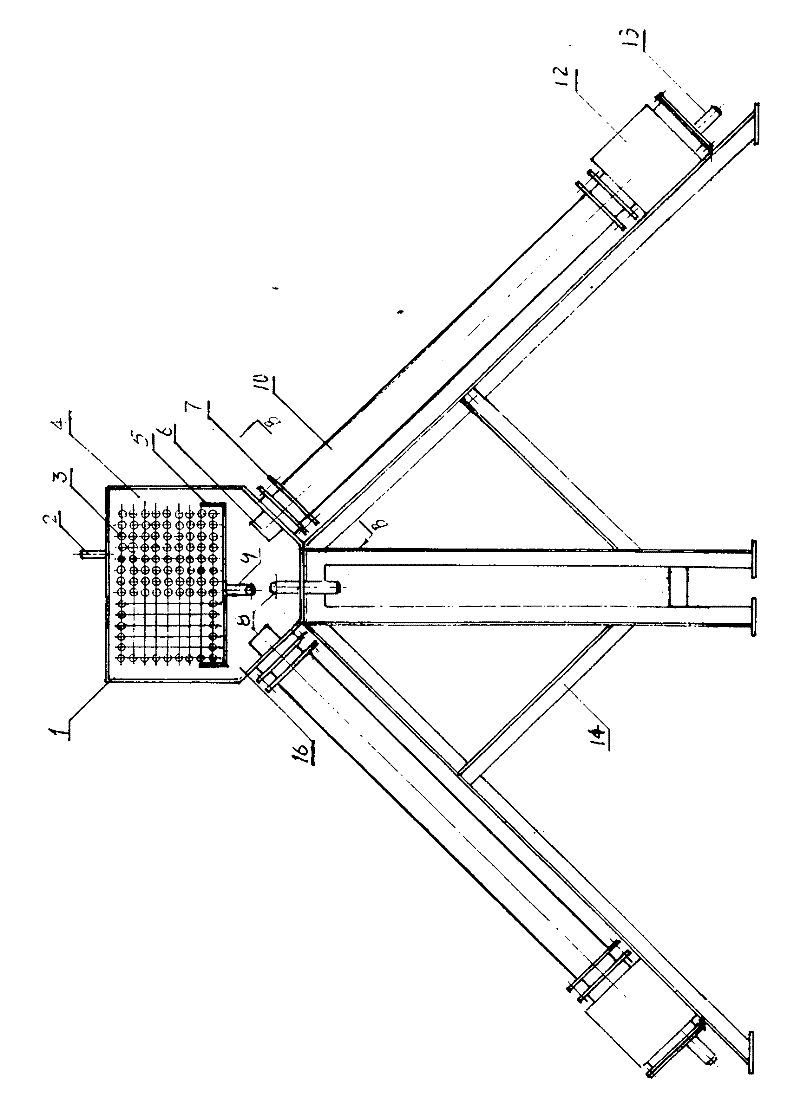

[0027] Figure 6 to Figure 11 is the system figure 1 The structural diagram of solar energy fast heater (18) is a kind of concrete embodiment of the present invention, and its technological process is as follows: the seawater that absorbs latent heat of vaporization and is heated to certain temperature through multi-stage condenser, by water inlet pipe (12) Enter the solar rapid heater water inlet tank (11), and flow to the water outlet tank (2) through the gap between the heat absorption pipe (7) and the heat pipe (8). The heat-absorbing pipe (7) is made of corrosion-resistant metal material, and the surface is coated with a selective heat-absorbing film. The heat-preserving pipe (6) adopts a through-type tubular double-layer vacuum transparent glass tube, and the heat-absorbing pipe (7) is set in the heat-preserving pipe (6) Inside, both ends are sealed. The heat pipe (8) is a tube-shaped airtight container with both ends sealed, and a liquid heat-conducting medium and a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com