Cotton seeds processing technique

A processing technology, cotton seed technology, applied in the field of seed preparation technology before planting, can solve the problems of affecting the appearance of seeds and germination rate, affecting the germination rate, unable to guarantee the quality of seeds, seed drug coating, etc., to improve reliability and safety The effects of reliability, damage rate reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

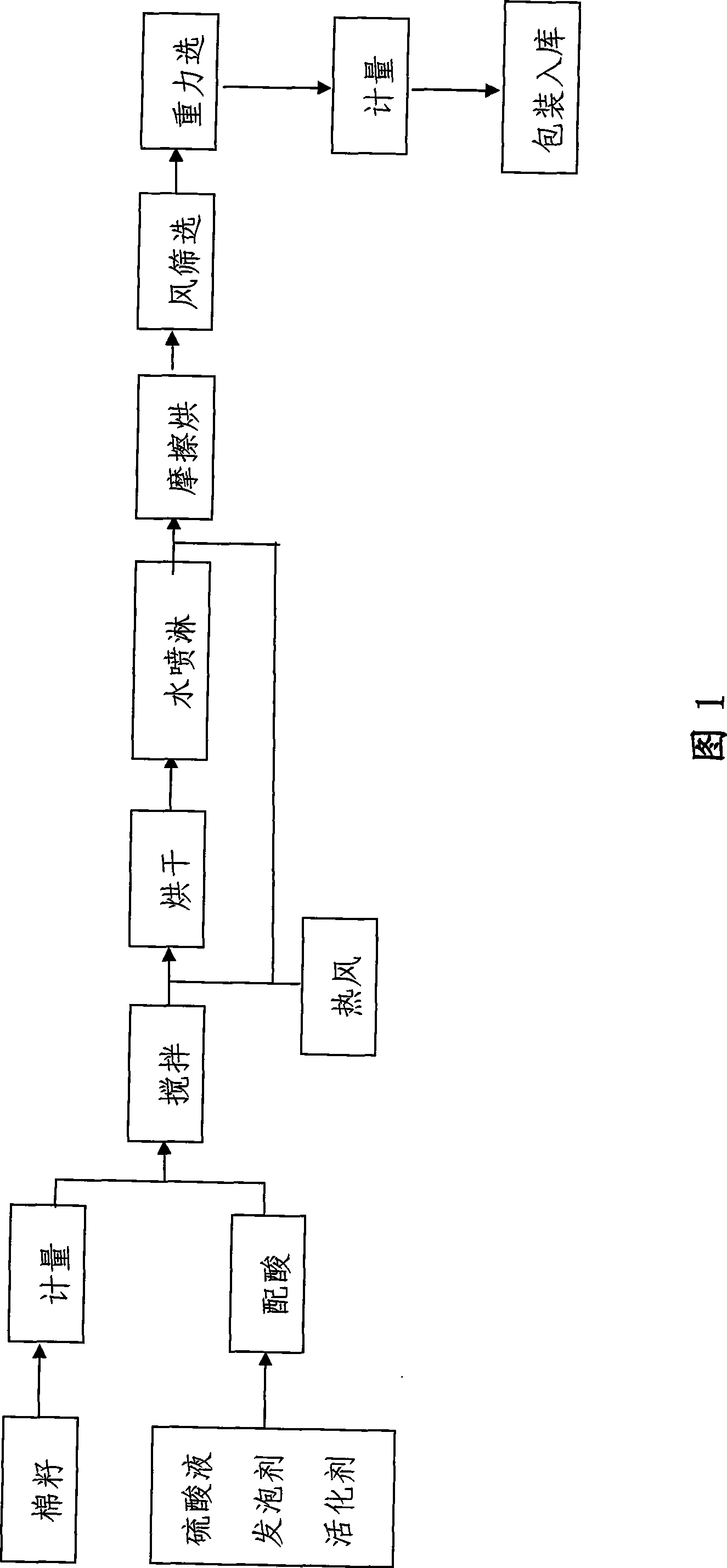

[0024] Embodiment 1 (foam acid technique)

[0025] 1. Measure the cottonseed to be processed;

[0026] 2. Prepare the acid treatment solution, the solution composition is:

[0027] dilute H 2 SO 4 The concentration is 7.0%, foaming agent 0.20%, activator 0.10%;

[0028] 3. Evenly input the cottonseed and acid treatment solution into the mixing tank according to the measurement, and stir for 8 minutes, and it is advisable that the cottonseed fluff is completely soaked;

[0029] 4. Put the acid-treated cottonseed into the drying cylinder, and dry it at 250°C for half an hour, and the remaining velvet will become light seeds after being carbonized;

[0030] 5. Put the dried photoseed into the spray mixer for cleaning, spray with clean water for 2 minutes, the photoseed is stirred and rinsed in a short time, and the excess water flows away through the leak hole at the bottom;

[0031] 6. Transport the cleaned photoseeds to the friction cylinder for drying and rubbing for half...

Embodiment 2

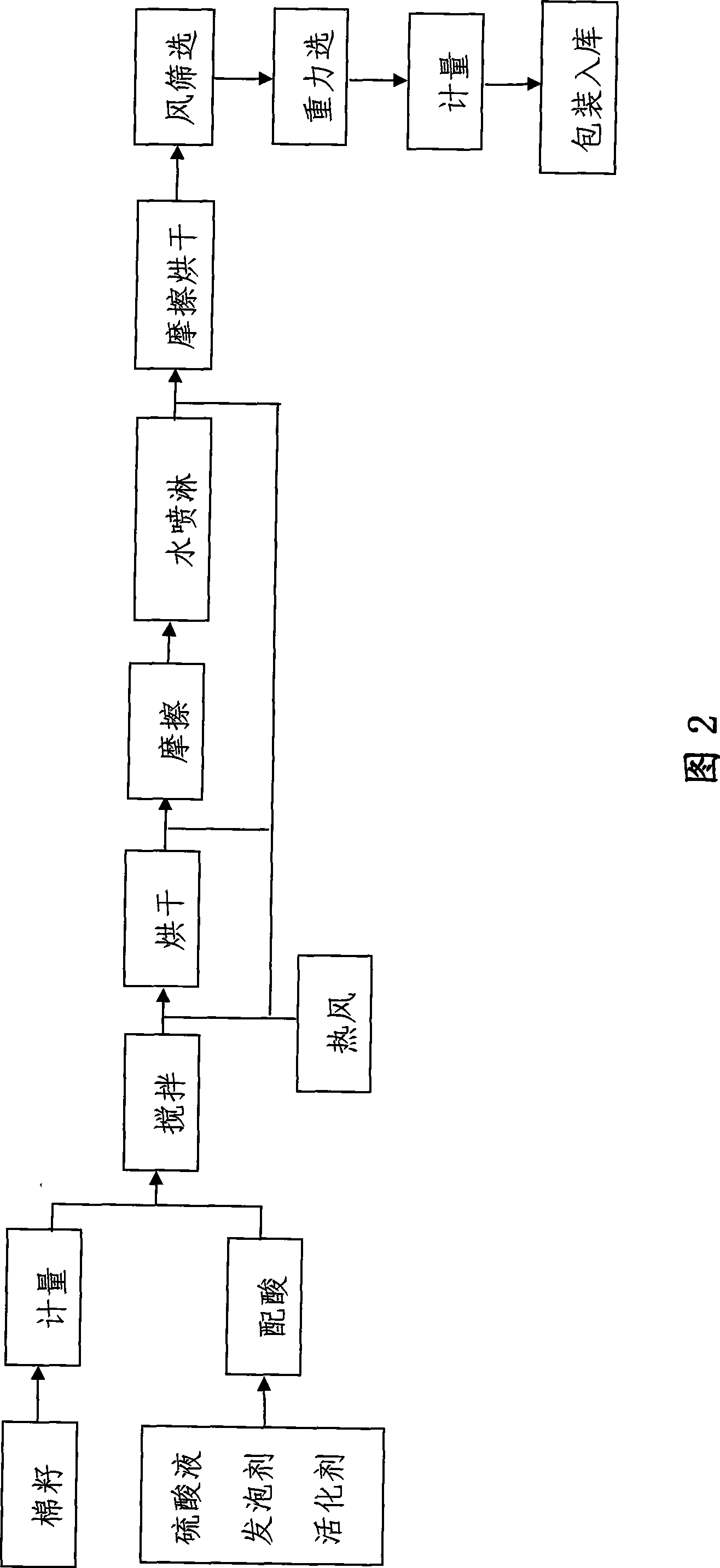

[0033] Embodiment 2 (foam acid technique)

[0034] 1. Measure the cottonseed to be processed;

[0035] 2. Prepare the acid treatment solution, the solution composition is:

[0036] h 2 SO 4 10.0%, foaming agent 0.20%, activator 0.15%;

[0037] 3. Evenly input the cottonseed and acid treatment solution into the mixing tank according to the measurement, and stir for 8 minutes, and it is advisable that the cottonseed fluff is completely soaked;

[0038] 4. Put the acid-treated cottonseed into the drying cylinder, and dry it at 300°C for half an hour, and the remaining velvet on the cottonseed will be carbonized to become light seeds;

[0039] 5. Put the dried photoseed into the friction cylinder and rub for half an hour;

[0040] 6. Put the cottonseed into the spray vibrator for cleaning, spray with clean water for 3 minutes, the light seeds will be rinsed under the vibration in a short time, and the excess water will flow away through the leakage hole at the bottom;

[00...

Embodiment 3

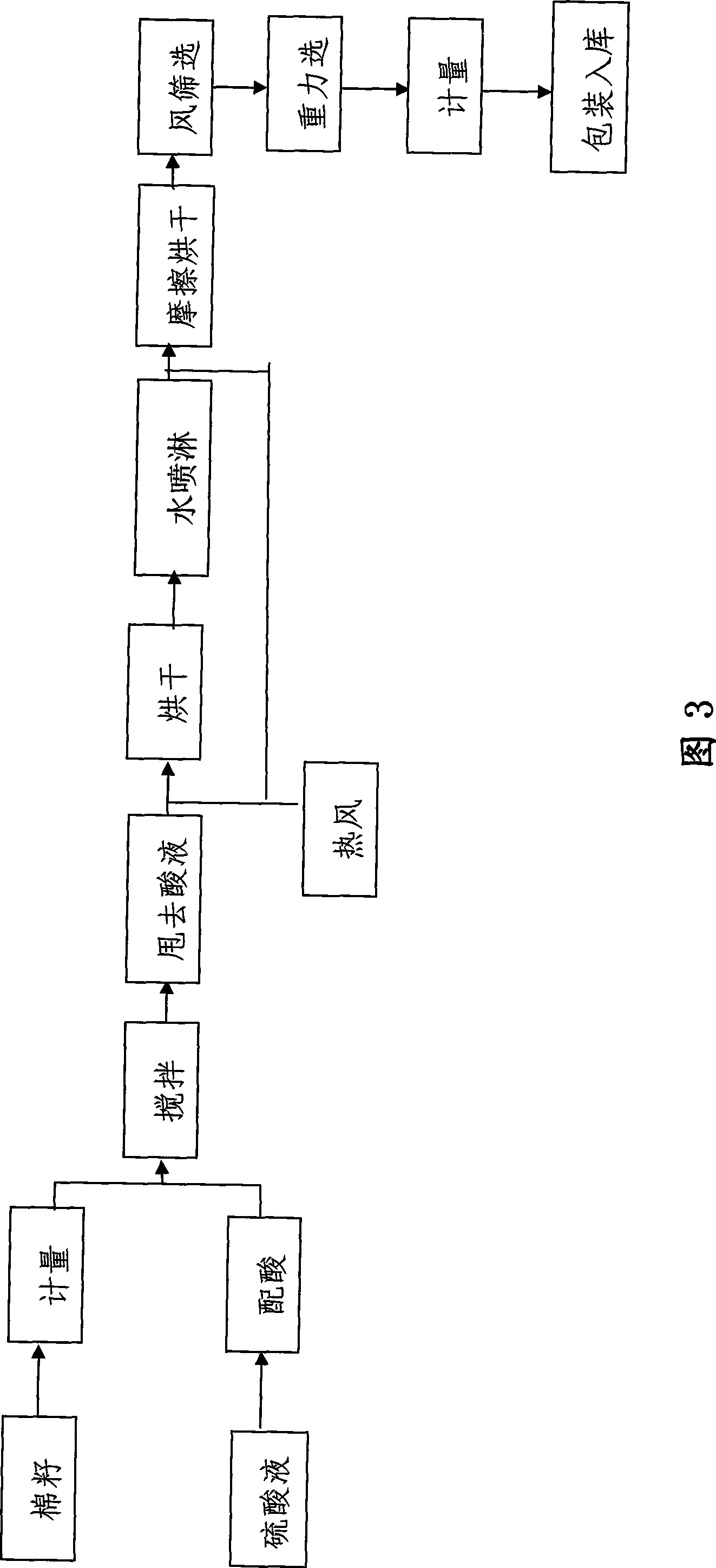

[0043] Embodiment 3 (dilute sulfuric acid process)

[0044] 1. Measure the cottonseed to be processed;

[0045] 2. Prepare acid treatment solution, sulfuric acid in the solution: 15%;

[0046] 3. Pour the cottonseed and acid treatment solution into the mixing tank, it is advisable that the seed fluff is completely soaked, and stir for 8 minutes;

[0047] 4. The soaked hair seeds are removed by a centrifuge to remove excess acid.

[0048] 5. Put the acid-treated cottonseed into the drying cylinder, and dry it at 250°C for half an hour. The remaining velvet on the cottonseed is carbonized and becomes light seed;

[0049] 6. Put the light seeds into the spray vibrator for cleaning, spray with clean water for 2 minutes, the light seeds are rinsed under vibration or stirring, and the excess water flows away through the leakage hole at the bottom;

[0050] 7. Put the cleaned photoseed into the rubbing cylinder to dry and rub for half an hour. The temperature of the cottonseed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com