Tube-jet combined pile supporting underground wall structure and construction method for same

A construction method and technology for underground walls, which can be used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of wasting manpower, financial resources, environmental pollution, and high requirements for supporting facilities, saving construction costs and reducing the amount of excavation. , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

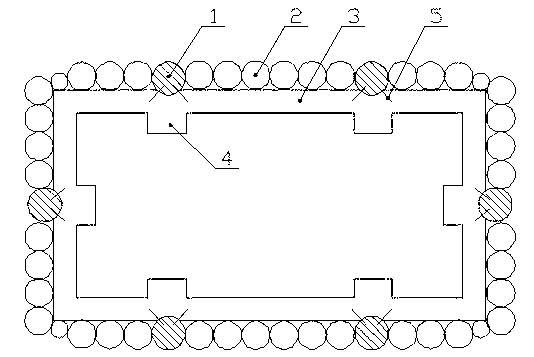

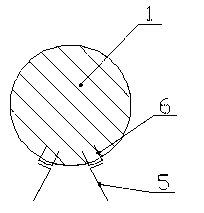

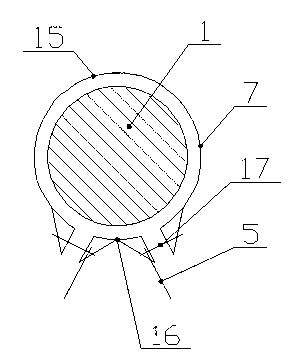

[0024] Please check Figures 1 to 4 , a pipe-spray joint pile supporting underground wall structure, the underground wall structure includes prestressed pipe piles 1 pressed into the soil at intervals, and these prestressed pipe piles 1 form a circle around the basement to be constructed; Adjacent prestressed pipe piles 1 are arranged closely side by side with high-pressure jet grouting cement-soil piles 2 to form a combined pile of prestressed pipe piles 1 and high-pressure jet-jetted cement-soil piles 2, and the combined piles can be used as a soil retaining function within a short height distance , to provide a reliable construction environment for the follow-up operation of the diaphragm wall in the basement; the reinforced concrete basement annular wall is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com