Patents

Literature

70results about How to "Simple and reliable construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

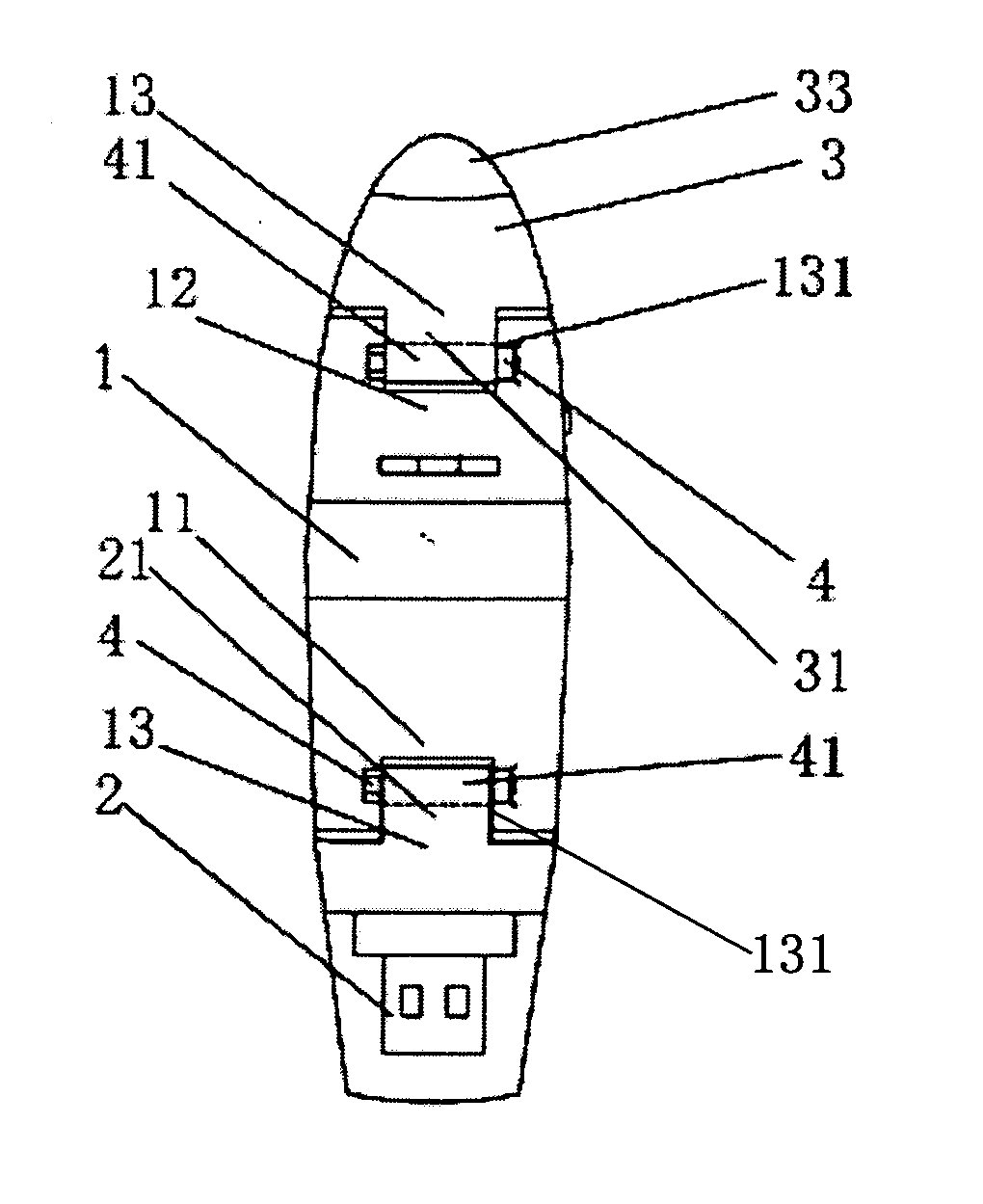

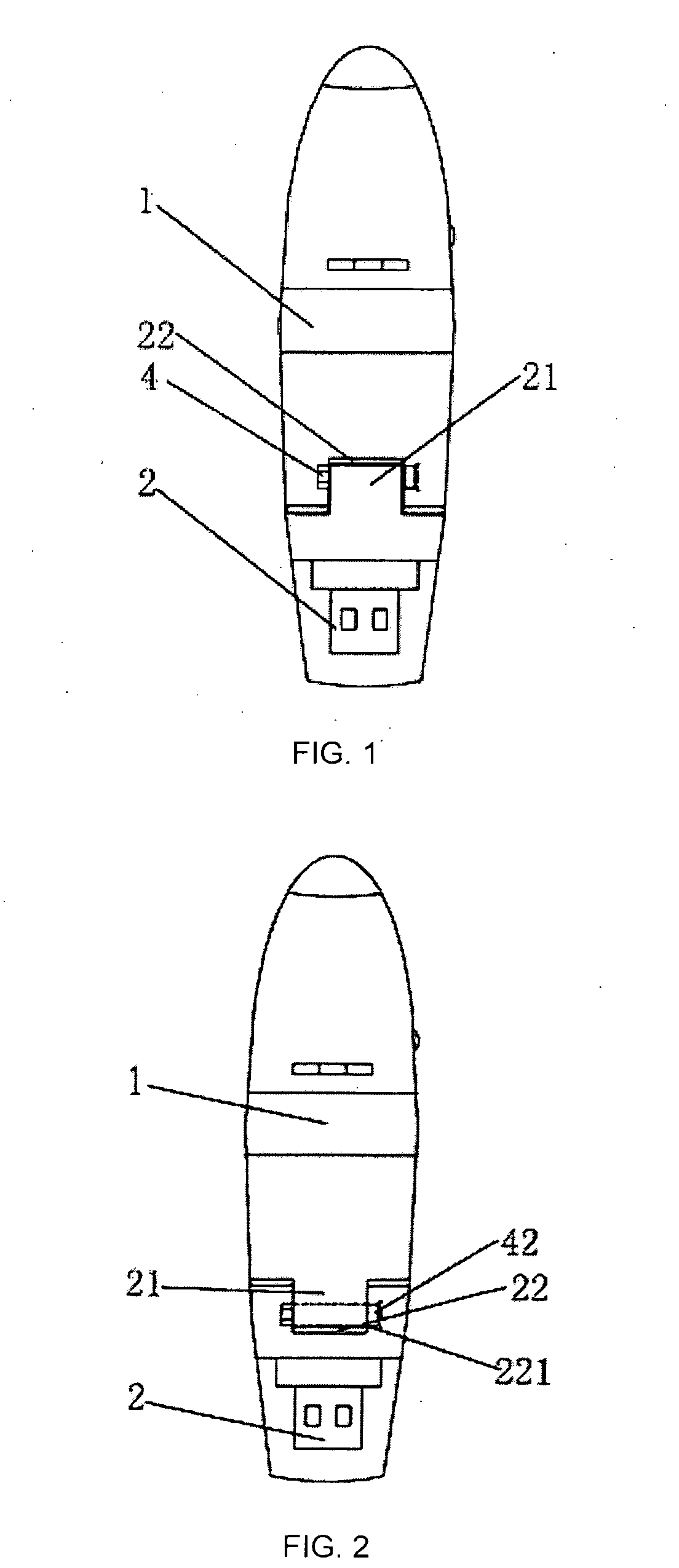

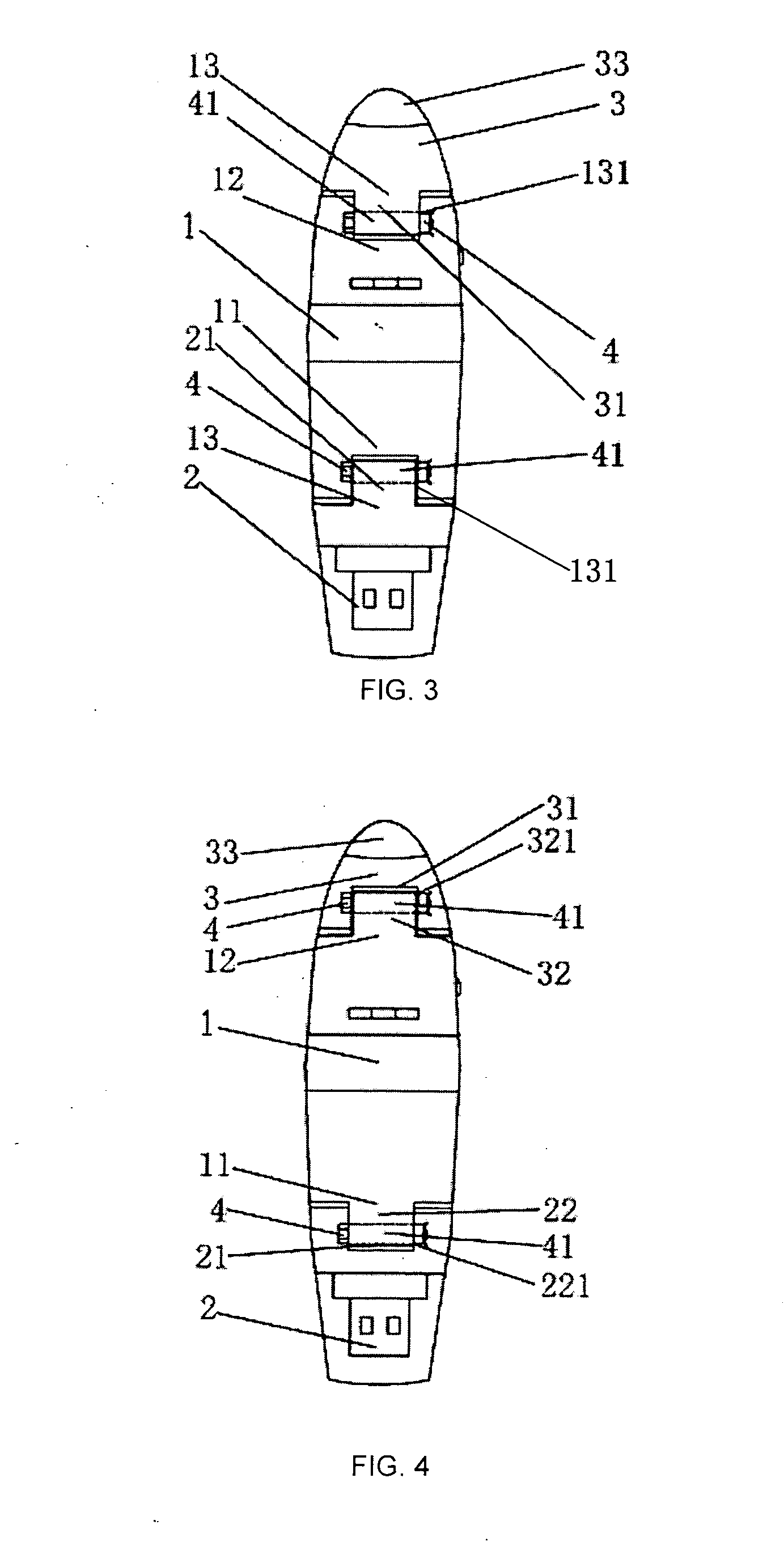

Device with hinged USB port

InactiveUS20060223369A1Simple and reliable constructionConvenient to use and carryCoupling protective earth/shielding arrangementsFlexible/turnable line connectorsHinge angleEngineering

The present invention relates to a device with hinged USB connector, in which electric power or data is supplied via a computer to the USB connector, thereby providing power or data to the device. One or more ends of the device are connected to a USB connector in a hinged manner. At the foldable end of the device, there is a recess in the centre which forms a receiving slot, on each of the two sides of which, there is an insertion hole for insertion of a hinge shaft; the USB connector has an integrally formed protruding part, which corresponds to and is inserted into the receiving slot and has a through hole for insertion of the hinge shaft, which connects the USB connector and the device. The device can be a lighting device, UBS drive, MP3, blue-tooth device, anion generator, charger or mini digital camera.

Owner:ZHENG BO

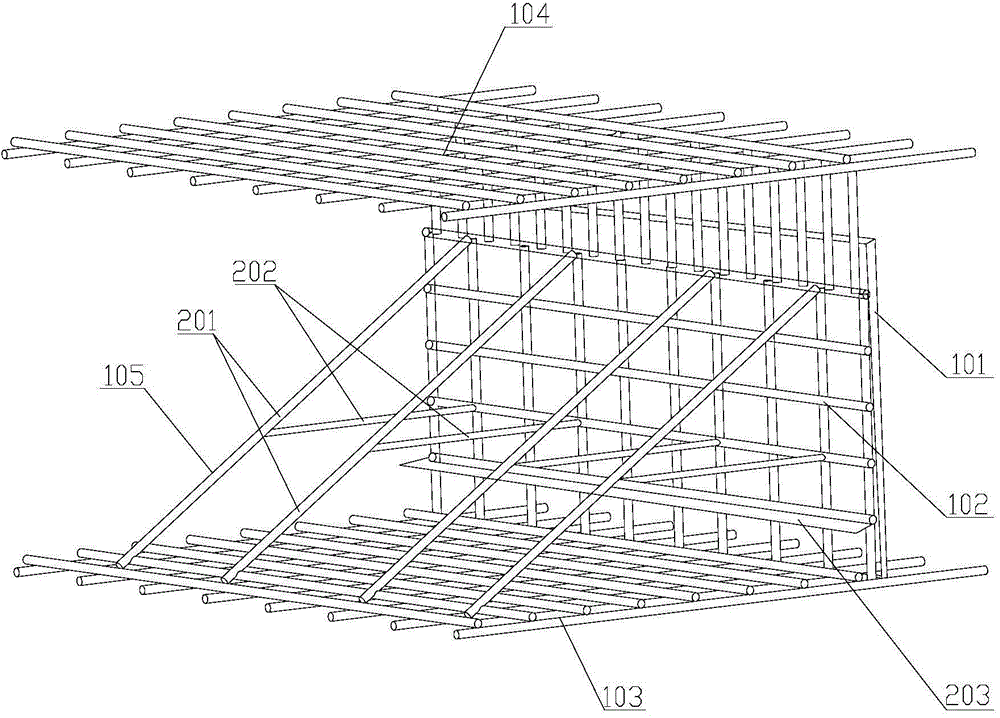

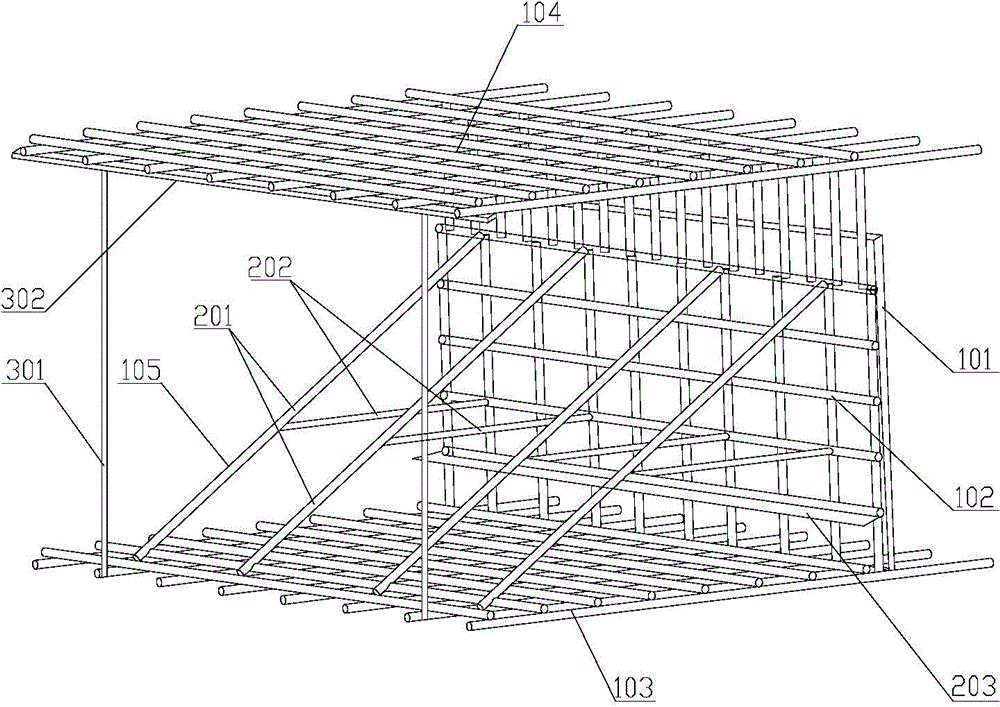

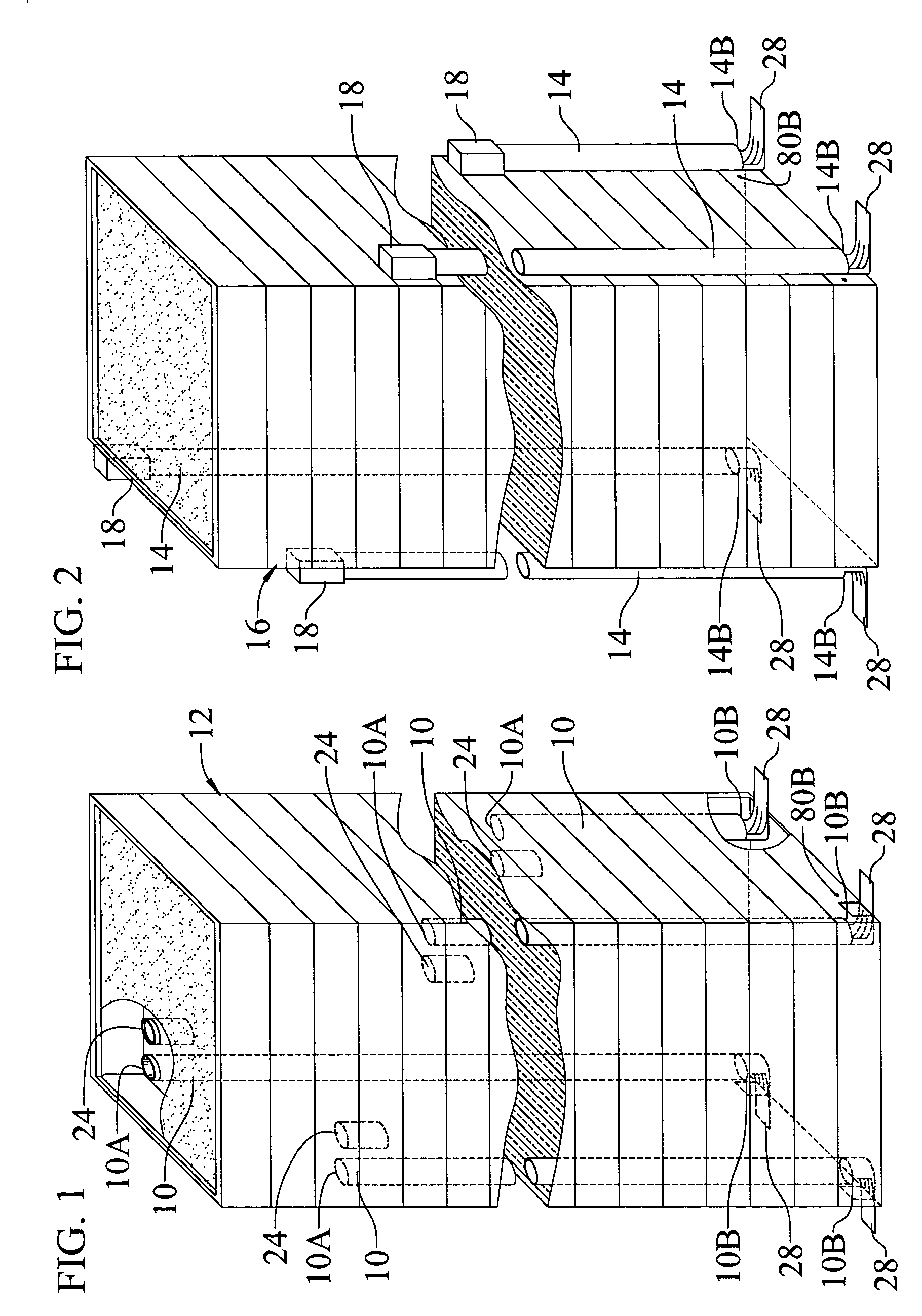

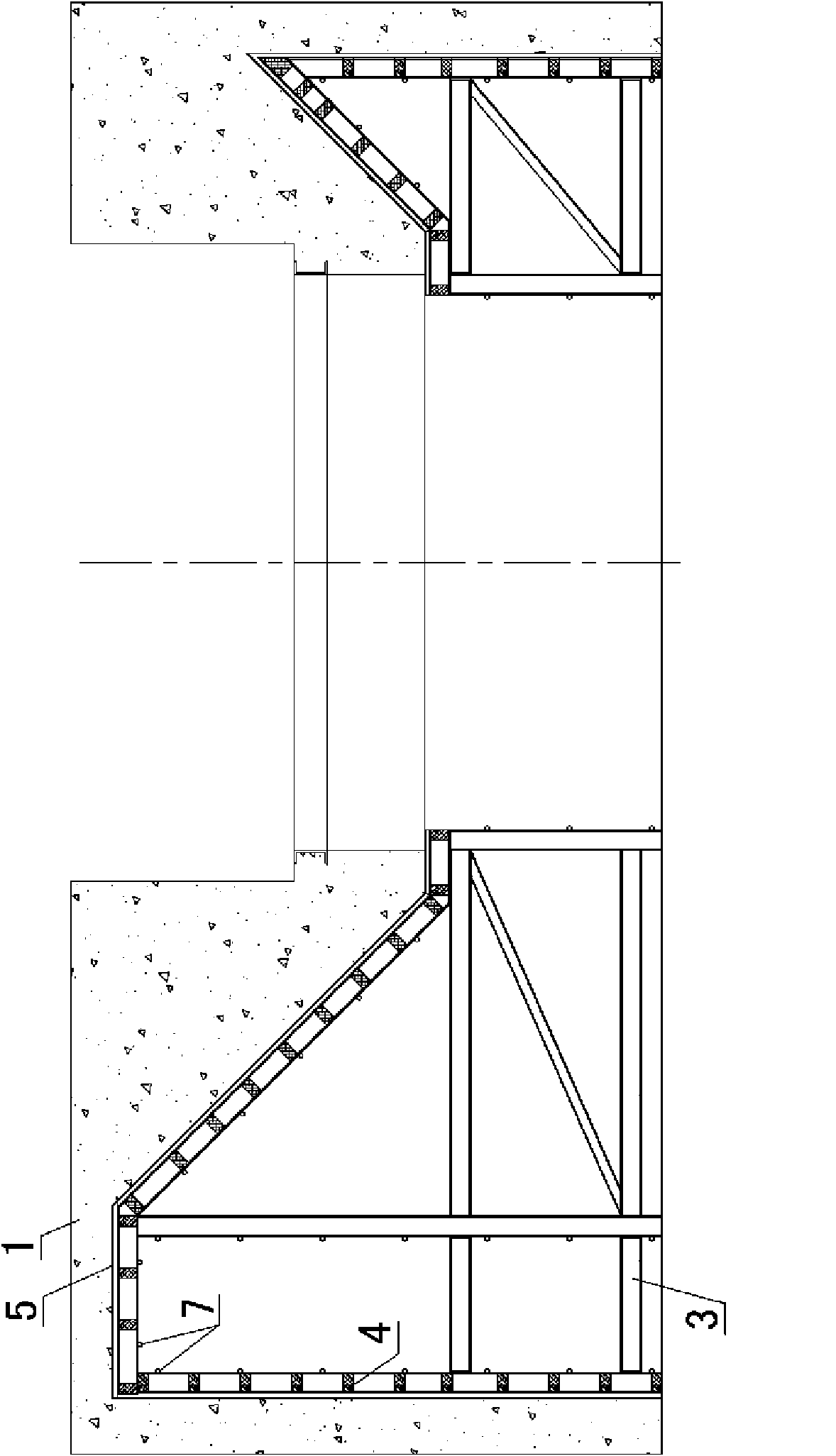

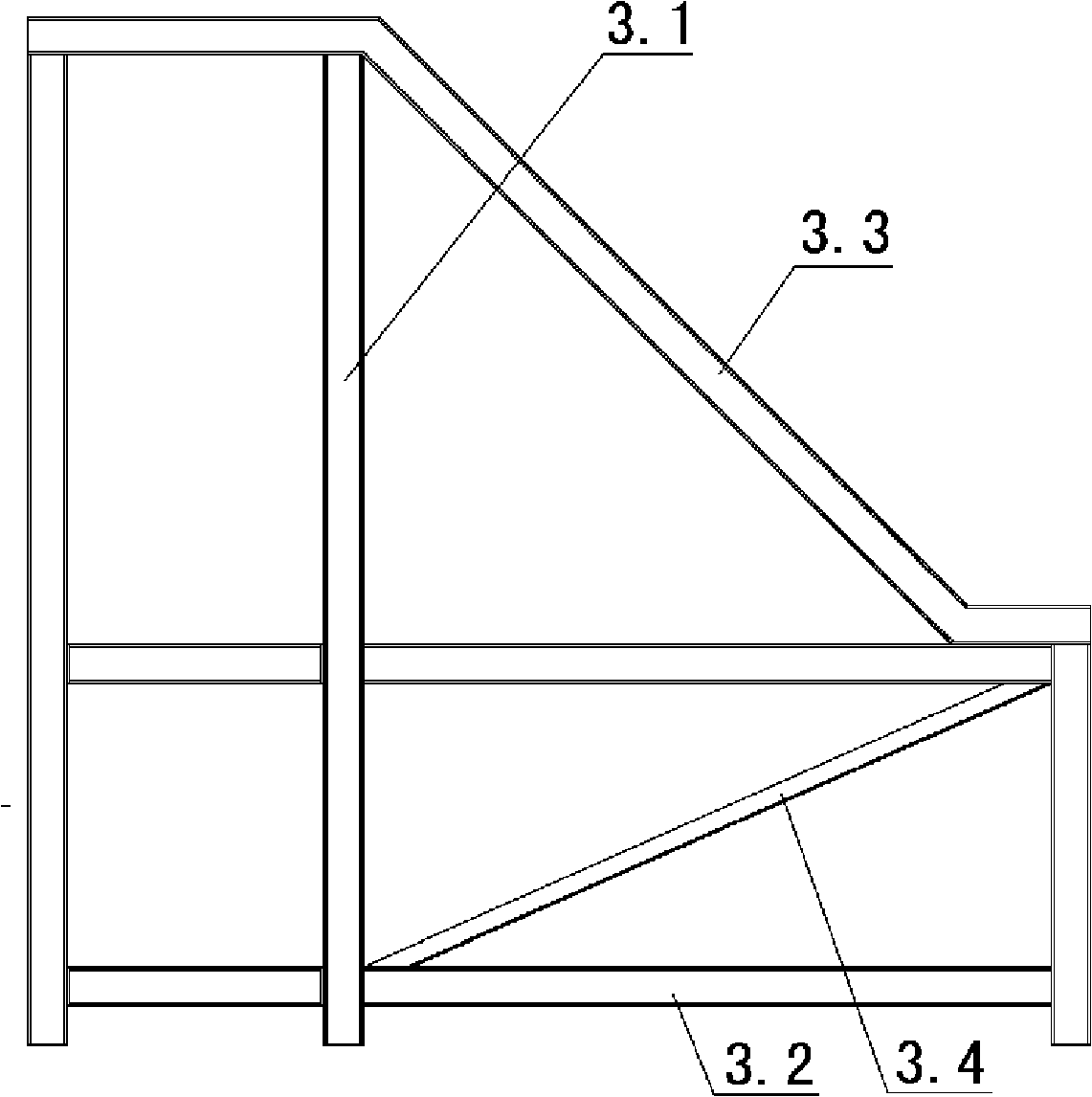

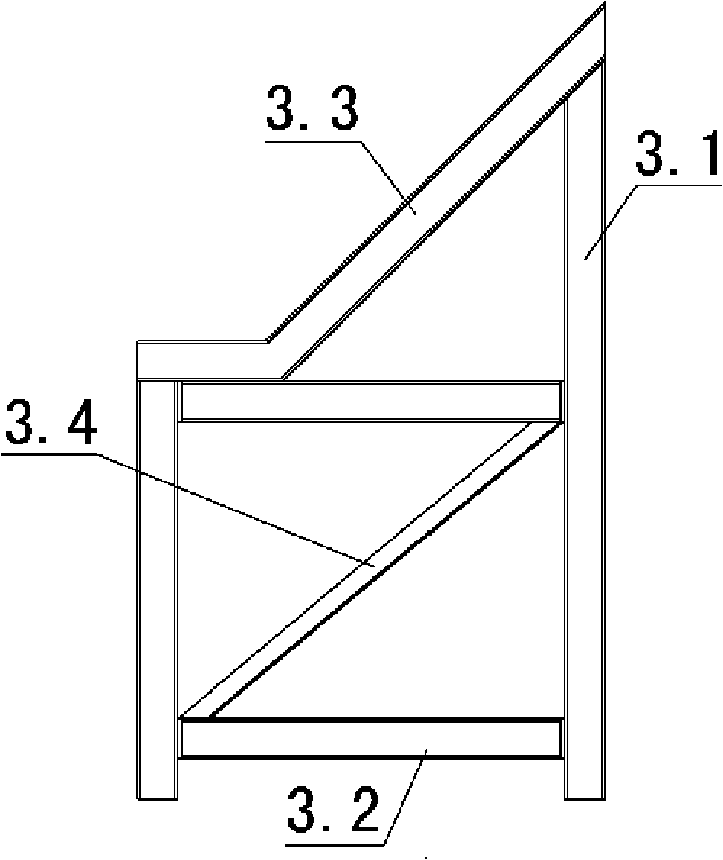

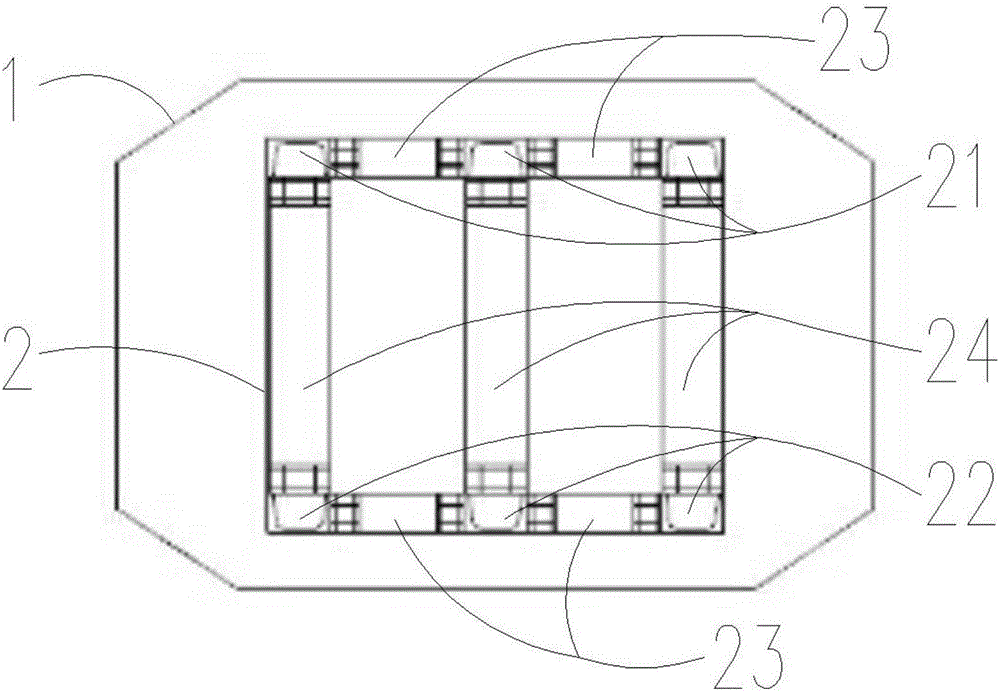

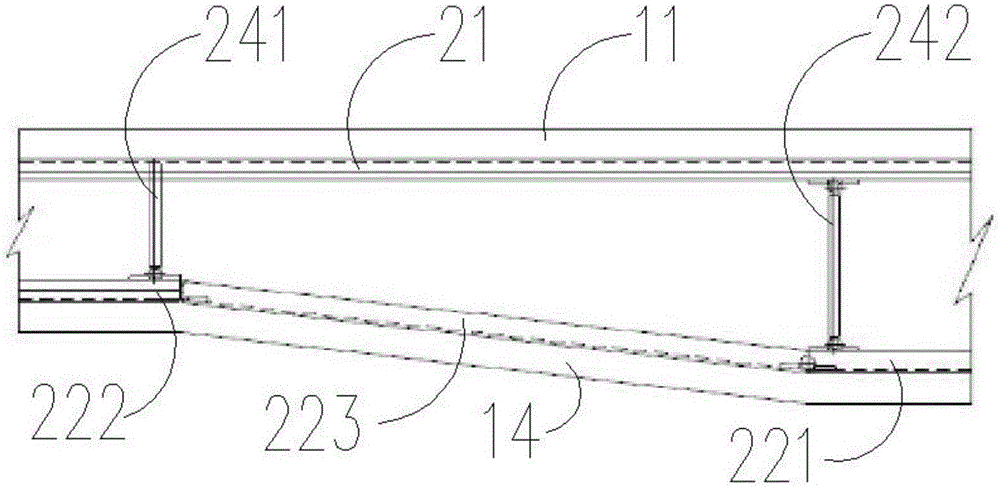

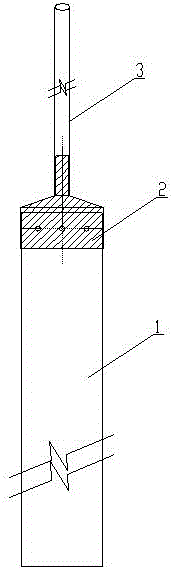

Raft plate post-cast strip pouring template and construction method thereof

ActiveCN104806011AImprove pouring qualitySimple structureForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringRebar

The invention provides a raft plate post-cast strip pouring template and a construction method thereof, which belong to the field of building construction equipment. The pouring template comprises a template and a support for supporting the template, wherein the support comprises a vertical beam arranged vertically, and a lower layer reinforcing mesh and an upper layer reinforcing mesh arranged horizontally; the template and the vertical beam are respectively located between the lower layer reinforcing mesh and the upper layer reinforcing mesh; the vertical beam is connected with the upper layer reinforcing mesh and the lower layer reinforcing mesh; the template is attached to the vertical beam; the support also comprises a support beam; one end of the support beam is connected with the vertical beam; the other end of the support beam is connected with the lower layer reinforcing mesh. The construction method is used for manufacturing the raft plate post-cast strip pouring template. The raft plate post-cast strip pouring template can be built in a less space and is convenient to construct in a time and labor saving way, and the cost is saved.

Owner:CHINA MCC5 GROUP CORP

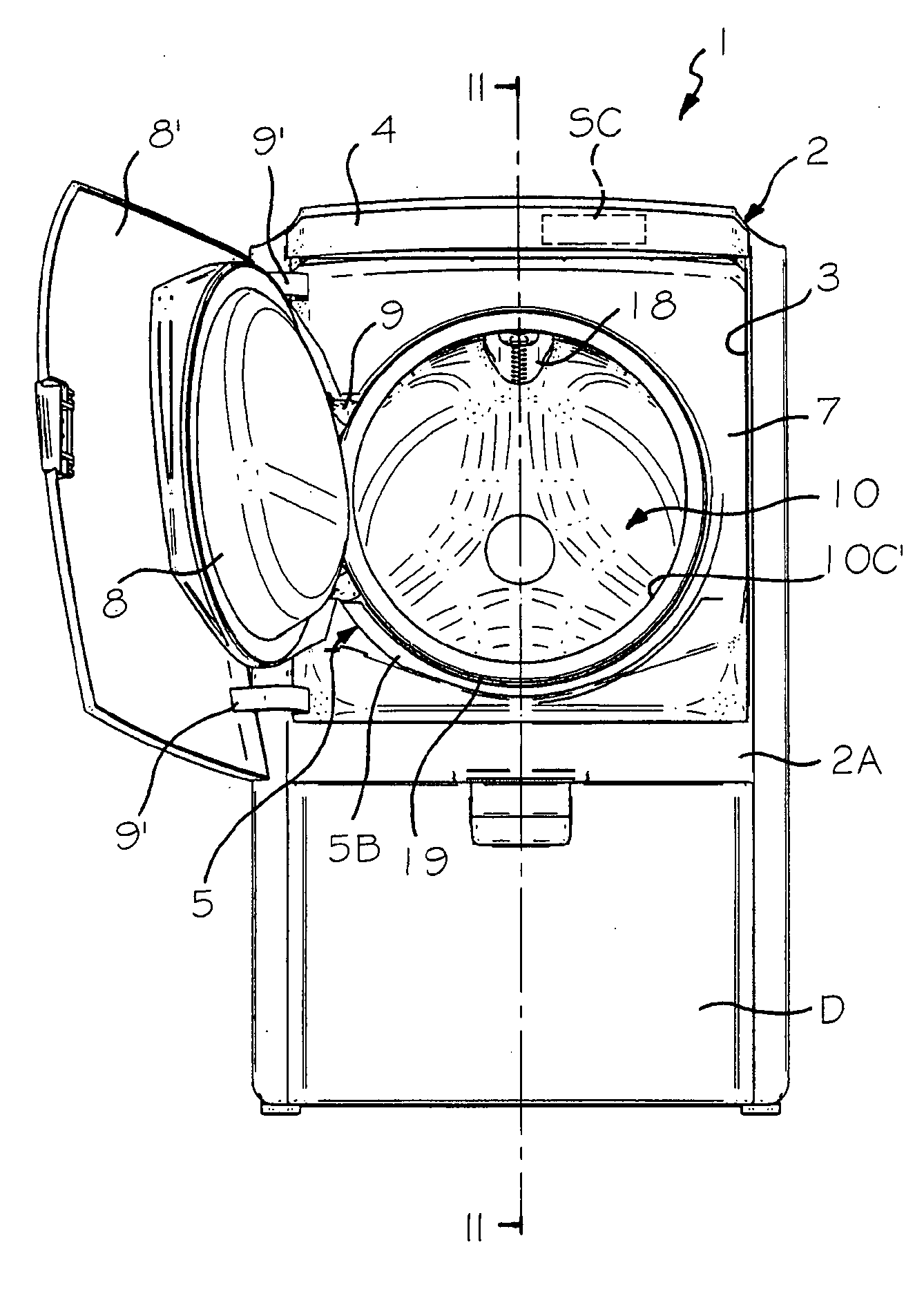

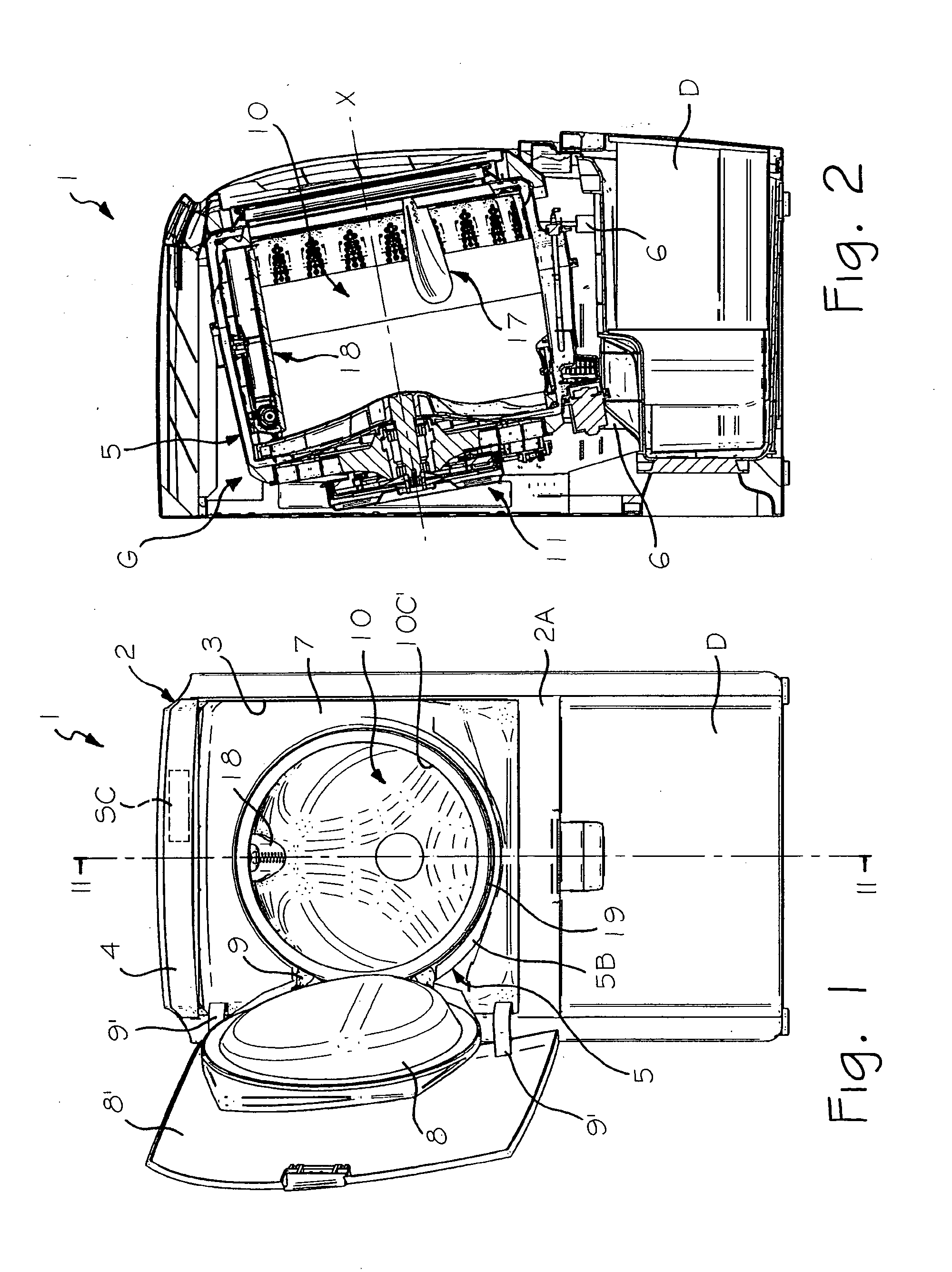

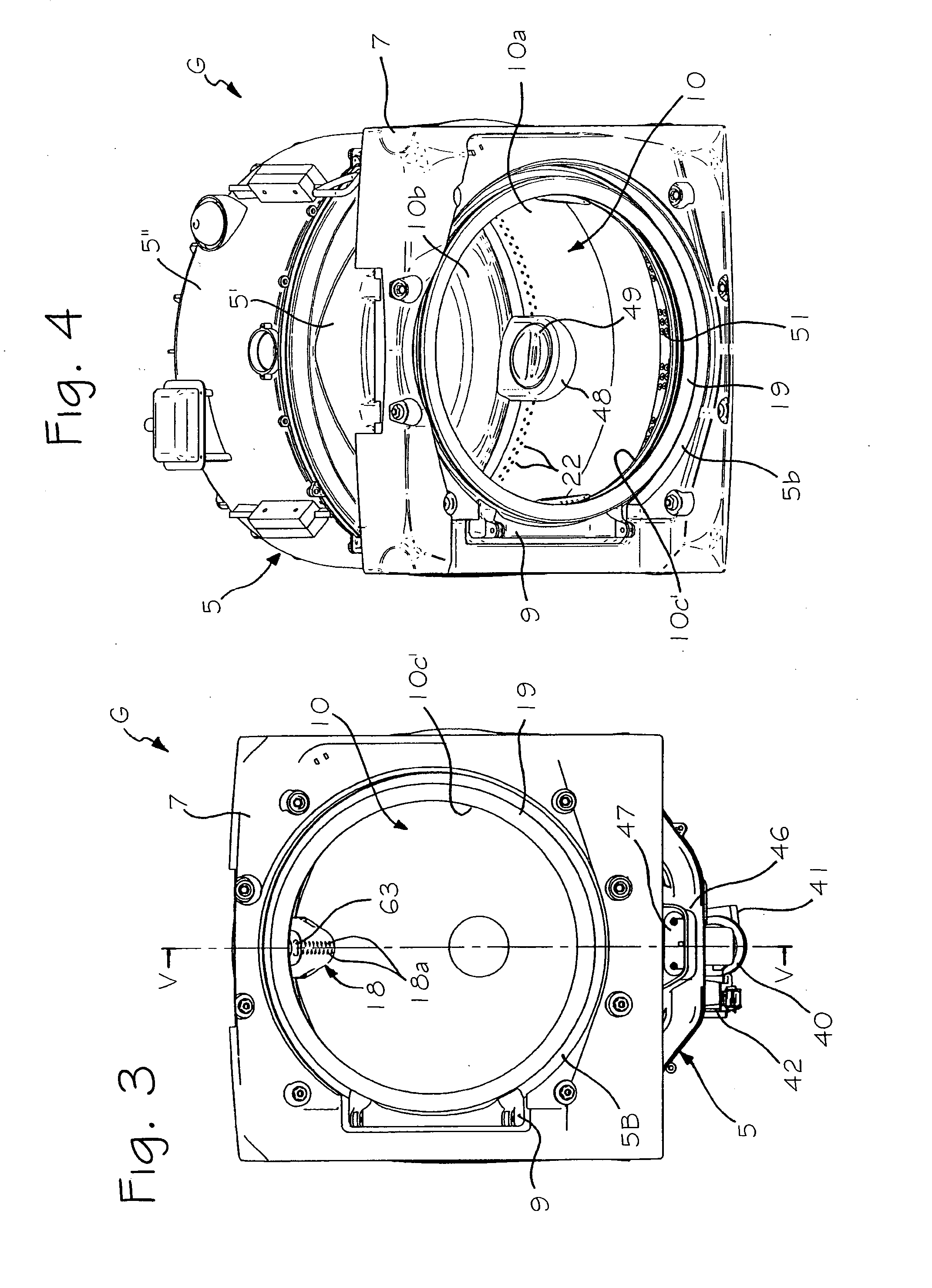

Laundry washing machine

InactiveUS20100050700A1Simple and reliable constructionThe overall structure is simple and reliableOther washing machinesWashing machine with receptaclesFront loadingEngineering

A front loading laundry washing machine is provided. The laundry washing machine includes a washing tub, a laundry basket mounted in the tub, a motor to actuate the basket in rotation and a system for feeding liquid in the basket. The basket has a first and second end wall between which a peripheral wall extends. The liquid feeding system comprises at least one inflow passage formed in a prevalently imperforated annular region of the peripheral wall of the basket and an inflow conduit having a delivery outlet facing toward the prevalently imperforated annular region. The laundry washing system is further provided with a positioning system designed for bringing and maintaining the basket in a substantially predetermined angular position within the tub, in such a position the inflow passage being substantially aligned with the delivery outlet of the inflow conduit to receive therefrom a liquid flow for the purpose of loading of liquid in the basket.

Owner:INDESIT

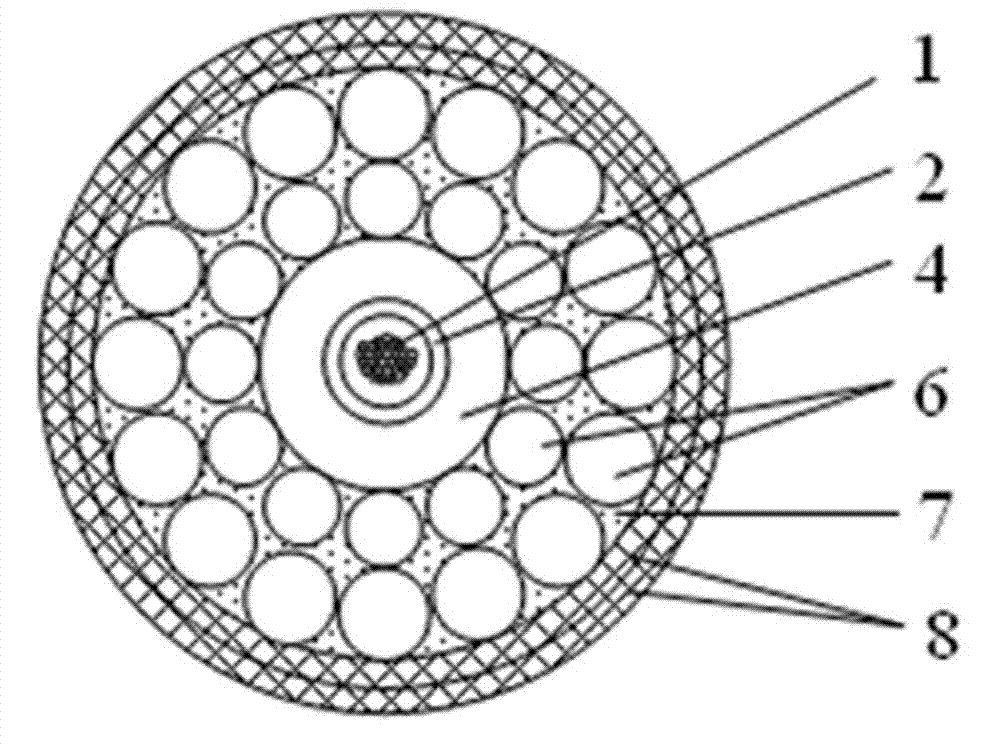

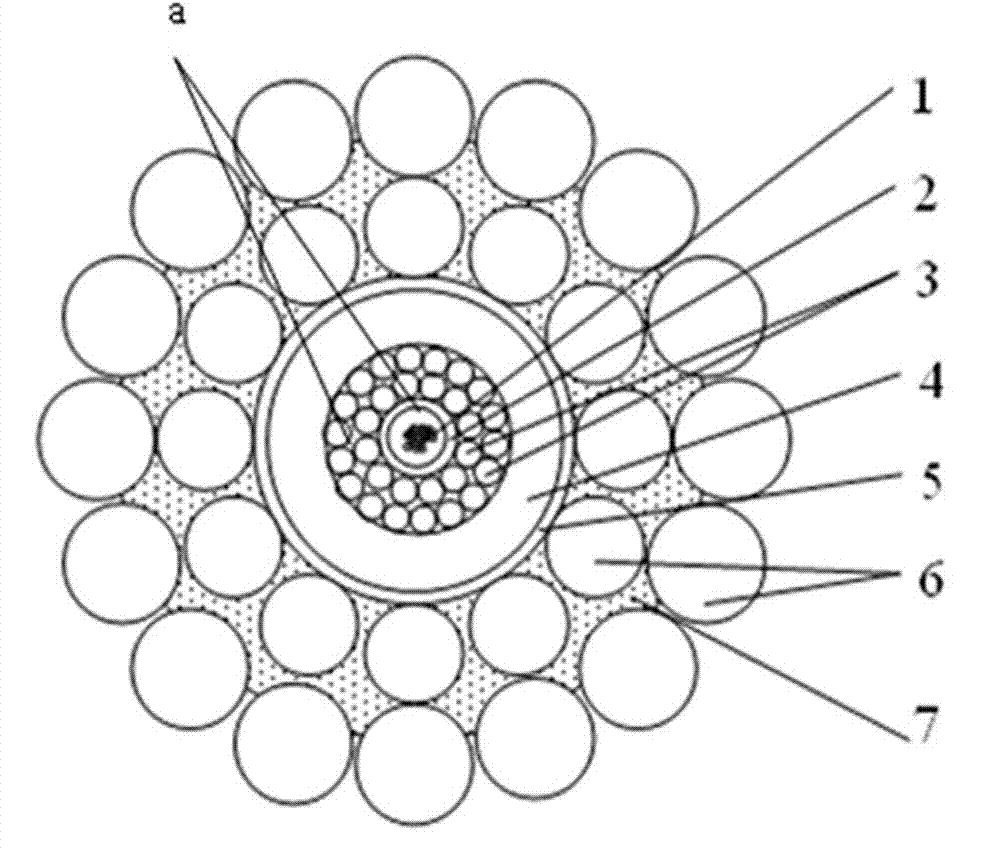

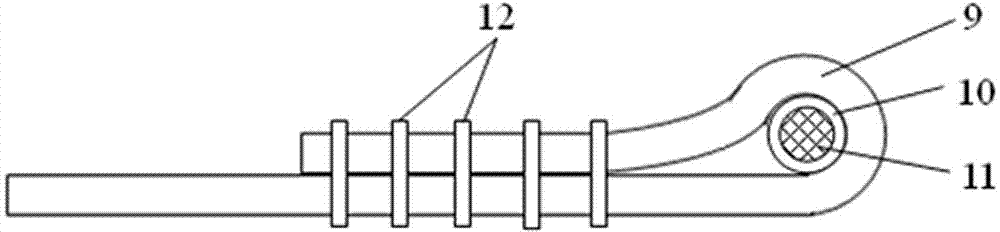

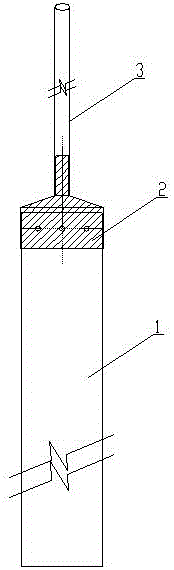

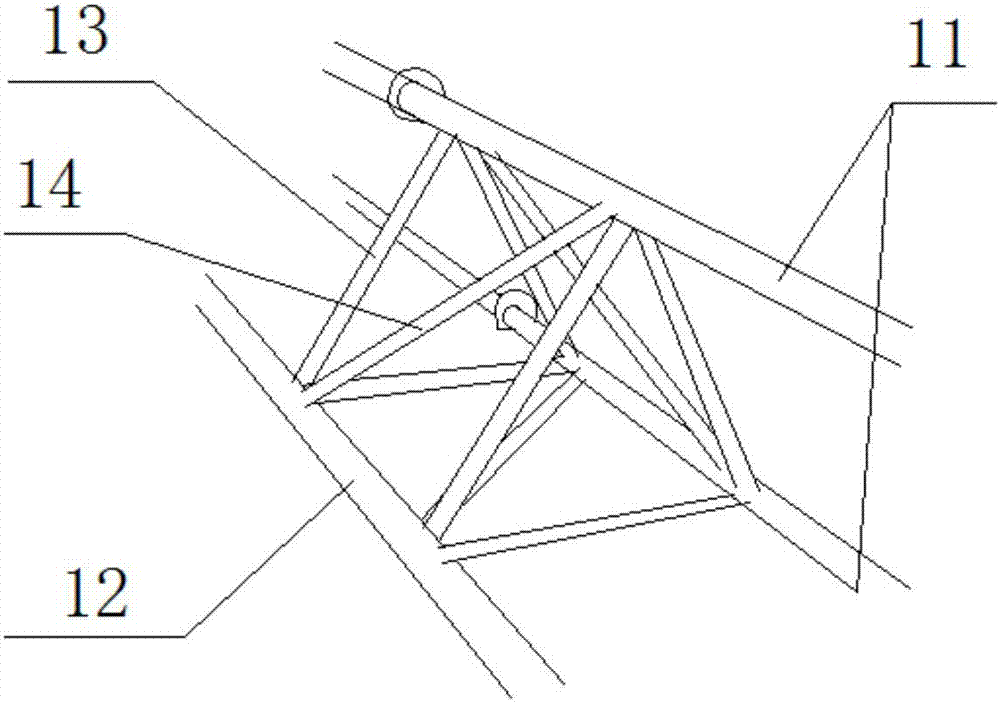

Optical cable and special construction draft gear for oil and gas pipeline 'towing back in one hole'

ActiveCN103487907AEnsure safetyReasonable structureOptical fibre/cable installationFibre mechanical structuresHigh intensityDegrees of freedom

The invention discloses an optical cable and a special construction draft gear for oil and gas pipeline 'towing back in one hole'. The optical cable comprises optical fibers, an optical fiber unit protective tube, an internal sheath reinforcing piece, an internal protective sleeve, a buffer layer, an external sheath reinforcing piece, water stop materials and anticorrosion pitch. The special construction draft gear comprises an outer shell, an outer cone, an inner cone, a locking end cap and an optical cable drafting ring. The optical cable and the special construction draft gear have the advantages that two layers of internal sheath steel wires are arranged outside the optical fiber unit protective tube, and therefore tensile and side pressure resistant performance of a cable core are improved; the high-strength external sheath steel wire on the outermost layer is smooth and flat, therefore, friction coefficients of the external steel wire and a drill hole wall are reduced, and abrasion resistant performance is improved; the special construction draft gear only drafts the external sheath steel wire, and therefore the cable core can have a certain degree of freedom and almost not being stressed; the cable core end is contained in the steel shell, and therefore safety of the optical fibers in the cable can be guaranteed. The optical cable and the draft gear are reasonable in structure and used in cooperation with each other, and construction is easy, convenient and reliable.

Owner:江苏通光海洋光电科技有限公司

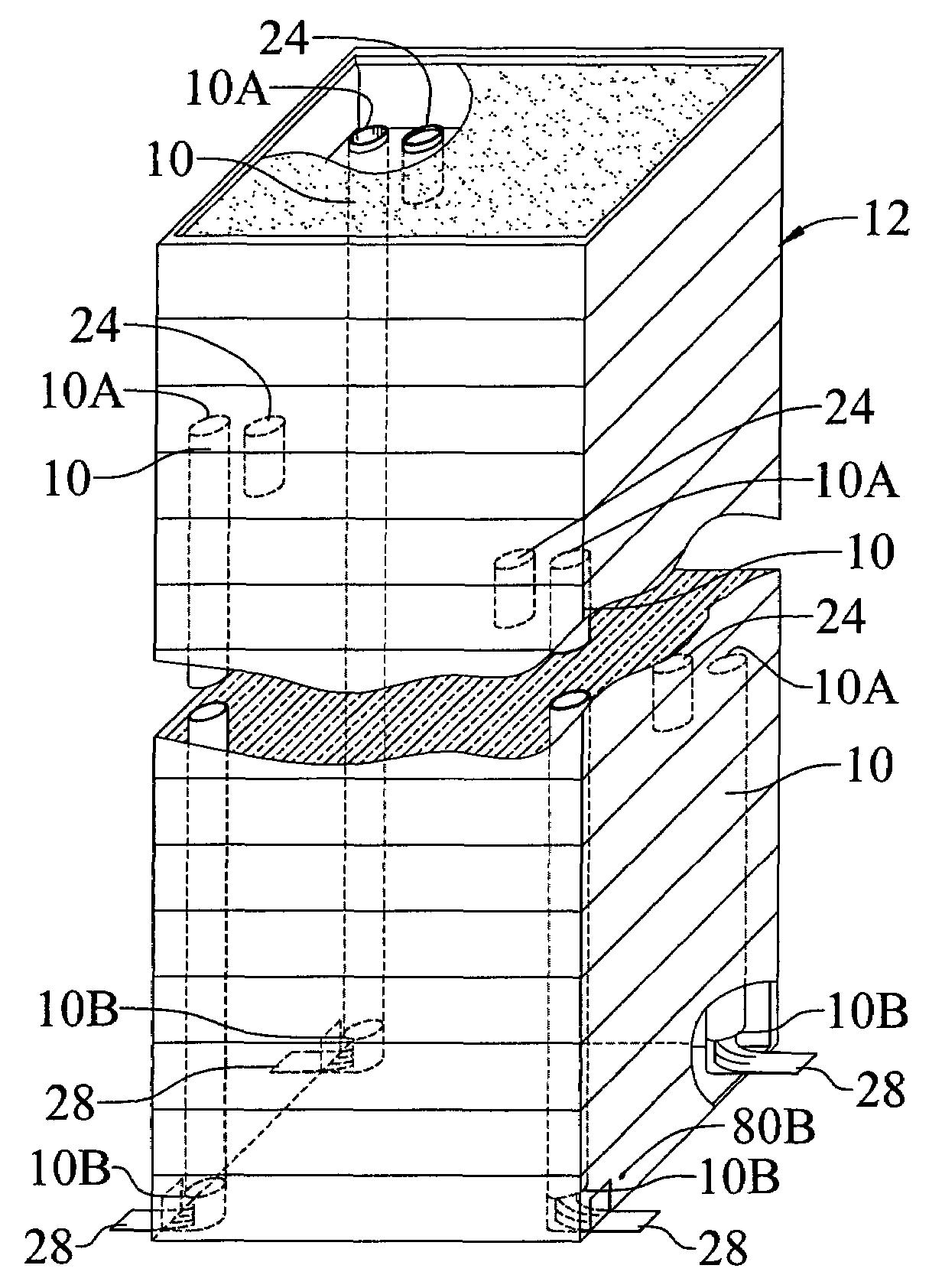

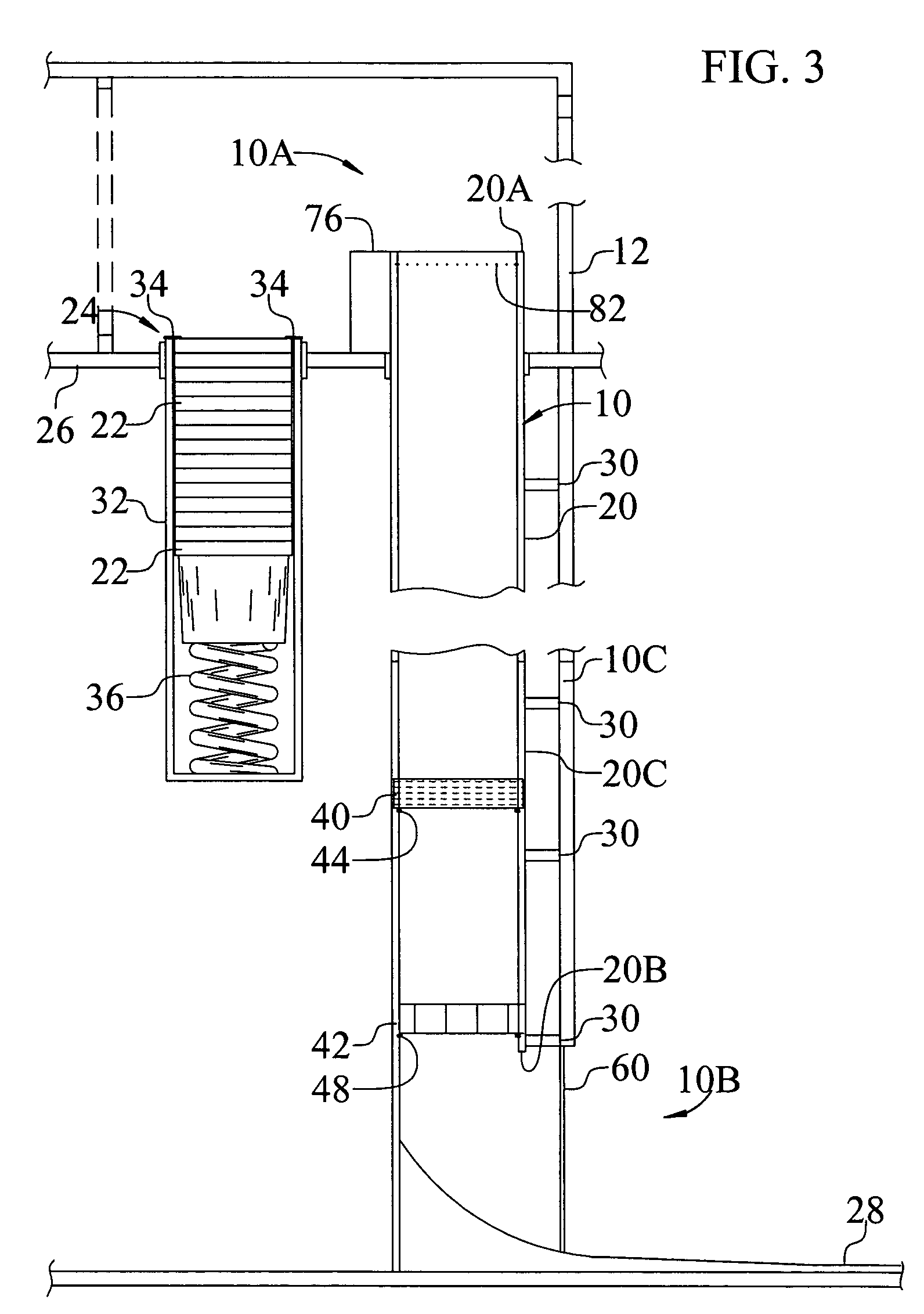

Emergency evacuation system for high-rise buildings

An evacuation system for high-rise buildings includes an evacuation tube that extends vertically from an entrance on an upper floor to ground level, and a carrier that descends freely through the tube to swiftly carry a person from the upper floor to the ground. A storage tube holds multiple carriers near the entrance to the evacuation tube. The evacuation tube is configured to control the rate of descent of the carrier via established radial clearances and resulting progressively increasing pneumatic pressured-air damping under the carrier, to achieve an initial rapid descent, then a slower descent as the carrier approaches ground lever. Exiting the evacuation tube in the carrier is controlled through large sequenced valves that establish an airlock between the inside of the tube and the outside environment.

Owner:FUHRMANN KURT F

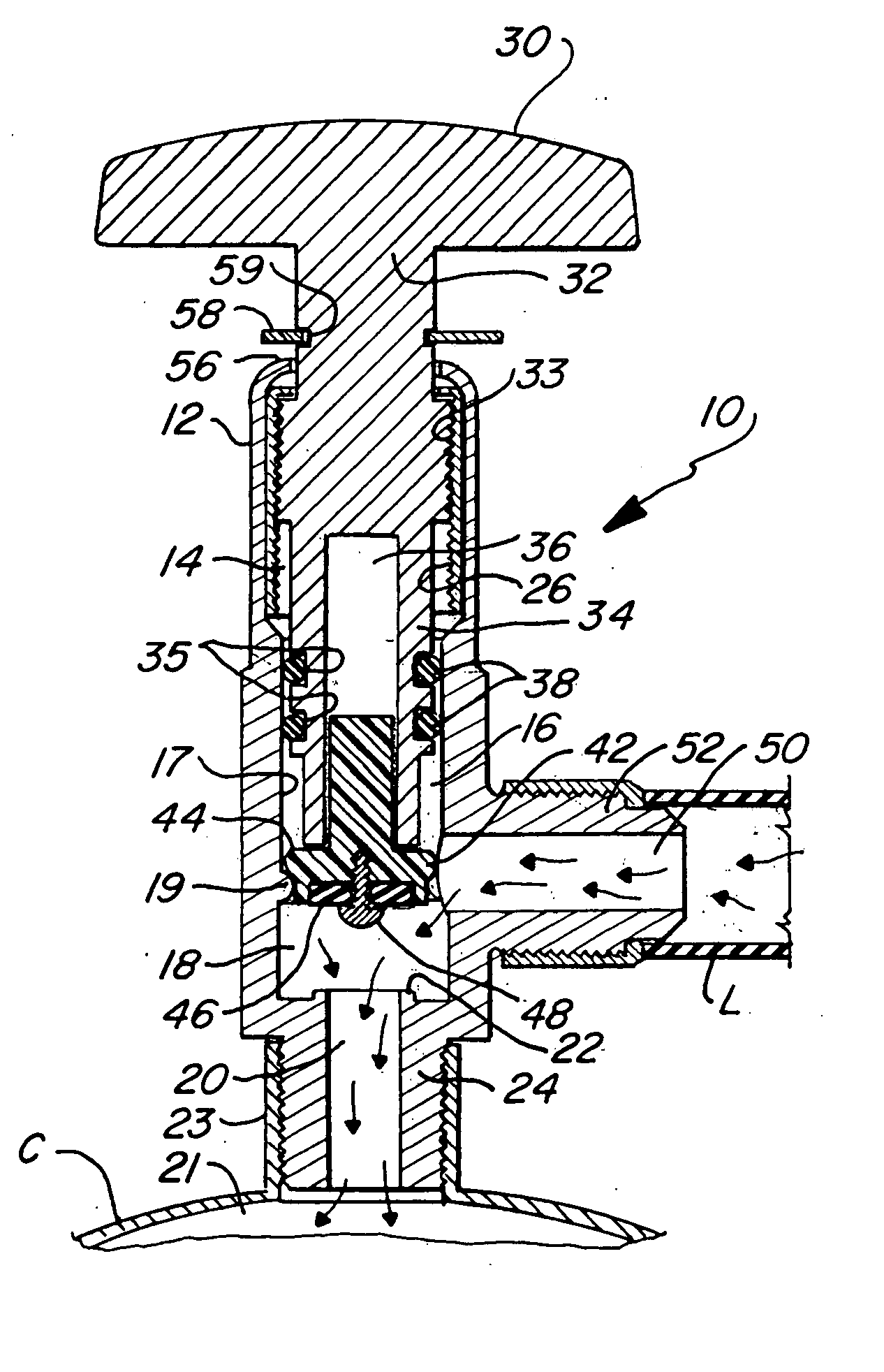

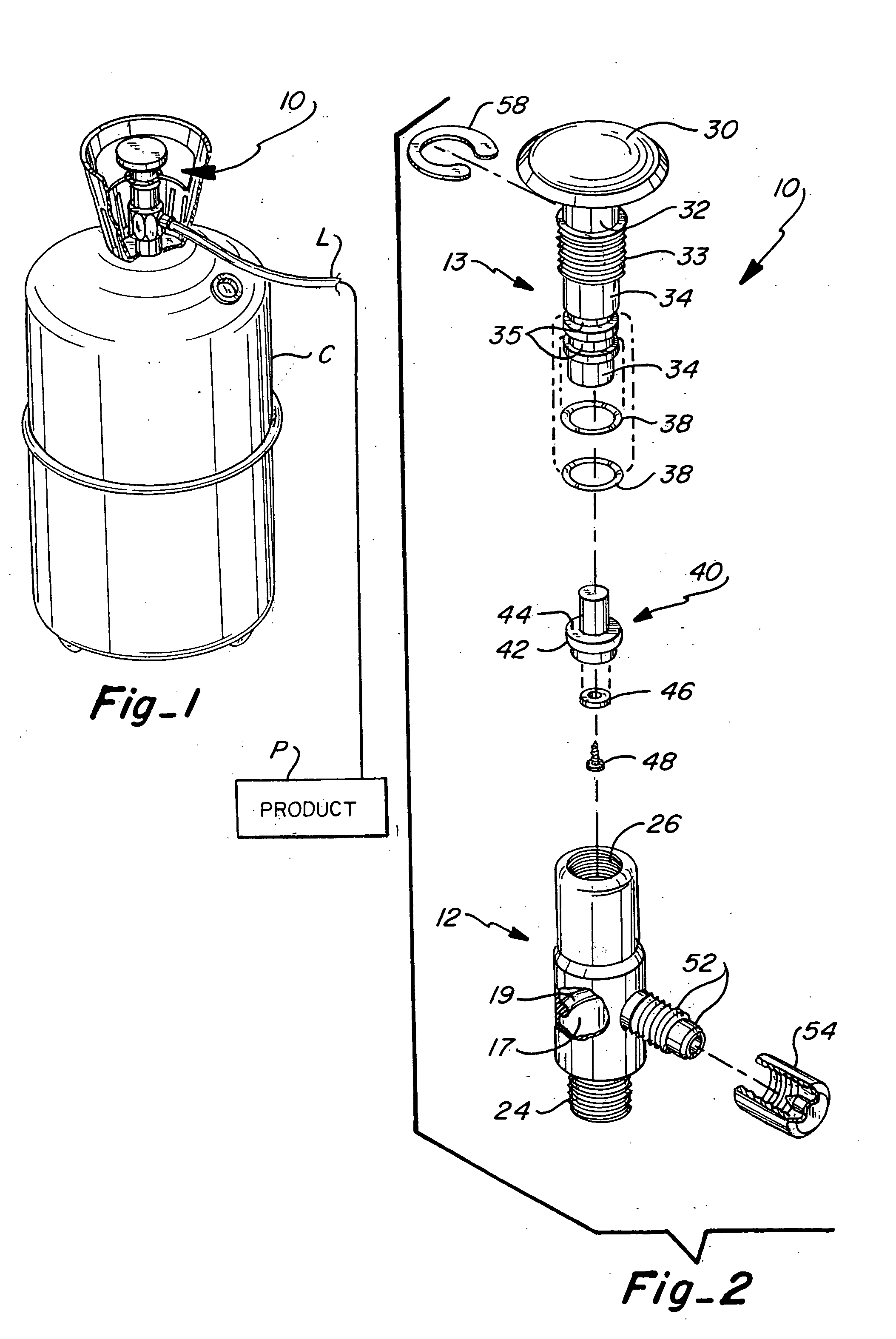

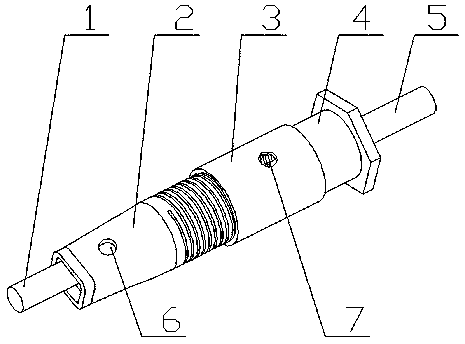

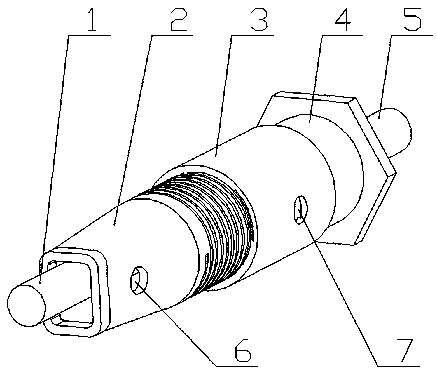

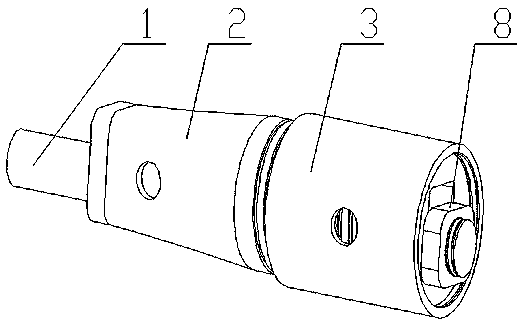

Non-refillable valve

InactiveUS20050082501A1Simple and reliable constructionThe overall structure is simple and reliableOperating means/releasing devices for valvesLift valveValve stemEngineering

A nonrefillable valve is provided that allows for an initial filling of a container, but prevents subsequent refilling of the container. The valve operating assembly includes a valve stem and a valve core which is slidably received in the distal end of the valve stem. In a first position, the valve core resides above a rim or protrusion within the chamber. After filling of the container, a second position is defined when the valve stem is operated to force the valve core beyond the protrusion and in seating engagement with a valve seat, thus sealing the container. The valve is then selectively operated in a third or open position to discharge the container as desired. Subsequent refilling of the container is prevented by the force of fluid reentering the valve which forces the valve core to its seated engagement with the valve seat.

Owner:DISCOUNT REFRIGERANTS

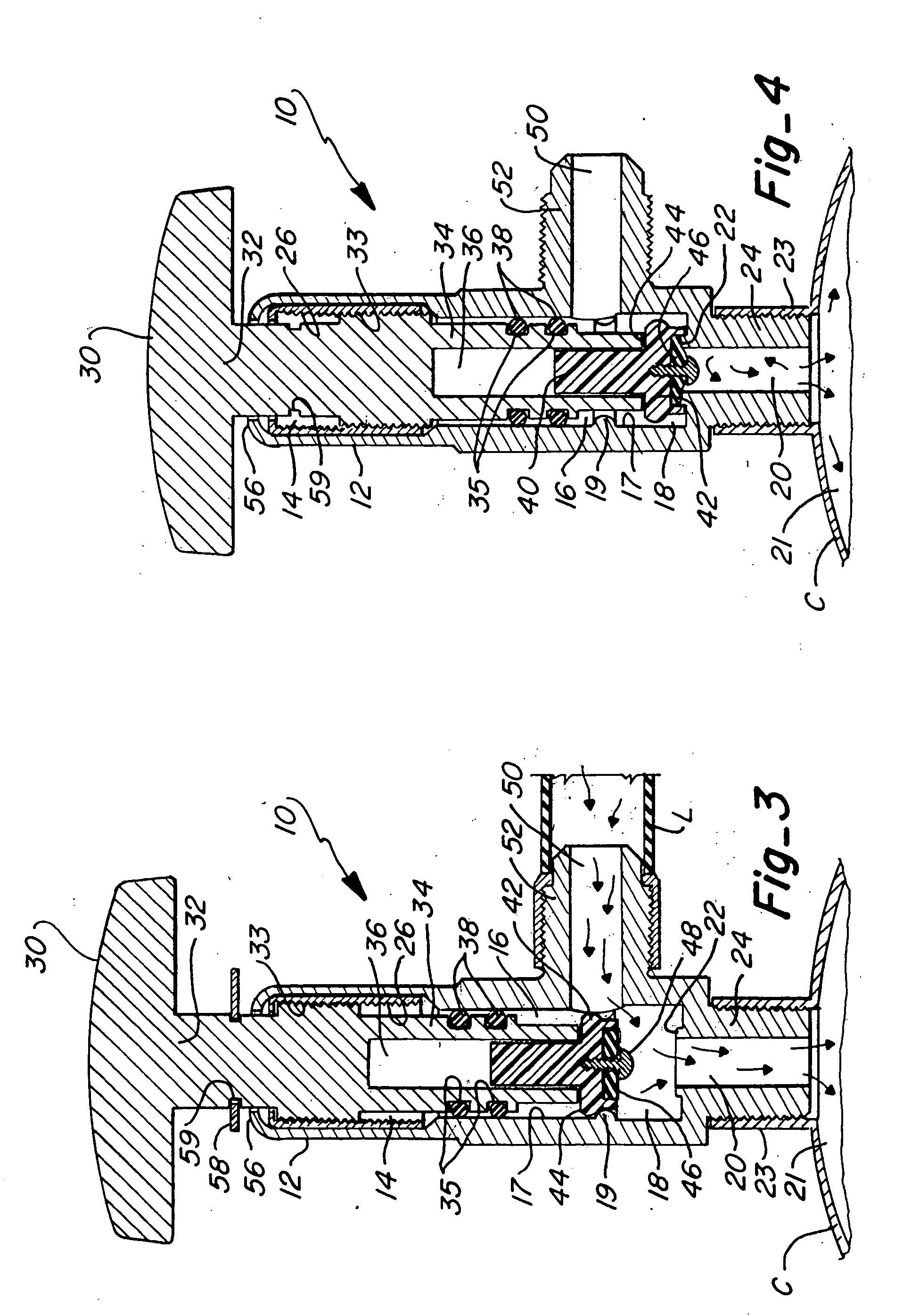

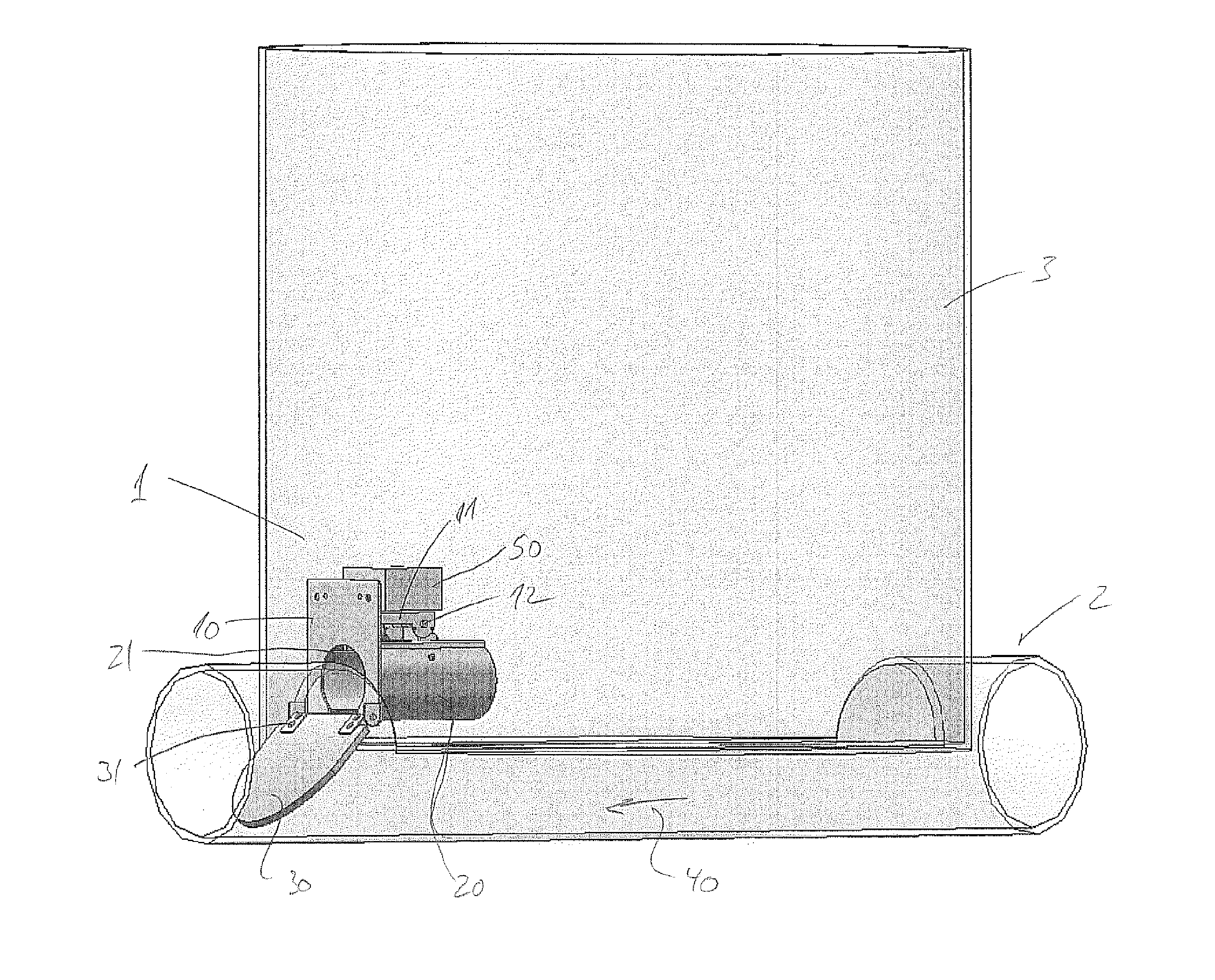

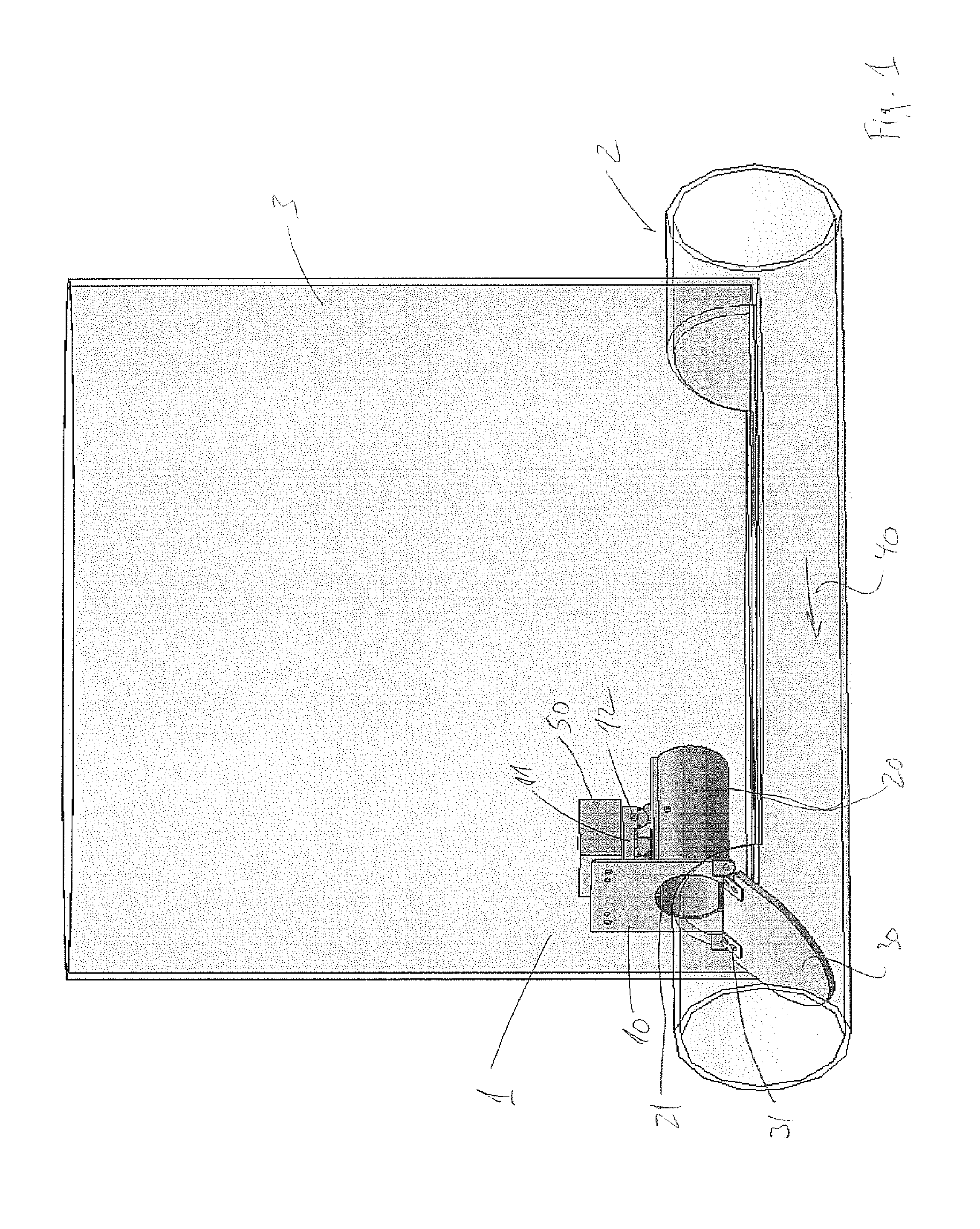

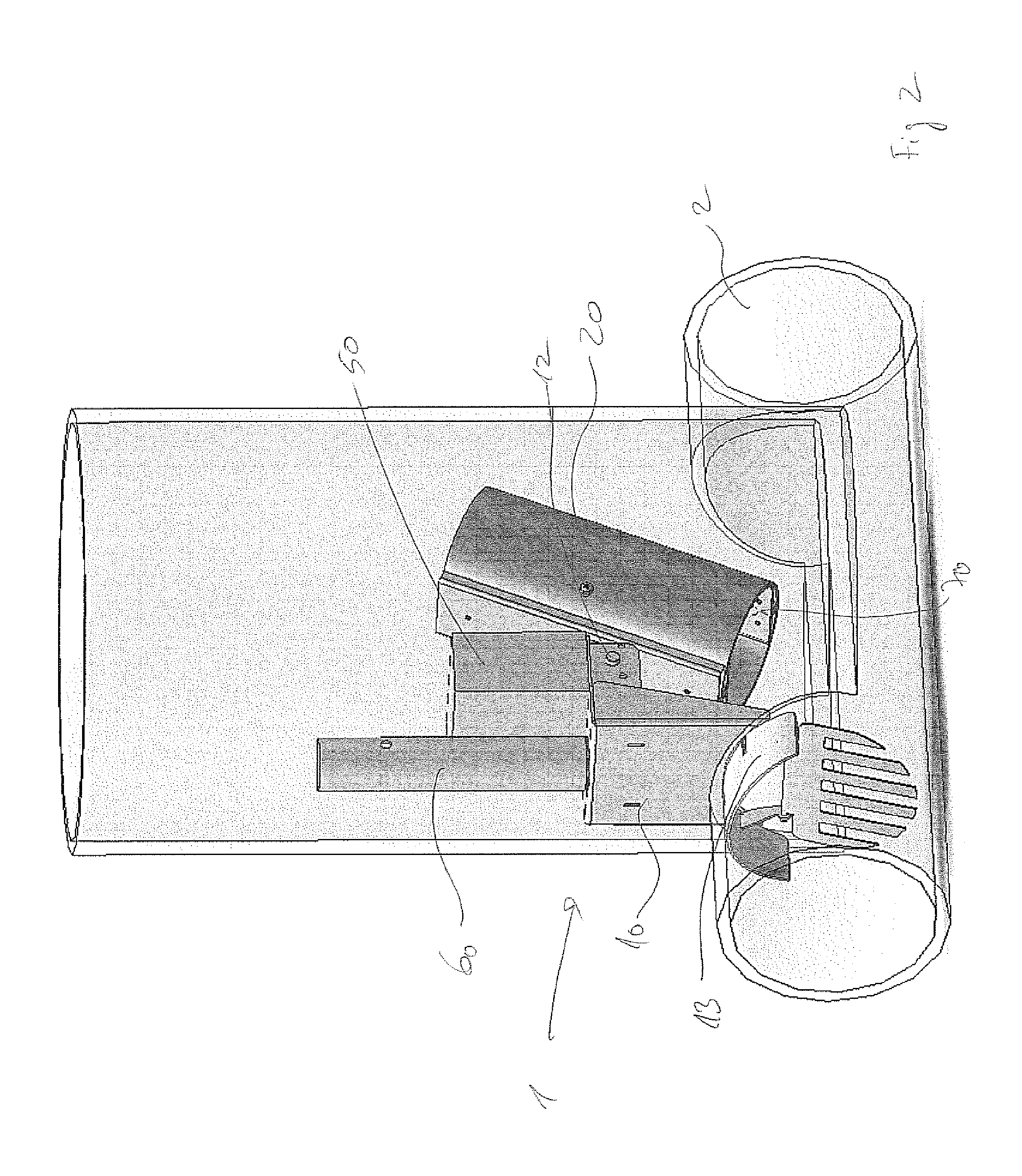

Pest electrocution device

InactiveUS20140373430A1Fast and effective waySimple and reliable constructionElectric shock equipmentsAnimal trapsEngineeringElectrocution

Pest electrocution device, suitable to be mounted in a pipe (2) or conduit, wherein the electrocution device comprises a ramp (30) hingely attached to a chassis (10), which chassis has means to be fastened to said pipe or conduit, where said chassis further comprises a chassis arm (11), and a tunnel element (20), which tunnel element is pivotably fastened to said chassis arm, and where the tunnel element in a first position extends to an upper end of said ramp, such that a pest travelling up the ramp can enter the tunnel element at a first end, where activating means are provided inside the tunnel element, which activation means activate at least three electrodes (70, 71, 72) by supplying electrical current to said electrodes arranged as separate floor plates in the tunnel, such that after activation and a predetermined period of time, the tunnel element pivots the first end downwards into a second position, in which second position the electrocuted pest slides out of the tunnel element, after which the tunnel element is pivoted back in its first position.

Owner:RATEL

Method for preparing water-based natural rubber waterproofing coating

InactiveCN101880495AEasy to findSimple and reliable constructionNatural rubber coatingsWater basedTurpentine

The invention provides a method for preparing a water-based natural rubber waterproofing coating. The coating comprises the following ingredients in part by weight: 50 to 65 parts of water-based natural rubber, 3 to 4.5 parts of ethanol butyl ether, 0.2 to 0.30 part of triethanolamine, 0.2 to 0.35 part of BX-12, 2.0 to 3.5 parts of ethylene glycol, 0.6 to 0.8 part of melamine, 10 to 13 parts of turpentine, 50 to 65 parts of styrene-acrylate emulsion and 10 to 13 parts of kaolin. The method comprises the following steps of: placing natural rubber into a stirrer; adding the ethanol butyl ether, the triethanolamine, the BX-12, the ethylene glycol, the melamine and the turpentine sequentially; uniformly stirring the mixture at normal temperature and normal pressure; and continuously adding the styrene-acrylate emulsion and the kaolin, and uniformly stirring the mixture to obtain the waterproofing coating. The strength of the coating is reinforced by adding 5 to 40-mesh quartz sand in a ratio of 1:1 into the coating during use. The selected ingredients are products sold in markets, and have 46 percent of solid content of the water-based natural rubber and 48 percent of solid content of the styrene-acrylate emulsion.

Owner:程海应

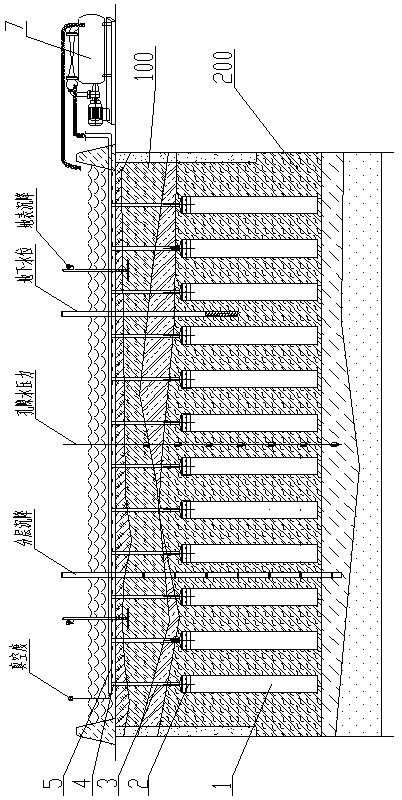

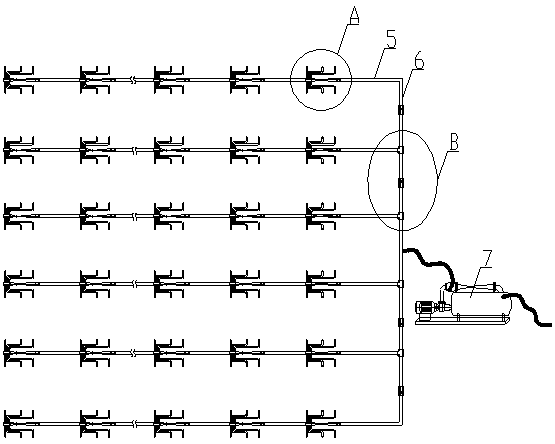

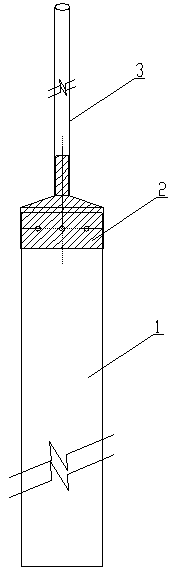

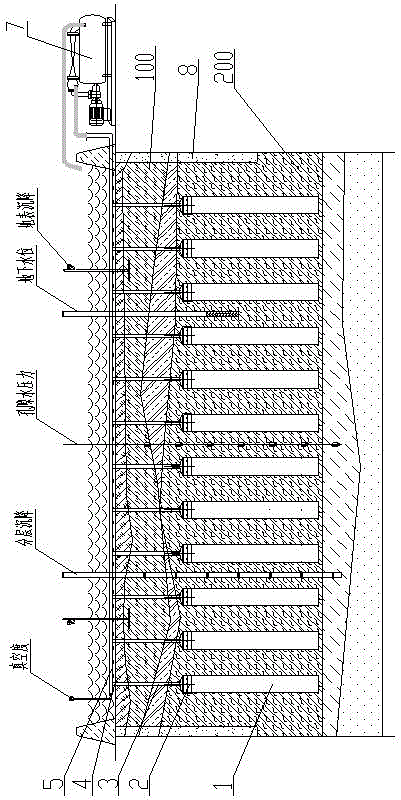

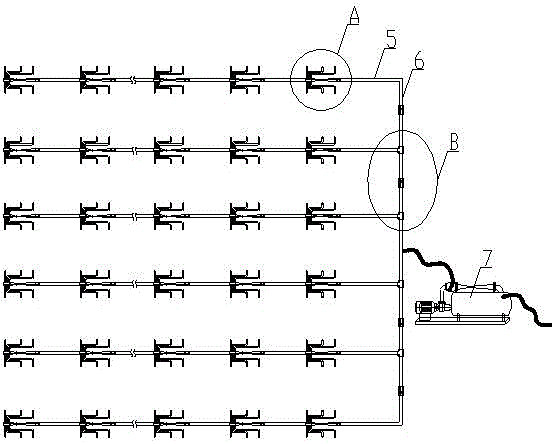

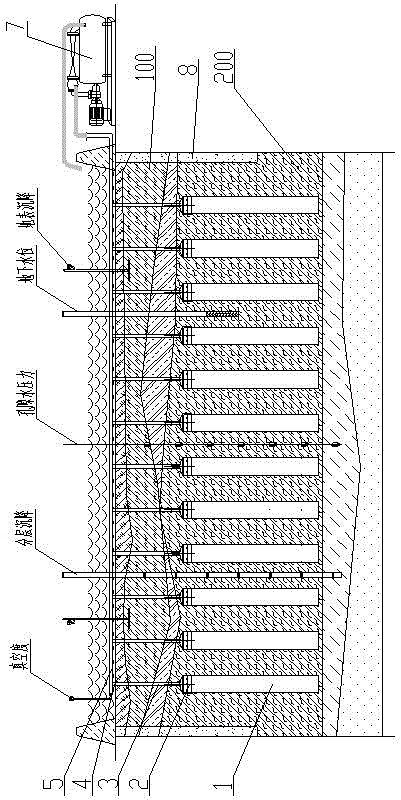

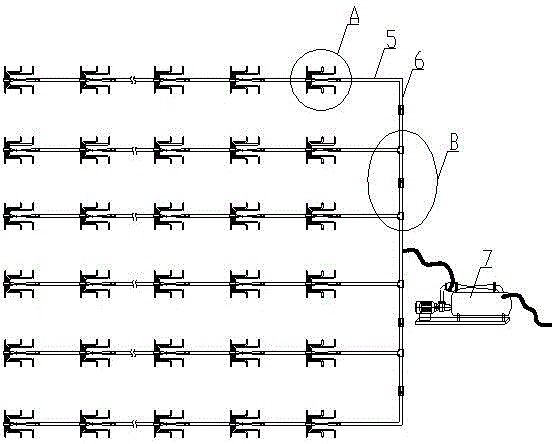

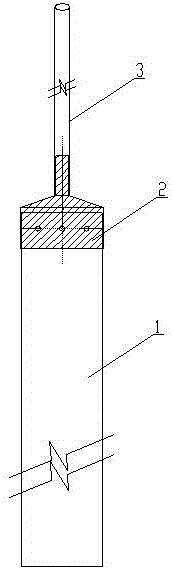

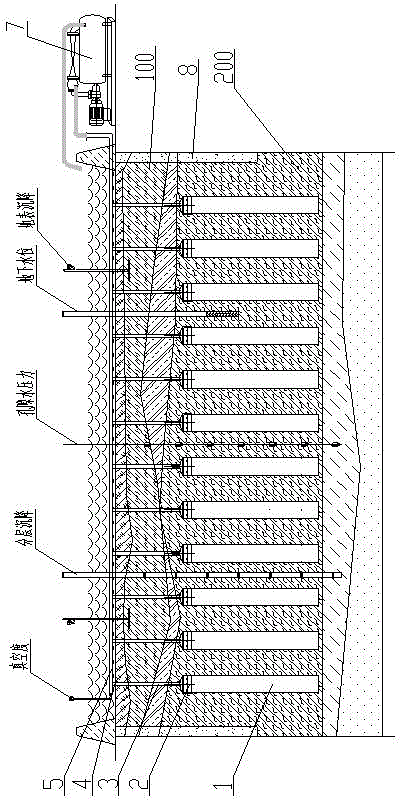

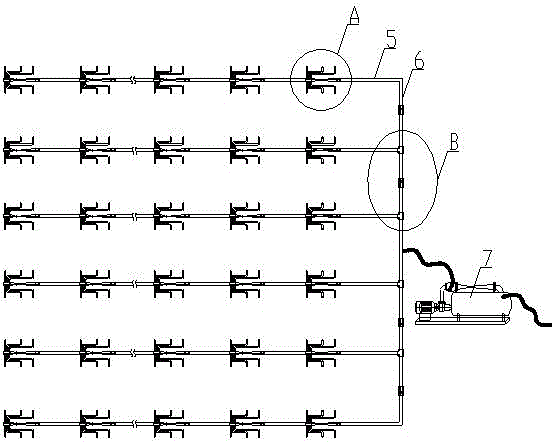

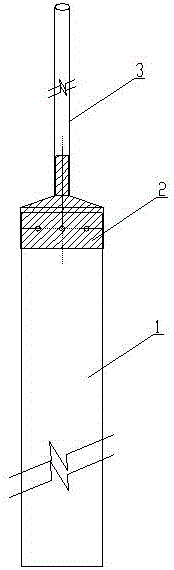

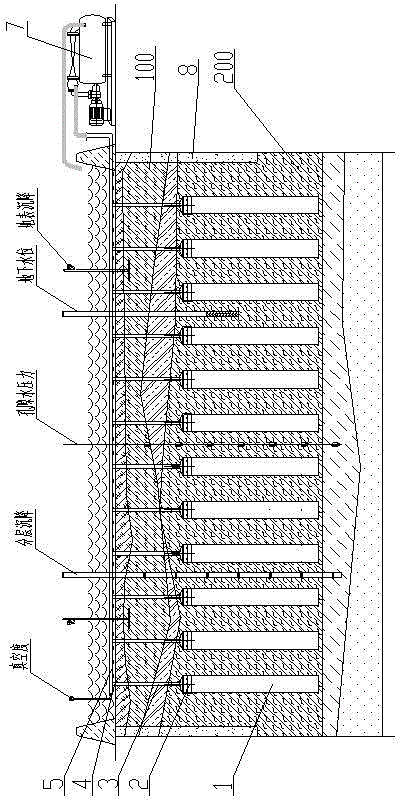

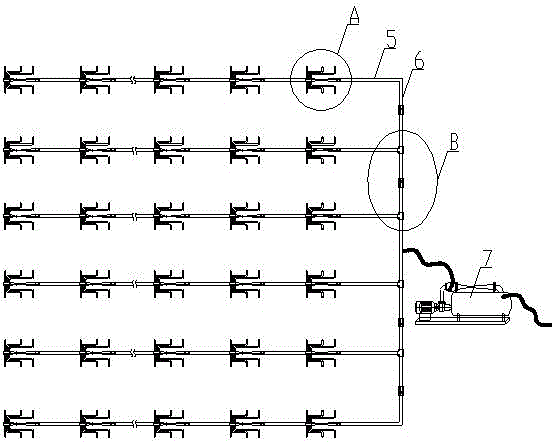

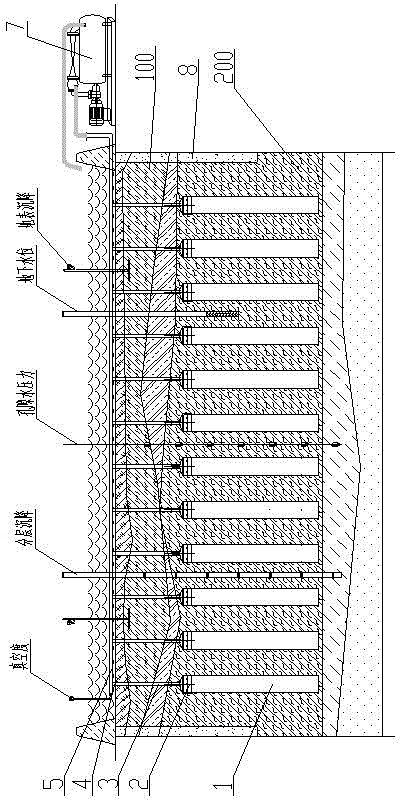

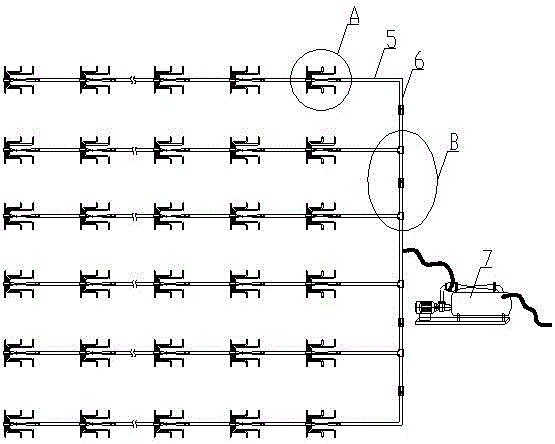

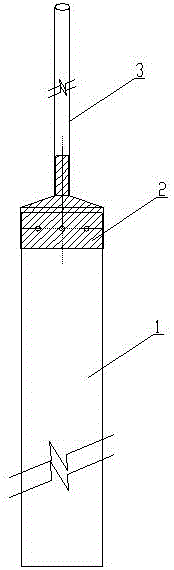

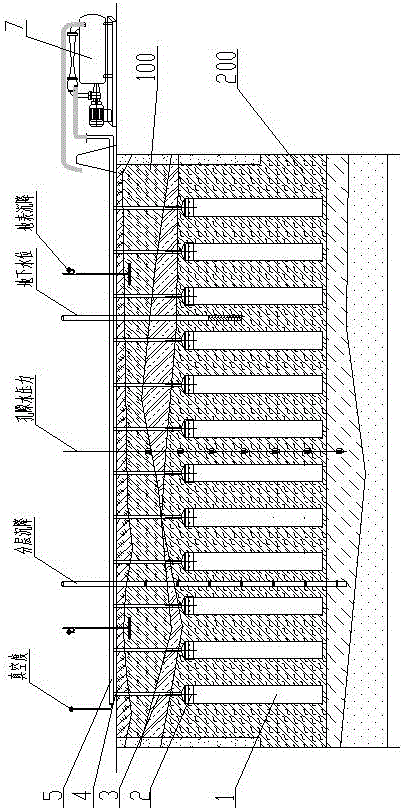

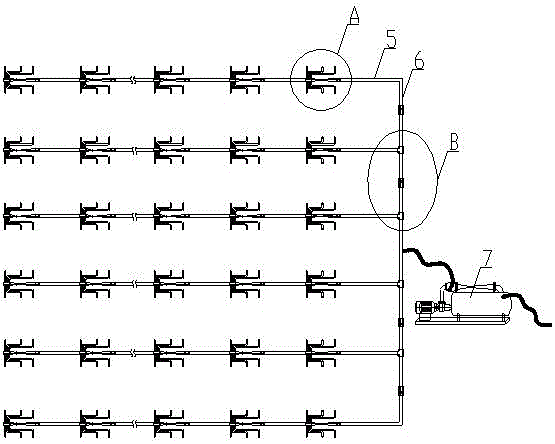

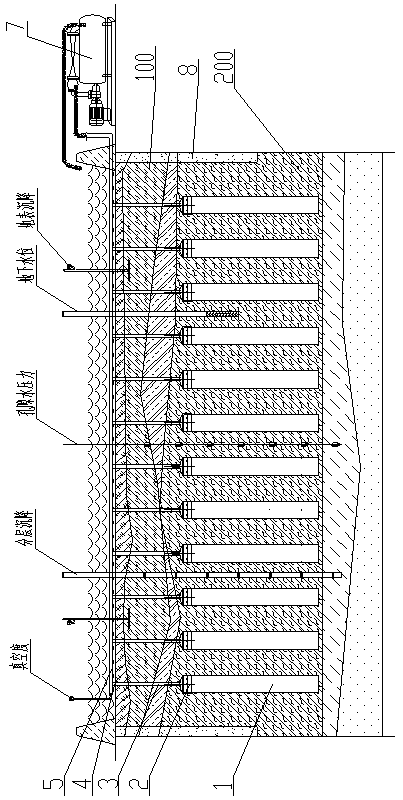

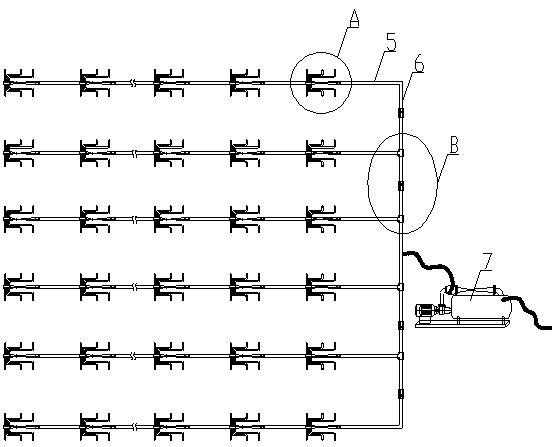

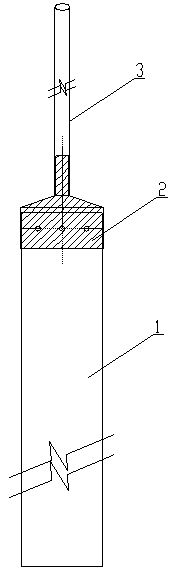

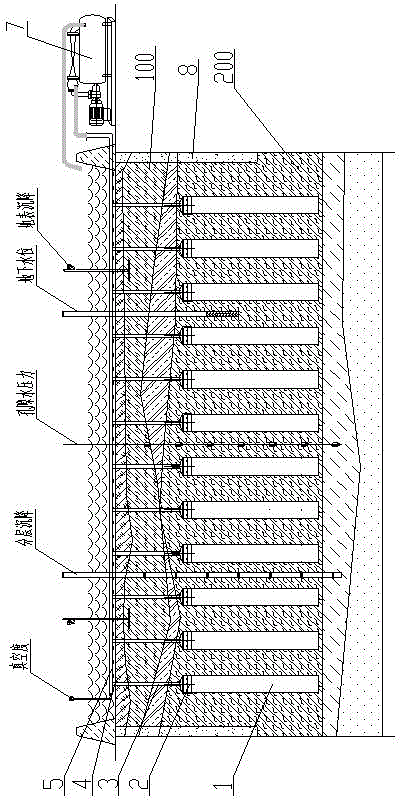

Vacuum preloading seepage consolidation combined with precipitation preloading consolidation method for ultra-soft foundation

ActiveCN106013048BImprove sealingSimple and reliable constructionSoil preservationClassical mechanicsStructural engineering

The invention relates to a super-soft foundation seepage consolidation method combining vacuum preloading and dewatering preloading. The super-soft foundation seepage consolidation method combining vacuum preloading and dewatering preloading is characterized by comprising the following steps that step one, an integrated well point plastic drain vacuum system is arranged, specifically, 1.1, integrated well point plastic drain pipes are subjected to insertion construction to form an integrated well point plastic drain pipe grid, and 1.2, the integrated well point plastic drain vacuum system is formed by connecting the integrated well point plastic drain pipe grid with a header pipe and a vacuum pump; step two, vacuum preloading is conducted; and step three, vacuum dewatering preloading is conducted. The super-soft foundation seepage consolidation method combining vacuum preloading and dewatering preloading has the advantages of being easy to operate, low in cost and good in construction effect.

Owner:CABR FOUND ENG CO LTD

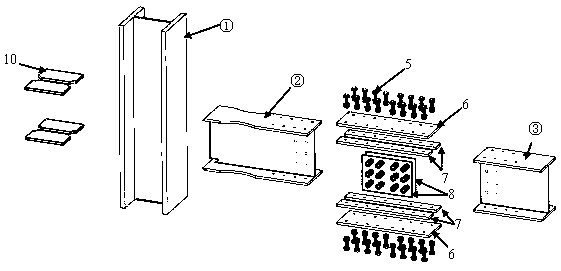

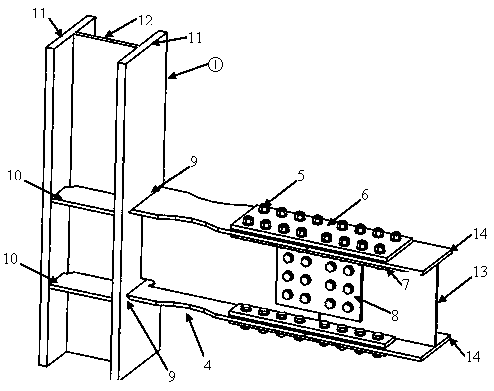

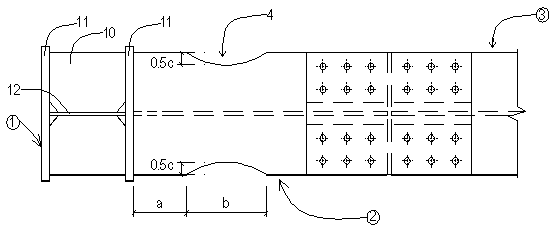

Assembly type bone-shaped shock-resistance node

InactiveCN111287337AEasy to manufactureRealize on-site assemblyProtective buildings/sheltersShock proofingShaped beamStructural engineering

The invention discloses an assembly type bone-shaped shock-resistance node. The assembly type bone-shaped shock-resistance node is mainly composed of an H-shaped steel column, an H-shaped steel beam,a bone-shaped beam and a splice node, wherein the bone-shaped beam is added on the outer side of the joint between the H-shaped steel beam and the H-shaped steel column and is formed by cutting wing edges of a section of the H-shaped steel beam, the middle is small and two ends are large to form a bone-shaped structure, the bone-shaped beam is located between the steel column and the steel beam, one end of the bone-shaped beam is connected with the H-shaped steel beam through the splice node, the other end of the bone-shaped beam is welded to the steel column, bone-shaped beam wing edges are connected with steel beam wing edges through beam wing edge outer connection plates, beam wing edge inner connection plates and high-strength bolts, and a bone-shaped beam ventral plate and a steel beam ventral plate are connected through double-clamping-plate bolts. According to the assembly type bone-shaped shock-resistance node, by means of combination between the bone-shaped beam and the splicenode, a pre-set plastic hinge is made to occur at the bone-shaped beam, under the action of large shock, the bone-shaped beam forms the plastic hinge to become an energy-consuming beam end, the wholestructure is protected from collapse under the large shock, welding preparatory work performed on the spot is not needed, the on-the-spot construction cost is greatly reduced, and the construction period is greatly shortened.

Owner:上海同煦工程咨询有限公司

Explosion method for demounting bridge

ActiveCN110645856AReduce the number of drilled holesImprove work efficiencyBlastingBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses an explosion method for demounting a bridge. The method comprises the following steps that (1) drilling is carried out; (2) powder filling and tamping are carried out; (3) piers and other explosion positions are protected through a double-layer protection material, a layer of bamboo board is additionally arranged on the outer side, a layer of bamboo board is laid on the bridge deck, and a layer of sand bags presses the bamboo board; (4) equipment or buildings nearby are covered with sand bags; (5) bamboo boards or double-layer dense screens are hung around the bridge for shielding protection; (6) three detonating cords are arranged on each of the two sides of the bridge, after the two ends of each detonating cord are connected through a rope, the detonating cords are fixed towards both banks, stone is hung on the detonating cords every other section for assisting in sinking, the detonating cords are obliquely pulled through the ropes fixed to the bridge to reduce the bending radian of the detonating cords; and (7) the detonating cords are delayed to be detonated when the bridge is exploded. According to the explosion method, flying stone and dust generated by explosions can be effectively controlled.

Owner:江西荣达爆破新技术开发有限公司

Prefabricated reinforced concrete volute template and construction method thereof

InactiveCN101936067ASolve complexitySolve problemsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksReinforced concreteKeel

The invention discloses a prefabricated reinforced concrete volute template and a construction method thereof. A volute inner die comprises an inner die support and an inner die template, and the inner die support connects radial steel trusses of each roof truss at radial intervals from the volute inner wall to the volute outer wall into a whole by using annular connecting steel bars; the radial steel truss has a shape with wide lower edge and narrow upper edge, the outer end of the radial steel truss is vertical, the upper part of the inner end of the radial steel truss accords with the volute inner wall in shape, the middle part of the inner end of the radial steel truss is horizontal, and the lower part of the inner end of the radial steel truss is vertical; and the inner die template takes joist steels connected at the inner end of the radial steel truss as main keels and takes battens blocked between the joist steels as secondary keels, lining plates are fixedly connected on the battens, and inner die panels are nailed on the surfaces of the lining plates. The template solves the problem of complex and difficult construction of the prefabricated reinforced concrete volute with complex shape, and does not need high-precision processing equipment; and the steel-wood combined template can be reused, has low cost, simple and reliable construction process and convenient operation, and greatly saves the construction cost.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

Vacuum prepressing seepage consolidation method

The invention relates to a vacuum prepressing seepage consolidation method. The vacuum prepressing seepage consolidation method is characterized by comprising the following steps that firstly, an integrated well point plastic vacuumizing system is arranged, specifically, insertion construction of integrated well point plastic vacuumizing pipes is conducted, so that an integrated well point plastic vacuumizing pipe mesh is formed; the integrated well point plastic vacuumizing pipe mesh is connected with a main pipe and a vacuum pump, so that the integrated well point plastic vacuumizing vacuum system is formed; and secondly, vacuum prepressing is conducted, specially, cofferdam diking is conducted around an area to be reinforced, a water source around the outside of the reinforced area is pumped into a cofferdam in the area to be reinforced in the early stage, then vacuum prepressing is conducted through the integrated well point plastic vacuumizing system, pumped underground water is completely recharged to the surface of the area to be reinforced during vacuum prepressing, and after the surface of the area to be reinforced is completely immersed in water by a certain height, water-covered prepressing, water-covered sealing and water-covered seepage are achieved. The vacuum prepressing seepage consolidation method has the advantages that operation is easy, the cost is low, and the construction effect is good.

Owner:CABR FOUND ENG CO LTD

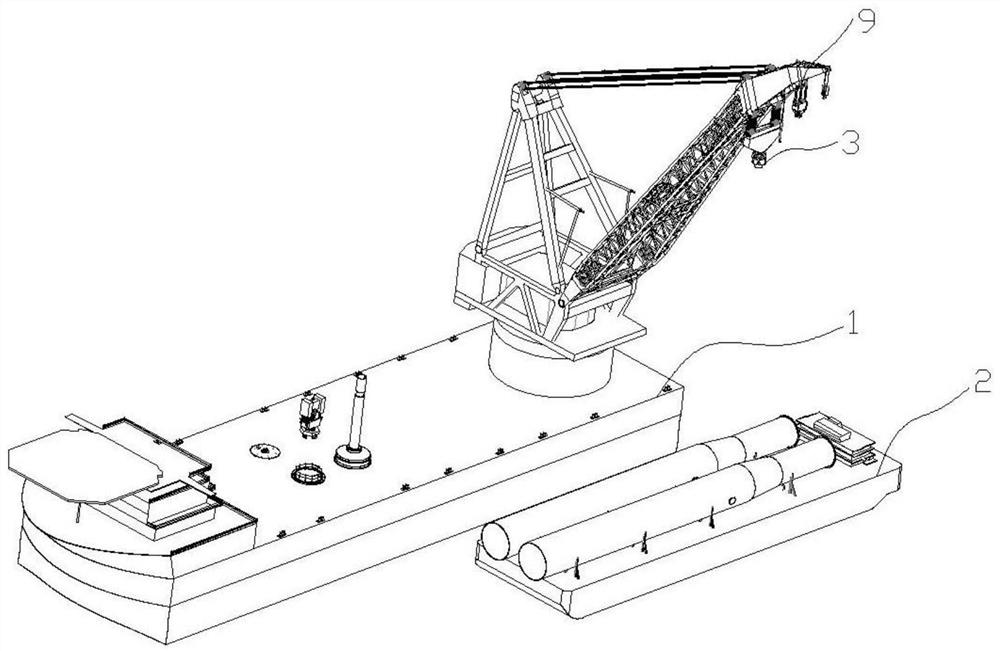

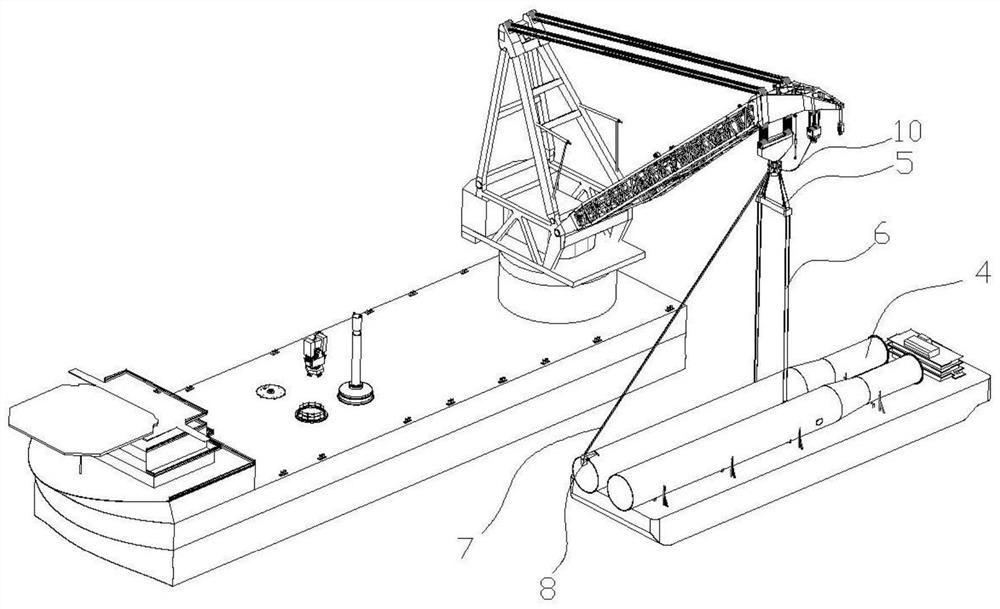

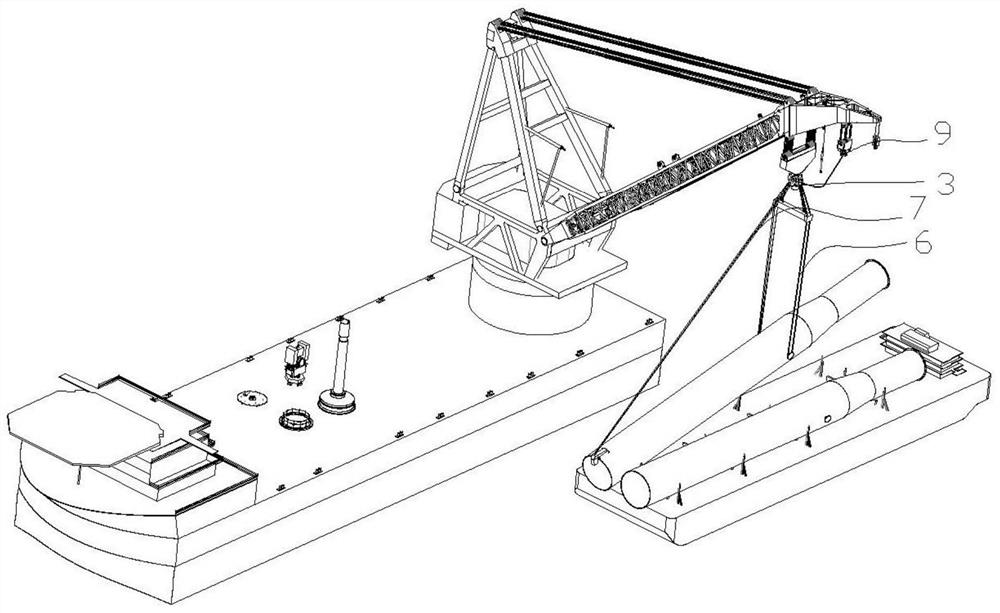

Method for pile turning of large-diameter single pile through full-rotation crane ship

PendingCN112897339ALow input costIncrease job securityLoad-engaging elementsCranesMarine engineeringStructural engineering

The invention discloses a method for pile turning of a large-diameter single pile through a full-rotation crane ship. The method comprises the following steps that S1, ship positioning is conducted, specifically, the crane ship and a transport ship travel to a wind field machine position to be anchored and positioned, and the positions are kept relatively stable; S2, an appropriate sling, an appropriate main lifting rope and an appropriate auxiliary lifting rope are selected, a bearing beam and a limiting stopper are welded on the transport ship in advance, and the single pile can be fixedly placed conveniently; S3, the sling is parallelly hung on a main hook through the main lifting rope, an auxiliary rope is hung on an auxiliary hook, one end of the auxiliary lifting rope is hung on the main hook, the main lifting rope is connected with lifting lugs on the two sides of the single pile, and a tail slipping hook fixed to the other end of the single pile is arranged at the other end of the auxiliary lifting rope; and S4, the single pile is hoisted by the main hook, after the single pile leaves the transport ship, the transport ship is driven away from the crane ship, after the single pile is hoisted until the tail slipping hook is unhooked, the single pile continues to be hoisted to be vertical, and pile turning is completed. The main lifting rope and the auxiliary lifting rope on the crane ship enable the single pile to be more stable under the cooperation of a lifting pile, operation safety is improved, the whole construction process is simple and reliable, and construction efficiency is high.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

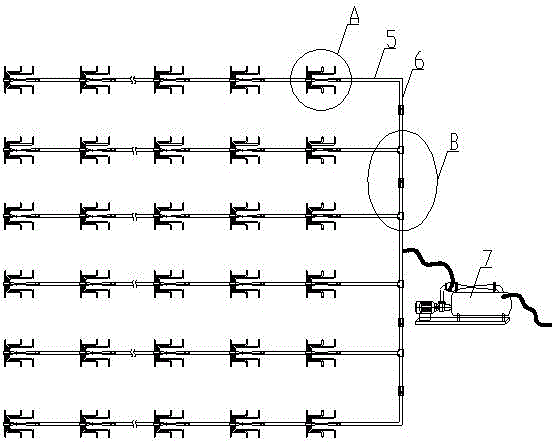

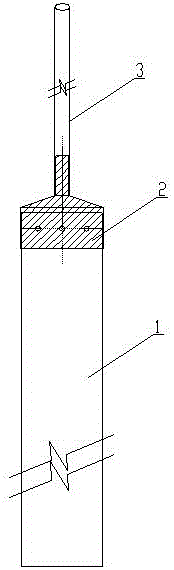

Soft foundation water cover type integrated well point plastic strip vacuum system

ActiveCN105862714AImprove sealingSimple and reliable constructionSoil preservationEngineeringVacuum pump

The invention relates to a soft foundation water cover type integrated well point plastic strip vacuum system. The vacuum system is characterized by comprising an integrated well point plastic strip pipe grid formed through insertion and construction of integrated well point plastic strip pipes, wherein the integrated well point plastic strip pipes include draining plates, connecting boxes, well point pipes and connecting pipes, the draining plates are vertically distributed in a deep soil body, the well point pipes are distributed in a shallow soil body, the upper ends of the draining plates are connected with the lower ends of the well point pipes through the connecting boxes, the upper ends of the well point pipes are exposed outside the shallow soil body, and the upper ends of the well point pipes are connected with one ends of the connecting pipes; and the integrated well point plastic strip pipe grid is connected with a main pipe and a vacuum pump to form the integrated well point plastic strip vacuum system, and a water cover layer is arranged on surface of a to-be-reinforced region for distributing the integrated well point plastic strip pipe grid. The vacuum system has the advantages that the operation is simple, the cost is low, and the construction effect is good.

Owner:CABR FOUND ENG CO LTD

Well point plastic draining pipe type vacuum preloading seepage consolidation and dewatering preloading power consolidation combined method

ActiveCN105970909AResidual settlement reductionReduce the impactSoil preservationWater sourceCombined method

The invention relates to a well point plastic draining pipe type vacuum preloading seepage consolidation and dewatering preloading power consolidation combined method. The method is characterized by comprising the following steps: levelling a site, and draining an area to be reinforced; then determining to carry out or not carry out pre-tamping before dewatering; arranging an integrated well point plastic draining pipe vacuum system; performing vacuum preloading, namely, constructing dams of cofferdams around the area to be reinforced, and pumping water from a water source in the periphery of the area to be reinforced into the cofferdams around the area to be reinforced, and then carrying out vacuum preloading, wherein underground water is completely pumped and returned to the surface of the area to be reinforced during the vacuum preloading; performing vacuum dewatering preloading, namely, forming openings in the constructed dams of the cofferdams to drain water stored in the dams of the cofferdams, and carrying out vacuum dewatering preloading at a plurality of times, wherein light tamping is carried out between every two adjacent vacuum dewatering preloading processes, and full tamping is carried out after the last vacuum dewatering preloading; finally, vibrating and rolling in the whole site, then measuring the elevation, and handing over the completed project. The method has the advantages of being simple to operate, low in cost, and good in construction effect.

Owner:CABR FOUND ENG CO LTD

Acid-and-alkali-resistant root-puncture-resistant polyurethane waterproof coating and preparation method thereof

The invention relates to an acid-and-alkali-resistant root-puncture-resistant polyurethane waterproof coating, which is made from trifunctional polyether, bifunctional polyether, isocyanate, a latentcuring agent, a chemical root retarder, an antifoaming agent, a dispersant, a levelling agent, a plasticizer, an accelerating agent, a filling material, a pigment, a catalyst, fumed silica and a diluent. The coating is high in strength, the coating film is compact and is free of bubbles or seams, and the coating is convenient and reliable to apply and can form a whole body together with the structure base. The coating has physical and chemical root retardant effect, is good in root puncture resistance, and excellent in waterproofness and impervious performance. The coating has anti-channelingperformance. When leaking happens, leakage points are easy to find, and the coating is convenient to maintain.

Owner:唐山德生科技有限公司

Reinforced foundation

ActiveCN105862719AImprove sealingSimple and reliable constructionSoil preservationEngineeringBuilding construction

Owner:CABR FOUND ENG CO LTD

Implementation method of petrochemical pipe anti-corrosion insulating layer

InactiveCN108006370AGood mechanical propertiesGood anti-aging performanceThermal insulationChloropene polymer coatingsPetrochemicalPre treatment

The invention discloses an implementation method of a petrochemical pipe anti-corrosion insulating layer. The method comprises following steps that firstly, steel pipe surface pretreatment; secondly,defect repairing and sand blasting of structures like a welding line; thirdly, insulating layer laying; fourthly, anti-corrosion layer spraying; fifthly, operation of repeated spraying for two to three times. Liquid rubber spraying paint has the good mechanical property and anti-aging performance; the coating can perfectly wrap substrates, coating is achieved, the substrates are in seamless connection, opening, stripping and falling are avoided, the good protection effect on a base layer is achieved, and a bend, a connector, a valve and other special structures or base layer can be constructedmore simply, conveniently and reliably; in the spraying process, the construction is convenient, efficiency is high, after spraying, instant forming is achieved, and through one-time rapid hardening,a firm is formed. The excellent chemical corrosion resistance is achieved, acid, alkali, salt and chlorine can be resisted, and the method is particularly suitable for anti-corrosion heat preservation of a petrochemical pipe. The pipe anti-corrosion quality is improved, the pipe service life is prolonged, and the safety production is ensured.

Owner:大连美宸特环保节能产品有限公司

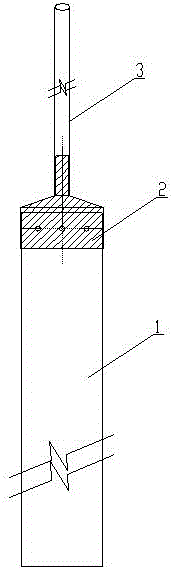

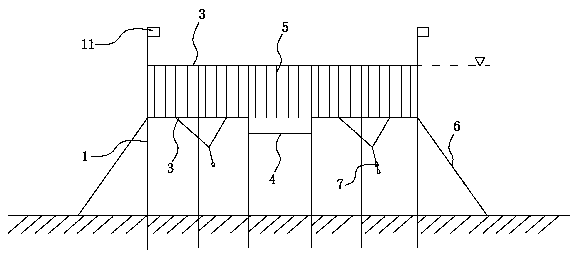

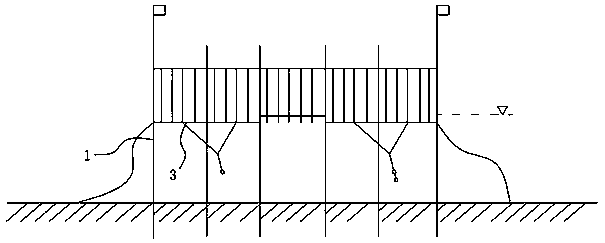

Cultivation method of porphyra in shallow water area of outer island reef sea area

InactiveCN107801627AEstimated outputSimple and reliable constructionCultivating equipmentsSeaweed cultivationWeight gainingPorphyra

The invention discloses a cultivation method of porphyra in a shallow water area of an outer island reef sea area. The cultivation method comprises the steps of selecting a sea area, fixing equipment,erecting equipment, performing daily management and the likes. According to the cultivation method, a special device is adopted, and a support floating frame which can freely slide up and down is arranged on the vertical columns of the special device; the upper and lower ends of the support floating frame are connected with traction ropes; the lower end of the support floating frame is also connected with anchor ropes; attachments which can be attached by the porphyra are arranged between the traction ropes; the traction ropes at the lower end of the support floating frame are provided with floating bodies, and are also connected with weight blocks. The support floating frame has a buoyancy force, so that the porphyra on the attachments can be pushed out of water surface at a low tide level, thereby playing a dry dew effect. When a tide rises to a high tide level, seawater will submerge the traction ropes at the upper end of the support floating frame, thereby causing all the porphyraon the attachments to be immersed in water and stopping the dry dew. Therefore the cultivation method has the advantages that the efficient dry dew can promote weight gain, yield can be estimated during the production process, construction is simple and reliable, and management is convenient.

Owner:吴常文

Construction method and pouring structure in prestressed tendon position of prestressed coal bin cylinder wall

The invention discloses a construction method and a pouring structure in the prestressed tendon position of a prestressed coal bin cylinder wall, which are convenient to construct, and can shorten the construction period. The construction method and the pouring structure mainly adopt the steps as follows: slip form templates corresponding to prestressed tendons are dismantled when slip form dies and a supporting platform move to the position under the prestressed tendons, and wooden templates are arranged in the positions corresponding to the prestressed tendons; the wooden templates are connected with cylinder wall reinforcement bars; through holes are formed in the wooden templates; the prestressed tendons penetrate out from the through holes, and notches used for avoiding the prestressed tendons are formed on the supporting platform; the slip form dies are slide to a layer, in which the prestressed tendons are arranged; the wooden templates and the slip form dies can form a prestressed tendon layer pouring die together; and concretes are poured into the prestressed tendon layer pouring die. Further, two sets of the wooden templates can be recycled, that is, the slip form construction technology and reverse mould construction technology are used in combination, so that the use amount of the wooden templates can be reduced, and the construction period can also be shortened.

Owner:CHINA 19TH METALLURGICAL CORP

Grading loading method for variable-stress path well point plastic drainage vacuum preloading seepage consolidation

ActiveCN106013046ACertain residual settlement after construction is reducedResidual settlement reductionSoil preservationEngineeringStress path

The invention relates to a grading loading method for variable-stress path well point plastic drainage vacuum preloading seepage consolidation. The method is characterized in that in a vacuum preloading stage, vacuum pumps perform vacuumization in a grading loading manner, and the operation that vacuum pumps perform vacuumization in the grading loading manner includes the following steps that the vacuum pumps perform grading loading on the first stage, the treatment area of each vacuum pump ranges from 1800 square meters to 2000 square meters, the negative pressure of the first segment of a header pipe is full-meter 100 kPa, and the pressure of the tail end of the header pipe is not lower than 90 kPa; when sedimentation meets the requirement that sedimentation in continuous three days is not larger than 3 mm, the vacuum pumps perform grading loading on the second stage, and the treatment area of each vacuum pump ranges from 1300 square meters to 1500 square meters; when sedimentation meets the requirement that sedimentation in continuous three days is not larger than 3 mm, the vacuum pumps perform grading loading on the third stage, the treatment area of each vacuum pump ranges from 800 square meters to 1000 square meters or below; and in the same way, when sedimentation meets the requirement that sedimentation in continuous five days is not larger than 2 mm, the vacuum preloading treatment requirement is met. The grading loading method has the beneficial effects of being easy to operate, low in cost and good in construction effect.

Owner:CABR FOUND ENG CO LTD

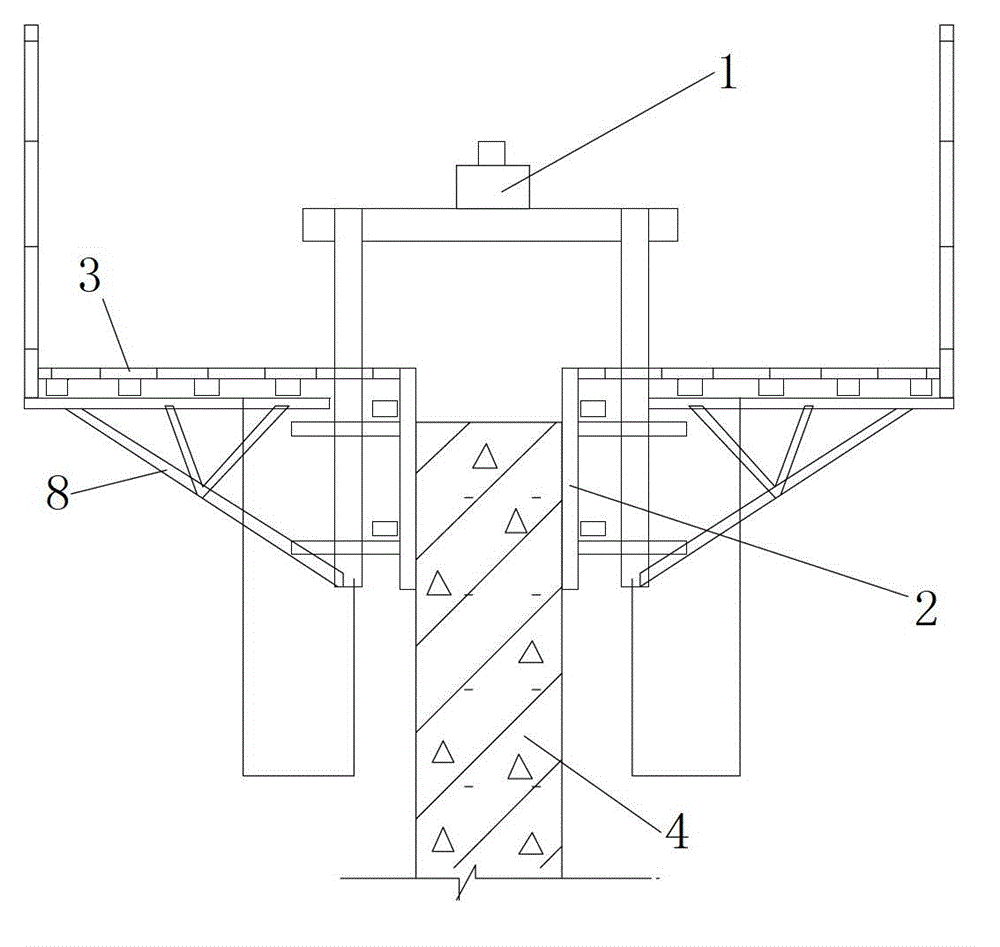

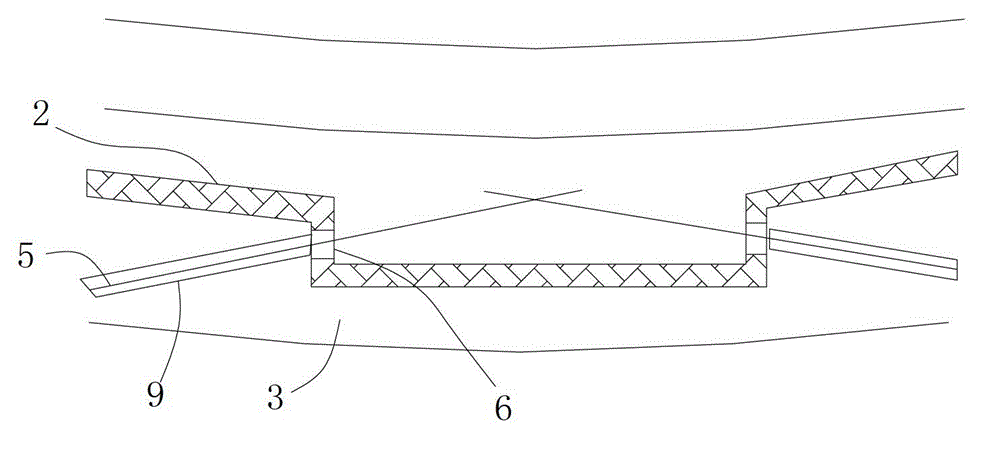

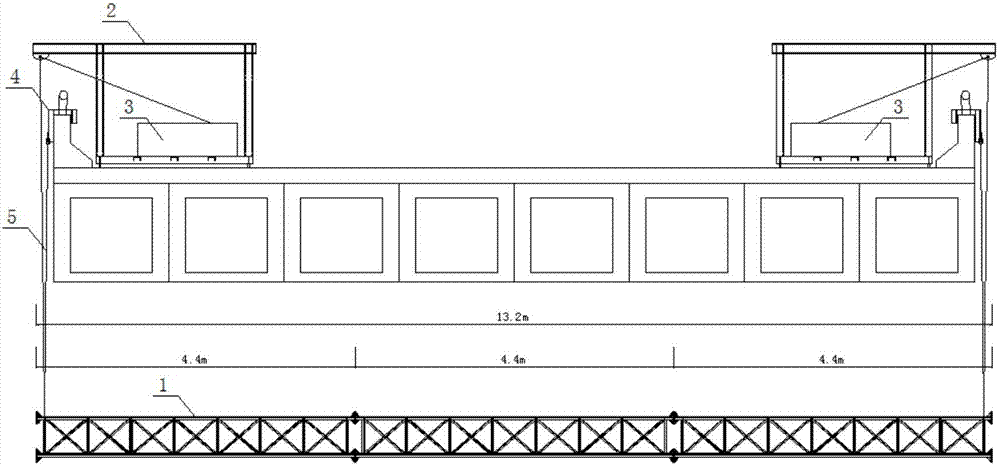

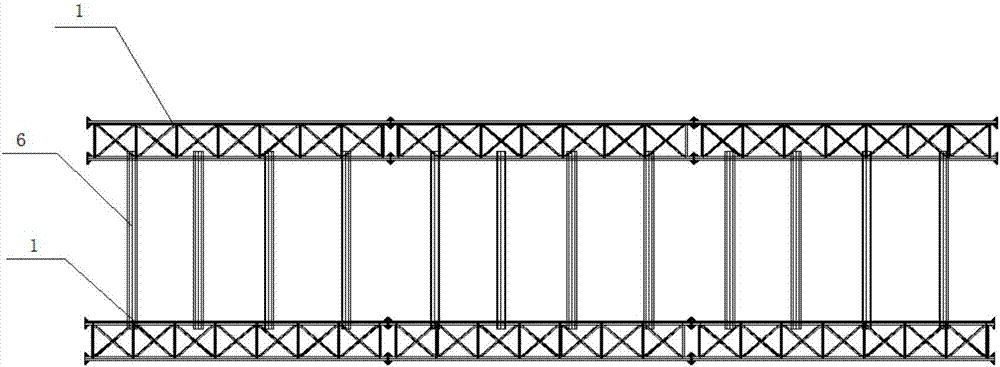

Overhauling construction platform capable of being quickly installed and detached, and construction method for same

ActiveCN106906756AImprove bearing capacityReduce construction costsBridge erection/assemblyBridge strengtheningEngineeringSurface plate

The invention discloses an overhauling construction platform capable of being quickly installed and detached and a construction method for the same. The overhauling construction platform comprises a suspension bracket platform system, a hoisting mobile system and an anchoring system, wherein the hoisting mobile system is arranged on a bridge structure body to hoist and move the suspension bracket platform system; triangular truss main beams are fixed under the bridge structure body via the anchoring system; the suspension bracket platform system has a plurality of triangular truss main beams mounted under the bridge structure body and longitudinally distributed along the bridge structure body, a plurality of secondary beams fixed on two adjacent triangular truss main beams at intervals to form a stress skeleton for the platform system, and a panel placed and fixed on the secondary beams to form the platform. The overhauling construction platform capable of being quickly installed and detached is economically suitable and safe in structure; bridge strengthening effect and quality can be guaranteed; construction safety can be ensured; and construction work efficiency can be improved.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

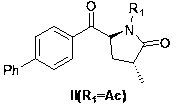

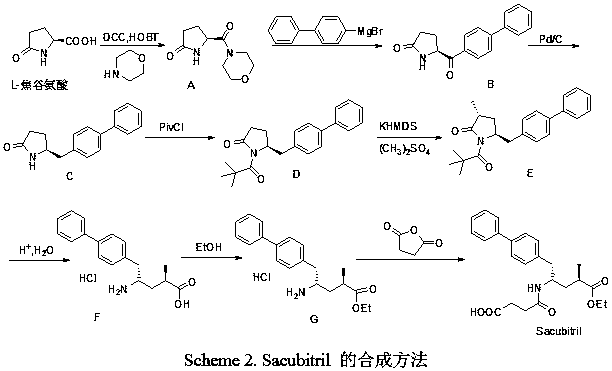

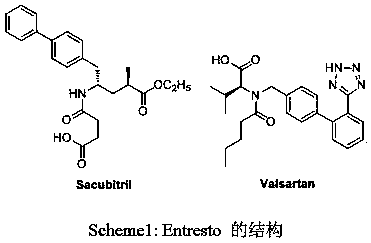

Synthesis of enkephalinase inhibitor

ActiveCN108203396ASimple and reliable constructionReduce riskOrganic compound preparationOrganic chemistry methodsEnkephalinase inhibitorL-Pyroglutamic Acid

The invention discloses a novel synthesis method of enkephalinase inhibitor Sacubitril. According to the novel synthesis method, L-Pyroglutamic acid is taken as a raw material, a plurality of steps ofreaction are carried out, and a compound I with the chirality identical to that of Sacubitril is obtained via epimerization crystallization; the compound I is subjected to acylation, and is reacted with biphenyl so as to obtain a compound II; and hydrolysis ring-opening is carried out so as to obtain a compound III; the compound III is reacted with succinic anhydride, and reduction reaction is carried out so as to obtain Sacubitril. According to the synthesis method, a novel chirality control strategy is adopted, a novel chiral center is constructed using a simple and reliable method; controlof the chiral key intermediate is carried out at the early part of the synthesis routine, so that it is beneficial for reduction of risk and cost.

Owner:重庆博腾药业有限公司

Semi-grouting sleeve assembly for fabricated building and construction method thereof

InactiveCN111255162ASmall sizeReduced sleeve outer diameterBuilding reinforcementsBuilding material handlingArchitectural engineeringReducer

The invention discloses a semi-grouting sleeve assembly for prefabricated building. The semi-grouting sleeve assembly comprises a first steel bar provided with a first external thread, a second steelbar provided with a second external thread, an integrated nut bolt, a straight thread sleeve provided with a grout discharging hole, a semi-grouting sleeve and a square nut. The semi-grouting sleeve comprises a rectangular pipe, a square-round reducer pipe, a round pipe, an outer-round inner-square pipe and a grouting hole formed in the square-round reducer pipe; one end of the rectangular pipe istransitionally enlarged and gradually changed to one end of the round pipe through the square-round reducer pipe, the outer diameter of the round pipe is the same as that of the outer-round inner-square pipe, and fourth external threads are arranged on the outer surfaces of the round pipe and the outer-round inner-square pipe; and a rectangular hole allowing the first steel bar to penetrate through and allowing the square nut not to penetrate through is formed in the outer-round inner-square pipe, and first internal threads matched with the first external threads and third external threads are formed in the straight thread sleeve. The semi-grouting sleeve assembly is simple in structure and low in application cost, and the overall quality of the semi-grouting sleeve assembly can be guaranteed when the sleeve is not fully grouted.

Owner:梁雪芽

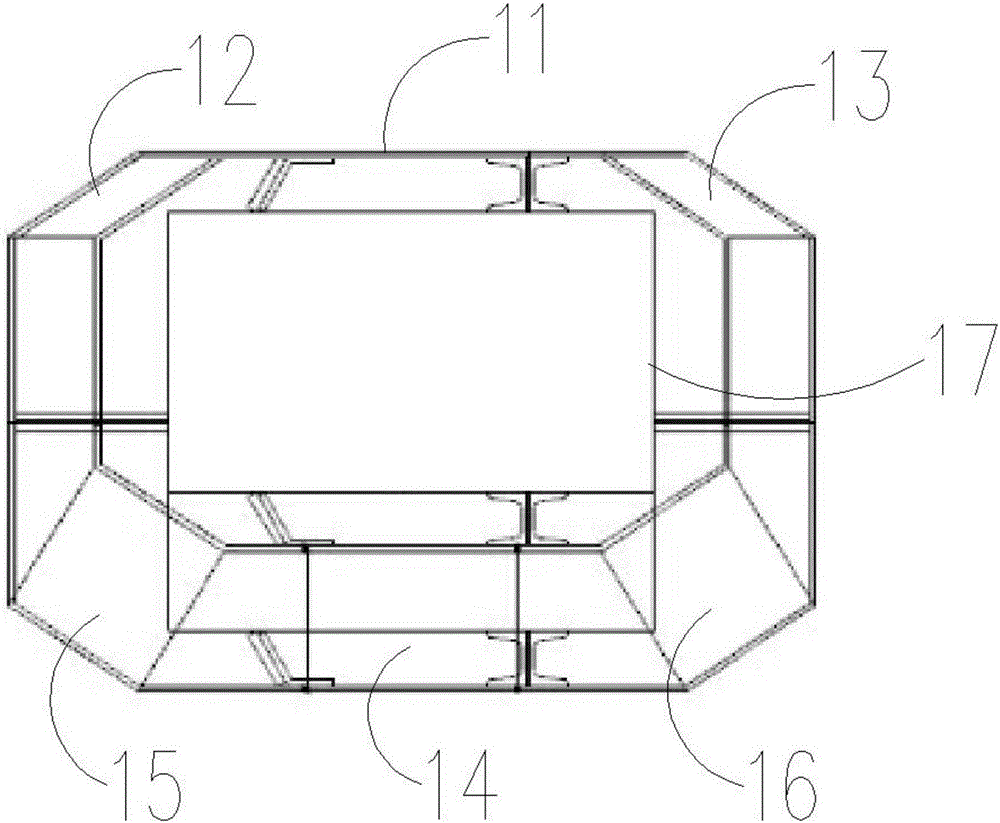

Internal mold and supporting system of double-variable-pitch hollow plate beam

ActiveCN106012772AImprove molding pass rateImprove construction efficiencyRoads maintainenceCorner angleSupport system

The invention provides an internal mold and supporting system of a double-variable-pitch hollow plate beam, comprising two parts including an internal mold and a supporting structure, wherein the supporting structure is fixedly supported in the internal mold to form a hollow cavity of the double-variable-pitch hollow plate beam; the internal mold is composed of a top plane mold, a left upper corner mold, a right upper corner mold, a bottom plane mold, a left lower corner mold and a right lower corner mold and is of a cuboid cavity shell body; a corner angle is of an inclined-plane chamfered angle and mold opening parts at the two ends are bent inwards to form a variable-pitch plane structure; the supporting structure is composed of upper horizontal rods, lower horizontal rods, a transverse supporting rod and a vertical supporting rod; the upper horizontal rods are in hinged connection with the lower horizontal rods through the vertical supporting rod; the two adjacent upper horizontal rods or the two adjacent lower horizontal rods are in hinged connection through the transverse supporting rod. The internal mold and supporting system of the double-variable-pitch hollow plate beam has the beneficial effects that the molding yield and the construction efficiency are improved and the construction cost is reduced; the product can be easily drawn out from a mold opening and a template is low in damage degree, is completely preserved and can be repeatedly utilized for a plurality of times; the construction cost is greatly reduced.

Owner:宁夏宁博通模板有限责任公司

Soft soil foundation integrated well point plastic discharging vacuum system

ActiveCN105862713AImprove sealingSimple and reliable constructionSoil preservationWater dischargeEngineering

The invention relates to a soft soil foundation integrated well point plastic discharging vacuum system. The soft soil foundation integrated well point plastic discharging vacuum system is characterized by comprising an integrated well point plastic discharging pipe grid formed by carrying out inserting construction on an integrated well point plastic discharging pipe; the integrated well point plastic discharging pipe comprises a water discharging plate, a connection box, a well point pipe and a connection pipe; the water discharging plate is vertically distributed in a deep-layer soil body; the well point pipe is vertically distributed in a shallow-layer soil body; the upper end of the water discharging plate is connected with the lower end of the well point pipe through the connection box; the upper end of the well point pipe is exposed out of the shallow-layer soil body; the upper end of the well point pipe is connected with one end of the connection pipe; and the integrated well point plastic discharging pipe grid is connected with a general pipe and a vacuum pump to form the integrated well point plastic discharging vacuum system. The soft soil foundation integrated well point plastic discharging vacuum system has the advantages of simplicity in operation, low cost and good construction effect.

Owner:CABR FOUND ENG CO LTD

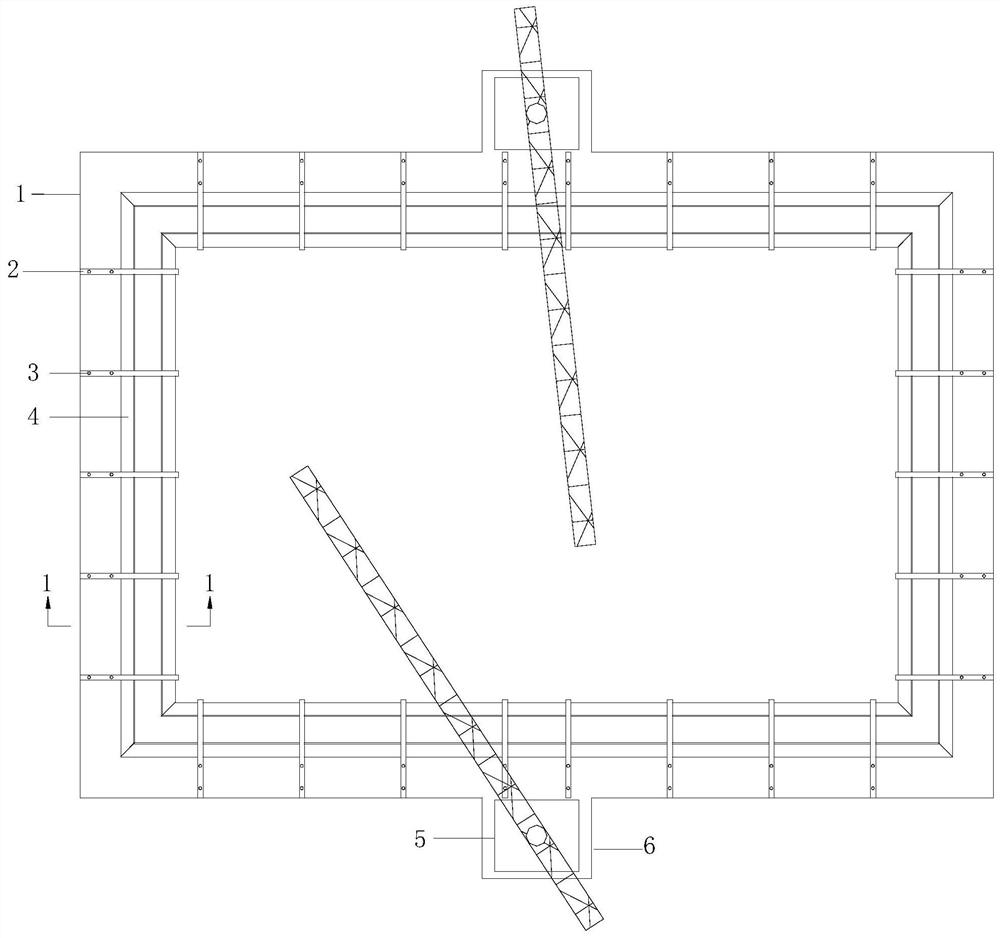

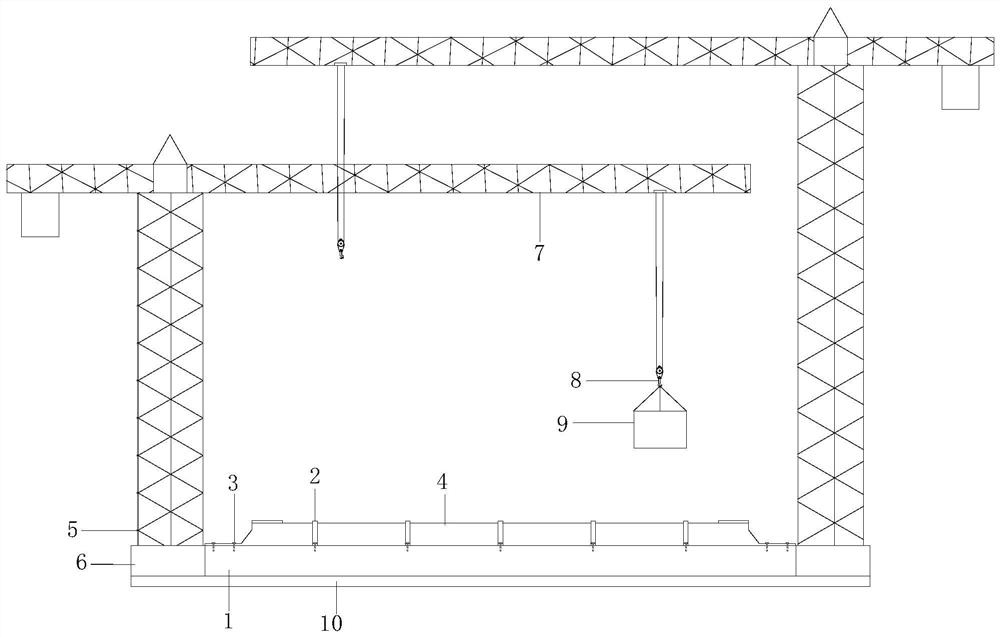

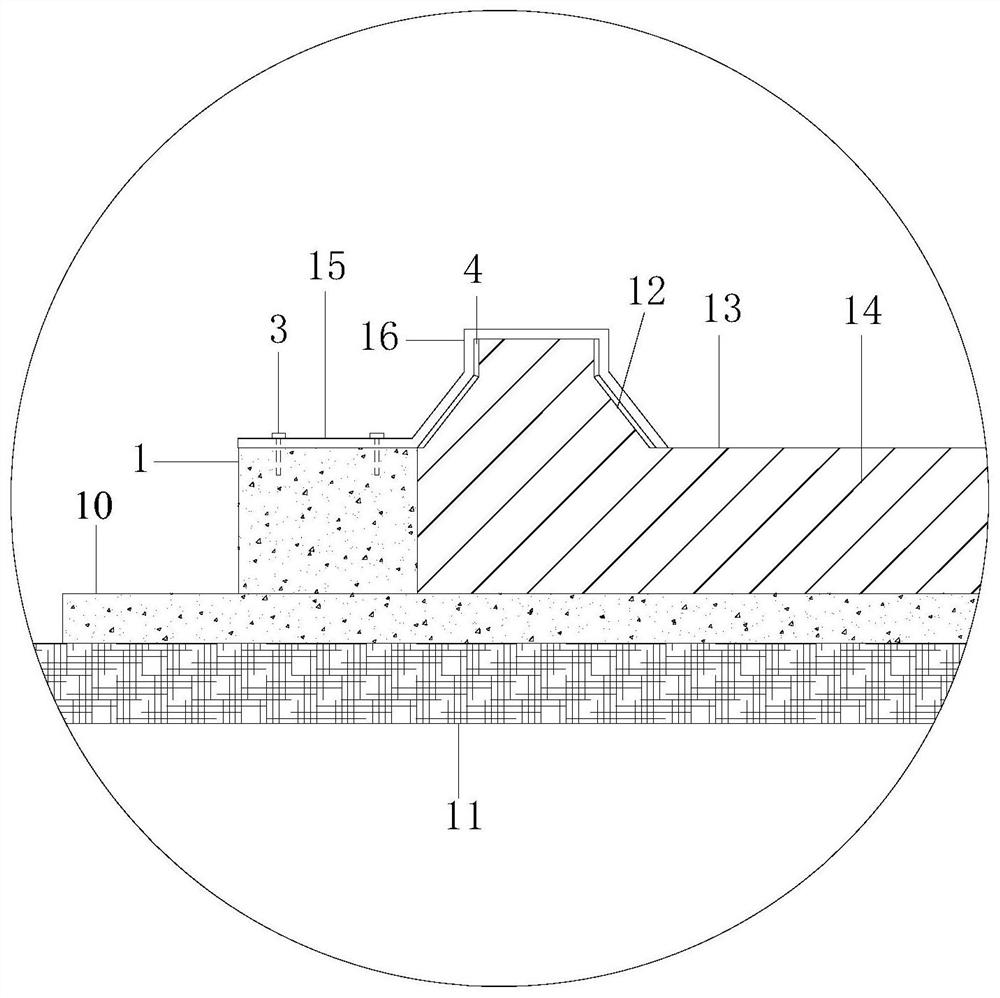

Cast-in-place reinforced concrete pool bottom formwork system and construction method

ActiveCN110439272BImprove stabilitySimple and reliable constructionForms/shuttering/falseworksGymnasiumSupporting systemReinforced concrete

The invention relates to a cast-in-situ reinforced concrete pool bottom plate formwork system, including ground beams, cantilever formwork, bolts, tower cranes, tower crane foundations, cushions, foundations, bottom plates and steel mesh; the cushions are arranged above the foundations, and the bottom plate and The steel mesh is arranged above the cushion, and the ground beam surrounds the bottom plate and serves as the outer formwork of the bottom plate; the cantilever form includes a steel formwork, a fixed rod, a cantilever and a bolt hole, and the fixed rod is provided with a bolt hole, and the fixed rod Connected with the cantilever, the cantilever is bolted and anchored on the ground beam through bolts and fixed rods, the steel formwork is set on the cantilever; the tower crane foundation is respectively set at the symmetrical position in the middle of the two long sides of the ground beam, and the tower crane is respectively set On the basis of the tower crane. The beneficial effect of the present invention is that: the present invention adopts the cast-in-place ground beam as the outer formwork of the bottom plate of the pool, the construction is simple and reliable, and the stability of the entire cast-in-place reinforced concrete pool can also be increased.

Owner:浙江恒鸿建设有限公司

reinforced foundation

ActiveCN105862719BImprove sealingSimple and reliable constructionSoil preservationEngineeringBuilding construction

Owner:CABR FOUND ENG CO LTD

Well point plastic draining pipe film coating type vacuum preloading and dewatering preloading combined power consolidation method

The invention relates to a well point plastic draining pipe film coating type vacuum preloading and dewatering preloading combined power consolidation method. The method is characterized by comprising the following steps: levelling a site; determining to carry out or not carry out pre-tamping before dewatering; arranging a waterproof curtain; arranging an integrated well point plastic draining pipe vacuum system; coating the surface of a main pipe of the integrated well point plastic draining pipe vacuum system with a geotextile and a sealing film; then performing vacuum preloading, namely, constructing dams of cofferdams around the area to be reinforced, and pumping water from a water source in the periphery of the area to be reinforced into the cofferdams around the area to be reinforced, and then carrying out vacuum preloading, wherein underground water is completely pumped and returned to the surface of the area to be reinforced during the vacuum preloading; performing vacuum dewatering preloading, namely, forming openings in the constructed dams of the cofferdams to drain water stored in the dams of the cofferdams, and then carrying out vacuum dewatering preloading at a plurality of times, wherein full tamping is carried out after the last vacuum dewatering preloading; finally, vibrating and rolling in the whole site, then measuring the elevation, and handing over the completed project. The method has the advantages of being simple to operate, low in cost, and good in construction effect.

Owner:CABR FOUND ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com