Laundry washing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

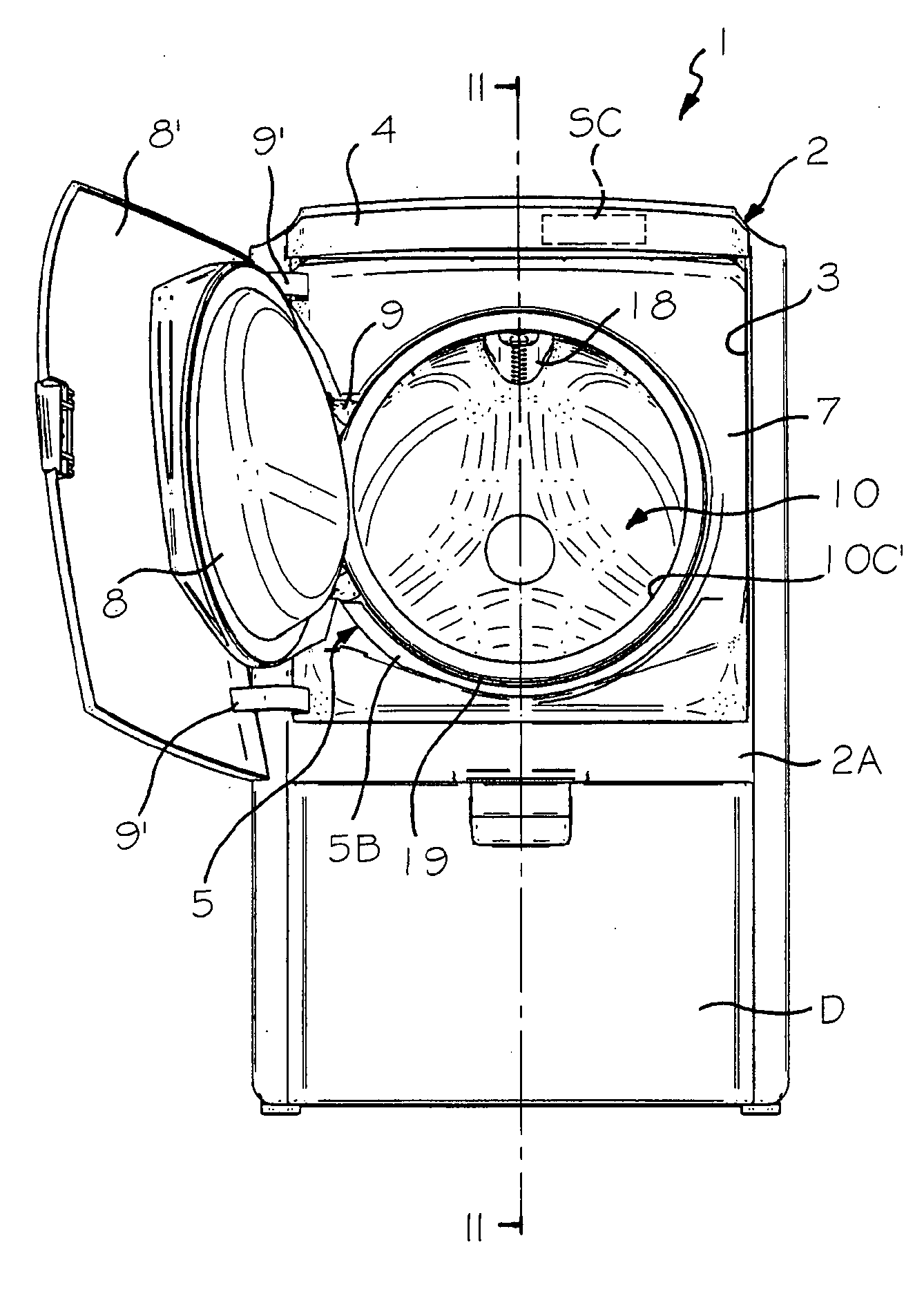

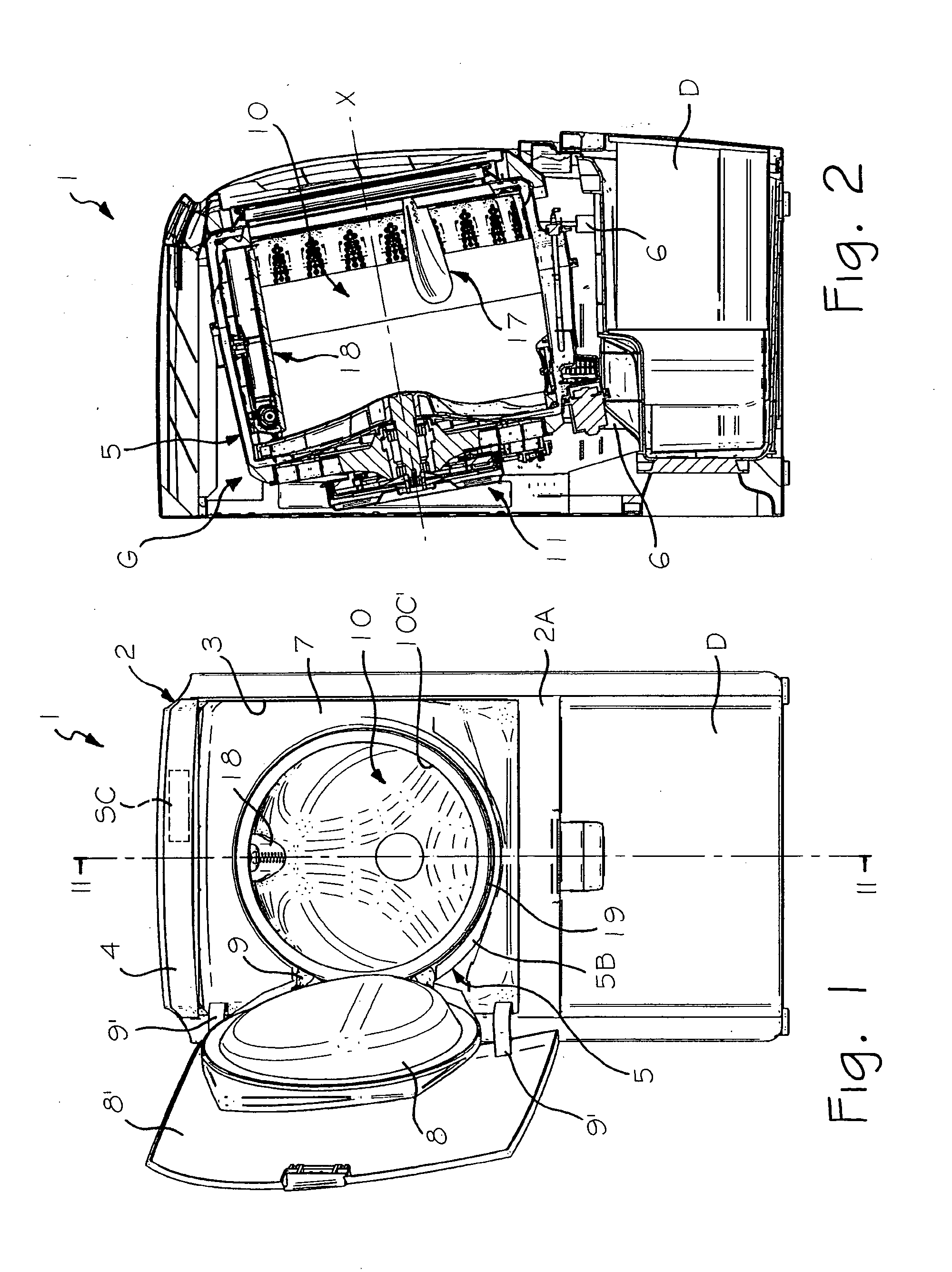

[0058]The machine has a cabinet 2 with a front wall 2a wherein an opening 3 is obtained, having a substantially square shape in the non-limiting example. A control panel 4, only schematically represented and including a display and some command buttons, is mounted on the wall 2a; the control panel 4 is associated with a machine control system, particularly of the microcontroller type, schematically represented by the block CS.

[0059]In the following, only the components of the machine 1 useful for understanding the inventive aspects of interest will be described, taking for granted that the machine includes all of the other elements—being known per se—required for its normal functioning, such as valve means and conduits for loading water into the tub, level sensing means, drain conduit, likely anti-flood means, likely drying circuit, suspension / shock absorbing means, and so on.

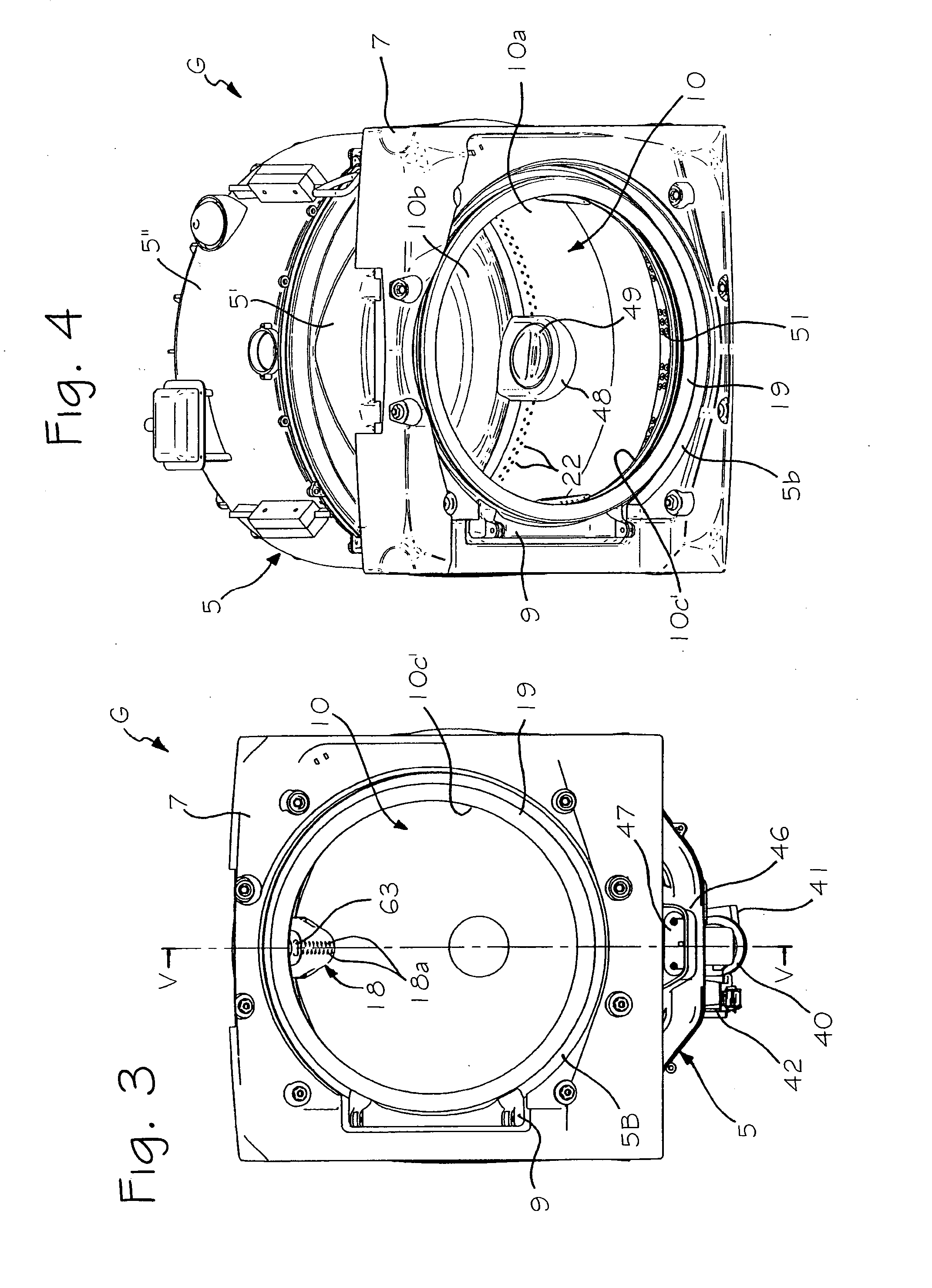

[0060]Inside the cabinet 2 a so-called oscillating group is provided, indicated as a whole with G in FIG. 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com