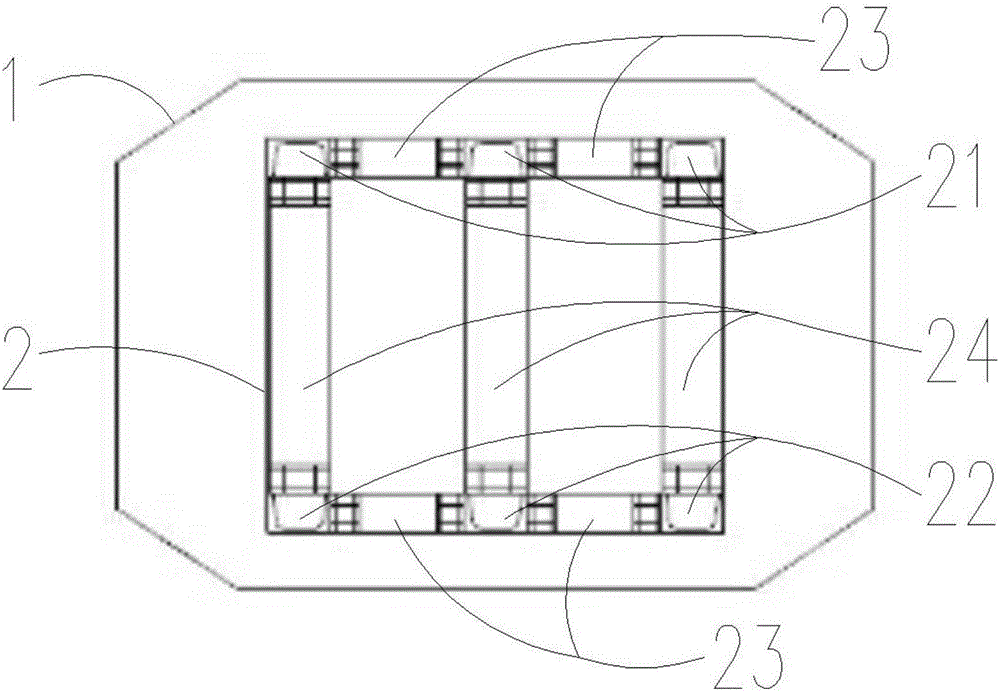

Internal mold and supporting system of double-variable-pitch hollow plate beam

A technology of hollow slab beams and support systems, applied in roads, buildings, road repairs, etc., can solve the problems of high construction cost and difficulty in dismantling the inner formwork of double-section hollow slab girders, etc., to improve construction efficiency, simple and reliable construction, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The double-section hollow slab beam inner mold and the support system of the present invention are very suitable for pouring reinforced concrete hollow slab beams with a height of less than 13 meters. Following is the installation process of the present invention:

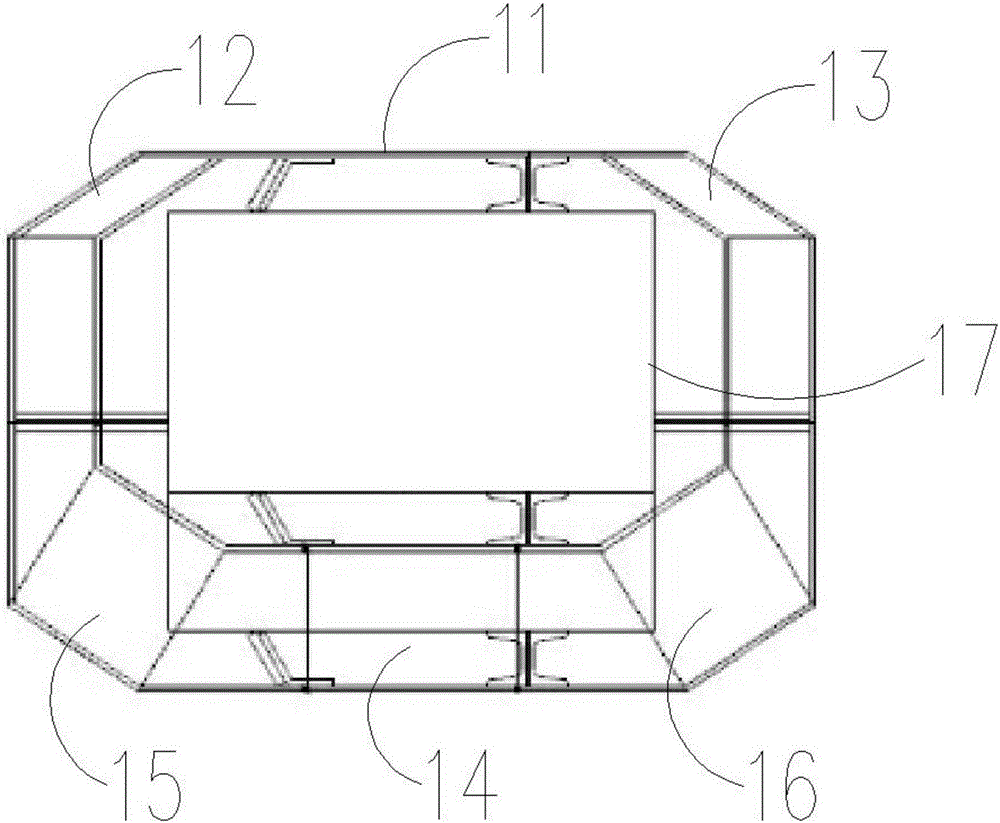

[0027] 1) Hang the bottom plane mold 14, the lower left corner mold 15 and the lower right corner mold 16 into the installation frame, and assemble and splice;

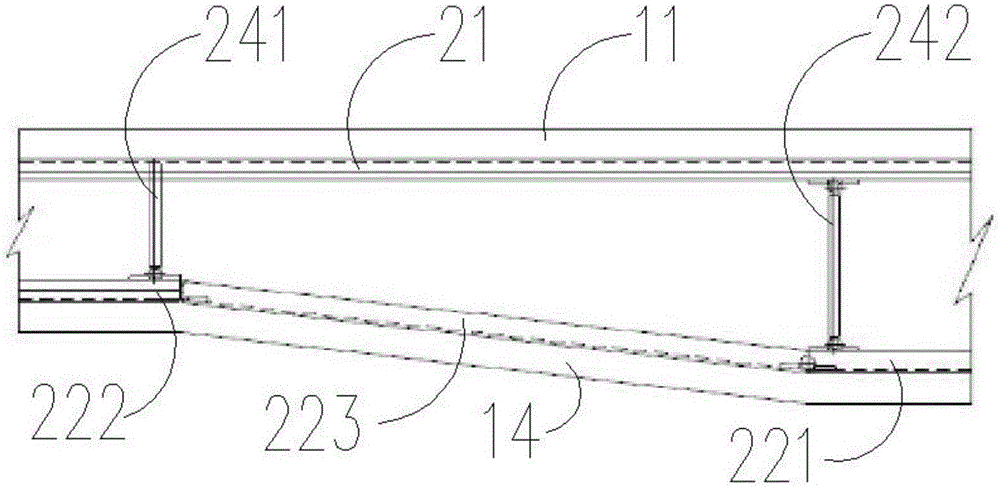

[0028] 2) Open and stretch the support structure 2, pull the horizontal support bar 23 and the vertical support bar 24 to lock the upper horizontal bar 21 and the lower horizontal bar 22, hang them into the mounting frame, and place them on the bottom plane mold 14;

[0029] 3) Lift the top plane mold 11, the upper left corner mold 12 and the upper right corner mold 13 in sequence, and install them on the top of the support structure 2;

[0030] 4) Bind and fix the top plane mold 11, the upper left corner mold 12, the upper right corner mold 13, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com