Well point plastic draining pipe film coating type vacuum preloading and dewatering preloading combined power consolidation method

A technology of dynamic consolidation and well point, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of difficult to find air leakage points, complicated process, and non-environmental protection of PVC sealing film, and achieve good construction effect and easy operation Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Basic information before foundation treatment:

[0104] The third layer of muddy clay layer of the foundation has a water content of 55%, a compressive modulus of 2.3MPa, an average layer thickness of 15 meters, a buried depth of 5 meters at the top of the layer, and a buried depth of 20 meters at the bottom.

[0105] Implementation steps:

[0106] Step 1. The site is leveled, and drainage ditches are excavated around the area to be reinforced;

[0107] Step 2. Pre-tamping, energy level 800kN.m, square tamping point spacing 4m*4m, after tamping, construct cement mixing pile lateral sealing retaining wall or mud lateral sealing retaining wall;

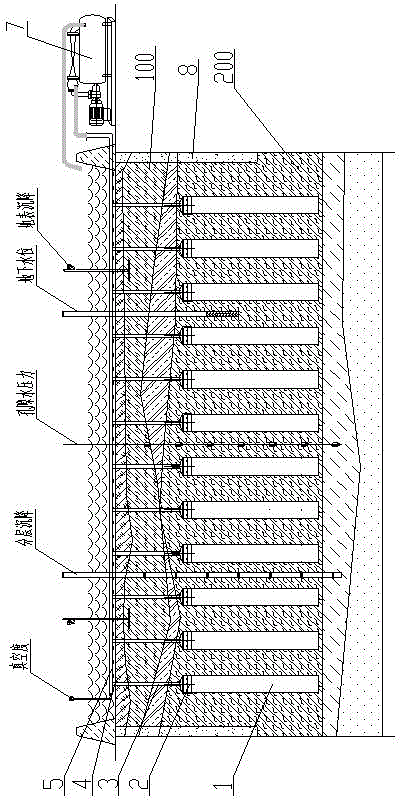

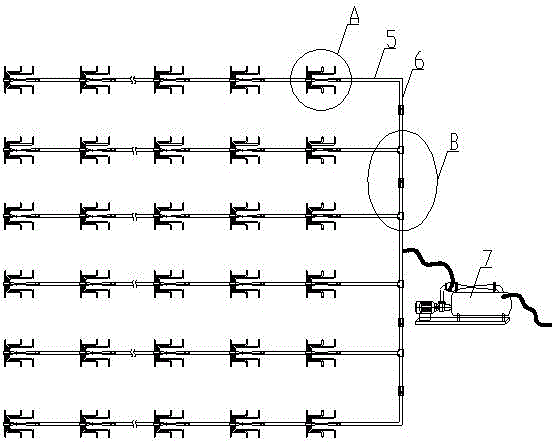

[0108] Step 3. Arrangement of integrated well point plastic exhaust vacuum system

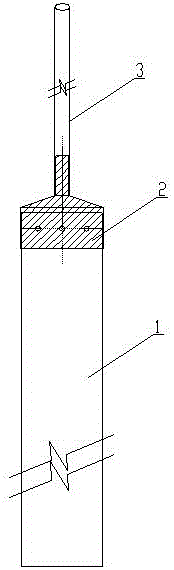

[0109] 3.1. The integrated well point plastic pipe is inserted and constructed to form an integrated well point plastic pipe grid;

[0110] The grid spacing of the integrated well point plastic pipe grid is 1.2m, and the insertion depth of the ...

Embodiment 2

[0127] Basic information before foundation treatment

[0128] The fourth silty clay layer of the foundation has a water content of 38%, a compressive modulus of 3.8 MPa, an average thickness of 13 meters, a buried depth of 3 meters at the top of the layer, and a buried depth of 16 meters at the bottom of the layer.

[0129] Step 1. The site is leveled, and drainage ditches are excavated around the area to be reinforced;

[0130] Step 2. Do not carry out pre-tamping before precipitation, and construct lateral sealing retaining wall of cement mixing pile or lateral sealing retaining wall of mud;

[0131] Step 3. Arrangement of integrated well point plastic exhaust vacuum system

[0132] 3.1. The integrated well point plastic pipe is inserted and constructed to form an integrated well point plastic pipe grid;

[0133] The grid spacing of the integrated well point plastic pipe grid is 1.5m, and the insertion depth of the integrated well point pipe is 16m

[0134] The length of ...

Embodiment 3

[0150] Basic information before foundation treatment

[0151] The silty clay in the second layer of the foundation has a water content of 78%, a compressive modulus of 2.1 MPa, an average thickness of 20 meters, a buried depth of 4 meters at the top of the layer, and a buried depth of 24 meters at the bottom of the layer.

[0152] Step 1. The site is leveled, and drainage ditches are excavated around the reinforcement area;

[0153] Step 2. Pre-tamping before precipitation, energy level 600kN.m, square tamping point spacing 4m*7m, after tamping, construct cement mixing pile lateral sealing retaining wall or mud lateral sealing retaining wall;

[0154] Step 3. Arrangement of integrated well point plastic exhaust vacuum system

[0155] 3.1. The integrated well point plastic pipe is inserted and constructed to form an integrated well point plastic pipe grid;

[0156] The grid spacing of the integrated well point plastic pipe grid is 1.0m, and the insertion depth of the integrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bearing capacity of foundation | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com