Optical cable and special construction draft gear for oil and gas pipeline 'towing back in one hole'

A technology for oil and gas pipelines and traction devices, applied in the field of optical cables and construction, can solve the problems of high cost, long construction period, high risk, etc., and achieve the effects of reducing friction coefficient, simple and reliable construction, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

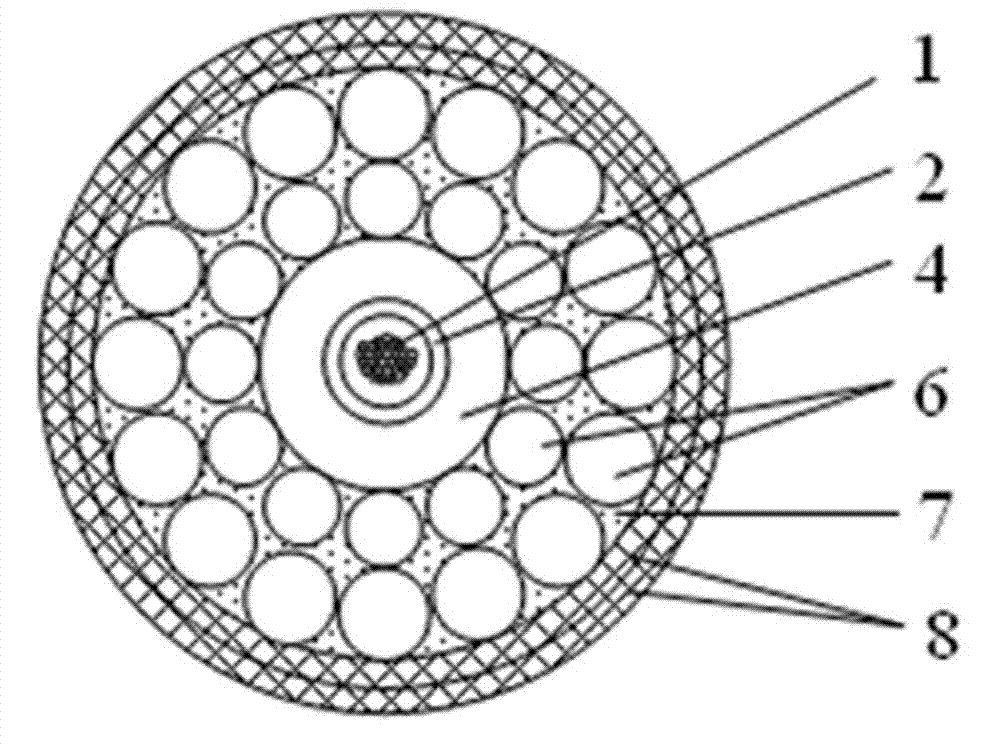

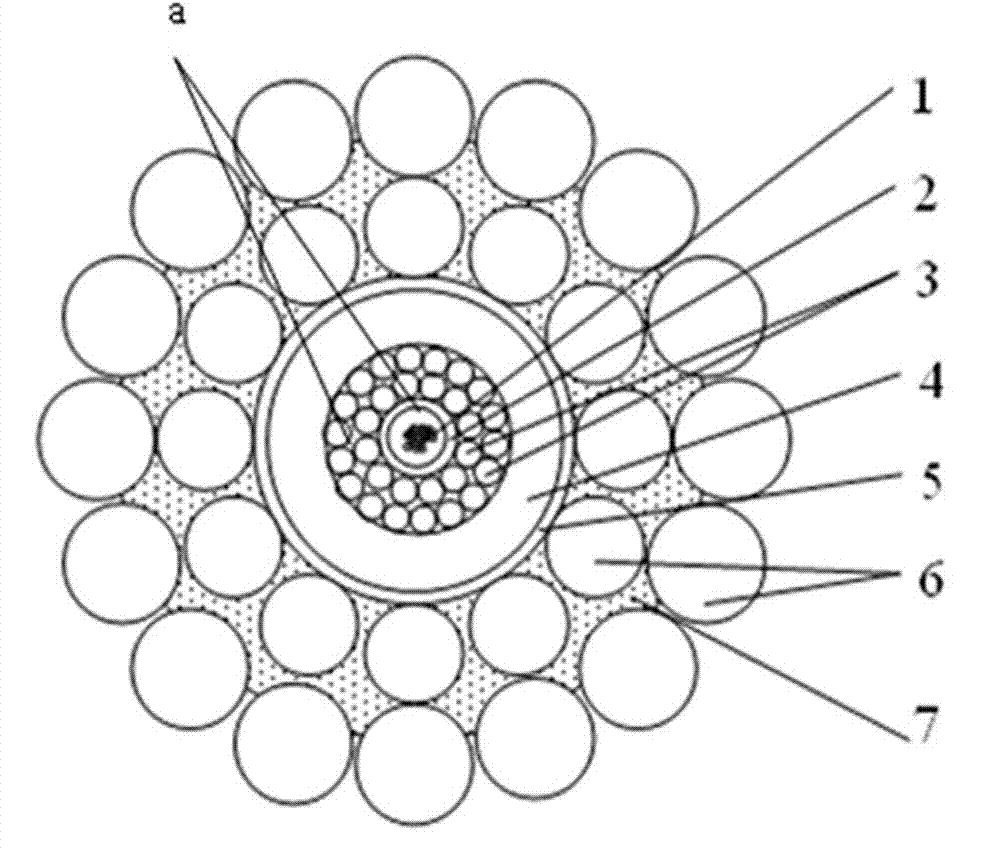

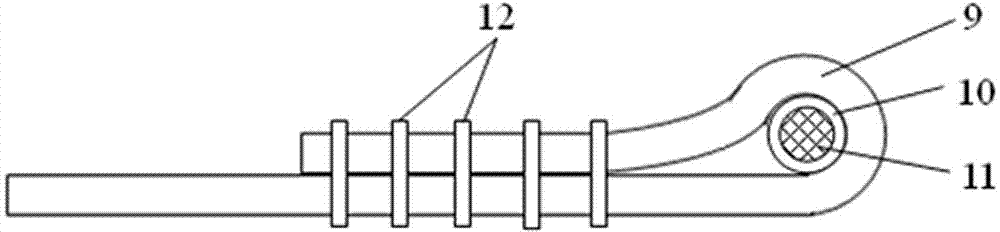

[0021] like figure 2 Shown: an optical cable for dragging oil and gas pipelines with the same hole, consisting of optical fiber 1, optical fiber unit protection tube 2, inner armor reinforcement 3, inner sheath 4, buffer layer 5, outer armor reinforcement 6, water-blocking material a and Anti-corrosion asphalt 7 composition. Among them, the optical fiber unit protection tube 2 is made of stainless steel, the stranded wire of the inner armor reinforcement is galvanized steel wire, the material of the inner sheath 4 is high-density polyethylene, and the stranded wire of the outer armor reinforcement is high-strength galvanized steel wire. Two layers of galvanized steel wires are directly stranded outside the stainless steel optical fiber unit protection tube 2 with built-in optical fiber 1 and filled with water-blocking material a as the inner armor reinforcement 3, and water-blocking material a is filled between the stranded wire and the stranded layer, and then extruded outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com