Prefabricated reinforced concrete volute template and construction method thereof

A technology of reinforced concrete and concrete, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve difficult and complicated construction methods of volute low cost, simple and reliable construction process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

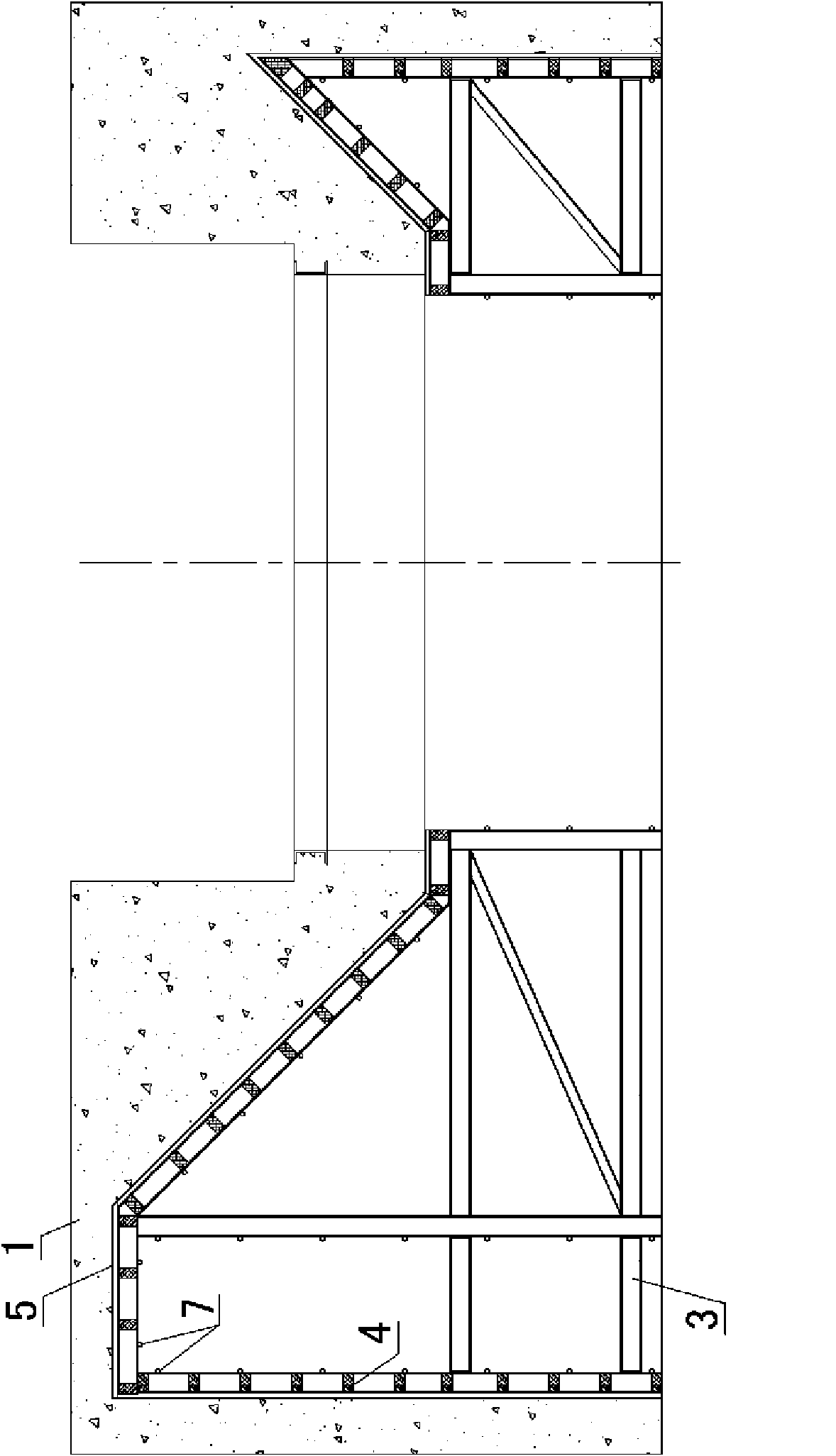

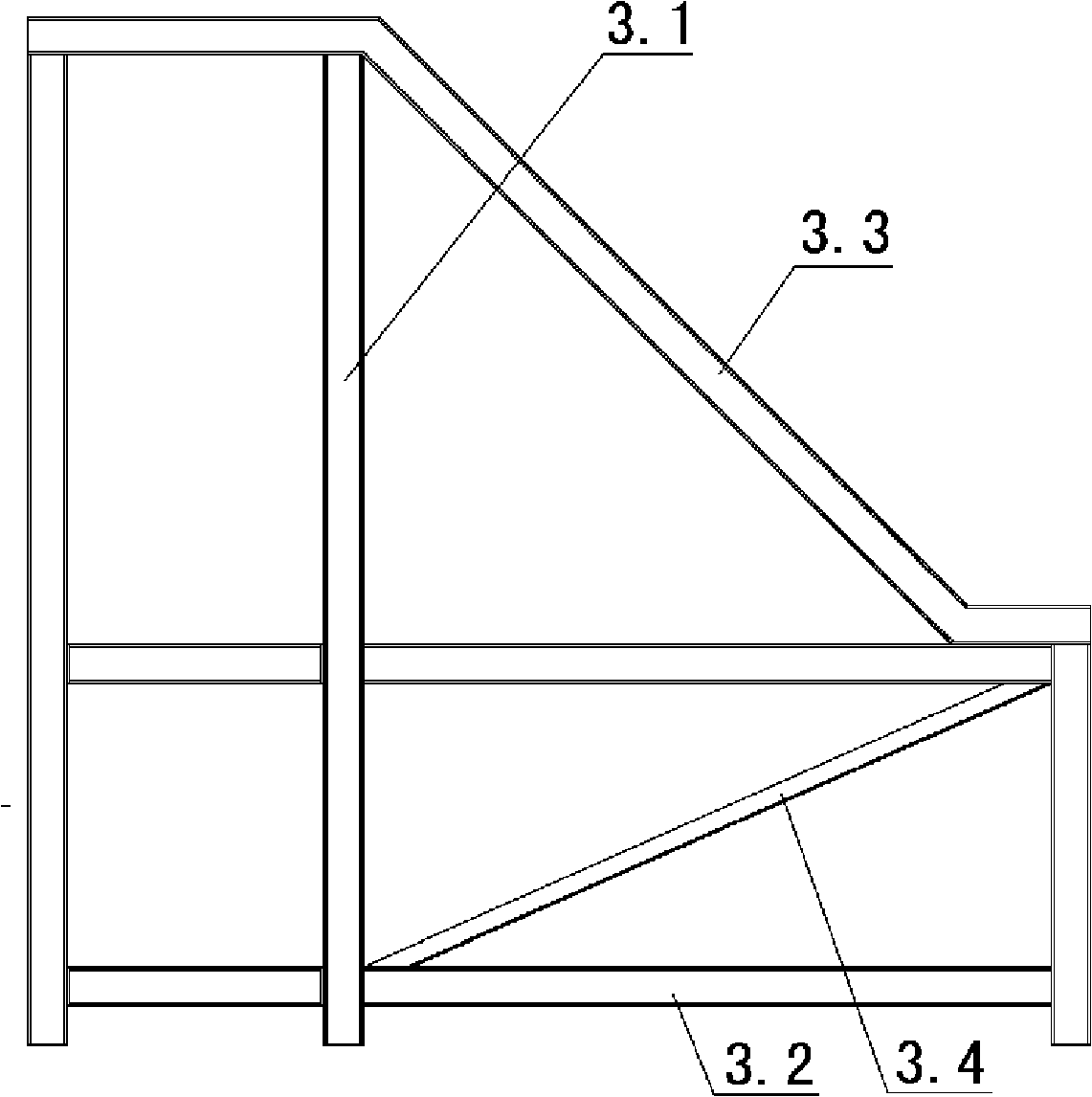

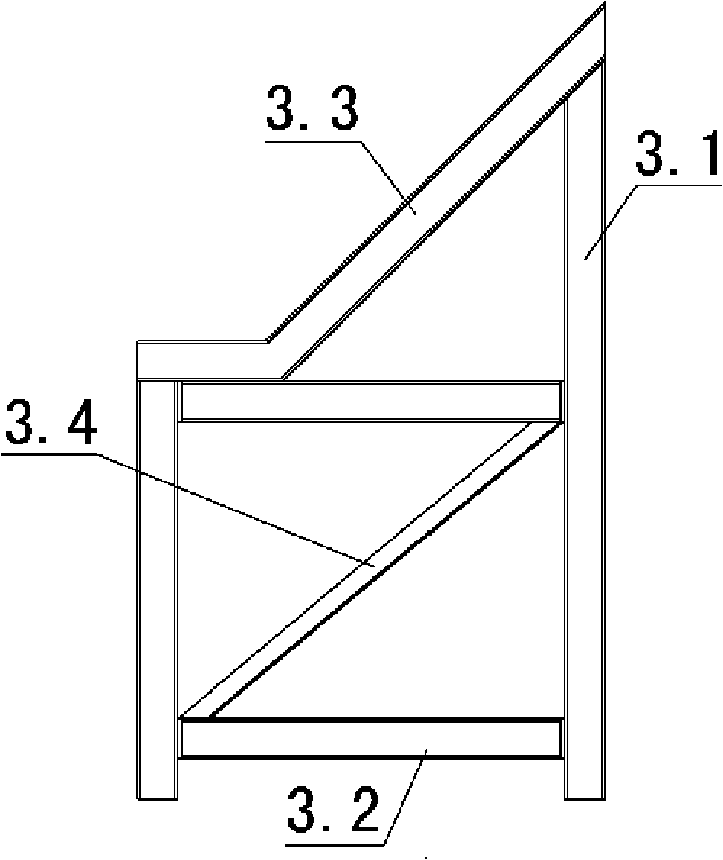

[0044] Examples see figure 1 , Image 6 , Figure 7 As shown, this prefabricated reinforced concrete volute formwork is composed of a volute outer mold, a volute inner mold and a volute mandrel 13, the volute inner mold includes an inner mold support and an inner mold template, and the volute outer mold includes an outer mold Support and outer mold formwork, the inner mold support is connected as a whole by the radial steel trusses 3 that are radially spaced from the inner wall of the volute to the outer wall of the volute by the hoop connecting steel bars 7; the radial steel trusses 3 are The shape of the lower side is wide and the upper side is narrow, the outer end is vertical, the upper part of the inner end is consistent with the shape of the inner wall of the volute, the middle part of the inner end is horizontal, and the lower part of the inner end is vertical; the inner mold template is connected to the The I-shaped steel at the inner end of the radial steel truss is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com