Well point plastic draining pipe type vacuum preloading seepage consolidation and dewatering preloading power consolidation combined method

A dynamic consolidation and well point technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of low strength of pvc sealing film, poor preloading effect, difficult construction of sealing film, etc., to reduce post-construction The effect of residual settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] Basic information before foundation treatment:

[0108] The third layer of muddy clay layer of the foundation has a water content of 55%, a compressive modulus of 2.3MPa, an average layer thickness of 15 meters, a buried depth of 5 meters at the top of the layer, and a buried depth of 20 meters at the bottom.

[0109] Implementation steps:

[0110] Step 1. The site is leveled, and drainage ditches are excavated around the area to be reinforced;

[0111] Step 2. Pre-tamping, energy level 800kN.m, square tamping point spacing 4m*4m, after tamping, construct cement mixing pile lateral sealing retaining wall or mud lateral sealing retaining wall;

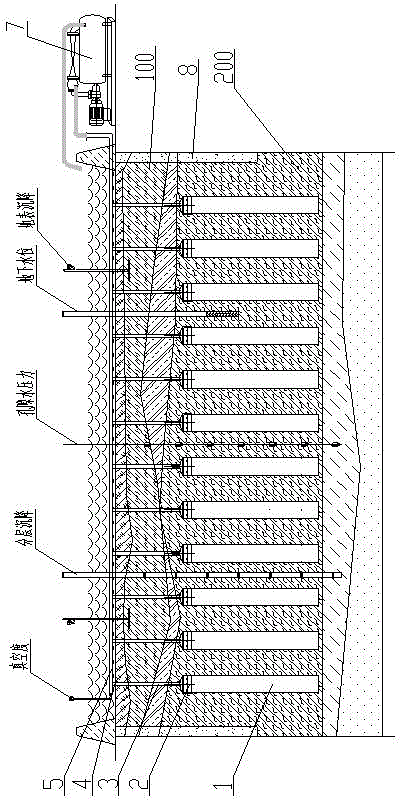

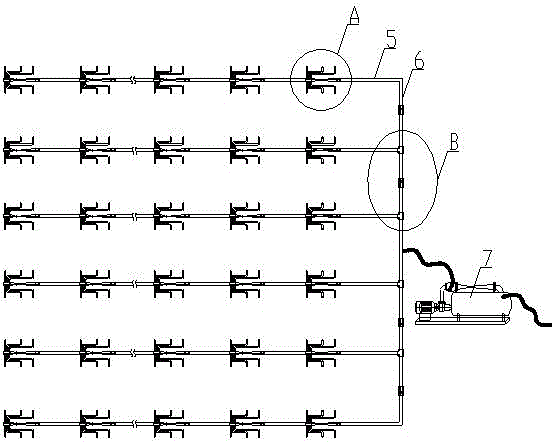

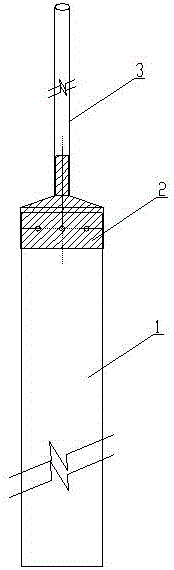

[0112] Step 3. Arrangement of integrated well point plastic exhaust vacuum system

[0113] 3.1. The integrated well point plastic pipe is inserted and constructed to form an integrated well point plastic pipe grid;

[0114] The grid spacing of the integrated well point plastic pipe grid is 1.2m, and the insertion depth of the ...

Embodiment 2

[0130] Basic information before foundation treatment

[0131] The fourth silty clay layer of the foundation has a water content of 38%, a compressive modulus of 3.8 MPa, an average thickness of 13 meters, a buried depth of 3 meters at the top of the layer, and a buried depth of 16 meters at the bottom of the layer.

[0132] Step 1. The site is leveled, and drainage ditches are excavated around the area to be reinforced;

[0133] Step 2. Do not carry out pre-tamping before precipitation, and construct lateral sealing retaining wall of cement mixing pile or lateral sealing retaining wall of mud;

[0134] Step 3. Arrangement of integrated well point plastic exhaust vacuum system

[0135] 3.1. The integrated well point plastic pipe is inserted and constructed to form an integrated well point plastic pipe grid;

[0136] The grid spacing of the integrated well point plastic pipe grid is 1.5m, and the insertion depth of the integrated well point pipe is 16m

[0137] The length of ...

Embodiment 3

[0152] Basic information before foundation treatment

[0153] The silty clay in the second layer of the foundation has a water content of 78%, a compressive modulus of 2.1 MPa, an average thickness of 20 meters, a buried depth of 4 meters at the top of the layer, and a buried depth of 24 meters at the bottom of the layer.

[0154] Step 1. The site is leveled, and drainage ditches are excavated around the reinforcement area;

[0155] Step 2. Pre-tamping before precipitation, energy level 600kN.m, square tamping point spacing 4m*7m, after tamping, construct cement mixing pile lateral sealing retaining wall or mud lateral sealing retaining wall;

[0156] Step 3. Arrangement of integrated well point plastic exhaust vacuum system

[0157] 3.1. The integrated well point plastic pipe is inserted and constructed to form an integrated well point plastic pipe grid;

[0158] The grid spacing of the integrated well point plastic pipe grid is 1.0m, and the insertion depth of the integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com