Raft plate post-cast strip pouring template and construction method thereof

A construction method and post-casting belt technology are applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, construction, etc., which can solve the problems of high cost, inconvenient construction and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

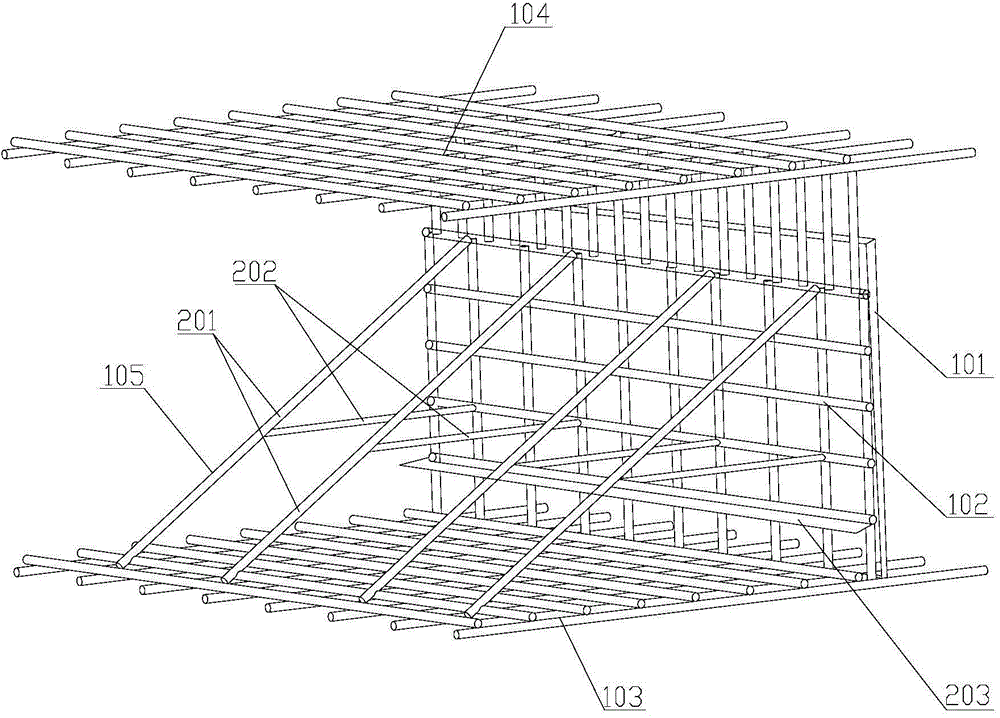

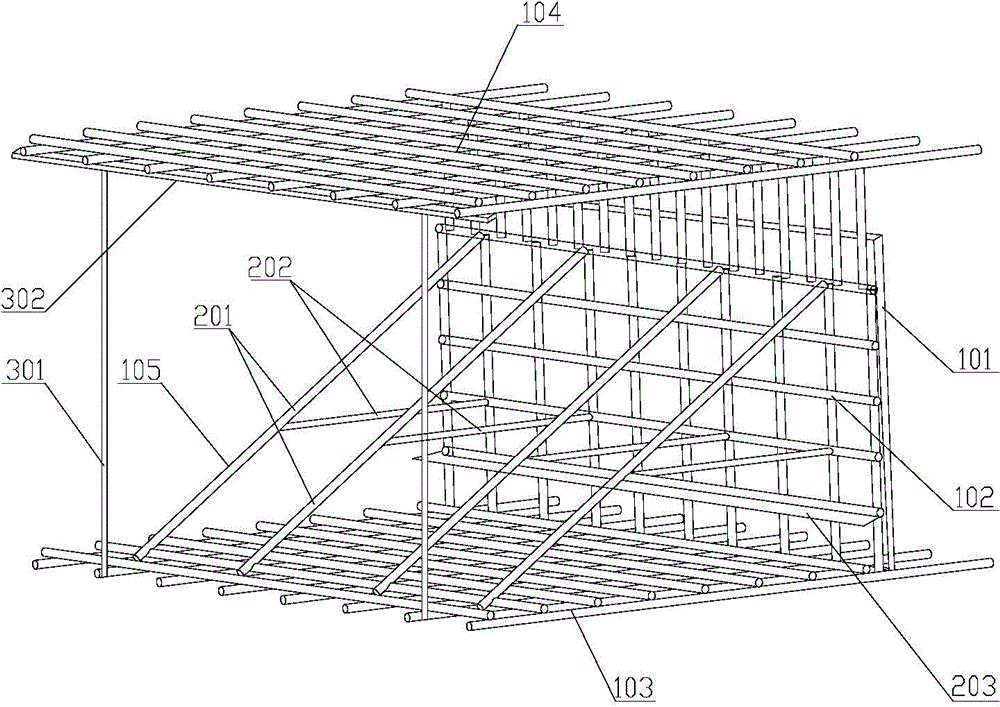

[0032] During building construction, the pouring of the post-pouring belt of the raft needs to build a pouring formwork. The support of the pouring formwork is made of multiple horizontal bars and multiple vertical bars. The horizontal bars and vertical bars are vertically arranged to form a three-dimensional frame structure. The structure is complex, and it takes time and effort to build, especially when the support is built in some small spaces. Due to the limited operating space, the support structure is relatively dense, which further increases the difficulty of construction and reduces the construction efficiency. At the same time, the dense support does not It is convenient for the subsequent pouring of the post-cast belt of the raft slab, and is inconvenient to use.

[0033] In view of this, the designer of the present invention has designed a kind of raft post-pouring tape formwork with support beam, and the structure of support beam is simple, and support beam is suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com