Assembly type bone-shaped shock-resistance node

A prefabricated, bone-shaped technology, applied in the direction of earthquake-proof, protective buildings/shelters, building components, etc., can solve the problems that cannot be connected by bolts, cannot meet the requirements of bending bearing capacity, and avoid high-altitude welding operations , simple and reliable construction, convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific implementation cases of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but this title is not limited to these embodiments.

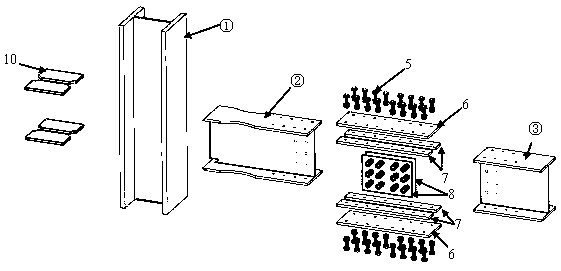

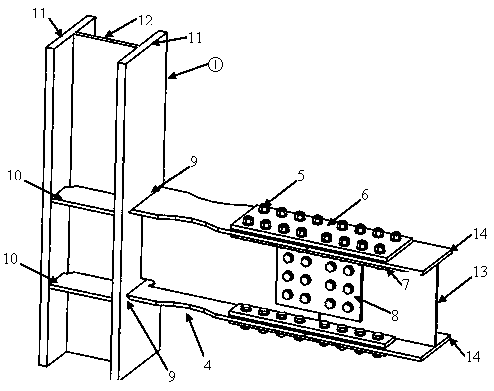

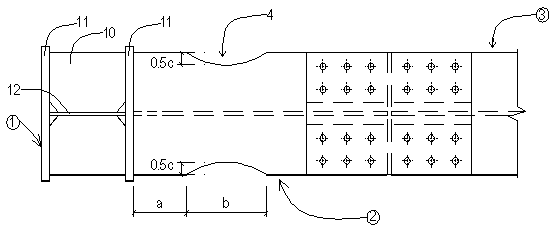

[0020] Such as figure 1 , 2 , 4, a prefabricated bone-shaped seismic joint mainly includes steel columns (1), H-shaped steel beams (3), bone-shaped beams (2), etc., and the steel columns are H-shaped ( figure 1 shown), box or cross (as Figure 4 shown).

[0021] Such as figure 2 As shown, the H-shaped steel column includes two column flange plates (11) parallel to each other, a column web (12) vertically between the two column flange plates, and a column stiffener (10).

[0022] The H-shaped steel beam includes two beam flange plates (14) parallel to each other and a beam web (13) perpendicular to the space between the two beam flange plates.

[0023] The bone-shaped beam (2) is formed by cutting the flange of a sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com