Non-refillable valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

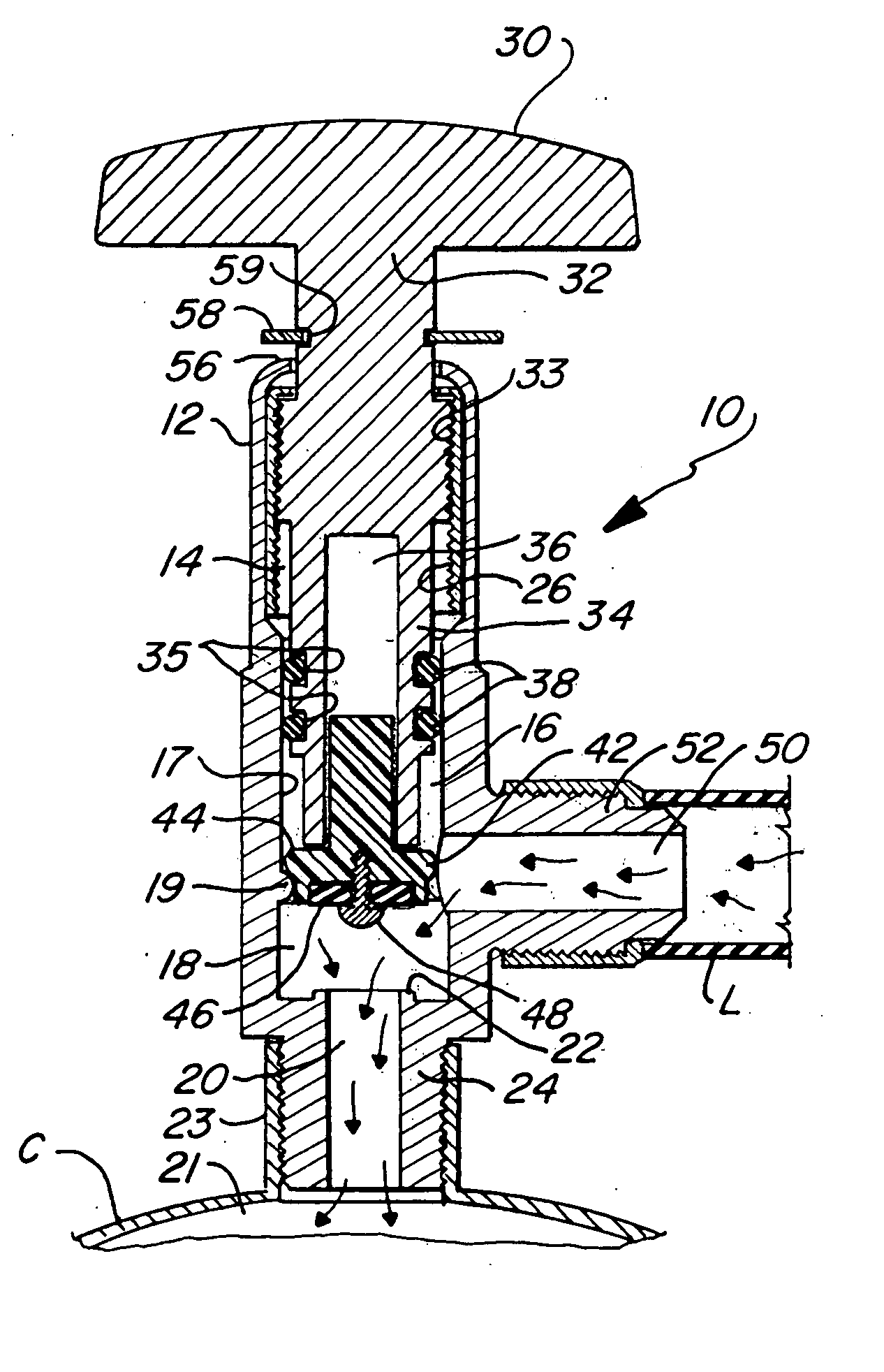

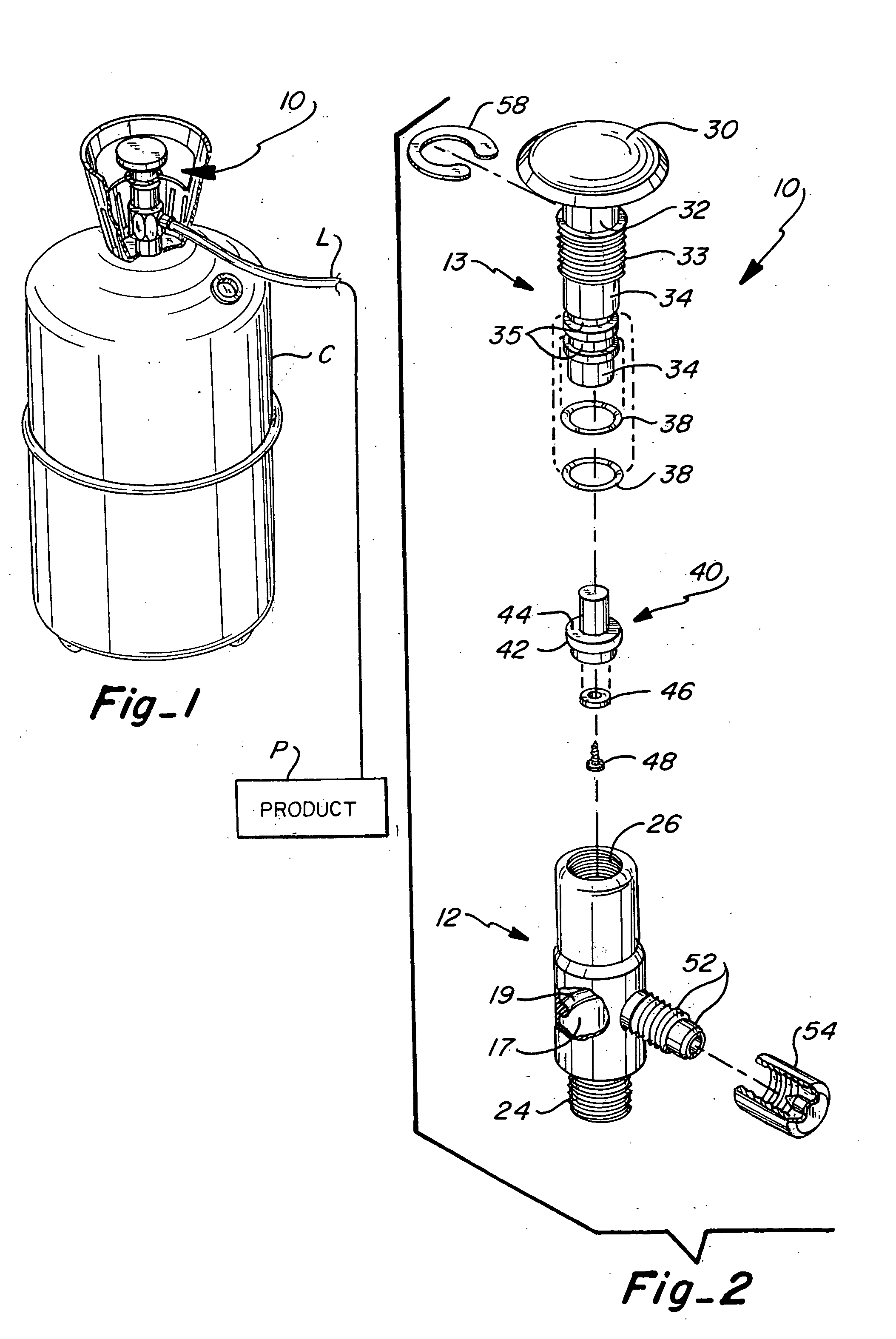

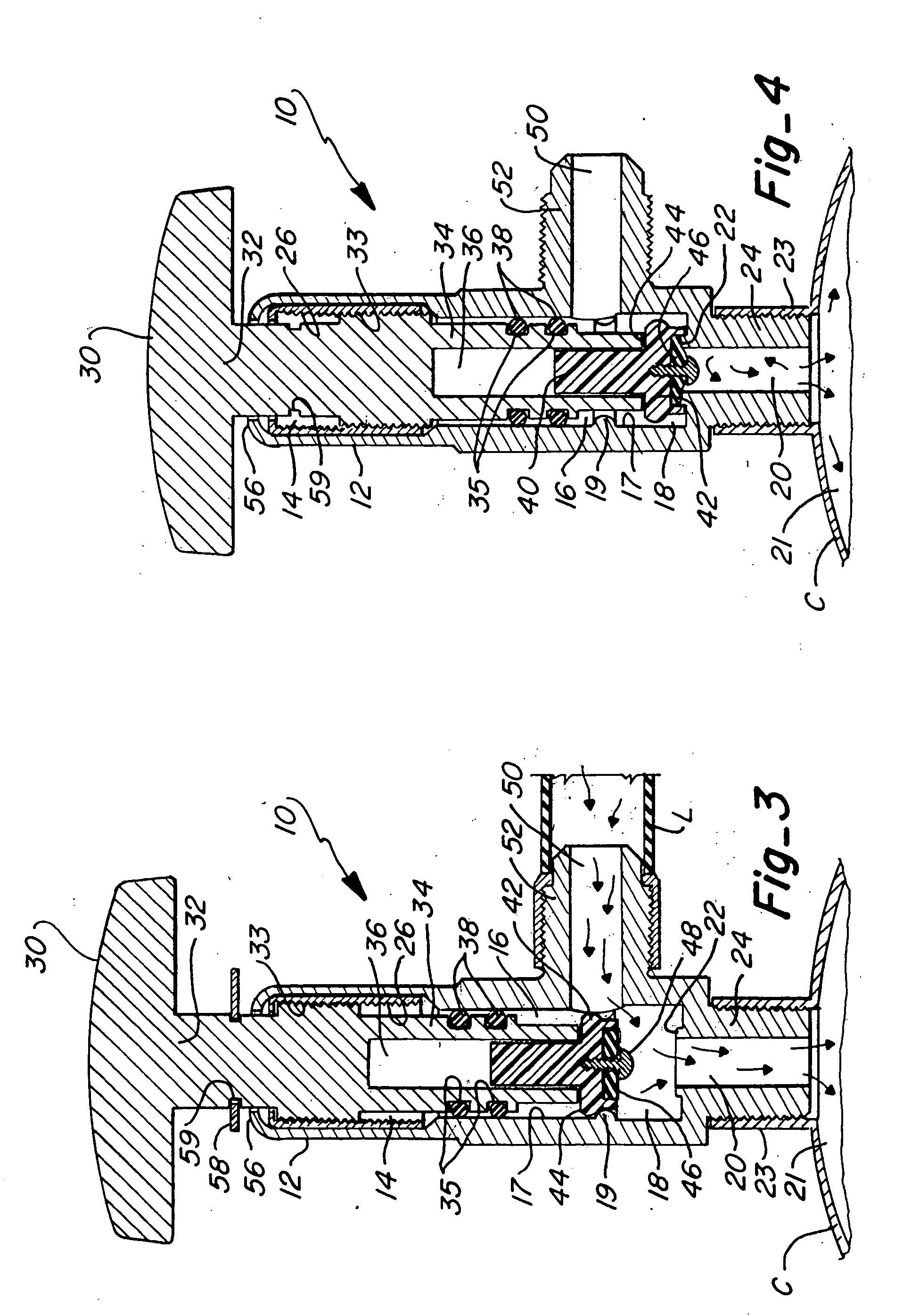

[0021] Referring to FIG. 1, a pressure container or pressure vessel C is provided with the nonrefillable valve 10 of the invention for filling and selective emptying of the container C. Valve 10 can be welded, threaded or otherwise affixed to the container C. In order to fill the container, a product source P produces a flow of fluid through line L which communicates with the valve 10. Container C simply represents a common industrial cylinder or tank which is specifically designed to hold a pressurized fluid / gas therein.

[0022] Now referring to FIGS. 2 and 3, the primary components of the valve 10 include a valve body 12 and a valve operating assembly 13, including a number of working parts which are received in the valve body when assembled. The valve body 12 is a cylindrical shaped member including a chamber extending longitudinally therethrough. When the valve operating assembly 13 is positioned within the chamber, the chamber can be conceptually separated into an upper portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com