Vacuum preloading seepage consolidation combined with precipitation preloading consolidation method for ultra-soft foundation

A preloading and vacuum technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as difficulty in finding air leaks, inability to construct mechanical equipment, and non-environmental protection of pvc sealing film, and achieve the effect of reducing residual settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

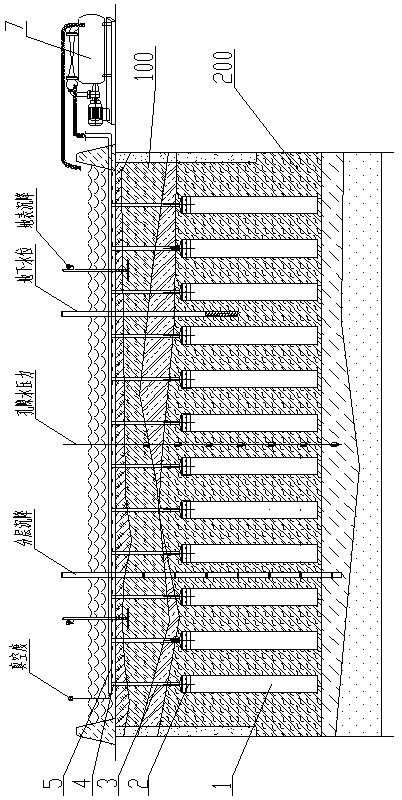

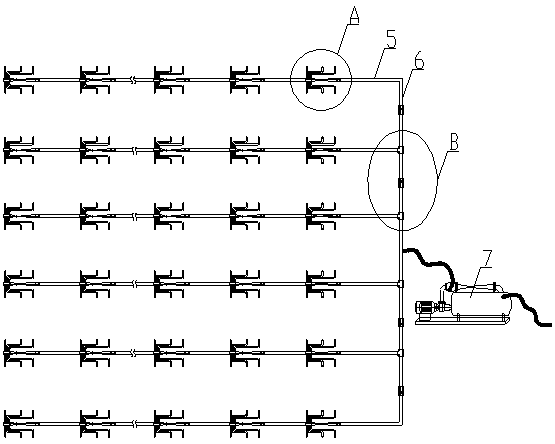

[0059] see Figure 1~Figure 8 , a kind of ultra-soft foundation vacuum preloading seepage consolidation combined precipitation preloading consolidation method that the present invention relates to, it comprises the following steps:

[0060] Step 1. Arrangement of integrated well point plastic exhaust vacuum system

[0061] 1.1. The integrated well point plastic pipe is inserted and constructed to form an integrated well point plastic pipe grid;

[0062] The grid spacing of the integrated well-point plastic pipe grid can be adjusted from 1 to 4m; the integrated well-point plastic pipe is inserted using manual inserting boards.

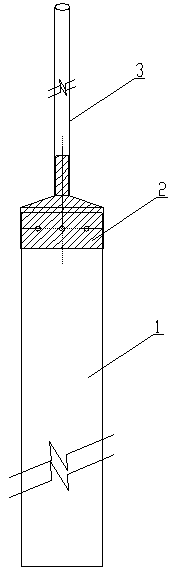

[0063] The integrated well point plastic drainage pipe (that is, the improved branch pipe) includes a drainage board 1, a connection box 2, a well point pipe 3 and a connection pipe 4. The drainage board 1 is vertically arranged in the deep soil 100, and the drainage board 1 is about 20m in length, the well point pipe 3 is vertically arranged in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com