Construction method and pouring structure in prestressed tendon position of prestressed coal bin cylinder wall

A technology of prestressed tendons and construction methods, which is applied in the direction of building types, buildings, and large-capacity bulk material storage, etc., can solve problems that affect the normal sliding of the sliding form, prolong the construction period, and be difficult to bend, etc., to achieve the construction process Convenient and reliable, shorten the construction period, save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

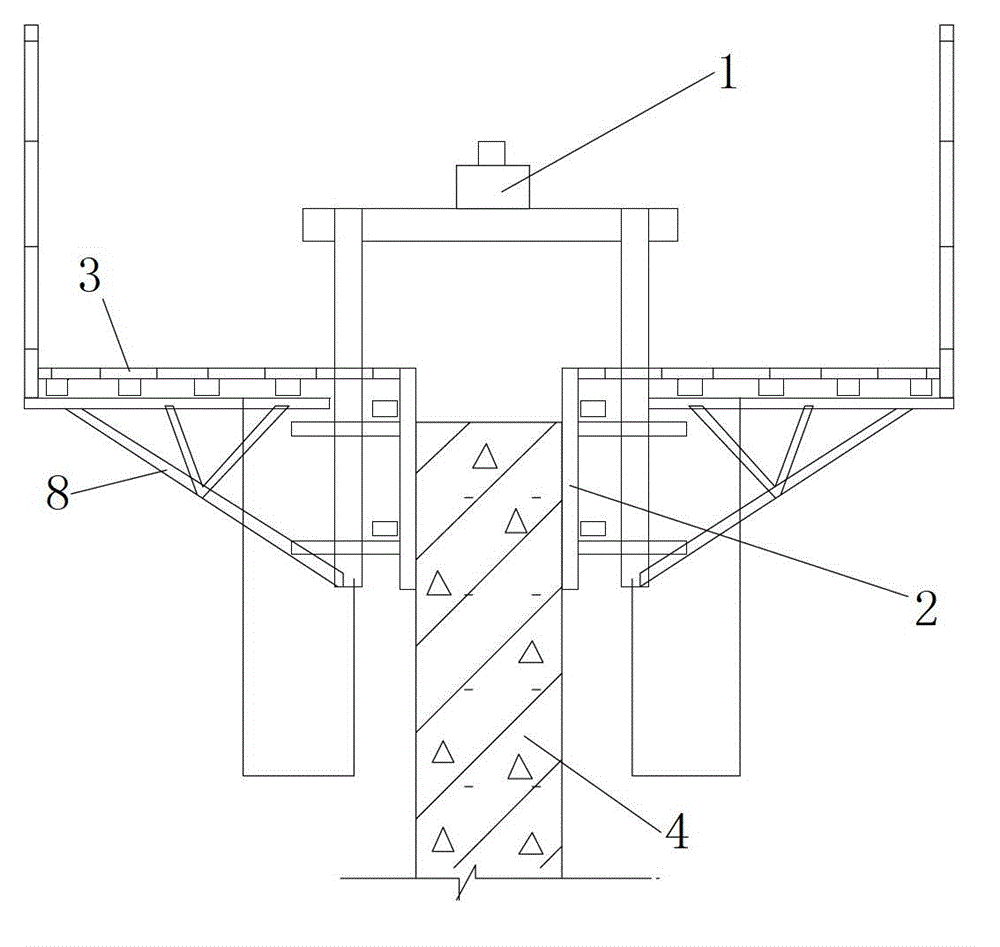

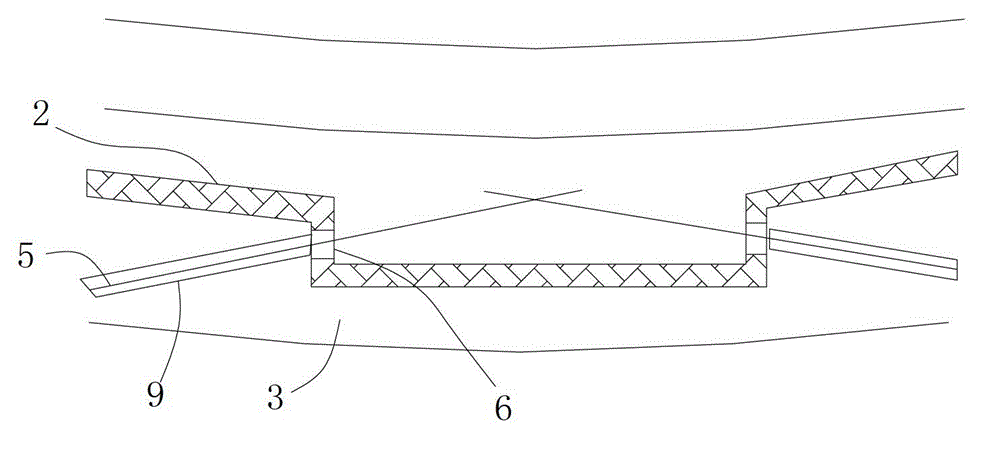

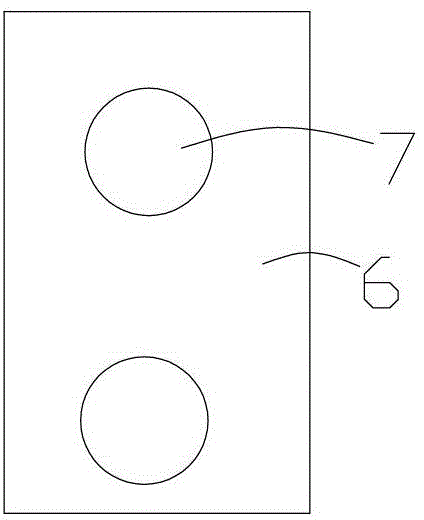

[0014] like figure 1 As shown, the construction method for the location of the prestressed tendons on the wall of the prestressed coal bunker includes setting the steel bars on the wall and arranging a plurality of prestressed tendons 5 sequentially from bottom to top along the axial direction of the wall, and setting up a slip-form construction system. The construction system includes a sliding form mold 2, a support platform 3 and a lifting system, and the lifting system includes a jack 1 and a sliding form hanger 8. The sliding form mold 2 includes a plurality of sliding formwork templates, and the corresponding sliding form molds of the prestressed tendons The slide formwork template is removed to form a mold gap on the slide mold, and a platform gap 9 for avoiding prestressed tendons is opened on the support platform 3, so that in the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com