Turn-back type stepped drop well

A drop well and return type technology, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of construction difficulty and project cost increase, foundation pit excavation with large amount of earthwork, and inconvenient maintenance in wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

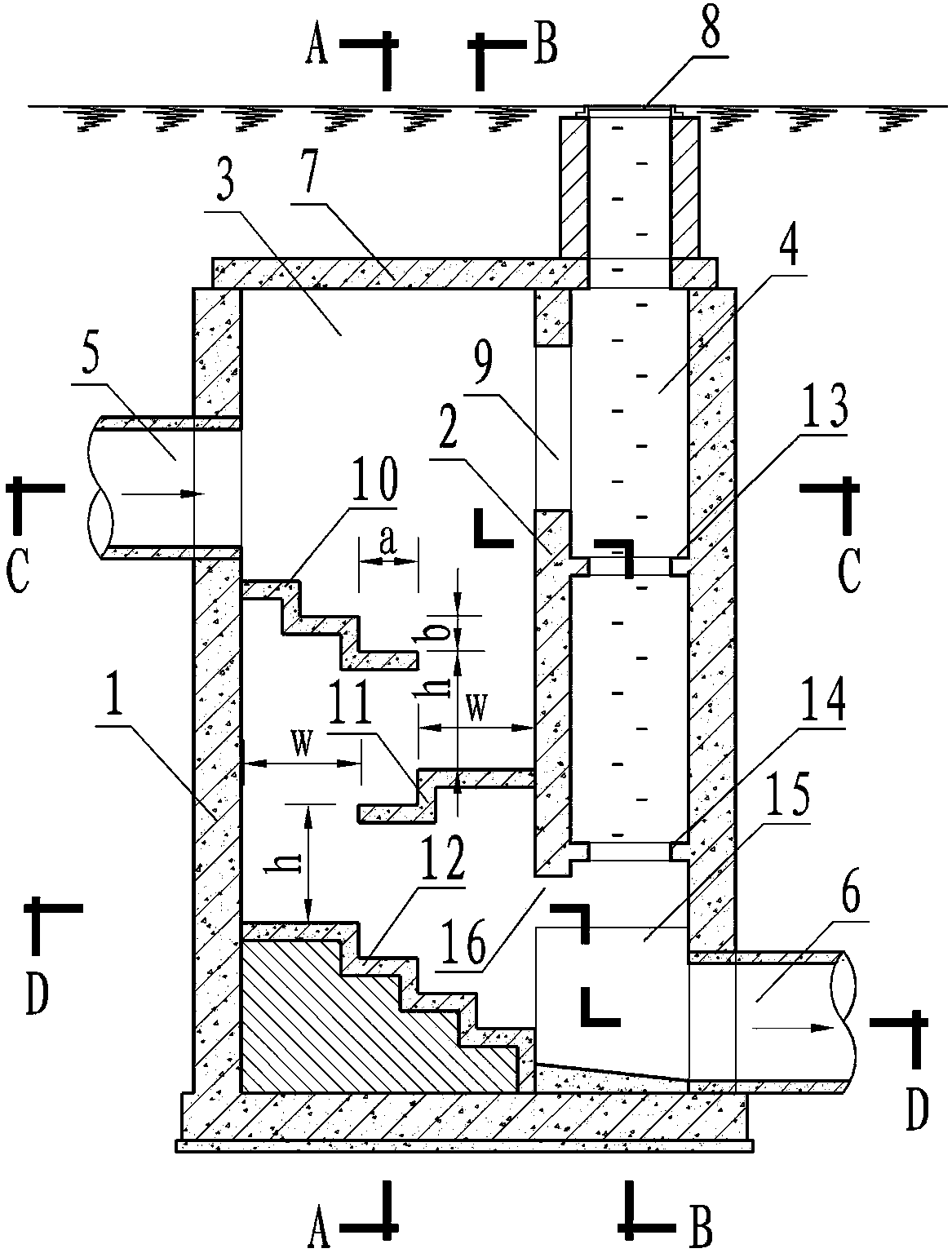

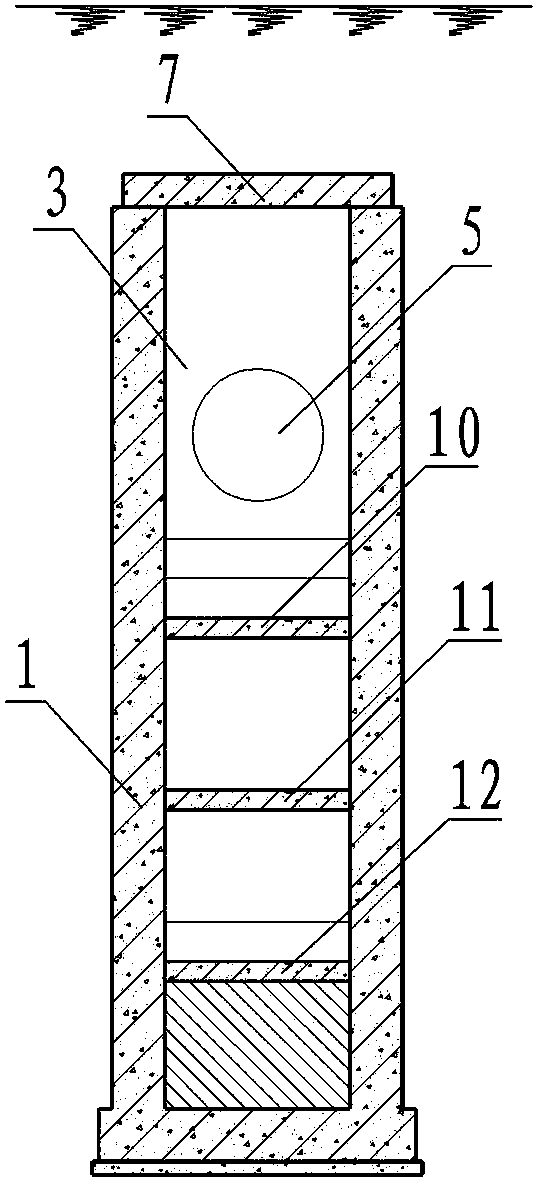

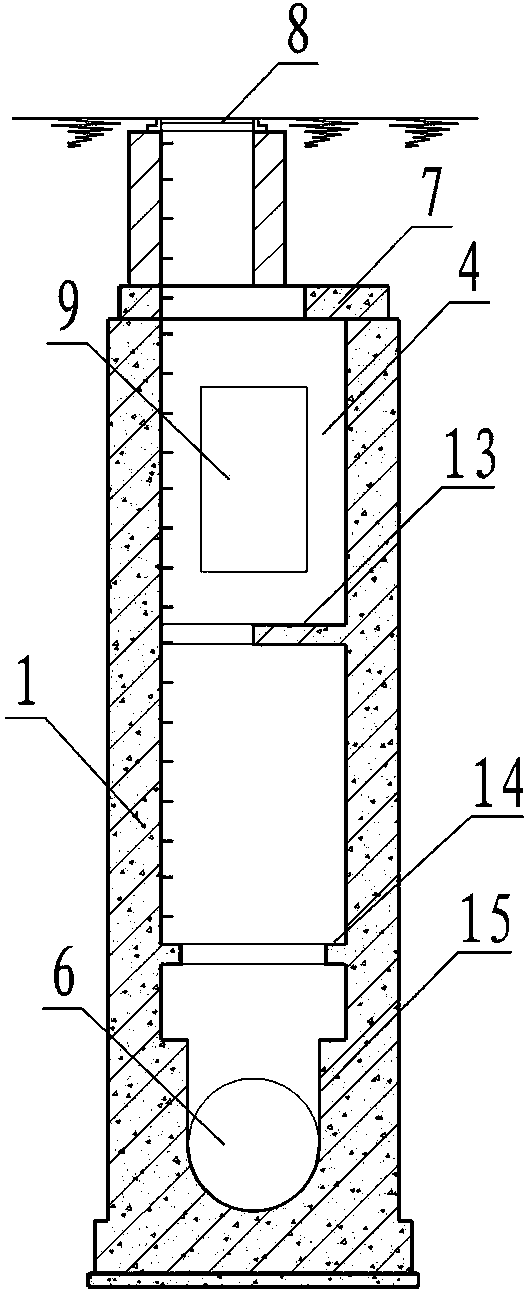

[0013] In the implementation of the present invention, the structural size of the water drop well shall be determined according to the pipe diameter and the height difference of the upstream and downstream pipelines. The water drop well shall be constructed with concrete or bricks. The thickness of the well wall shall be calculated according to the depth of the well and the surrounding soil conditions, and the step width a shall be adjusted. Different water drop heights and drop chamber lengths can be obtained from step height b and drop difference h. The width of the drop chamber is determined by adding 150-250 mm to both sides of the pipe diameter. The length of the operating room is 900-1200 mm. The water chambers are equal in width. The turn-back ladder drop well is mainly composed of a well body 1, a partition wall 2, a water drop chamber 3, an operating room 4, a water inlet pipe 5, and a water outlet pipe 6. There are two parts, the water drop chamber 3 and the operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com