Composite lining structure for super-large-span pile-foundation-joist-based bearing arched tunnel and construction method thereof

A composite lining and span technology, which is applied in tunnel lining, foundation structure engineering, tunnels, etc., can solve problems such as arch structure settlement, lining cracking, arch foot displacement is difficult to control, etc., to eliminate the risk of landslides, improve the safety of dismantling and bracing and Flexibility, the effect of reducing the amount of excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

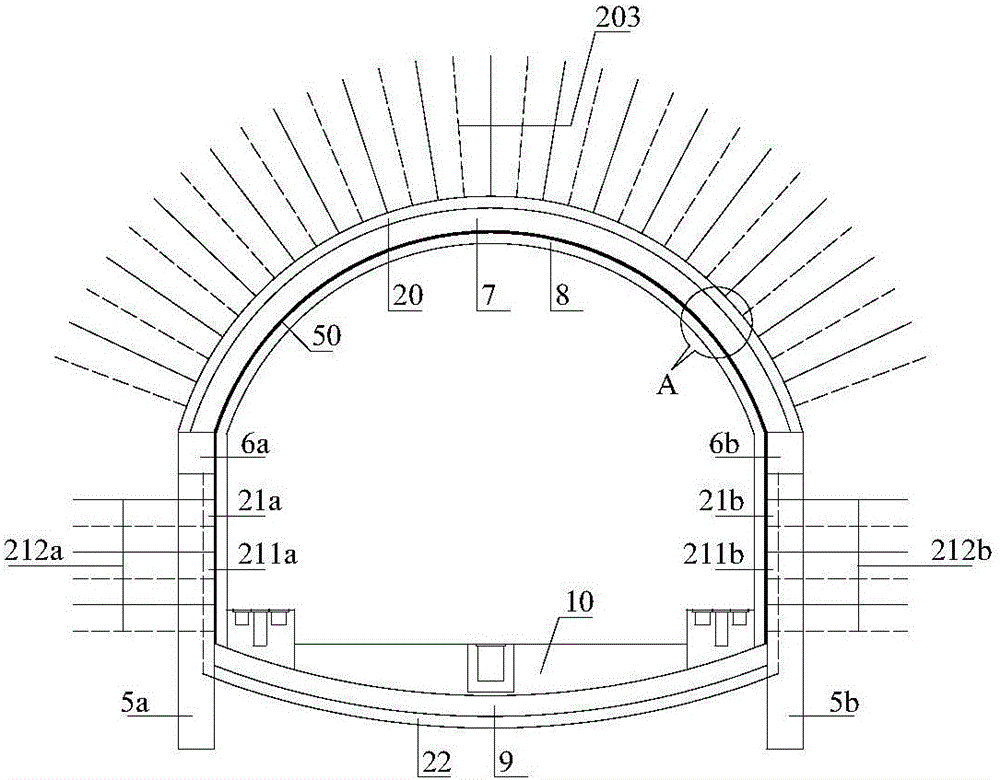

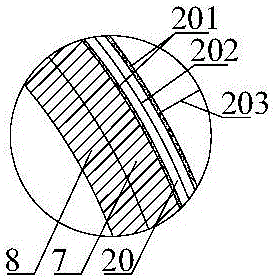

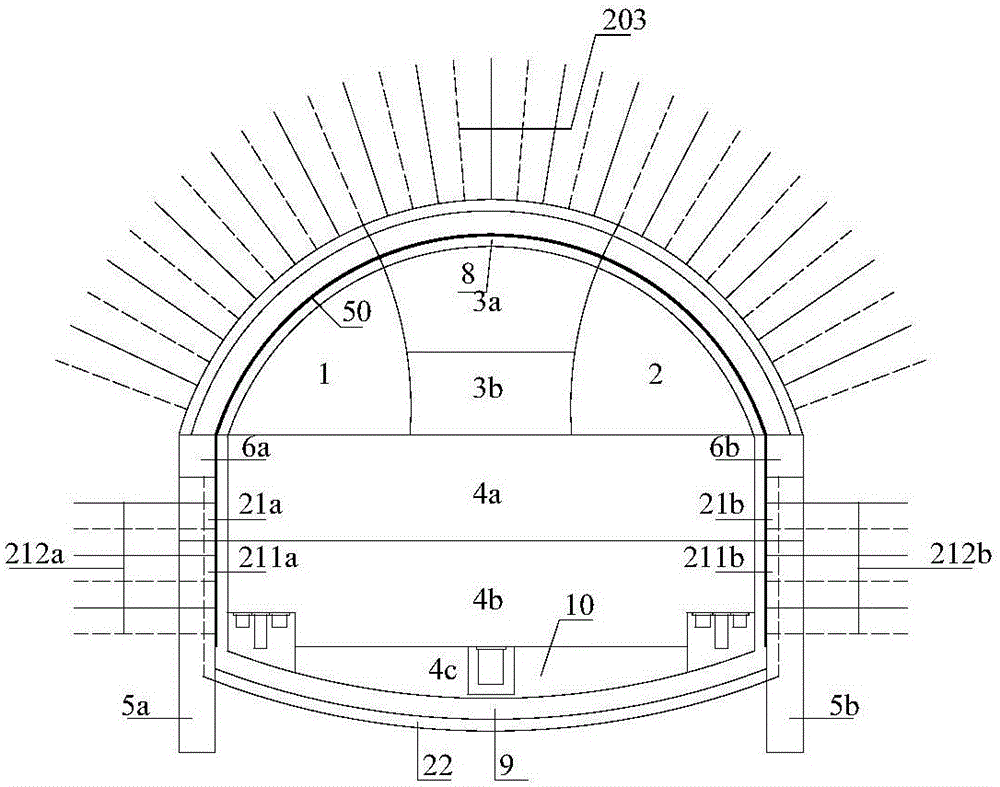

[0031] refer to figure 1 , a super-large-span pile foundation joist bearing arch tunnel composite lining structure of the present invention includes an advanced support structure, an initial support structure and a secondary lining structure arranged from inside to outside. The secondary lining structure includes an arch secondary lining structure 7 and an upward secondary lining structure 9, and the primary support structure includes an arch primary support structure 20, a left side wall primary support structure 21a, a right The primary support structure 21b of the side wall and the primary support structure 22 of the inverted arch; The side arch feet are supported on and connected to the right joist 6b; the left pile foundation 5a and the right pile foundation 5b are respectively arranged at intervals along the tunnel extension direction under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com