Composite liner structure of four-track large-span wall-foundation arched tunnel

A tunnel and arch technology, which is applied to the lining structure of four-line long-span tunnels in the shallow buried section of soft rock formations, can solve the problems of large subsidence, instability and collapse of the arch foot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

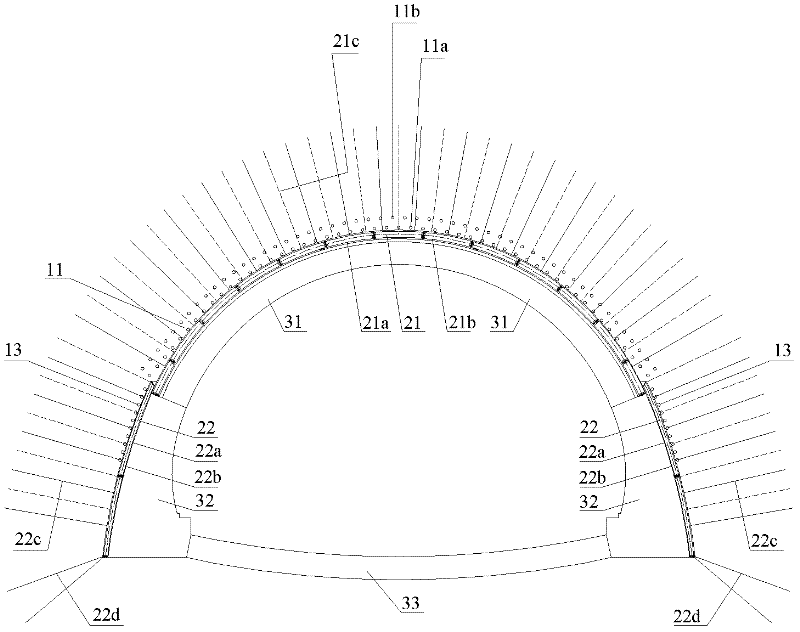

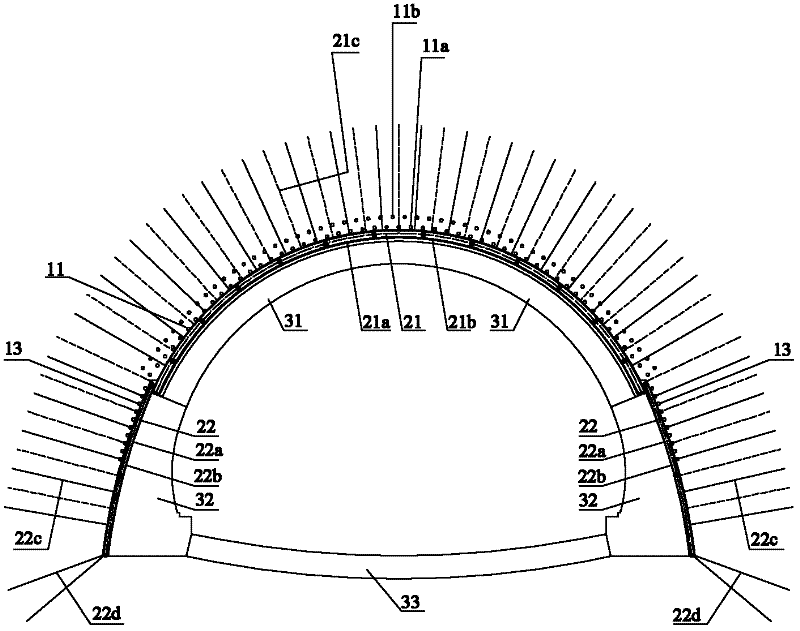

[0014] refer to figure 1 , the four-line long-span abutment composite arched tunnel lining structure of the present invention includes an advanced support structure, an initial support structure and a secondary lining structure arranged from outside to inside. The secondary lining structure includes the secondary lining structure 31 of the arch, the base structure 32 on both sides of the tunnel, and the inverted arch 33 . The advance support structure includes an arch advance support structure 11 and an advance support structure 12 on the side wall of the pedestal foundation. refer to figure 1 , the primary support structure includes an arch primary support structure 21 and a pedestal foundation side wall primary support structure 22 . The lower ends of the arch primary support structure 21 and the arch secondary lining structure 31 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com