Production system for preparing phycocyanin through low-temperature alcohol extraction as well as process method

A technology for phycocyanin and production system, which is applied in the field of production system for preparing phycocyanin by low-temperature alcohol extraction, can solve the problems of difficult control of production process and poor stability of phycocyanin, and achieves the effect of inhibiting the growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

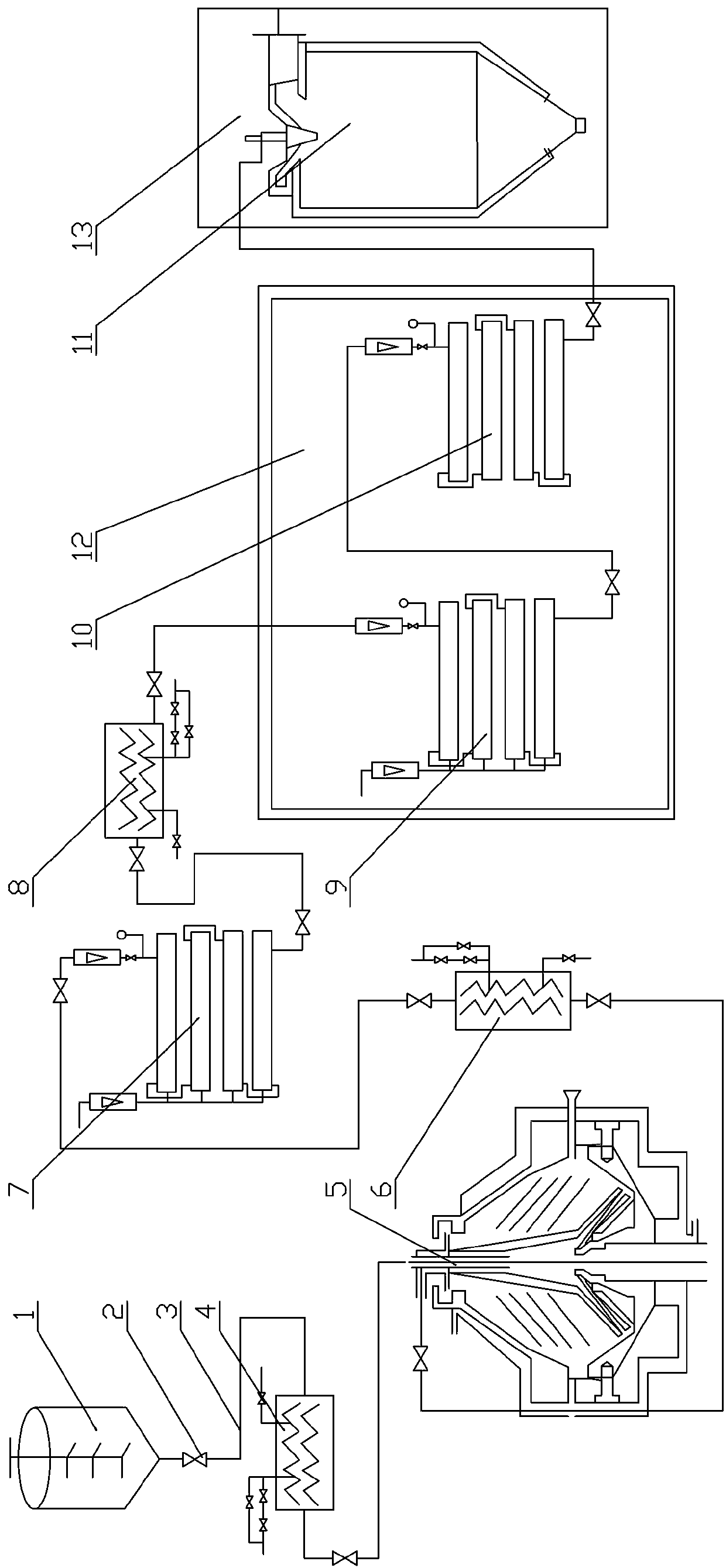

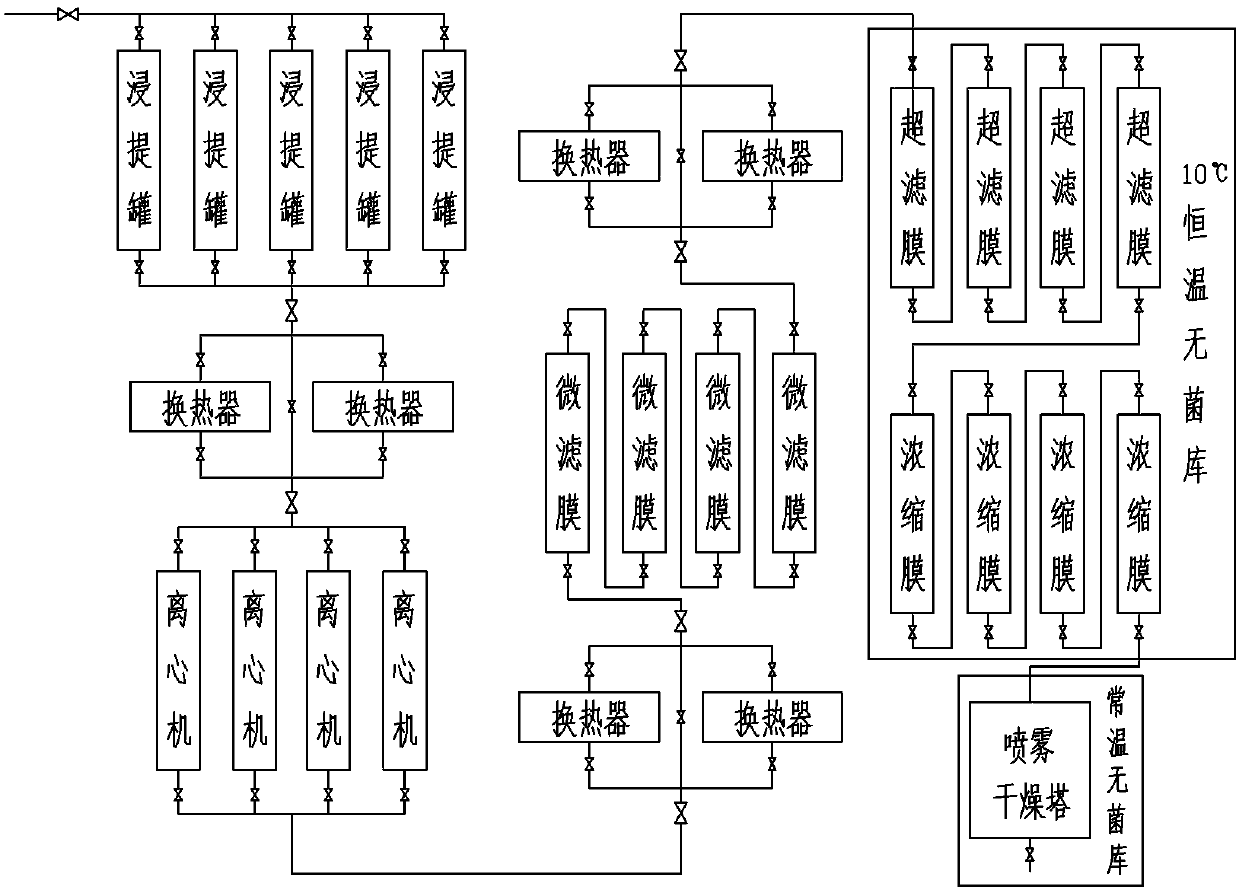

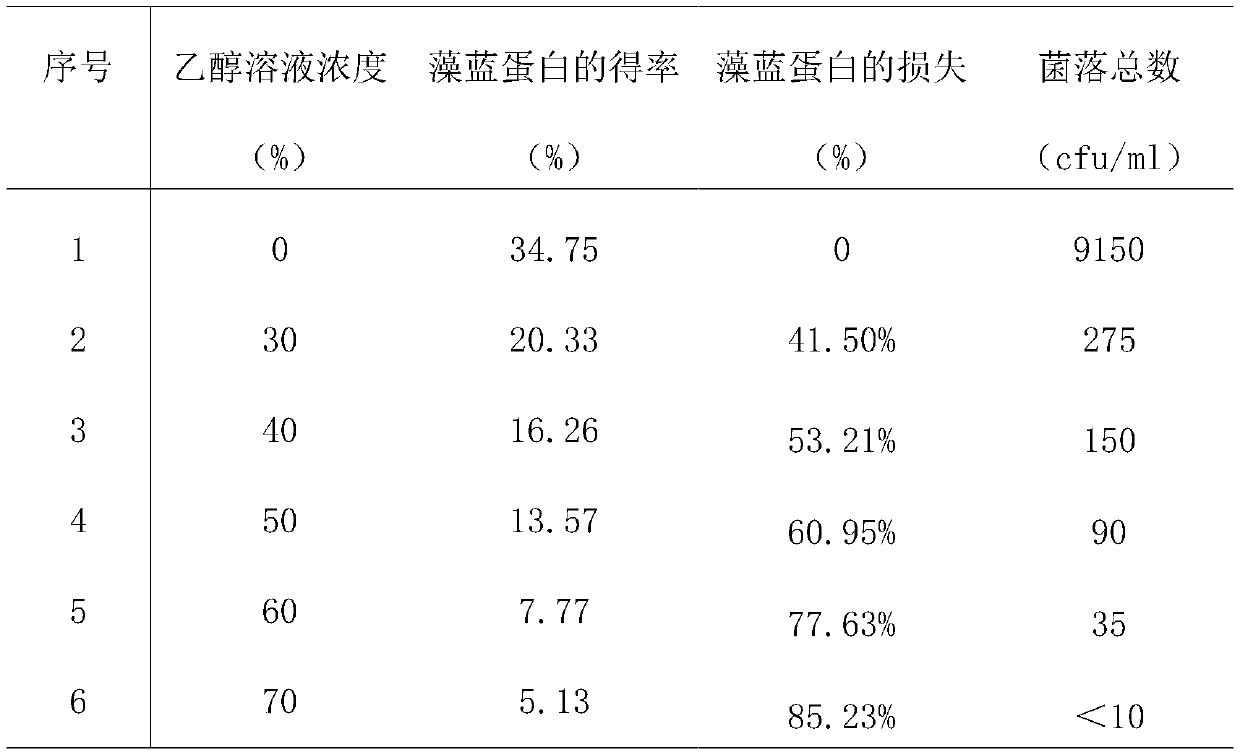

[0059] see figure 1 , figure 2 , a production system for preparing phycocyanin by low-temperature alcohol extraction in the present embodiment has an extraction tank 1, and after the extraction tank 1, a first-stage cold cycle device 4 and a cold cycle centrifuge are sequentially connected in series through a pipeline 2 and a valve 3 5. Two-stage cold circulation device 6, one-stage microfiltration membrane filter 7, three-stage cold circulation device 8, two-stage ultrafiltration membrane filter 9, three-stage concentration membrane filter 10, spray drying tower 11, the two Both the first-stage ultrafiltration membrane filter 9 and the third-stage concentration membrane filter 10 are located in a 10°C constant-temperature aseptic storehouse 12, and the spray drying tower 11 is located in a room-temperature aseptic storehouse 13.

[0060] In the present invention, there are 1 to 7 extraction tanks 1, and in this embodiment, there are 5 extraction tanks, which are connected i...

Embodiment 2

[0075] A production system for preparing phycocyanin by low-temperature alcohol extraction of the present invention has an extraction tank, and after the extraction tank, a primary cold cycle device, a cold cycle centrifuge, a secondary cold cycle device, One-stage microfiltration membrane filter, three-stage cold cycle device, two-stage ultrafiltration membrane filter, three-stage concentration membrane filter, spray drying tower, the two-stage ultrafiltration membrane filter and three-stage concentration membrane filter are all It is located in a 10°C constant temperature aseptic warehouse, and the spray drying tower is located in a normal temperature aseptic warehouse.

[0076] In the present invention, there are 1 to 7 extraction tanks, and in this embodiment, there are 7 extraction tanks, which are connected in parallel, and the batching time and timing of each extraction tank are adjusted according to the process requirements during use. During the discharge time, the ex...

Embodiment 3

[0090] A production system for preparing phycocyanin by low-temperature alcohol extraction in this embodiment has an extraction tank, and after the extraction tank, a primary cold cycle device, a cold cycle centrifuge, and a secondary cold cycle device are sequentially connected in series through pipelines and valves , one-stage microfiltration membrane filter, three-stage cold cycle device, two-stage ultrafiltration membrane filter, three-stage concentration membrane filter, spray drying tower, the two-stage ultrafiltration membrane filter and three-stage concentration membrane filter They are all located in a 10°C constant temperature aseptic warehouse, and the spray drying tower is located in a normal temperature aseptic warehouse.

[0091] In the present invention, there are 1 to 7 extraction tanks, and in this embodiment, one extraction tank is provided specifically, and the extraction tank is provided with a jacket and a stirring device.

[0092] The first-stage cold cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com