Method for comprehensively utilizing abandoned oil in coking industries

A waste oil and industry technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, chemical modification of fatty acids, etc., can solve the problems of increased coal preparation production costs, low energy utilization efficiency, high production costs, etc., to improve resource utilization efficiency, The effect of easy purchase of raw materials and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

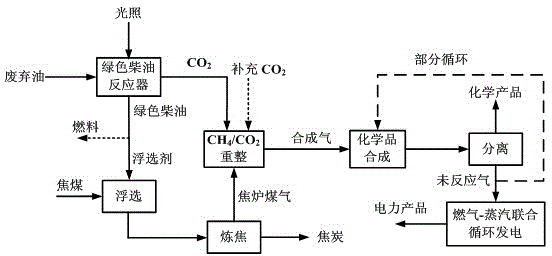

[0027] Such as figure 1 As shown, 100 t of raw materials were obtained after the collected waste oil was removed from impurities, and the raw materials were sent into a light-transmitting strengthened glass reactor filled with titanium dioxide photocatalysts. The mass ratio of raw materials to catalysts was 100:1. Under sunlight conditions, the reaction temperature is 25o C, the reaction pressure is 1 atm, waste oil undergoes decomposition reaction to produce 90 t of green diesel oil, and its composition mass percentage is 53% of hydrocarbons ((in C 16 Mainly straight chain alkanes, a small amount of C 5 -C 9 alkanes and C 5 -C 8 olefins)), fatty acids 10%, esters 34% and water 3%, and CO 2 Gas 10 t (CO 2 The mole percentage is greater than 75%, others are a small amount of C 3 The following low-carbon hydrocarbons). The generated green diesel oil is directly used as a flotation agent for the flotation of coking coal blending, and 90,000 tons of clean coking coal can b...

Embodiment approach 2

[0029] Such as figure 1 As shown, 100 t of raw materials are obtained after the collected waste oil is removed from impurities, and the raw materials are sent into a light-transmitting strengthened glass reactor filled with bismuth oxybromide photocatalyst, and the mass ratio of raw materials to catalysts is 100:1 , under sunlight conditions, the reaction temperature is 25 o C, the reaction pressure is 1 atm, waste oil undergoes decomposition reaction to produce 88 t of green diesel oil, and its composition mass percentage is 46.5% of hydrocarbons (in C 16 Mainly straight chain alkanes, a small amount of C 5 -C 9 alkanes and C 5 -C 8 olefins)), fatty acids 12.4%, esters 36.2% and water 4.9%, and CO 2 Gas 12 t (CO 2 The mole percentage is greater than 80%, the others are a small amount of C 3 The following low-carbon hydrocarbons). The generated green diesel oil is directly used as a flotation agent for the flotation of coking coal blending, and 86,000 tons of clean co...

Embodiment approach 3

[0031] Such as figure 1 As shown, 100 t of raw materials are obtained after the collected waste oil is removed from impurities, and the raw materials are sent into a light-transmitting strengthened glass reactor filled with bismuth oxyiodide photocatalyst, and the mass ratio of raw materials to catalysts is 100:1 , under sunlight conditions, the reaction temperature is 25 o C, the reaction pressure is 1 atm, waste oil undergoes decomposition reaction to produce 85 t of green diesel oil, and its composition mass percentage is 44.4% of hydrocarbons (in C 16 Mainly straight chain alkanes, a small amount of C 5 -C 9 alkanes and C 5 -C 8 olefins)), fatty acids 13.9%, esters 36.1% and water 6.6%, and CO 2 Gas 15 t (CO 2 The mole percentage is greater than 83%, the others are a small amount of C 3 The following low-carbon hydrocarbons). The generated green diesel is directly used as a flotation agent for flotation of coking coal blending, and 79,500 tons of clean coking coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com