Machining device for metal powder production

A metal powder and processing device technology, which is applied in the field of metal powder processing, can solve the problems of different droplet linear velocities, low powder spheroidization rate, and easy impact on the inner wall of the device, achieving good economic benefits, fast screening speed, and reduced The effect of operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

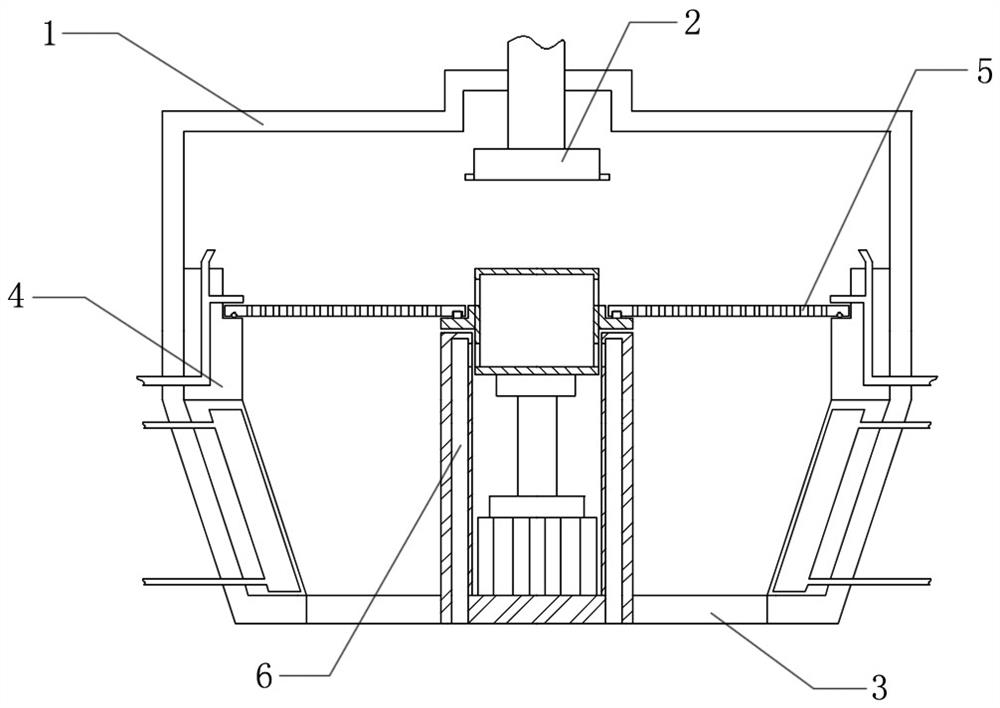

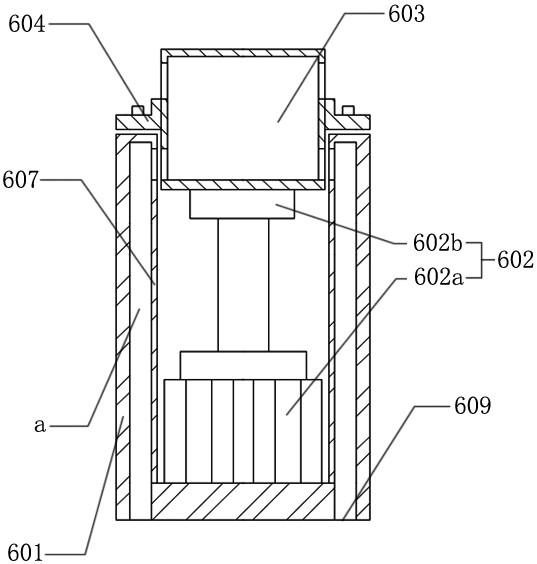

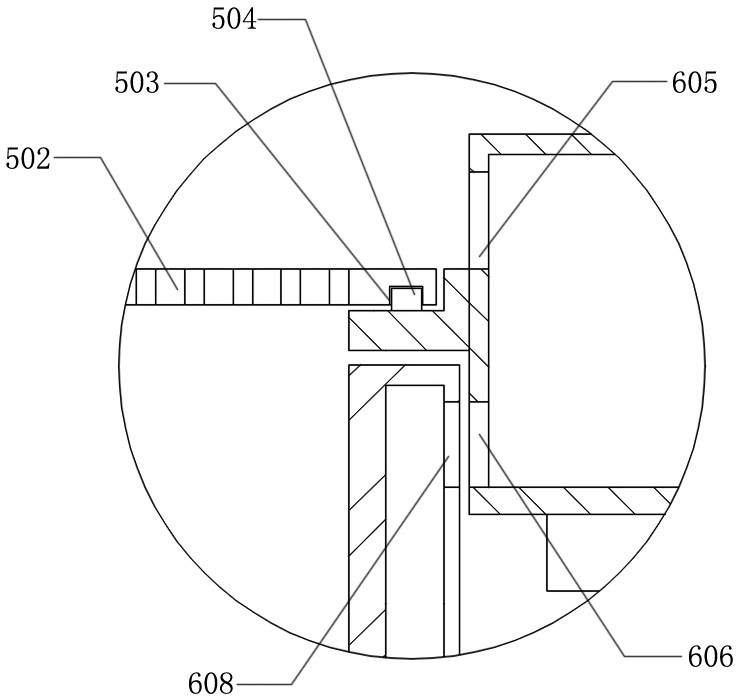

[0029] A processing device for metal powder production proposed in this embodiment, as attached Figure 1~5 As shown, it includes a tank body 1, an atomizing turntable 2 arranged at the upper end of the tank body 1, and a discharge port 3 arranged at the lower end of the tank body, and also includes a tank body 1 arranged on the inner wall and facing the tank body 1. The cooling structure 4 for cooling and solidifying the metal droplets sprayed from the atomizing turntable 2, the screening structure 5 for screening the metal powder after cooling and solidification in the tank body 1, and the The recovery structure 6 on the inner bottom of the tank body 1 is used to collect the coarse-grained metal powder located at the upper end of the screening structure 5 .

[0030] Wherein, the atomization turntable 2 mainly includes a turntable body, a feed pipe, and an atomization nozzle (not marked in the figure), and the above-mentioned structure can refer to the prior art, so it will n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com