Patents

Literature

64results about How to "Conducive to cost reduction and efficiency increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

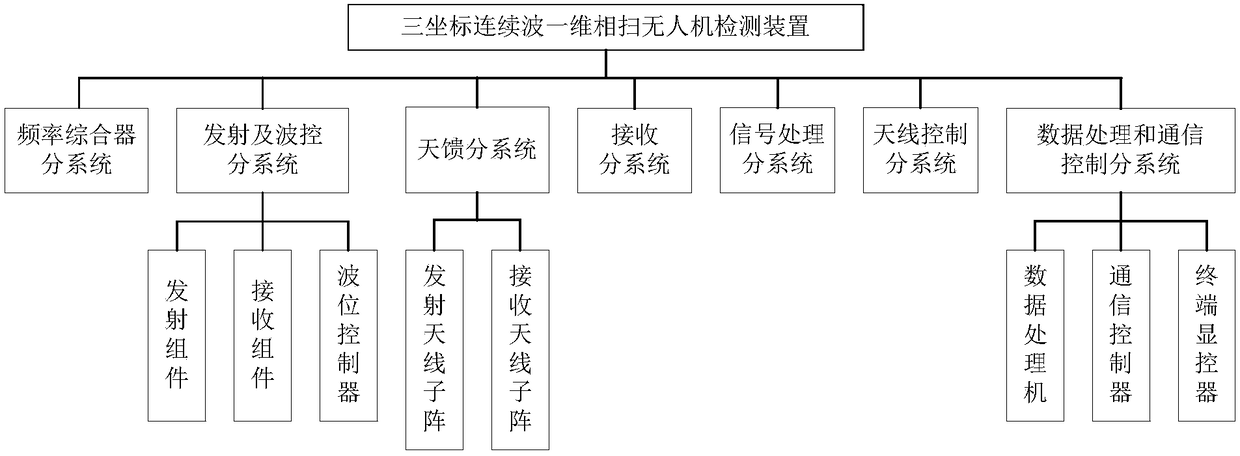

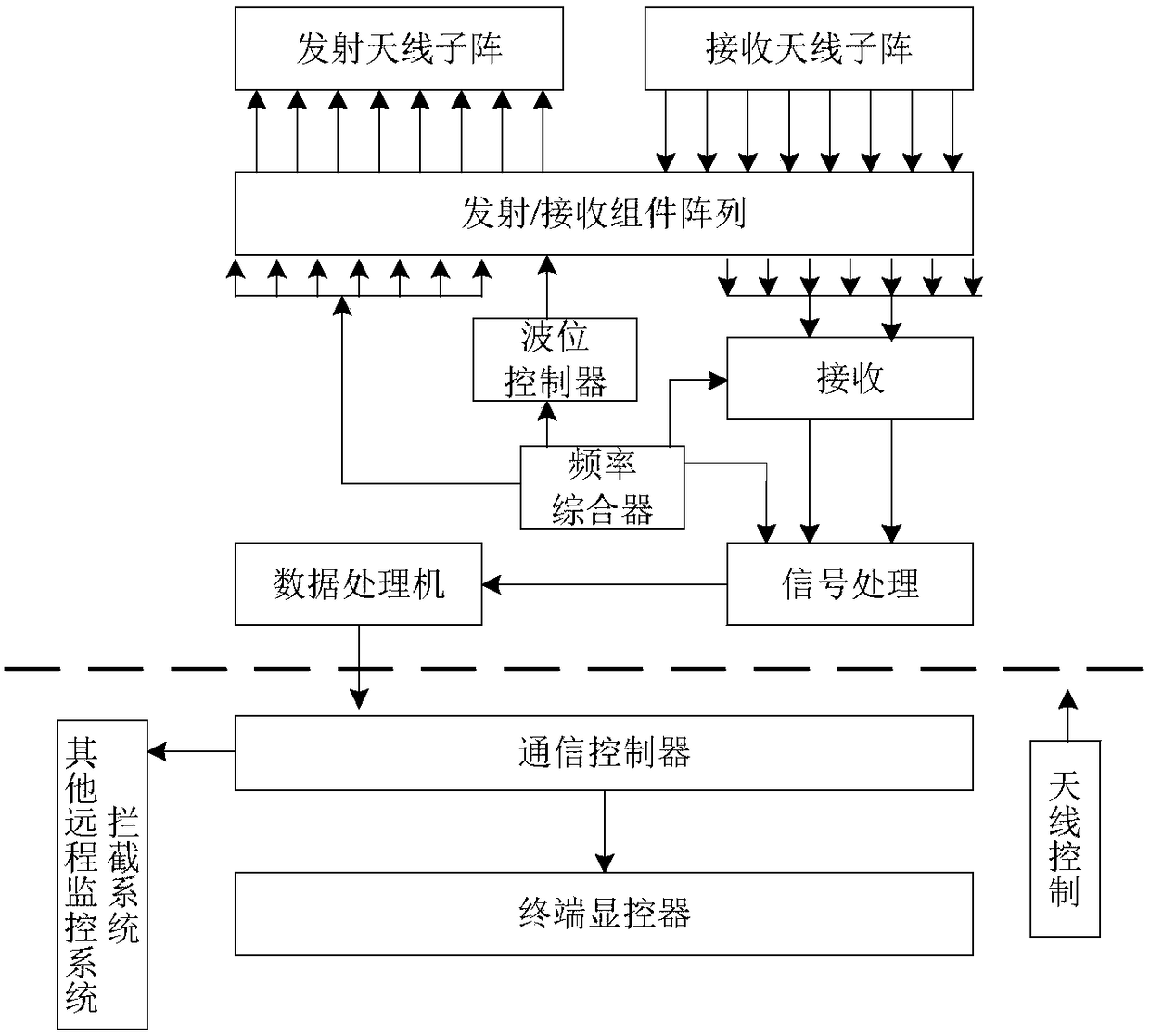

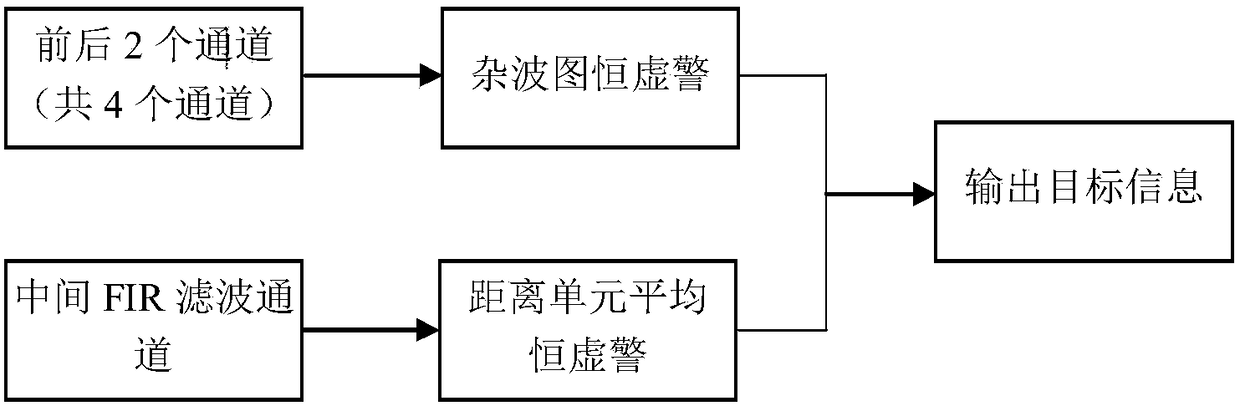

Low-altitude target detecting system of three-coordinate continuous wave one-dimensional phase sweeping unmanned aerial vehicle

ActiveCN108398677AStrong abilityHigh precisionRadio wave reradiation/reflectionLow altitudeEcho signal

The invention discloses a low-altitude target detecting system of a three-coordinate continuous wave one-dimensional phase sweeping unmanned aerial vehicle, and is aimed at providing a detecting device high in data detecting rate and anti-interference capacity. By means of the technical scheme, the system measures a target distance through a frequency modulation continuous wave ranging system, anantenna feedback subsystem converts radio frequency signals into electromagnetic wave signals to be radiated to the space, a receiving subsystem conducts amplifying, frequency varying and SFC controlprocessing on echo signals output by an emission and wave control subsystem, a signal processing subsystem generates the working time sequence of the whole system, measures the three-coordinate vectors of the distance, direction and pitching of a target position and calculates frequency modulation continuous wave ranging data of target signals, and a data processing and communication control subsystem parses the target angle, establishes the trajectory of target movement, controls the working mode of a radar and detects three-coordinate target information according to the target signals calculated by the signal processing subsystem and the antenna angle information output by the antenna control subsystem.

Owner:LINGBAYI ELECTRONICS GRP

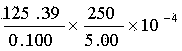

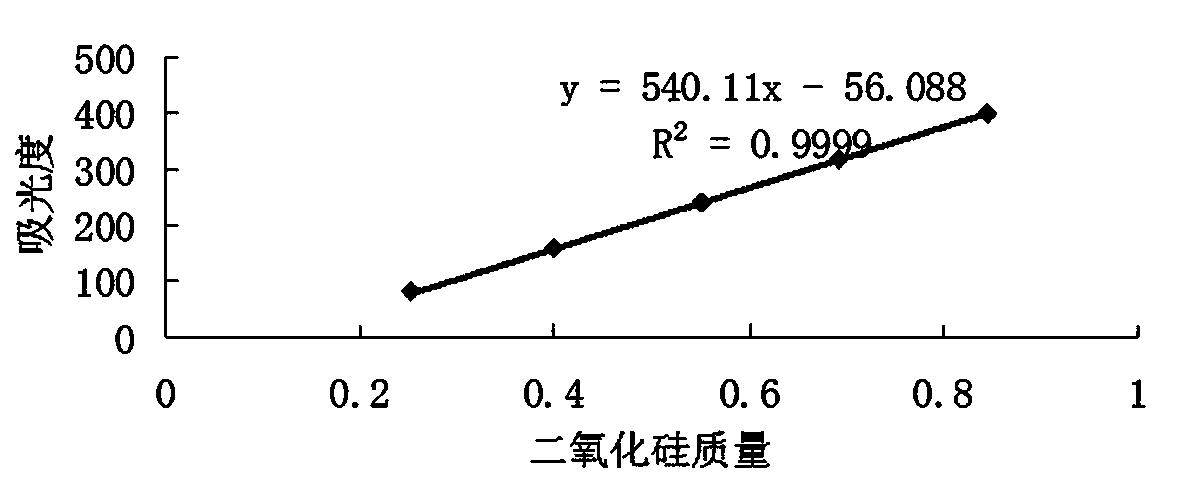

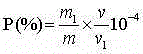

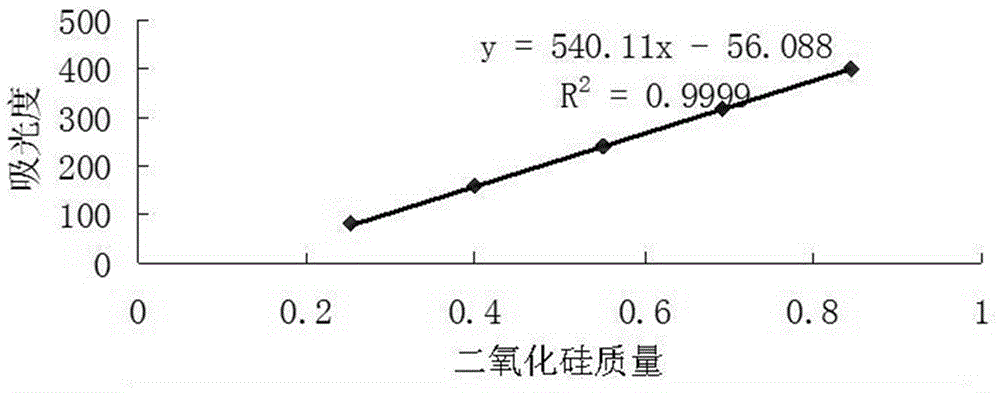

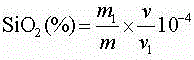

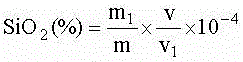

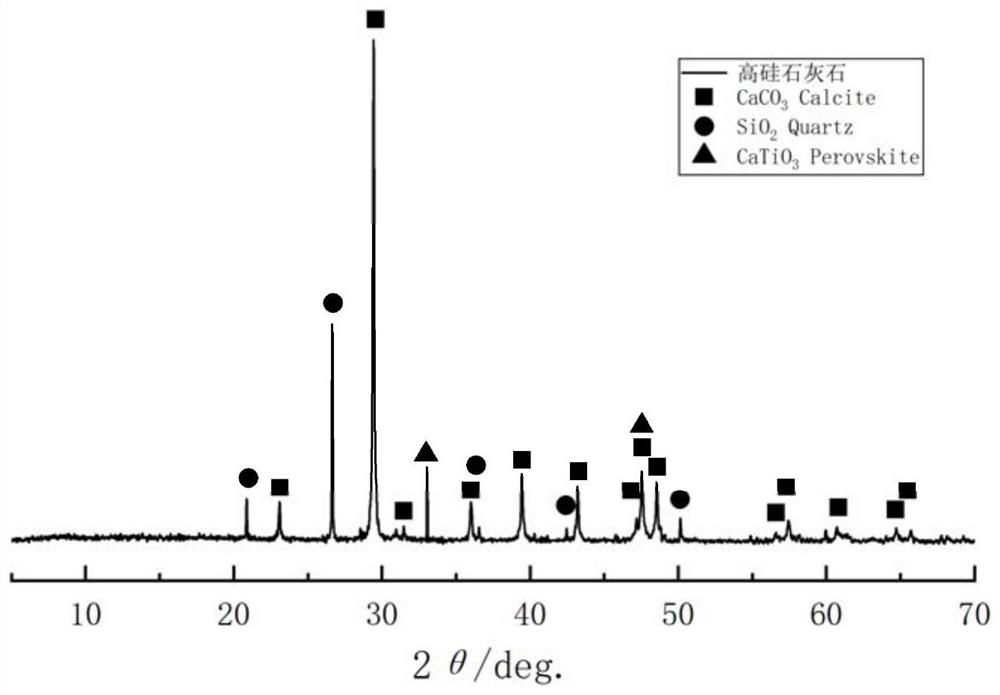

Fast and accurate detection method for silicon dioxide content in limestone, kalk and dolomite

ActiveCN103728261AConducive to complete dissolutionImprove stabilityColor/spectral properties measurementsOXALIC ACID DIHYDRATEAscorbic acid + ferrous sulphate

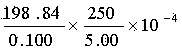

The invention discloses a fast and accurate detection method for silicon dioxide content in limestone, kalk and dolomite. The detection method comprises the following steps: crushing samples, and drying for 1.5-2.5 h under thea temperature of 105-110 DEG C; mixing 0.1000 g samples and 3.0-4.0 g mixed fluxing agent of sodium carbonate and boric acid evenly, liquating for 18-20 min under athe temperature of 890-910 DEG C, dissolving frits by a 45-55 ml hydrochloric acid and 25-35 ml water, and placing the test solution in a 250-ml volumetric flask; taking and adding 5.00 ml test solution in a 100-ml volumetric flask, adding 18-22 ml ammonium molybdate and still standing for 18-22 min, and adding 45-55 ml mixed acid of oxalic acid and sulfuric acid, 4.80-5.20 ml ascorbic acid-ammonium ferrous sulfate mixed solution; measuring the absorbency of a color development solution at the wavelength of 680 nm through a spectrophotometer, and using blank as a reference; preparing a silicon dioxide standard sample with the concentration of 40 ug / ml, moving and taking 0.00 ml, 2.00 ml, 4.00ml, 6.00 ml, 8.00 ml and 10.00 ml silicon dioxide standard samples, and placing the standard samples in 100-ml volumetric flasks respectively, adding 5.00 ml blank test solution in the volumetric flasks respectively, after color-developing, measuring the absorbency at the same conditions, and then drawing a working curve. The silicon dioxide content in the samples is calculated according to the following formula (shown in the specification). The detection method is fast and efficient, excellent in accuracy, reproducibility and stability, and particularly suitable for detection of samples with silicon dioxide content equal to or higher than 4 %.

Owner:WUKUN STEEL

Intelligent steel plate warehouse management system

InactiveCN103295116AReduce capital shareReduce liftCo-operative working arrangementsLogisticsTime informationTouchscreen

The invention provides an intelligent steel plate warehouse management system. The intelligent steel plate warehouse management system is characterized by comprising a barcode data collection module, a wireless transmission module, a material management module, a pc (personal computer) terminal comprising three-dimensional virtual warehouses, a mobile operating terminal and a lifting device, real-time information matching is performed between the three-dimensional virtual warehouses and actual storage locations, steel plate position changes of the actual storage locations are simulated dynamically, actual storage location changes are displayed through the mobile operating terminal, the mobile operating terminal displays the three-dimensional virtual warehouses in real time, location changes of the three-dimensional virtual warehouse are operated through a touch screen, and actual storage location information is matched with information of the changed three-dimensional virtual warehouses through the lifting device.

Owner:DONGFANG ELECTRIC MACHINERY

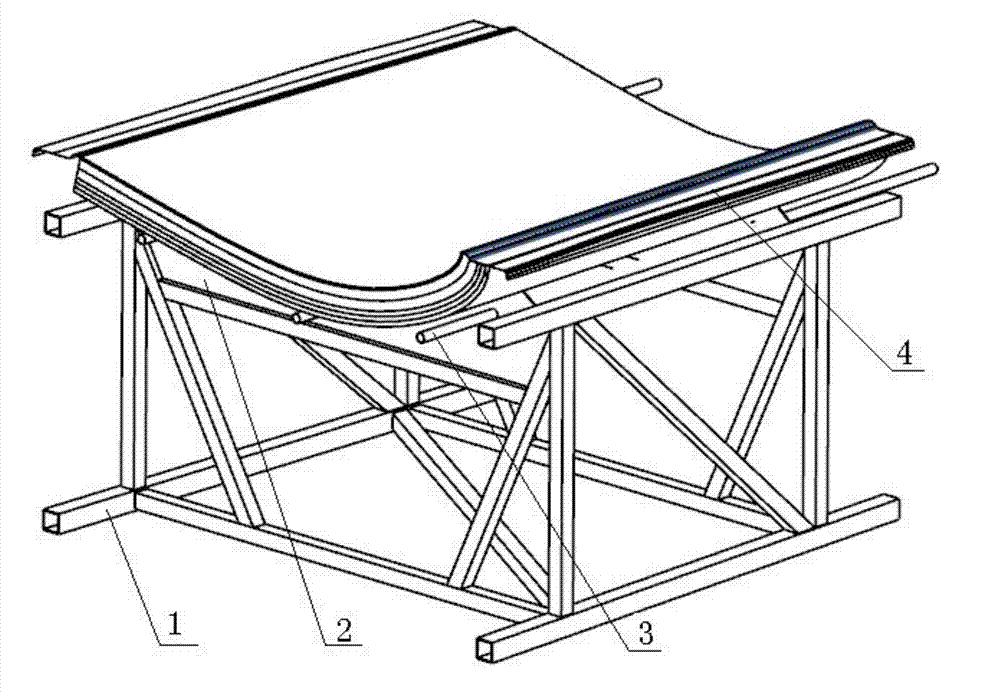

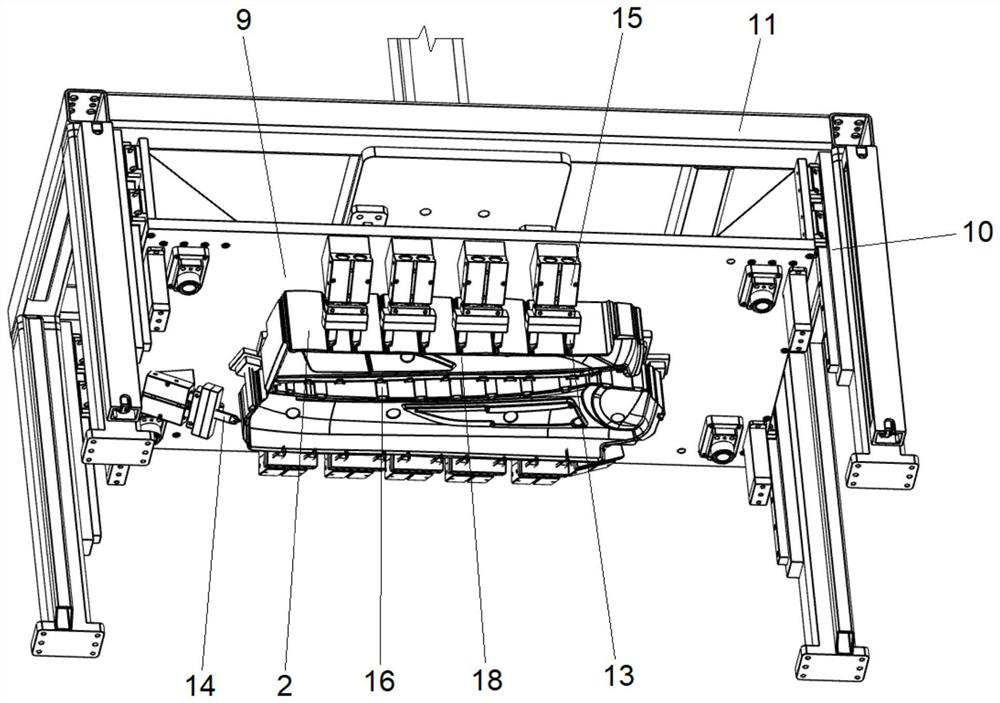

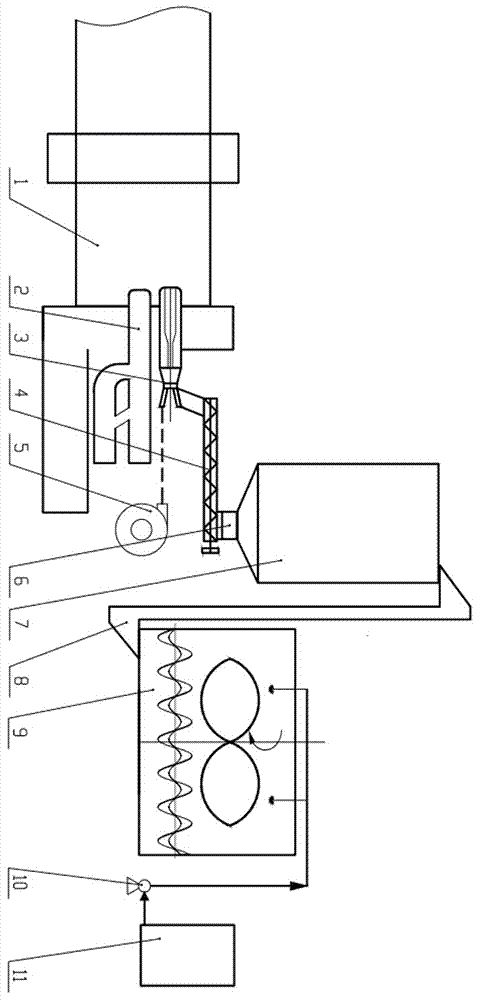

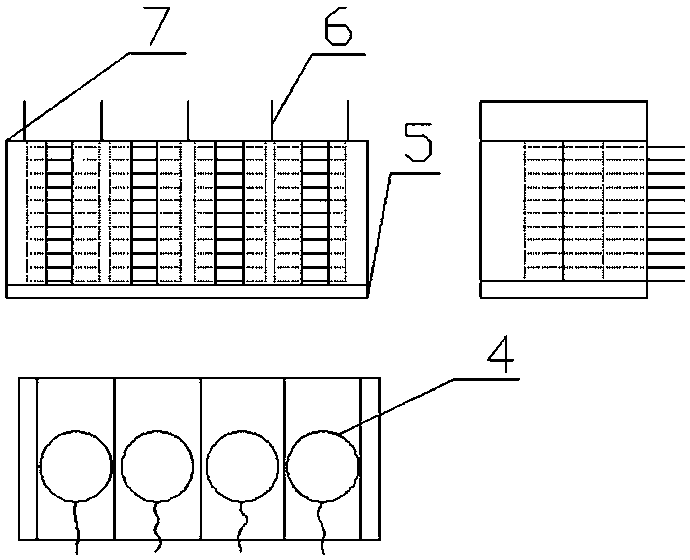

Method for machining megawatt wind turbine blade mould

The invention provides a method for machining a megawatt wind turbine blade mould. The method mainly comprises the following steps: 1, manufacturing a steel frame; 2, paving a thin-gauge skin laminated plate; 3, paving an isolation film; 4, manually pasting a pavement layer for the first time; 5, grinding and detaching part of the laminated plate, and connecting round steel and the steel frame firmly; 6, manually pasting a pavement layer for the second time; 7, paving a heating system layer; 8, manually pasting a pavement layer for the third time and curing; 9, machining the surface of the mould; 10, spraying a high-gloss gel coat and performing water mill; 11, checking and accepting. The method has the advantages that 1, a conventional mould manufacturing mode is changed, a mater mould machining link is skipped, and the production period is shortened; 2, the manufacturing cost is reduced, and the manufacturing efficiency is improved; 3, manufacturing processes are small in quantity and simple; 4, the controllability is high; 5, the requirement on master mould machining capacity is low; 6, the occupied space is small, and the occupied floor is small; 7, the cost reduction and the efficiency improvement of the mould are facilitated.

Owner:东方电气(天津)风电叶片工程有限公司

Technique for using calcium carbonate carbon spheres in LF (ladle furnace) steelmaking

The invention discloses a technique for using calcium carbonate carbon spheres in LF (ladle furnace) steelmaking, which comprises the following steps: pulverizing limestone to the granularity of 1mm below, evenly mixing with graphitic carbon, and pressing with a dry powder sphere presser to obtain calcium carbonate carbon spheres, wherein when producing every 100kg of calcium carbonate carbon spheres, the addition amount of limestone is y (y=83(100beta-51) / (83beta-12gamma)), the addition amount of the graphitic carbon is 100-y, beta is the carbon content (%) in the graphite, and gamma is the calcium carbonate content (%) in the limestone; and when smelting aluminum killed steel in a converter, adding the calcium carbonate carbon spheres according to the principle of equal addition amount to the substituted traditional calcium carbide, and using according to the traditional steelmaking technique.

Owner:北京璞域环保科技有限公司

Method for detecting content of active calcium oxide and non-active calcium oxide in lime

ActiveCN104297236APromote dissolutionUniform responseMaterial analysis by observing effect on chemical indicatorSodium acid carbonateTriethanolamine

The invention discloses a method for detecting the content of active calcium oxide and non-active calcium oxide in lime. The method comprises the steps of crushing lime until the particle diameter is less than or equal to 0.150mm, and drying at 105-110 DEG C for 1.5-2.5 hours; taking 0.5000g of a test sample, and mixing with a blend of 4g of anhydrous sodium carbonate and boric acid, fusing at 880-920 DEG C for 16-24 minutes, putting the fused blocks into 60ml of 8% hydrochloric acid and dissolving at 100-110 DEG C, enabling the volume of a solution to be constant by a 250ml volumetric flask so as to obtain a test solution a; taking 0.5000g of a test sample additionally, adding 5g of saccharose and 45-55ml of water which is boiled firstly and then cooled, vibrating closely for 18-22 minutes, enabling the volume of the solution to be constant by a 250ml volumetric flask so as to obtain a test solution b; removing 50.00ml of the test solution a and the test solution b, and respectively adding 5ml of triethanolamine and 20% potassium hydroxide or sodium hydroxide, so that the pH value of the test solution is greater than or equal to 12.5; then adding 4-5 drops of 1mg / ml magnesium oxide standard solution and 2-3 drops of calconcarboxylic acid, titrating the test solution by an EDTA standard solution until the test solution turns blue from red. The content of the active calcium oxide is calculated according to the following formula as shown in the specification, and the content of the non-active calcium oxide is calculated according to the following formula as shown in the specification, wherein W does not refer to CaO=WTCaO_WfCaO. The method is used for rapidly and accurately detecting the content of the active calcium oxide and non-active calcium oxide in a lime test sample, and is high in popularization and application value.

Owner:WUKUN STEEL

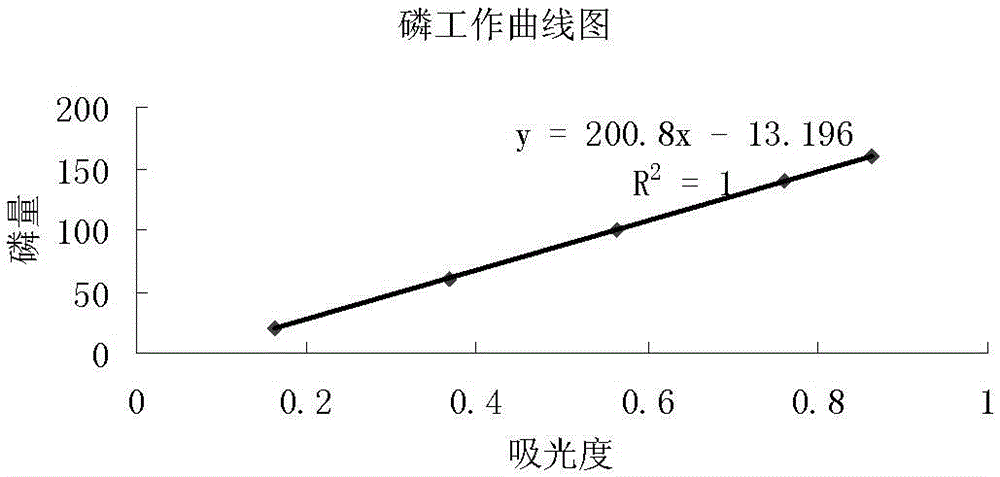

Detecting method for phosphorus content in vanadium slag

ActiveCN105300975AEasy to operateEasy to masterMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsSlagAntimony potassium tartrate

The invention discloses a detecting method for the phosphorus content in vanadium slag. According to the method, a sample is smashed and dried; the sample and sodium carbonate-boric acid mixed flux are mixed uniformly, the mixture is fused for 20-25 min at the temperature of 900 DEG C+ / -10 DEG C, frit is dissolved with 75 ml of hydrochloric acid, and the volume is metered to 250 ml; filtering is carried out, 20.00 ml of filter liquor is taken, three drops of paranitrophenol solution are added, a sodium hydroxide solution is dripped until the solution is yellow, hydrochloric acid is dripped until yellow fades, 5 ml of hydrochloric acid is added, 5 ml of ascorbic acid-hydroxylamine hydrochloride-bismuth nitrate mixed liquor is added, the mixed liquor is placed for 3-5 min, 5 ml of mecaammonium heptamolybdate tetrahydrate-antimony potassium tartrate mixed liquor is added, and the volume is metered to 100 ml; the mixed liquor is placed for 20 min, and with a blank as a reference, a spectrophotometer is used for measuring absorbance of developing liquid at the portion with the wavelength of 700 nm; a phosphorus standard sample with the concentration of 20 micrograms / ml is prepared, transferred and placed into volumetric flasks, water is added, hydrochloric acid is added, after developing, under the same condition, the absorbance is measured, and a working curve is drawn; the phosphorus content in the sample is calculated according to the following formula (see the formula in the description). The method is fast, efficient and particularly suitable for detecting the sample with the phosphorus content of 0.05-1.5%, and has high accuracy, repeatability and stability.

Owner:WUKUN STEEL

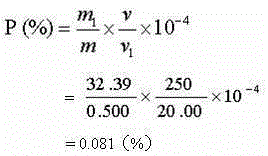

Oil field well site information management monitoring system

InactiveCN107105017AReduce labor intensityImprove productivityTransmission systemsClosed circuit television systemsData informationSurveillance camera

The present invention discloses an oil field well site information management monitoring system. The system comprises an oil field monitoring center, a GPRS network, a drilling crew monitoring work station and a field collection terminal. The field collection terminal comprises a field collection instrument, a monitoring camera and a GPRS transmission terminal and is configured to collect oil field site information data and images; the oil field monitoring center comprises a router, a switch connected with the router and a database server and a communication server which are connected with the switch and is configured to provide a communication channel for information data and images for transmission and storage; the GPRS network is configured to perform real-time transmission of the information data and images collected by the field collection terminal; and the drilling crew monitoring work station comprises a work terminal and is configured to receive and process the data information and take charge of processing of emergency cases appeared in a processing system. The oil field well site information management monitoring system can timely collect information data and discover problems so as to facilitate management and decision, reduce labor cost and facilitate improving economic benefit.

Owner:合肥酷睿网络科技有限公司

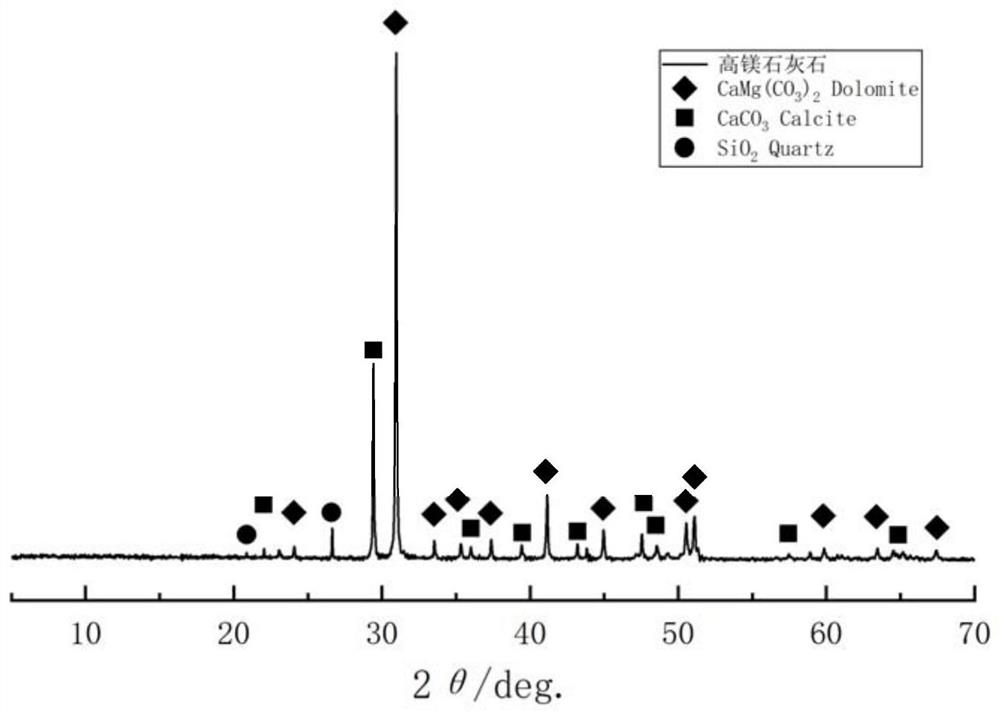

Process of using magnesia-calcium-carbon balls in LF steel making

The invention discloses a process of using magnesia-calcium-carbon balls in LF (ladle furnace) steel making. The process comprises the steps that dolomite and graphite carbon are uniformly mixed, then crushed, and pulverized till the particle size is below 1mm; the pulverized dolomite and graphite carbon are then put into a ball pressing machine to allow carbon, and calcium carbonate and magnesium carbonate that are in dolomite to be pressed together to form a homogeneous body of carbonate and carbon; and the homogeneous body is made into deoxidant carbon balls capable of replacing calcium carbide. Computational formulas of adding amounts of carbon and dolomite are as follows: (1) the content of carbon is controlled at 45%, the content of carbon in dolomite is assumed to be alpha, the content of carbon in graphite is assumed to beta, the adding amount of graphite is Q, then the computational formula of the adding amount (Q) of graphite is as follows: Q is equal to (45-100alpha) / (beta-alpha); and (2) the adding amount (G) of dolomite is controlled in accordance with 100-Q. When aluminium killed steel is smelted in a rotary furnace, according to the principle of replacing calcium carbide at the equal adding amount, the above deoxidant carbon balls are added, and are used according to the traditional steel melting process.

Owner:XINJIANG ZHONGHE DAZHENG COMMERCE & TRADE

Process of calcium carbonate carbon balls for converter or electric furnace steel tapping deoxidation

The invention discloses a process of calcium carbonate carbon balls for converter or electric furnace steel tapping deoxidation. Lime stones are grinded to powder with a particle size below 1 mm, are uniformly mixed with graphite carbons with a carbon content of 90%, and are pressed to calcium carbonate carbon balls with a diameter of 30 mm by a dry powder ball press, wherein the adding proportion of the lime stones is 93 mass% of the carbon balls; the adding proportion of the graphite carbons is 7 mass% of the carbon balls; the carbon content in the calcium carbonate carbon balls is controlled at 6 mass%; and in the steel tapping process of an electric furnace or a converter after smelting, 1.5 kg carbon balls are added in each tonnage of steel.

Owner:XINJIANG ZHONGHE DAZHENG COMMERCE & TRADE

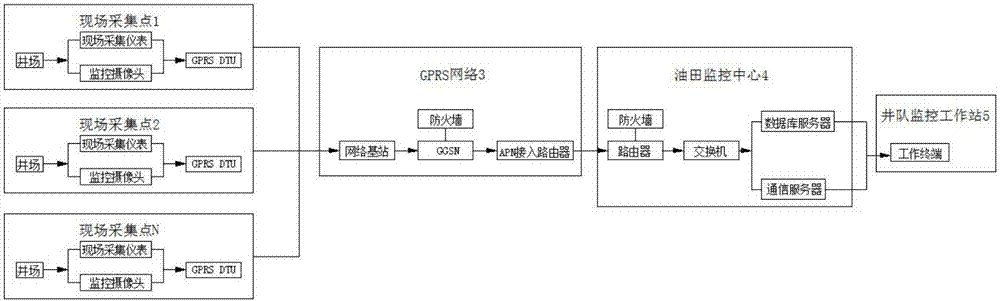

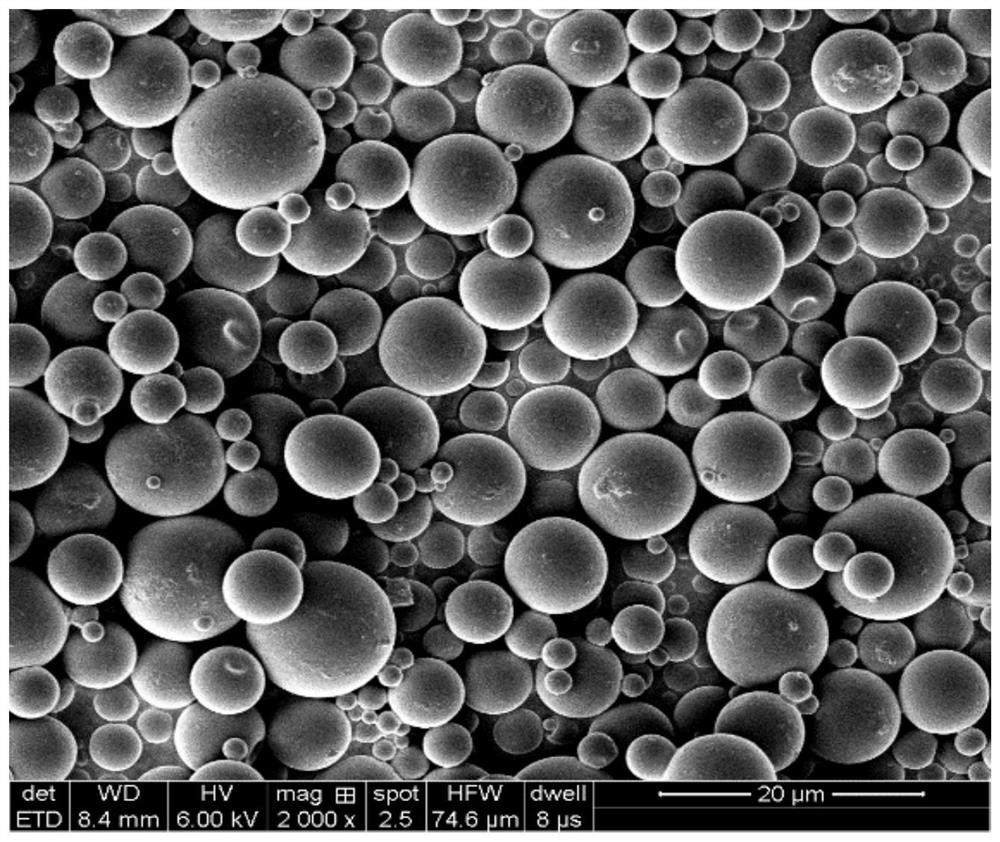

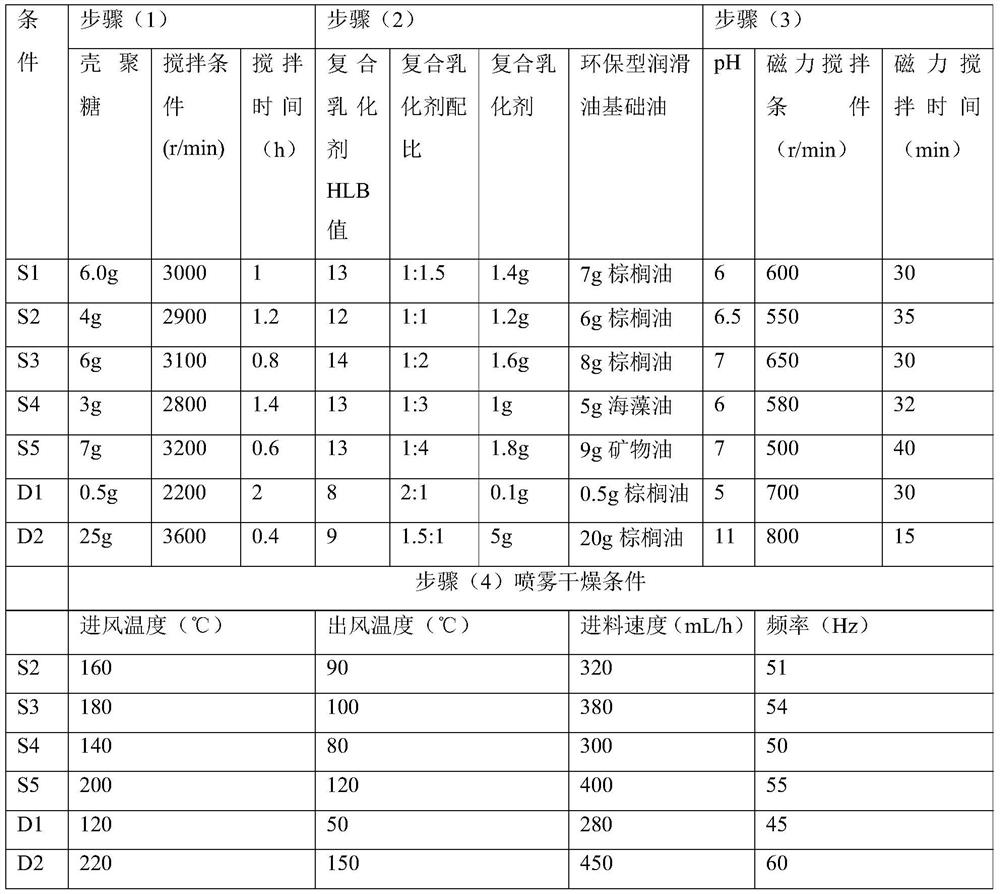

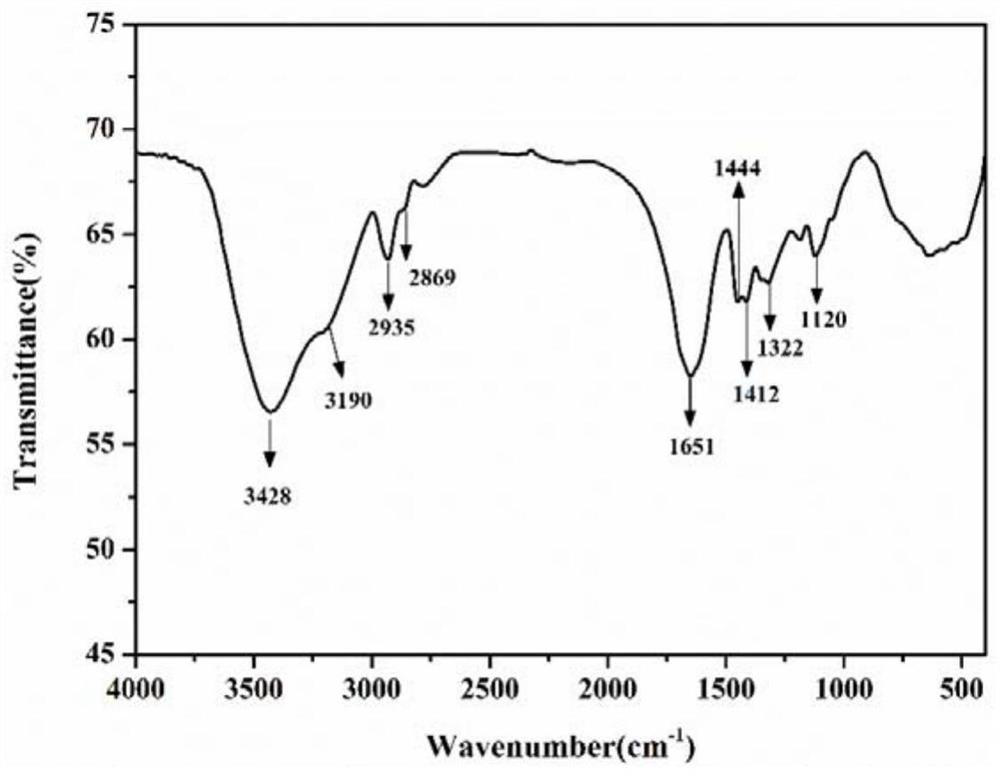

Capsule lubricant for drilling fluid, preparation method thereof, water-based drilling fluid and application

ActiveCN111826139ADoes not affect rheologyReduced extreme pressure lubrication coefficientDrilling compositionFirming agentSpray dried

The invention relates to the technical field of lubricant preparation, and discloses a capsule lubricant for drilling fluid, a preparation method thereof, water-based drilling fluid and application. The capsule lubricant comprises a core component and a wall component coating the outer surface of the core component, and on the basis of the total weight of the capsule lubricant, the content of thecore component is larger than or equal to 75 wt%, and the content of the wall component is smaller than or equal to 25 wt%. The capsule lubricant is prepared by the following method: in the presence of a curing agent, carrying out phase separation reaction on an oil-in-water emulsion and a wall component solution, and carrying out spray drying treatment on a reaction product; the oil-in-water emulsion includes a lubricant base oil, a composite emulsifier, and water, and the wall component solution includes a polysaccharide polymer and an acid. When the addition amount of the capsule lubricantis 1%, the reduction rate of the lubrication coefficient is basically 70% or above.

Owner:中石化石油工程技术服务有限公司 +2

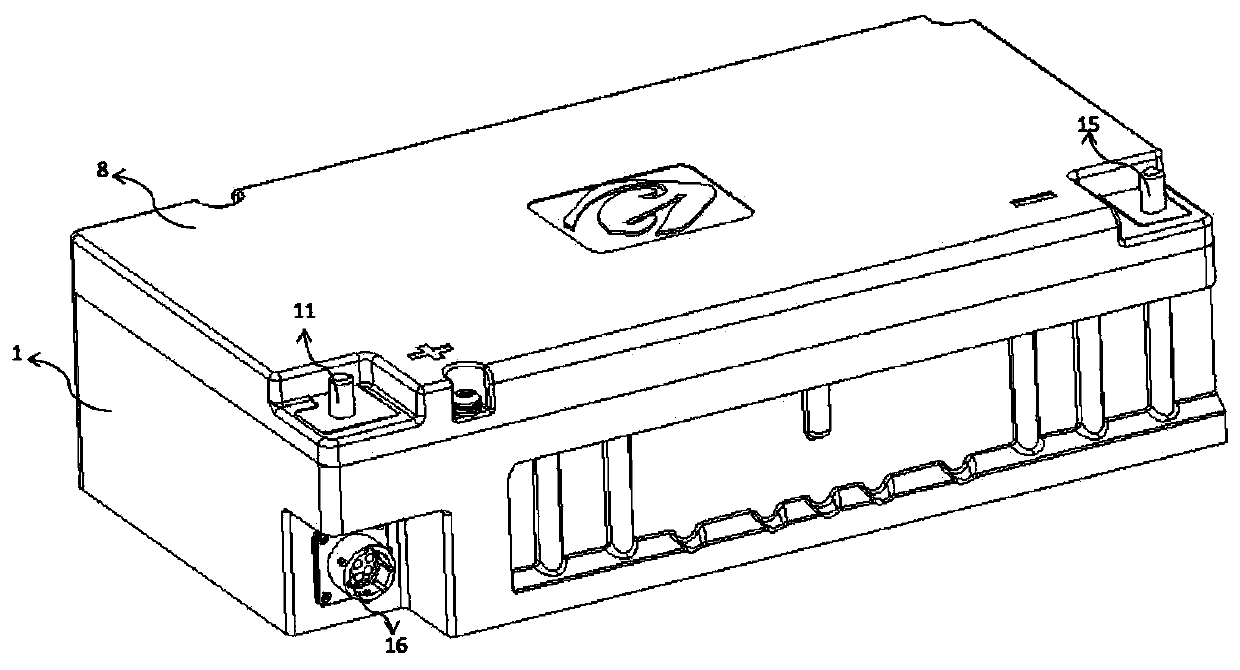

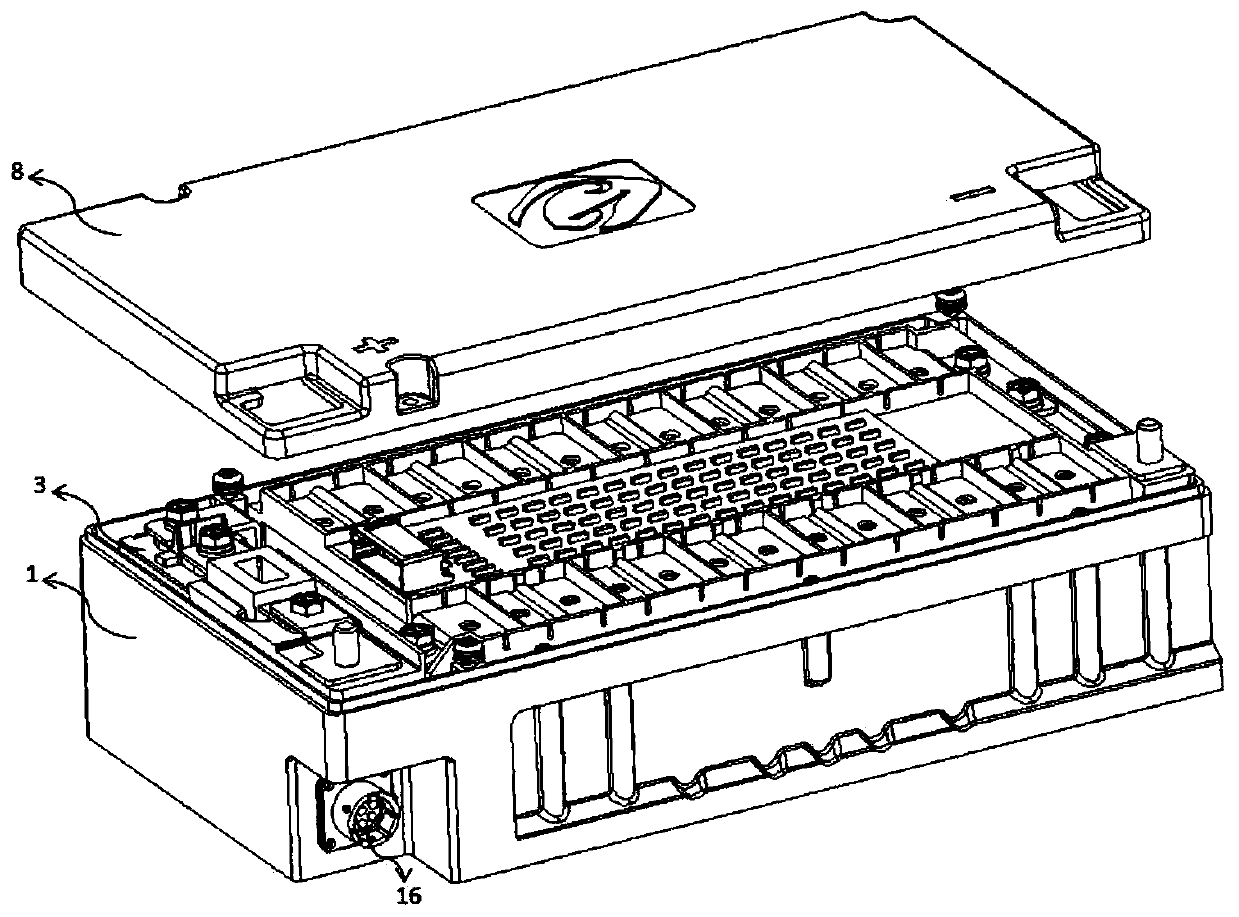

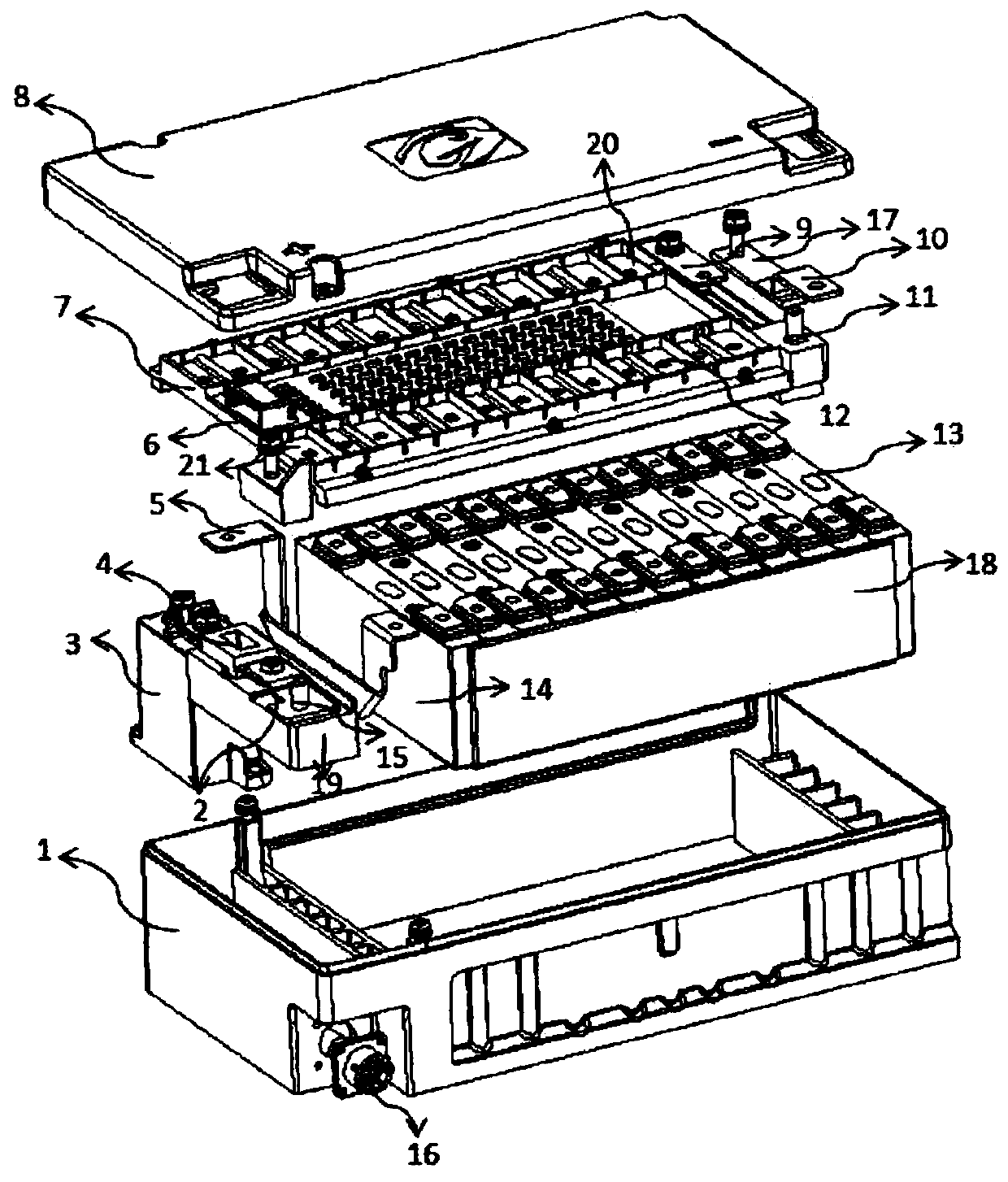

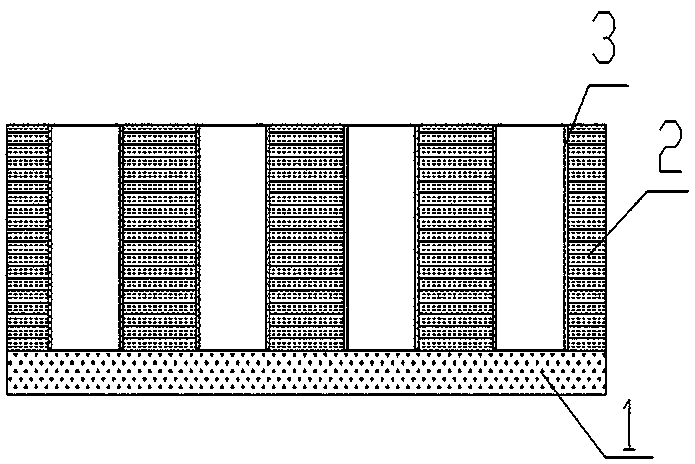

Power battery pack of automobile start-stop system

The invention relates to a power battery pack of an automobile start-stop system, comprising a box body and a battery pack arranged in the box body. The box body is provided with a plug connector. A box cover in screw fit with the box body is arranged on the upper end of the box body. The battery pack includes an electrical core component, a tray and a relay. The box body is provided with a fixingdevice inside. The electrical core component and the relay are connected with the fixing device by screws. The tray is fixed at the upper end of the electrical core component. The box cover is provided with gaps matching the positive and negative poles of the battery pack. The electrical core component is provided with insulating end plates at the two ends thereof, and the electrical core component is provided with heat conducting silica gel pads on the other two sides and at the bottom thereof. The types of materials are reduced, and cost is saved. The power battery pack has the advantages of more simple and compact structure design, reasonable layout and high integration. Natural heat dissipation is adopted, which can improve the reliability of the battery pack and is conducive to the cost reduction and efficiency increase of the battery pack.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A quick and accurate detection method for silica content in limestone, lime and dolomite

ActiveCN103728261BConducive to complete dissolutionImprove stabilityColor/spectral properties measurementsVolumetric flaskSilicon dioxide

The invention discloses a fast and accurate detection method for silicon dioxide content in limestone, kalk and dolomite. The detection method comprises the following steps: crushing samples, and drying for 1.5-2.5 h under thea temperature of 105-110 DEG C; mixing 0.1000 g samples and 3.0-4.0 g mixed fluxing agent of sodium carbonate and boric acid evenly, liquating for 18-20 min under athe temperature of 890-910 DEG C, dissolving frits by a 45-55 ml hydrochloric acid and 25-35 ml water, and placing the test solution in a 250-ml volumetric flask; taking and adding 5.00 ml test solution in a 100-ml volumetric flask, adding 18-22 ml ammonium molybdate and still standing for 18-22 min, and adding 45-55 ml mixed acid of oxalic acid and sulfuric acid, 4.80-5.20 ml ascorbic acid-ammonium ferrous sulfate mixed solution; measuring the absorbency of a color development solution at the wavelength of 680 nm through a spectrophotometer, and using blank as a reference; preparing a silicon dioxide standard sample with the concentration of 40 ug / ml, moving and taking 0.00 ml, 2.00 ml, 4.00ml, 6.00 ml, 8.00 ml and 10.00 ml silicon dioxide standard samples, and placing the standard samples in 100-ml volumetric flasks respectively, adding 5.00 ml blank test solution in the volumetric flasks respectively, after color-developing, measuring the absorbency at the same conditions, and then drawing a working curve. The silicon dioxide content in the samples is calculated according to the following formula (shown in the specification). The detection method is fast and efficient, excellent in accuracy, reproducibility and stability, and particularly suitable for detection of samples with silicon dioxide content equal to or higher than 4 %.

Owner:WUKUN STEEL

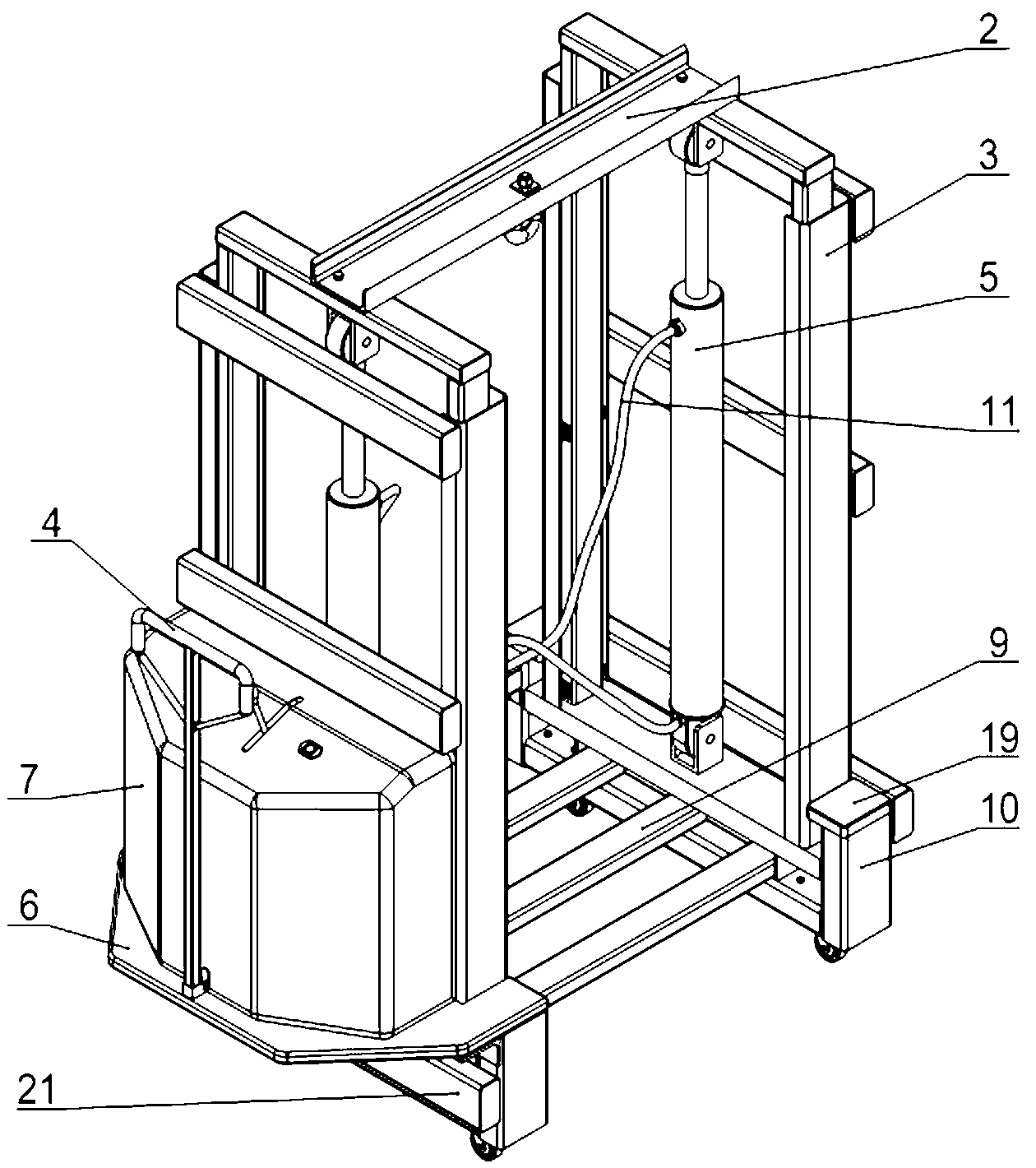

Hydraulic loading, unloading and moving device

InactiveCN102838061AImprove installation qualityImprove installation accuracyLifting devicesHoisting equipmentsHydraulic cylinderLow voltage

The invention discloses a hydraulic loading, unloading and moving device which is suitable for moving high-voltage and low-voltage electric equipment for a basement in a construction site of a high-rise building to improve mounting efficiency of the electric equipment, and can be also used in other loading, unloading and moving occasions. The hydraulic loading, unloading and moving device comprises leg wheels, a base and a hydraulic loading and unloading part, wherein the leg wheels are mounted beneath the base; the hydraulic loading and unloading part is arranged on the base and comprises a hydraulic station, hydraulic lifting doors, a door frame and a beam; the hydraulic lifting doors are sleeved in the door frame; the beam is fixed between the hydraulic lifting doors; the hydraulic station is connected with two hydraulic cylinders through a hydraulic oil pipe; the two hydraulic cylinders are respectively mounted between one hydraulic lifting door and the base and between another hydraulic lifting door and the base; and the electric equipment of an electric cabinet and the like or goods are loaded and unloaded by the hydraulic loading and unloading part. Due to the adoption of the hydraulic loading, unloading and moving device, mounting, moving and repairing operations are all quite convenient, the construction efficiency can be effectively improved, the labor intensity can be effectively reduced, damage and deformation of the equipment are reduced, safety guarantee of installation personnel is improved, and the equipment is protected.

Owner:CHINA PETROLEUM & CHEM CORP +1

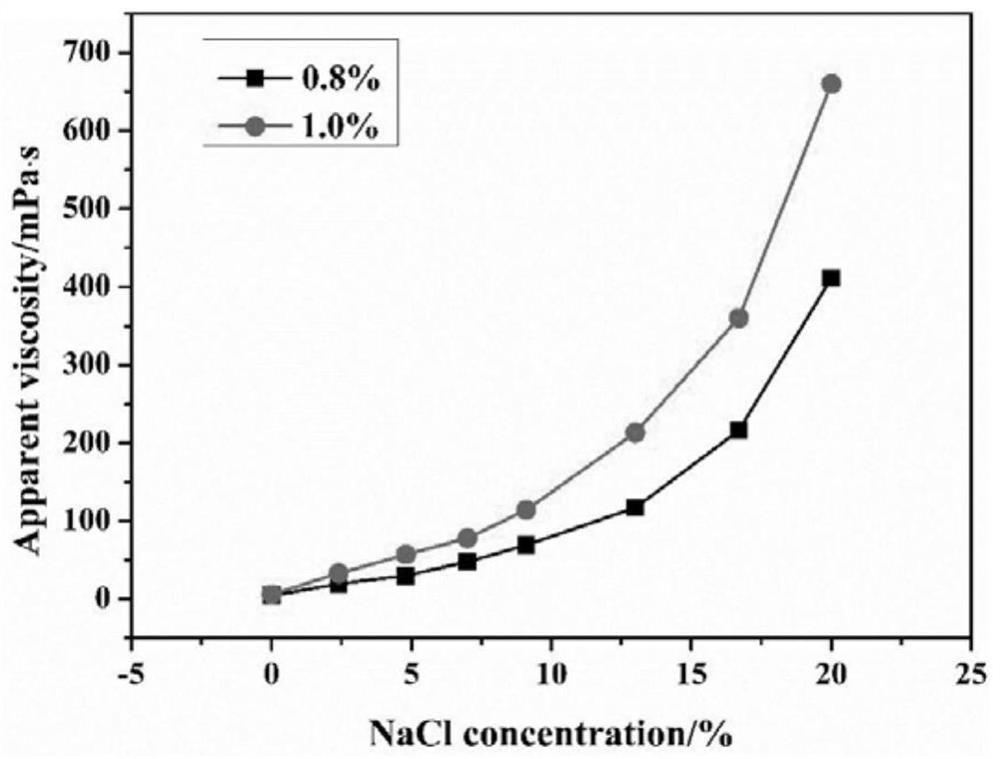

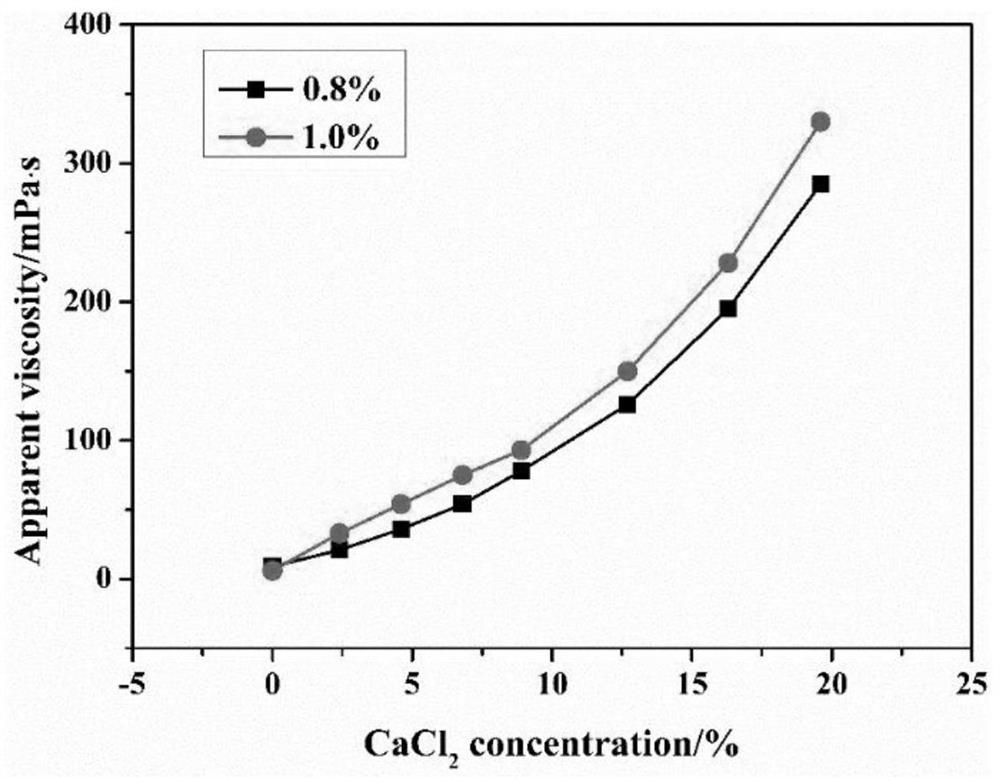

Polymer type salt thickener and preparation method thereof

The invention relates to the technical field of oilfield exploitation, and discloses a polymer type salt thickener and a preparation method thereof. The polymer type salt thickener is prepared from the following raw materials: monomers: acrylamide (AM), octadecyl dimethyl allyl ammonium chloride (DMAAC-18), allyl polyethylene glycol (APEG-400) and N-vinyl pyrrolidone (NVP); and an initiator. The preparation method has the beneficial effects that the prepared product is low in initial viscosity and can be easily pumped into the stratum, the viscosity of the polymer is always increased along with the increase of the salt concentration (sodium chloride and calcium chloride), and the product can be suitable for tertiary oil recovery of the extra-high-salt stratum; and meanwhile, the method can be suitable for preparation of a hypersalinity stratum return water oil-displacing agent, and the environmental problem caused by external drainage of stratum return water is avoided.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

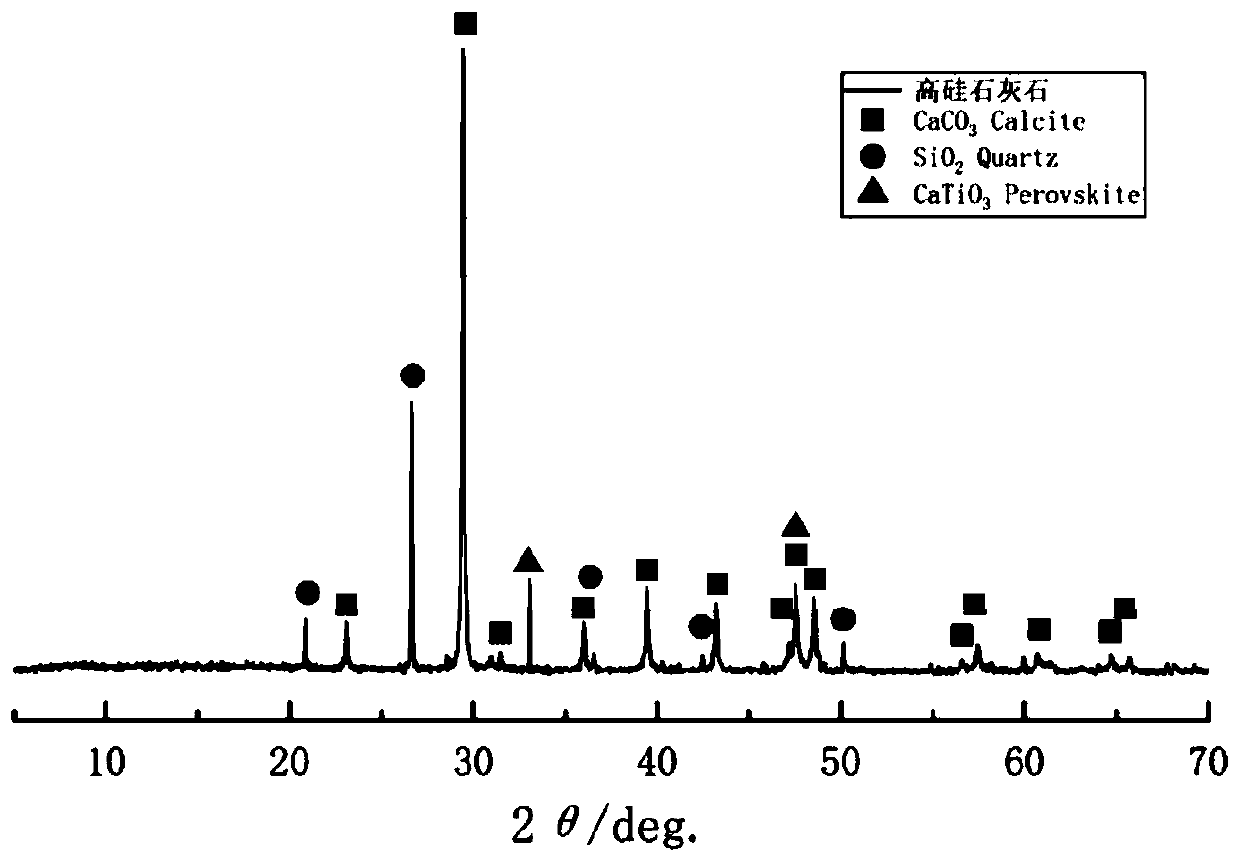

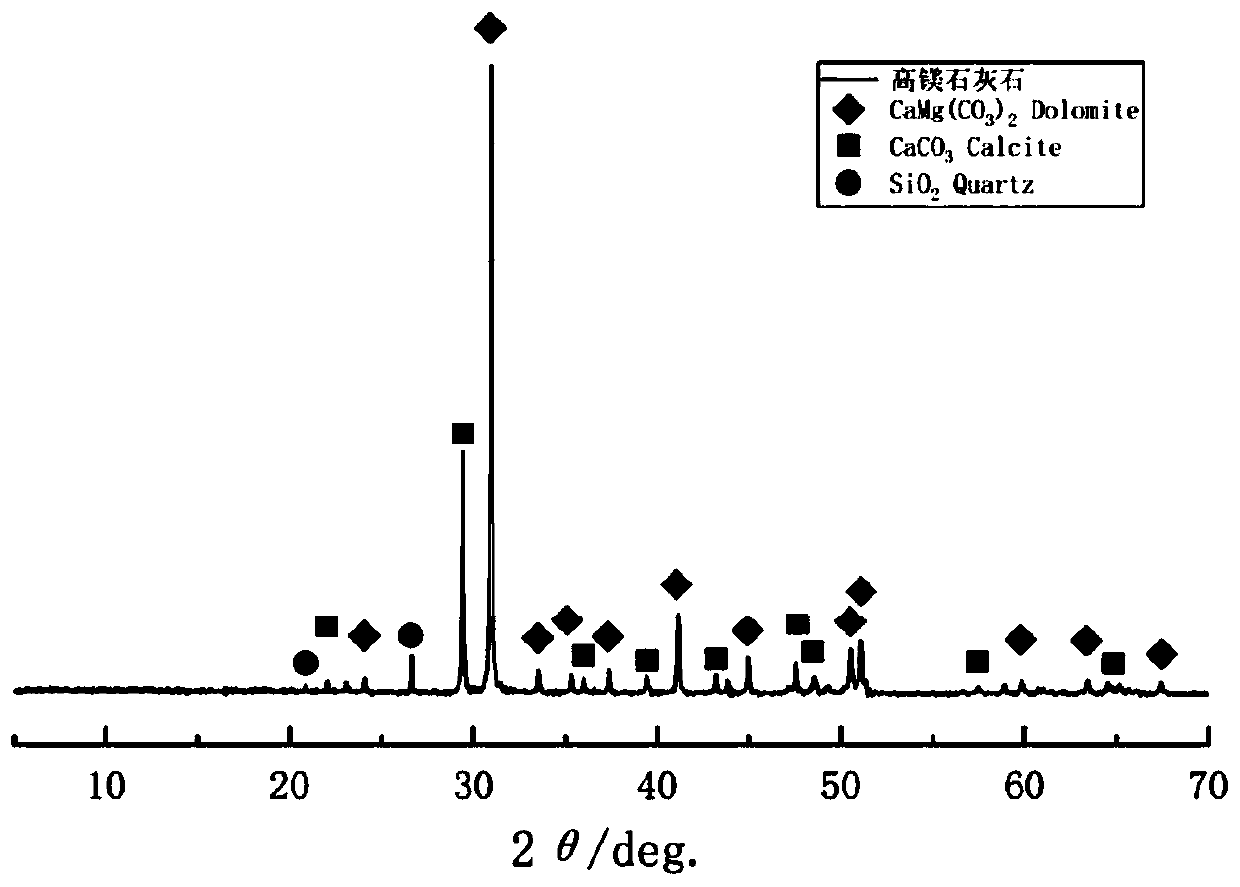

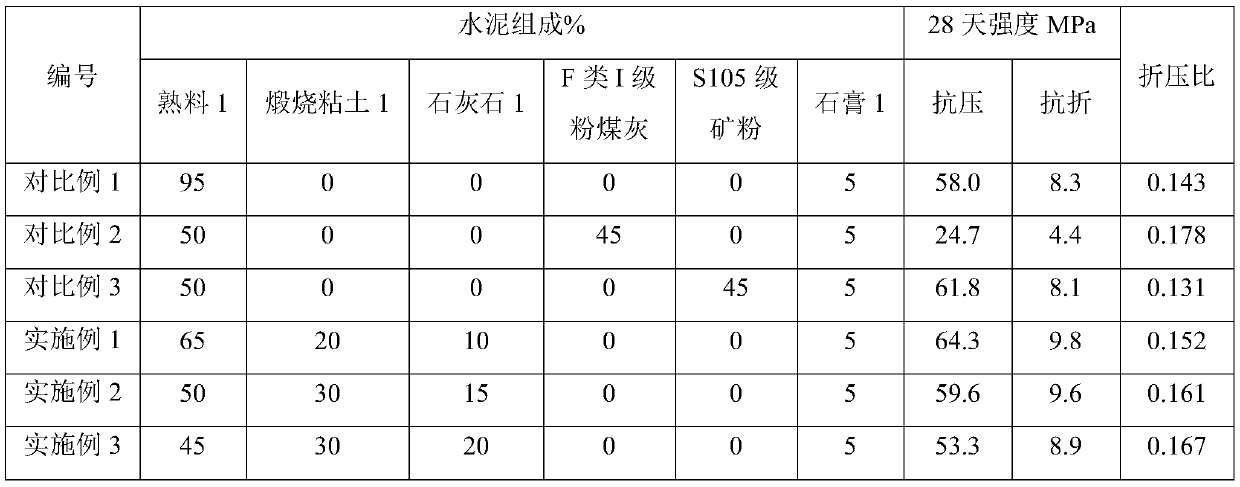

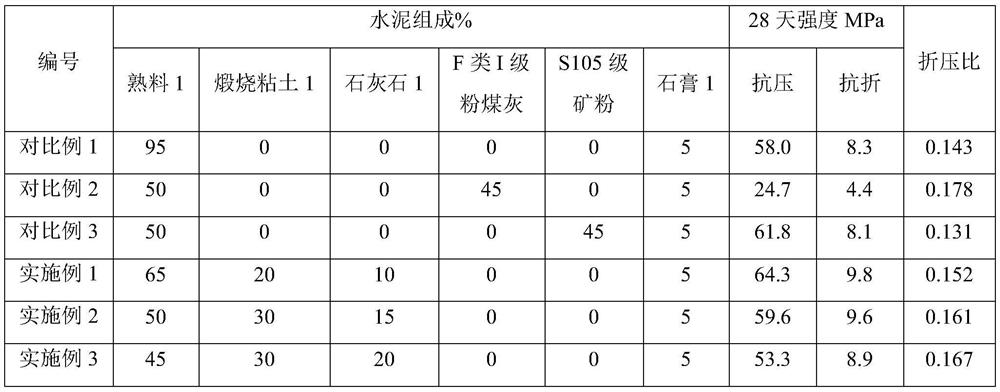

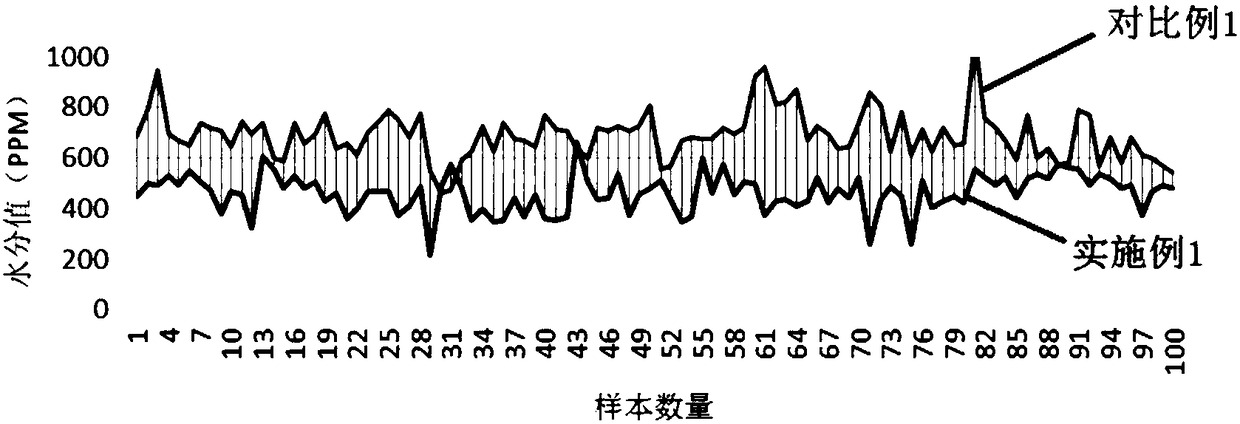

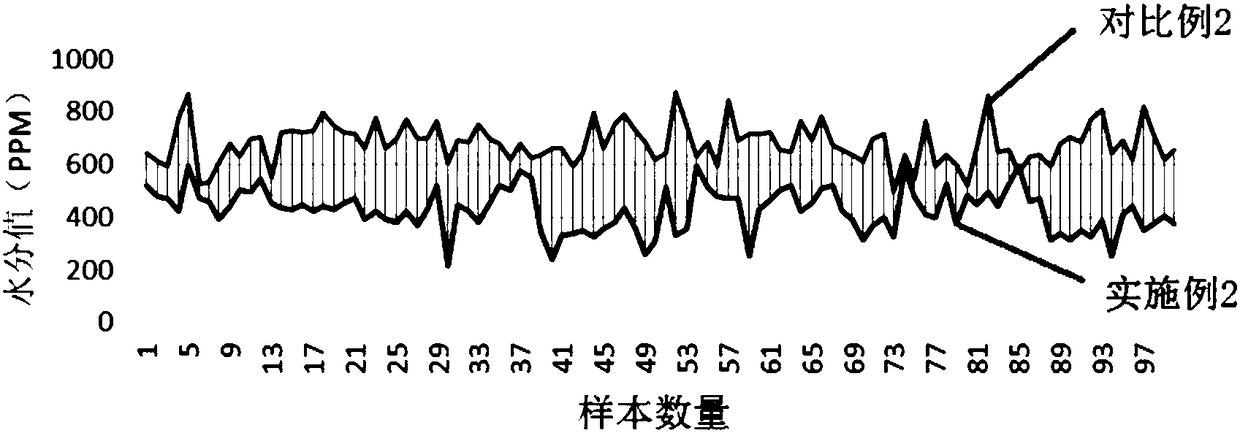

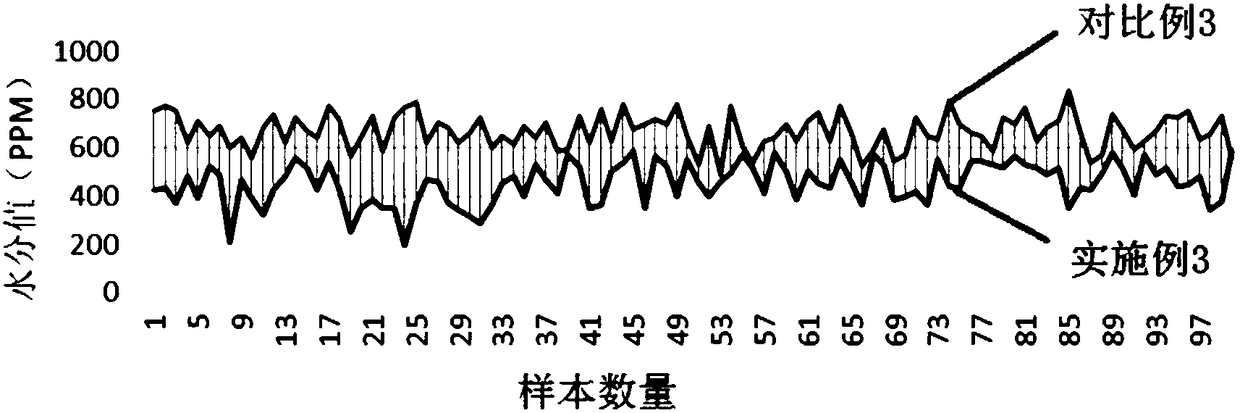

High flexural strength composite Portland cement and preparation method thereof

ActiveCN110436801AHigh flexural strengthImprove the structural strength in all directionsGypsumBuilding material

The invention belongs to the field of building materials, and especially relates to a high flexural strength composite Portland cement and a preparation method thereof. The high flexural strength composite Portland cement is prepared from, by weight, 35-65 parts of a Portland cement clinker, 17.5-40 parts of calcined clay, 10-22.5 parts of limestone and 1.5-5 parts of gypsum. The high flexural strength composite Portland cement mainly prepared from the ordinary Portland cement clinker, calcined clay and low-grade limestone concrete is prepared by starting from the concrete core raw material cement and improving the ratio of bending-compressive strength and the flexural strength of cement on the premise of ensuring a high compressive strength, and the preparation method has the characteristics of simple process, and suitableness for industrial production.

Owner:SINOMA INT ENG +1

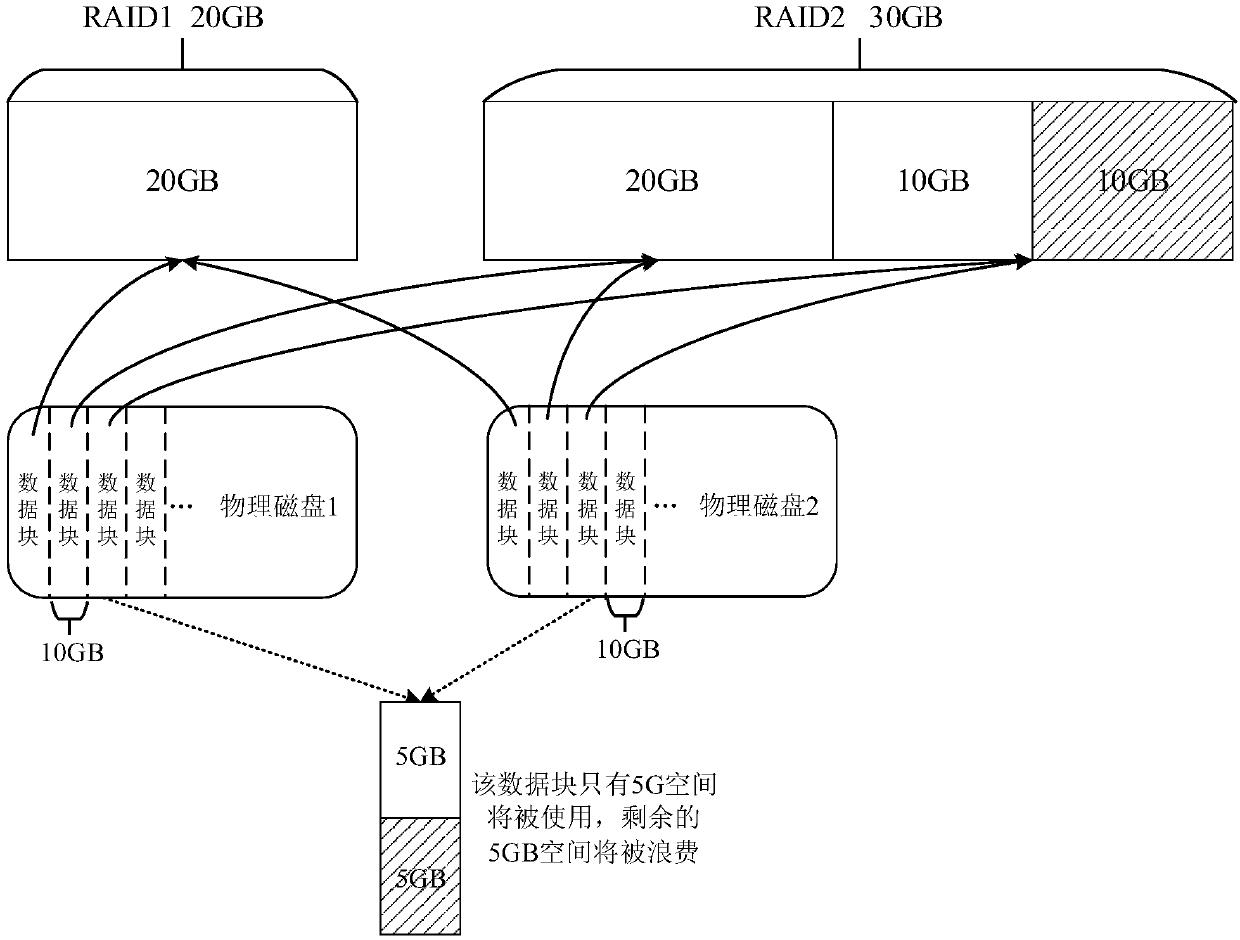

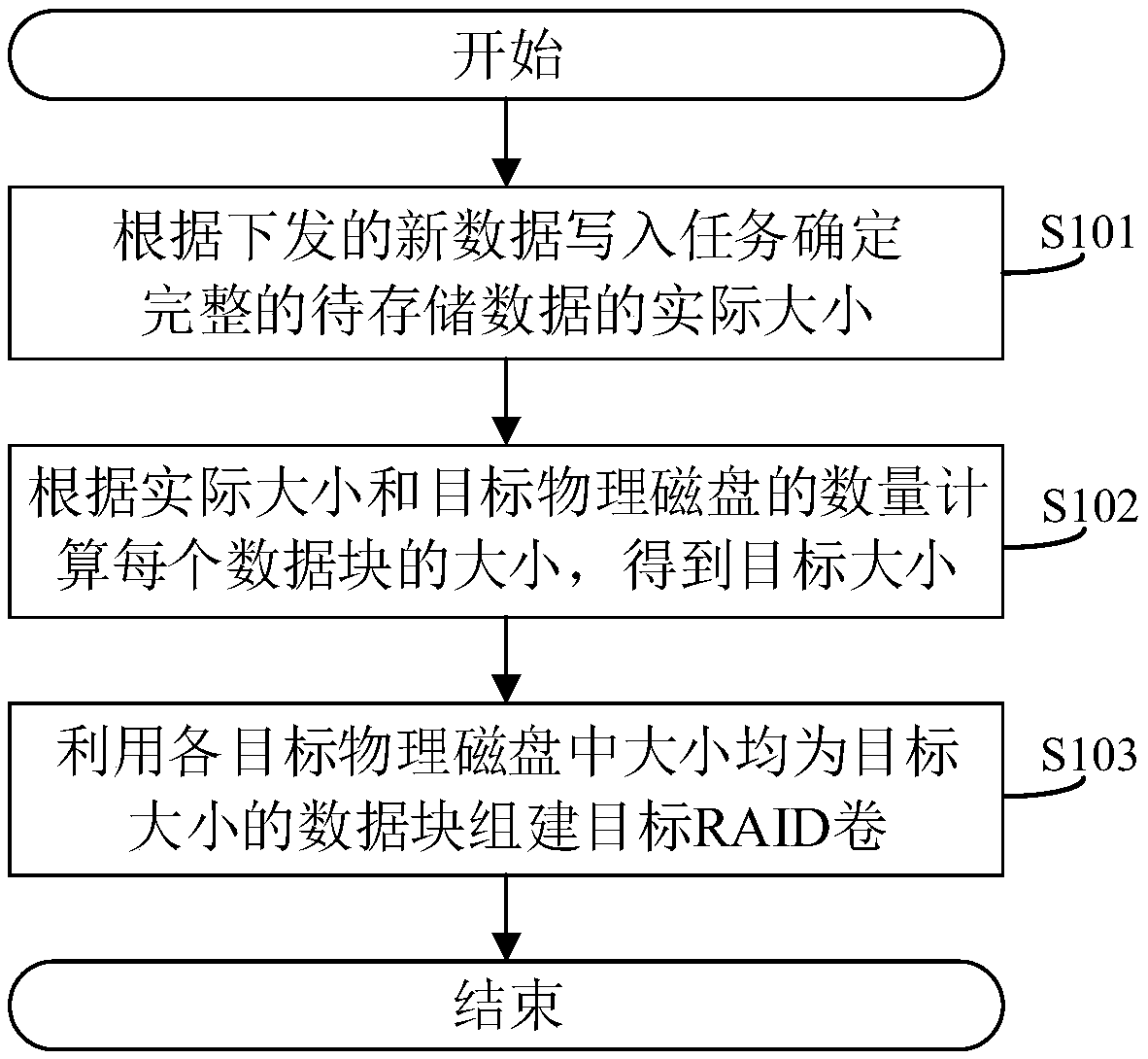

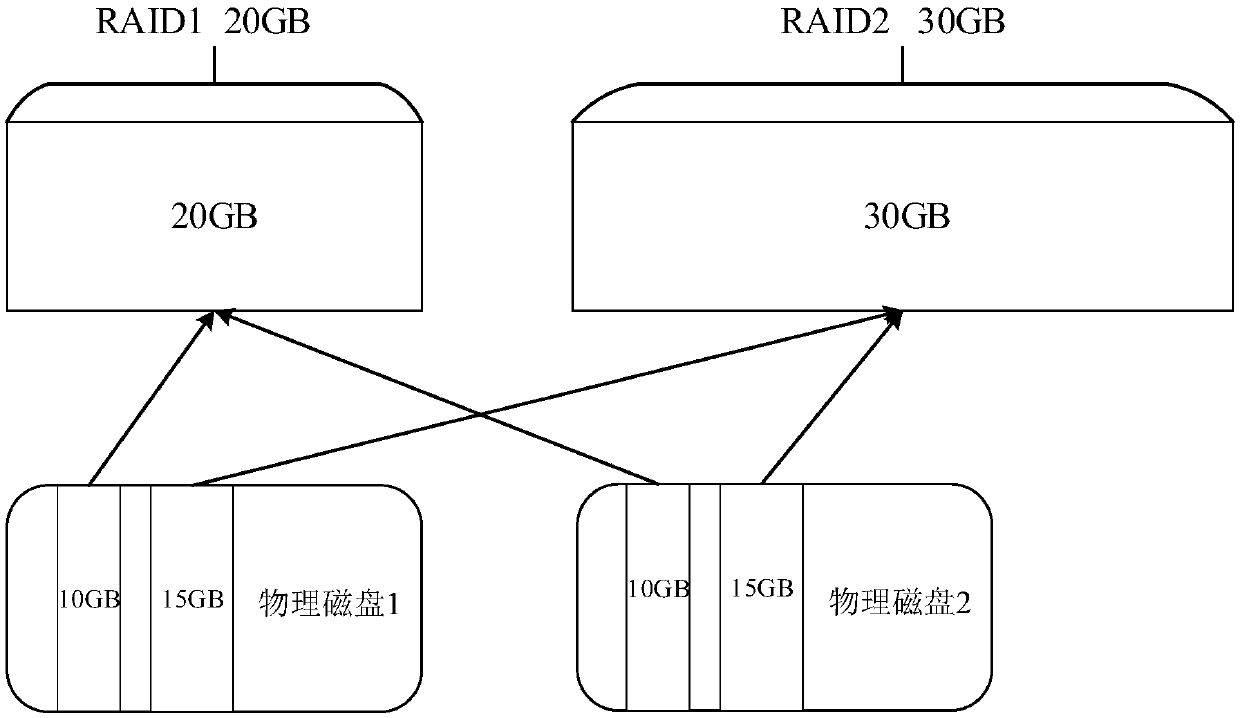

RAID volume forming method, system and device and readable storage medium

PendingCN111078124AImprove space utilizationConducive to cost reduction and efficiency increaseInput/output to record carriersRedundant data error correctionRAIDParallel computing

The invention discloses a RAID (Redundant Array of Independent Disks) volume forming method different from a method for establishing a RAID volume by using a data block which has a preset size and serves as a minimum unit. The RAID volume is no longer established by using data blocks with fixed sizes; after the actual size of the to-be-stored data is determined, the size of the data block servingas each minimum unit is dynamically determined according to the number of the physical disks for constructing the RAID volume; the invention discloses an object-based data block size determination mode and an RAID volume establishment method based on the object-based data block size determination mode. High-precision storage and test paper composition can be carried out by taking the minimum 4K (SSD minimum data storage unit) as the minimum unit, dynamic adjustment of the size of each RAID test paper becomes possible, the space utilization rate of a disk is improved as much as possible, and cost reduction and benefit increase are facilitated. The invention further discloses a RAID volume forming system and device and a computer readable storage medium, which have the above beneficial effects.

Owner:SANGFOR TECH INC

Method for high-temperature alkalization treatment of solid hazardous waste and co-treatment in a cement kiln

ActiveCN111825357AEffective burnoutSimple methodRotary drum furnacesCement productionClinker (waste)Physical chemistry

The invention discloses a method for high-temperature alkalization treatment of solid hazardous waste and co-treatment in a cement kiln. In the pretreatment process of the solid or plastic or slurry hazardous waste, a modification treatment agent is added for modification treatment to serve as a substitute raw material for cement production, and the modified solid hazardous waste is fed into a discharging pipeline at the conical part of a C5 or C6 preheater for high-temperature alkalization and enters a rotary kiln for high-temperature calcination to form clinker minerals. The method is easy to operate, low in investment, low in treatment energy consumption, low in treatment cost and free of secondary pollution. According to the invention, organic matters in the solid hazardous wastes canbe effectively burnt out, silicon-aluminum / calcium inorganic minerals in the solid hazardous wastes are converted into mineral components of the cement clinker, heavy metal and most of alkali are fused through silicon-aluminum root group / silicate group / aluminate group lattices, fluorine, chlorine and sulfur are converted into early-strength calcium fluoroaluminate, calcium chloroaluminate and calcium sulphoaluminate clinker minerals, accumulated materials of a kiln tail smoke chamber are prevented from being stuck and blocked, and cost reduction and efficiency improvement are facilitated.

Owner:长沙紫宸科技开发有限公司

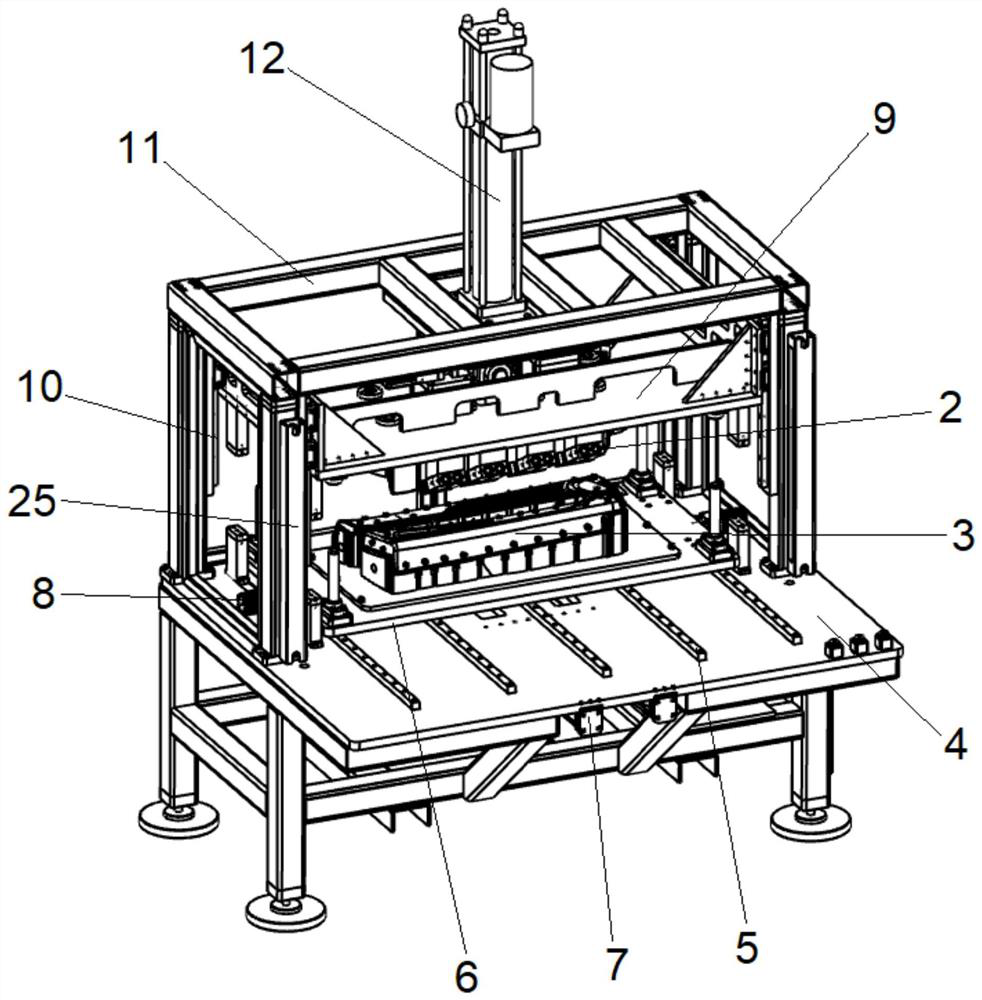

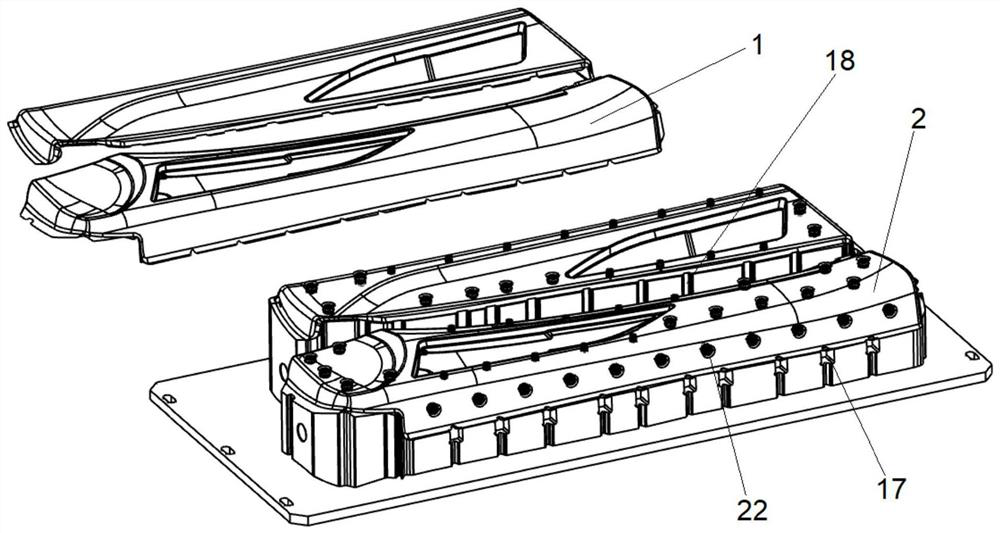

Decorating plate skin die cutting equipment

InactiveCN111673834AReasonable structural designFit compactMetal working apparatusDrill holeEngineering

The invention relates to the field of decorating plate machining equipment, in particular to decorating plate skin die cutting equipment. The equipment comprises an upper die and a lower die, whereinthe upper die and the lower die clamp and locate a decorating plate. The lower die is arranged on a feeding mechanism. The decorating plate is laid on the upper surface of the lower die. The upper dieis arranged on a vertical lifting mechanism. The vertical lifting mechanism is further provided with multiple die cutting cutters. The feeding mechanism moves the lower die right below the upper die.The upper die descends along with the vertical lifting mechanism and is attached to the upper surface of the lower die to compress and locate the decorating plate. The die cutting cutters carry out die cutting machining on the decorating plate. The equipment is reasonable in overall structural design, compact in connecting and matching, and capable of completing die cutting technologies of edge cutting, drilling and the like of decorating plate injection molding part fully automatically.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

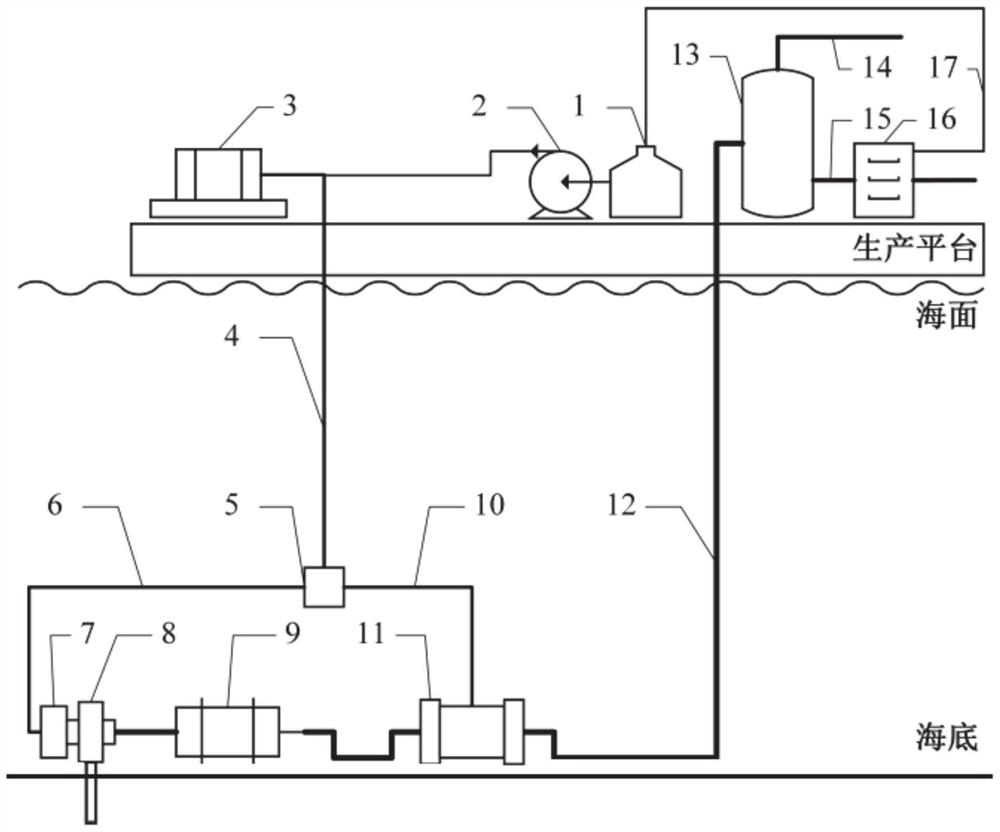

Magnetic targeted hydrate inhibitor transport system and method

ActiveCN111980635AAchieve targeted deliveryIncrease concentrationFluid removalPhysical chemistryPetroleum engineering

The invention discloses a magnetic targeted hydrate inhibitor transport system and method, and belongs to the technical field of flow guarantee of underwater production systems in deep water oil gas and hydrate resource development. The system can achieve targeted transport and controllable release of hydrate inhibitors and ensure accurate and efficient prevention and control of hydrates, and comprises a storage tank, an injection pump, a controller, a separator and a recoverer which are positioned above the water surface, wherein the storage tank communicates with the injection pump, the injection pump communicates with an underwater production tree and provides a magnetic targeted hydrate inhibitor for the underwater production tree, the injection pump is connected with the controller, the separator communicates with the underwater production tree, one end of the recoverer communicates with the separator to obtain liquid in the separator, and the other end of the recoverer communicates with the storage tank.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

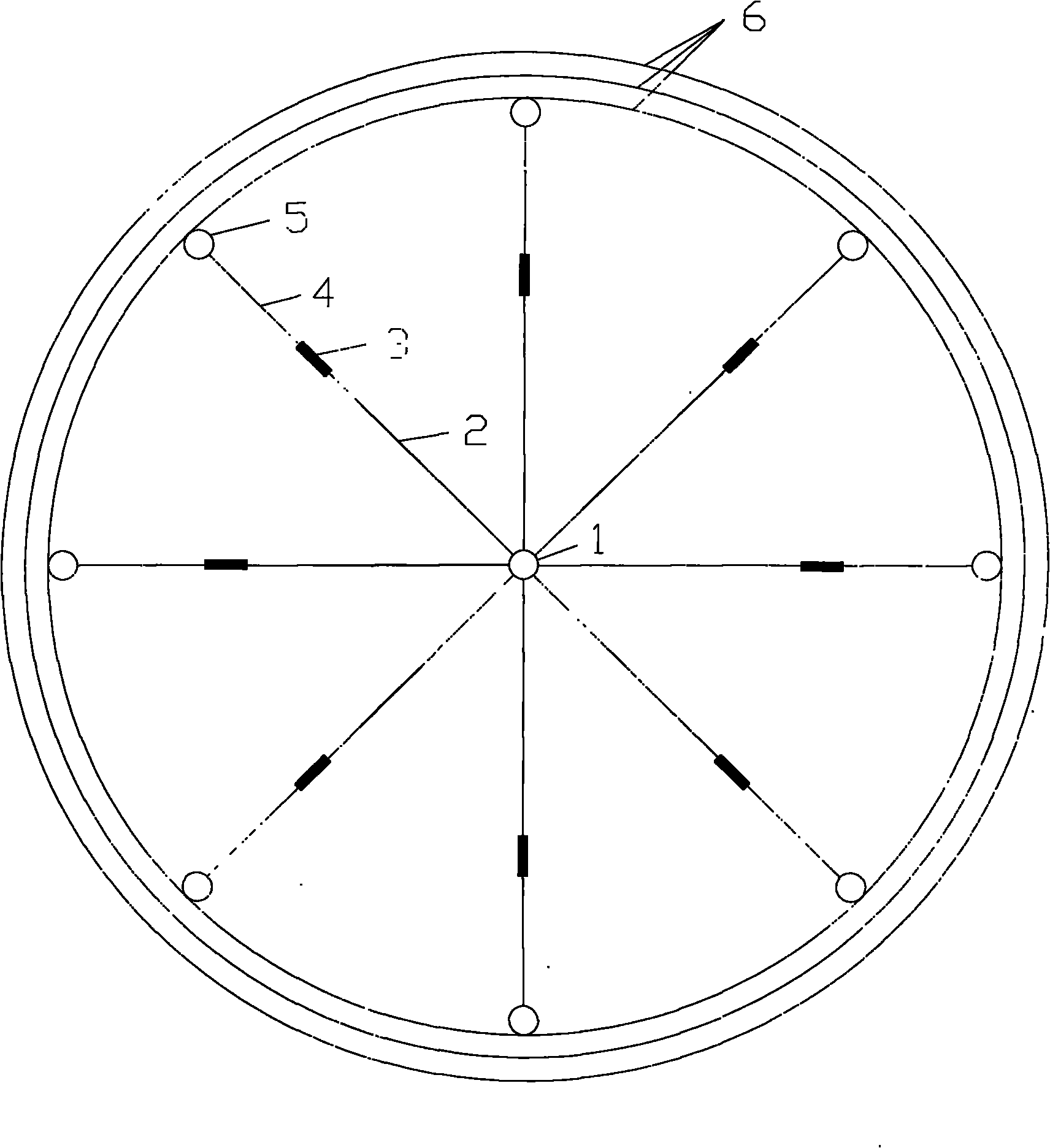

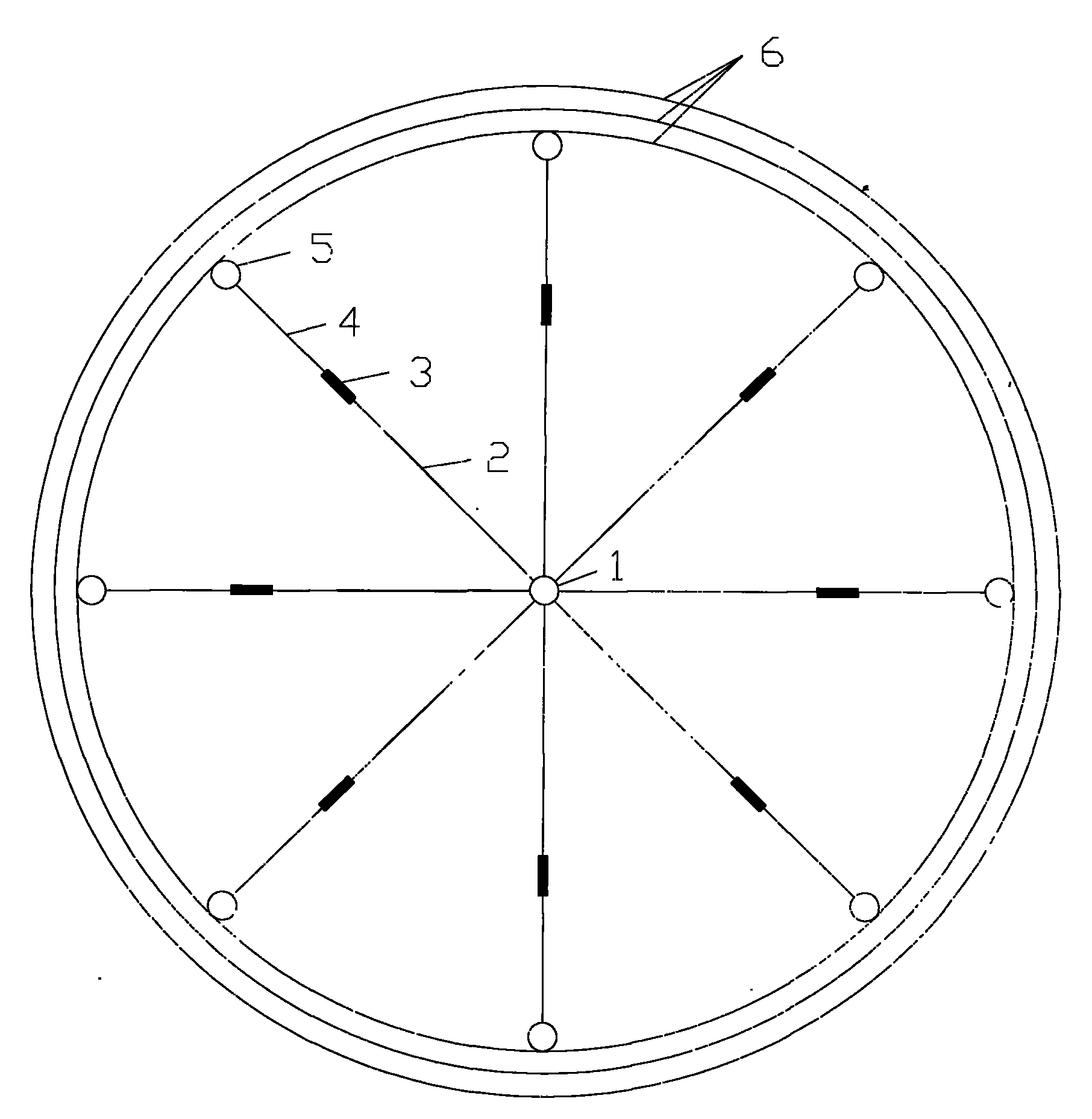

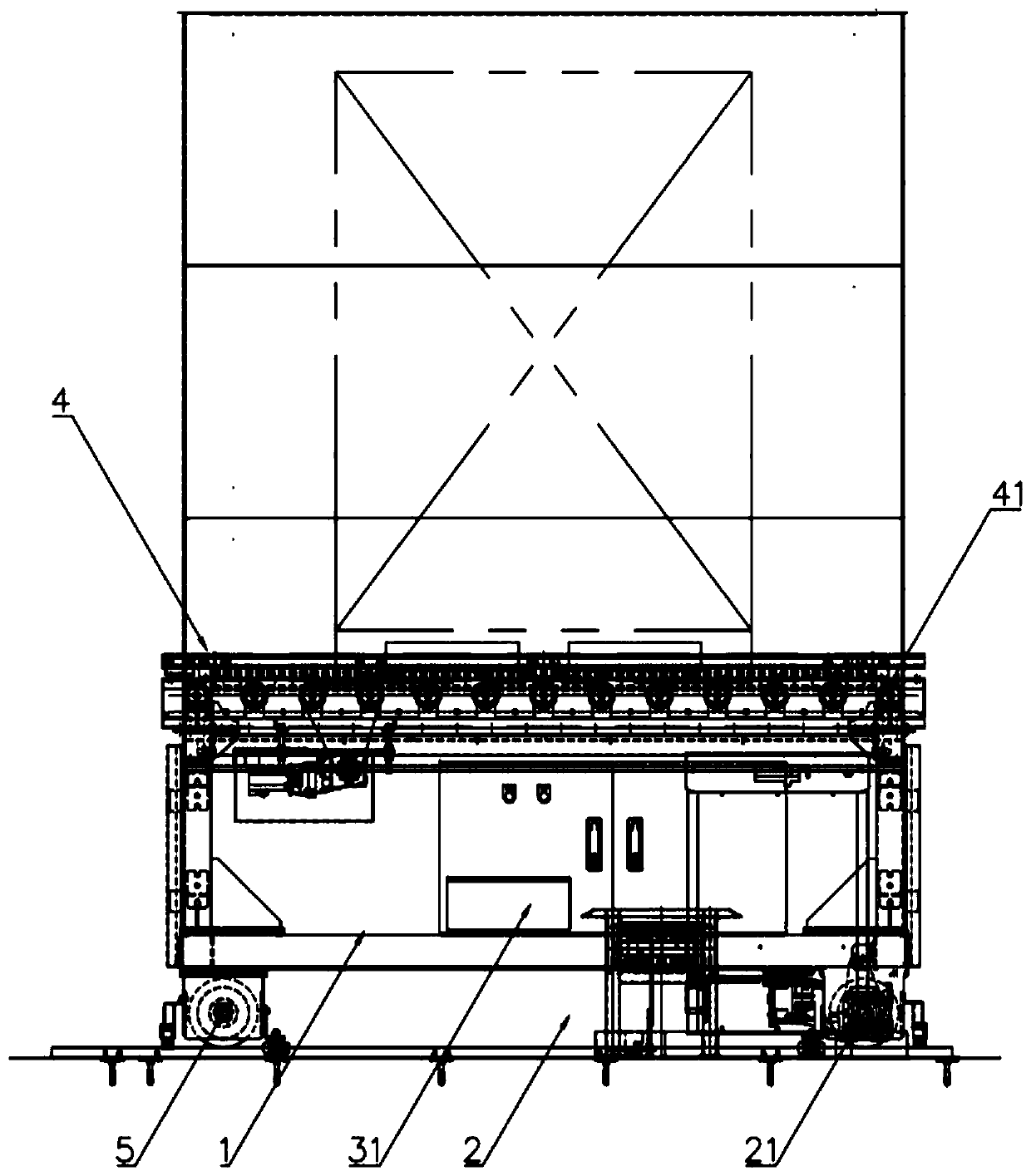

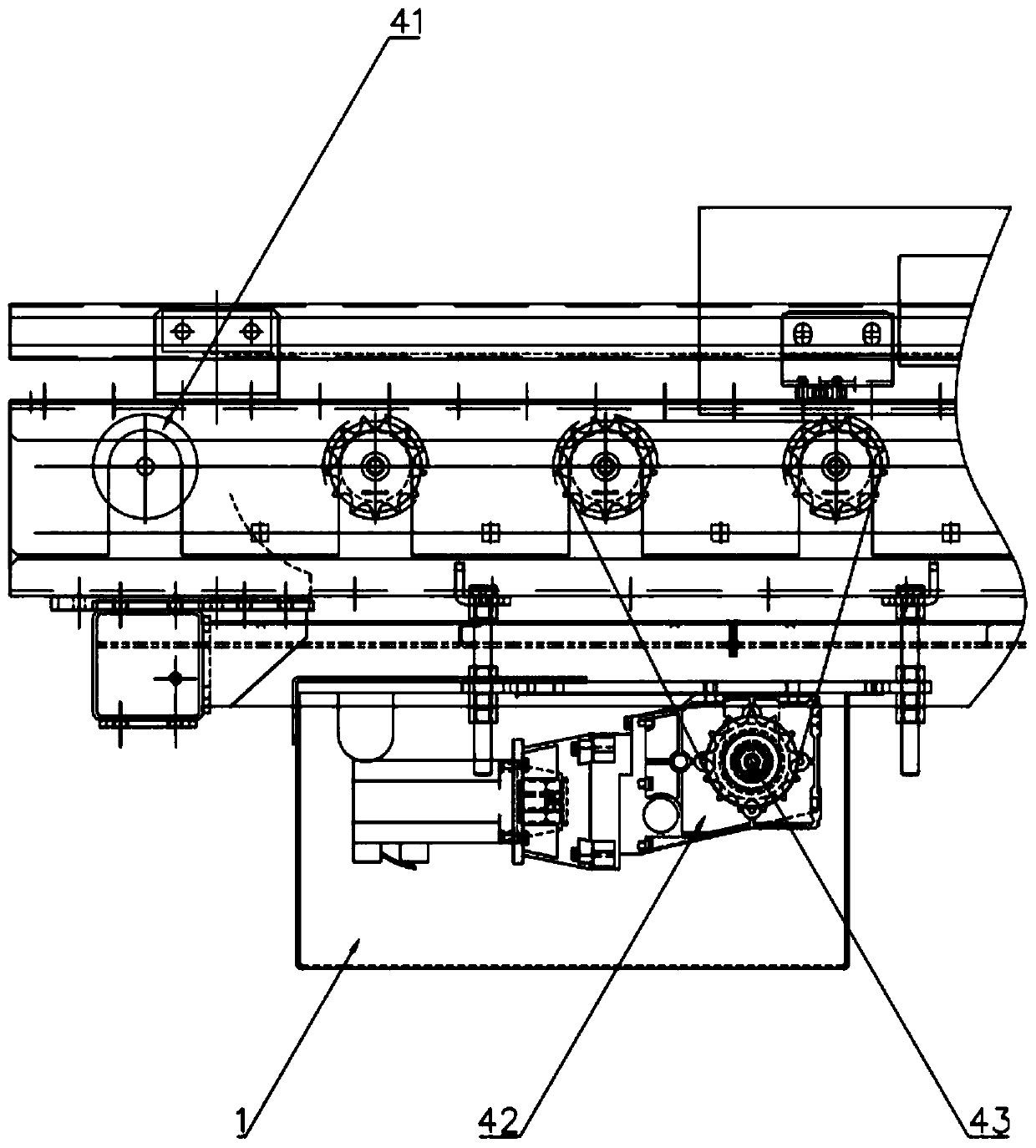

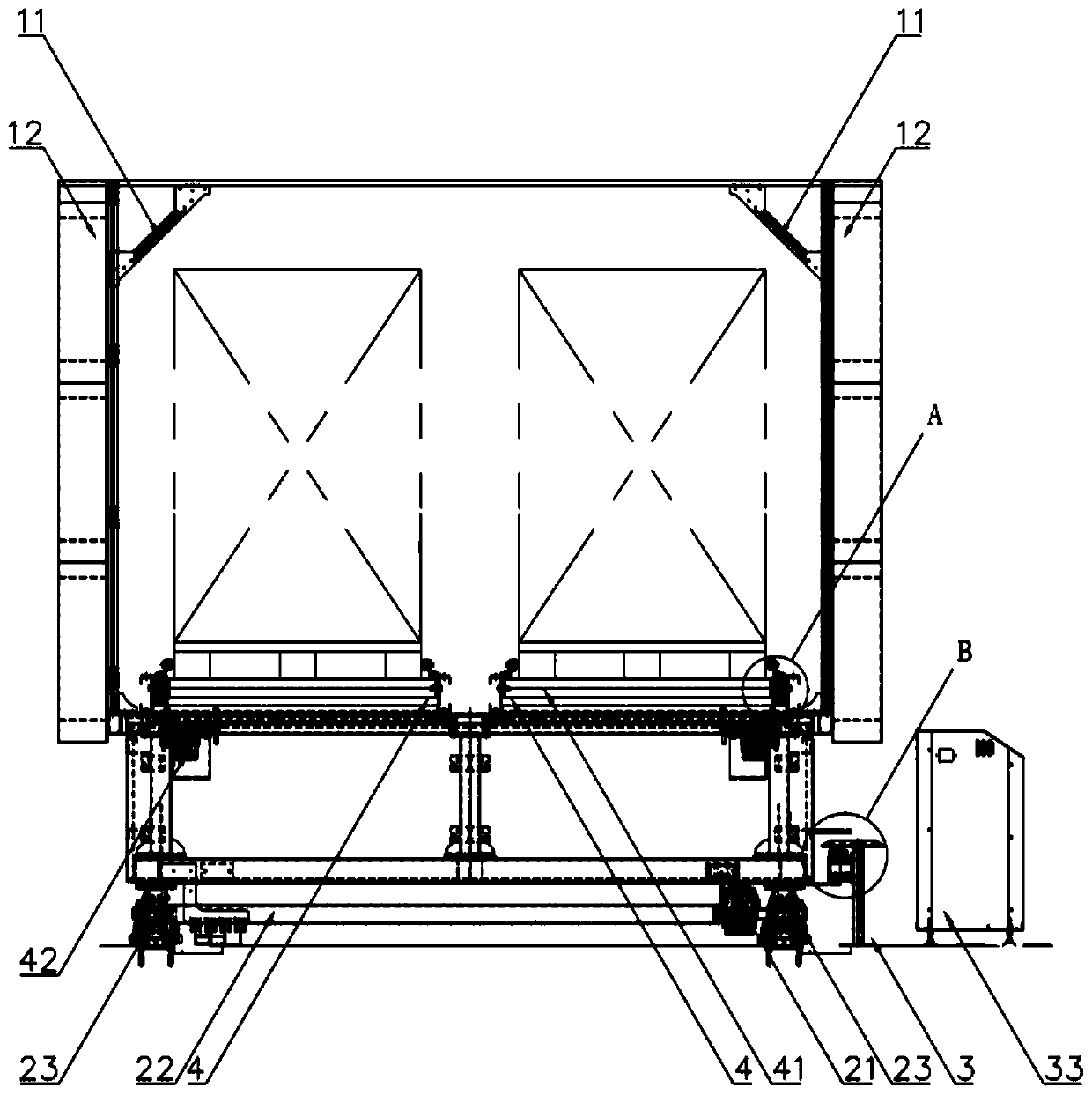

One-step bundling shaping method of culvert pipe multi-layer reinforcement cage and bundling shaping device

ActiveCN101892746AAdapt to processing requirementsReduce or enlarge diameterArtificial water canalsBuilding material handlingEngineeringRebar

The invention discloses a one-step bundling shaping method of a culvert pipe multi-layer reinforcement cage and a bundling shaping device, aiming at bundling and shaping the multi-layer reinforcement cage for culvert pipes for construction in one step and improving the processing speed of the culvert pipe reinforcement cage. The one-step bundling shaping method of the culvert pipe multi-layer reinforcement cage comprises the steps of with the bundling shaping device, adjusting the diameter of the bundling shaping device and bundling layer by layer from outside to inside. The bundling shaping device comprises a radial adjusting mechanism, a centre rod and an axial support rod, wherein the centre rod is sleeved in the radial adjusting mechanism and the both ends thereof are supported by a bracket; and the radial support rod is fixed together with the radial adjusting mechanism. The diameter of the device can be reduced or enlarged by adjusting the radial adjusting mechanism to meet the processing requirement of reinforcement cages with various sizes, the applied size range is large and the maintenance is simple. The invention can effectively improve the processing efficiency, reduce the labor intensity of workers and improve the construction progress of the project and is beneficial to reducing the cost and increasing the benefits.

Owner:中石化石油工程技术服务有限公司

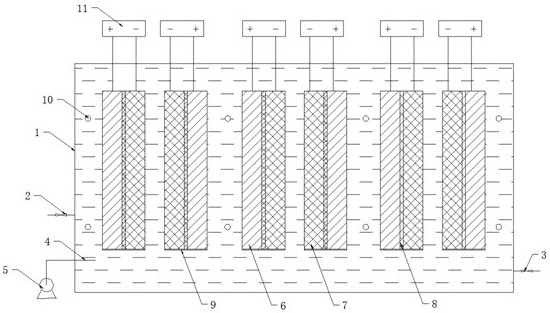

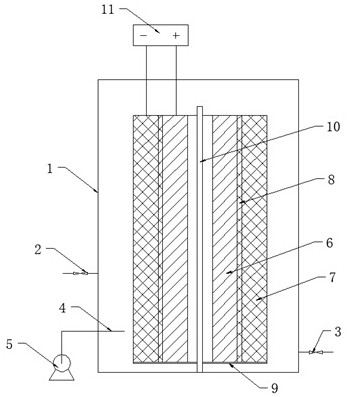

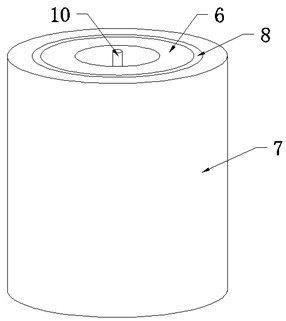

Photoelectric microorganism coupling nitrogen and carbon removal system

ActiveCN113845208AEasy to handleConducive to energy saving and emission reductionWater/sewage treatment by irradiationTreatment by combined electrochemical biological processesElectrolysisUltraviolet lights

The invention provides a photoelectric microorganism coupling nitrogen and carbon removal system which comprises a treatment unit, wherein the treatment unit comprises a modified photoelectric electrode plate, a biological cathode layer and a particle electrode layer clamped between the modified photoelectric electrode plate and the biological cathode layer, the modified photoelectric electrode plate is connected with a positive electrode of a power supply, the biological cathode layer is connected with a negative electrode of the power supply, and an ultraviolet lamp is arranged opposite to the modified photoelectric electrode plate; the particle electrode layer and the biological cathode layer are both inoculated with microbial denitrifying bacteria, the modified photoelectric electrode plate generates electron-hole pairs under the excitation of ultraviolet light, holes are used for removing carbon, and photo-generated electrons are transferred to the denitrifying bacteria of polyurethane foam for denitrification and nitrogen removal of microorganisms; and meanwhile, the modified photoelectric electrode plate and the biological cathode layer are connected with the power supply to form electrolysis, and electrons generated by electrolysis are transferred to the biological cathode layer to perform microbial denitrification nitrogen removal. According to the invention, the modified photoelectrode is introduced into a microbial electrochemical system and is coupled with a denitrification biological cathode, so that a photocatalytic biological membrane electrode technology is constructed, and nitrogen and carbon are synchronously removed.

Owner:TIANJIN ENVIRONMENTAL PROTECTION TECHNICAL DEV CENT DESIGNING INST

Method for cooperatively treating organic matter-containing solid hazardous waste substitute tailings in cement kiln

ActiveCN111807732AConducive to energy saving and emission reductionConducive to cost reduction and efficiency increaseSolid fuelsClinker productionEnvironmental engineeringCo-processing

The invention discloses a method for cooperatively treating organic matter-containing solid hazardous waste substitute tailings in a cement kiln. The method comprises the following steps: (1) modification treatment; (2) dehydrating and preheating; and (3) burning in a decomposing furnace. The method is simple to operate, low in treatment energy consumption, low in treatment cost and free of secondary pollution; and (2) the carbon-containing organic matter solid hazardous waste can effectively replace part of silicon-aluminum raw materials and about 60-65% of fire coal required by dry-process cement production, so that energy conservation, emission reduction, cost reduction and benefit increase of cement enterprises are facilitated.

Owner:长沙紫宸科技开发有限公司

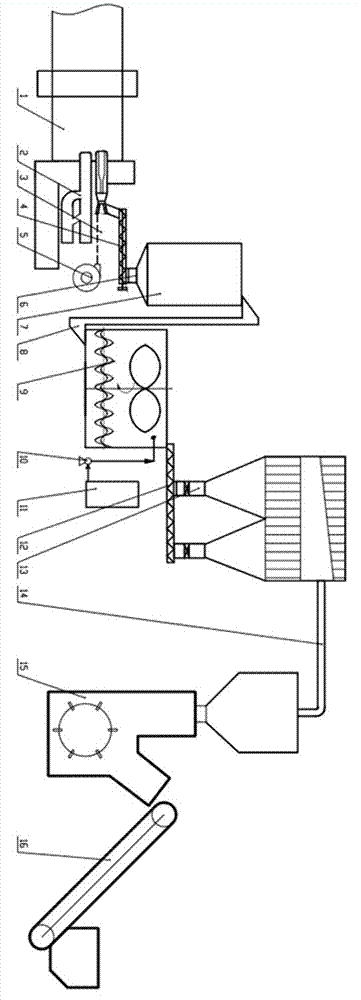

Equipment for catalytic cracking and combustion of waste rubber and plastic of cement kiln head

PendingCN107036439ASolve high temperature catalytic fast crackingSolve the problem of high-temperature catalytic rapid oxidation combustionRotary drum furnacesClinker productionEnvironmental resistanceWaste rubber

The invention provides equipment for catalytic cracking and combustion of waste rubber and plastic of a cement kiln head. The equipment comprises a pulverized coal burner, a waste fuel swirling burner, an airlock feeder, a high pressure fan, a meter feeder, a waste fuel bin, a conveyor I, a homogenizer, a meter feeding pump and a catalytic cracking oxidant storage tank. The equipment is simple, and relatively mature equipment is provided for selection; waste tires / waste plastic is used as alternative fuel, and the utilization cost is low; the equipment is high in economy and convenient for popularization; environmental pollution caused by the waste tires / waste plastic can be reduced effectively, and energy consumption and environmental pollution in the recycling and machining process of the waste tires / waste plastic are reduced, in favor of environmental protection; the invention provides new economic and practical equipment for utilizing the waste tires / waste plastic as the alternative fuel of the kiln head for cement enterprises, in favor of energy saving, emission reduction, cost decrease and benefit improvement of the cement enterprises.

Owner:长沙紫宸科技开发有限公司

Rapid logistics transport vehicle with outdoor transportation capability

The invention provides a rapid logistics transport vehicle with outdoor transportation capability. The rapid logistics transport vehicle comprises a frame, wherein an electric drive assembly is connected with the bottom of the frame, a charging assembly for charging the electric drive assembly is arranged on the side surface of the frame, and a conveying assembly is connected to the top of the frame; the electric drive assembly comprises a drive seat connected with the frame, the drive seat is connected with a direct current motor, the output end of the direct current electric machine is closely sleeved with a drive shaft, two ends of the drive shaft are connected with drive wheels, and the bottom of the frame is also connected with a plurality of driven wheels; the conveying assembly comprises a rack connected with the frame, the rack is rotatably connected with a plurality of conveying rollers, the conveying rollers are connected with a direct current motor, and a chain transmissionassembly is arranged between the direct current motor and the conveying rollers. The rapid logistics transport vehicle can achieve outdoor rapid logistics transportation between workshops.

Owner:SUZHOU HONGAN MACHINERY

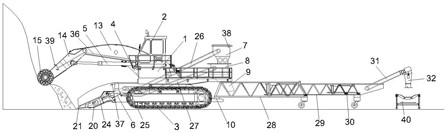

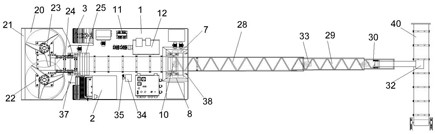

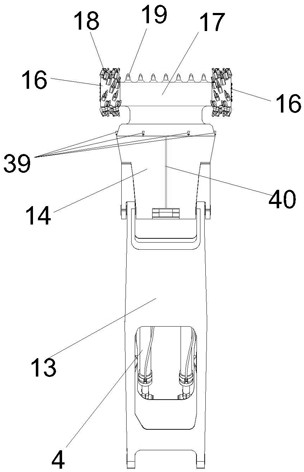

Dust-falling wheel pick press-planing type combined mining machine for strip mine

PendingCN112814670AFlexibleWith crushing functionDisloding machinesOpen-pit miningBrown coalMining engineering

The invention provides a dust-falling wheel pick press-planing type combined mining machine for a strip mine, and belongs to the technical field of mining machinery. The dust-falling wheel pick press-planing type combined mining machine for the strip mine realizes continuous mining, loading and transporting, transferring and direct coal storage of a lignite strip mine with loose blasting, is lower in purchase cost, saves energy and reduces consumption, is beneficial to cost reduction and benefit increase, realizes green mining, and reduces environmental pollution. The dust-falling wheel pick press-planing type combined mining machine for the strip mine comprises a main machine platform, wherein a cab is arranged on the upper part of the main machine platform; and a travelling crawler belt is arranged on the lower part of the main machine platform. The dust-falling wheel pick press-planing type combined mining machine for the strip mine is characterized in that a planing and mining mechanism is hinged to the front upper part of the main machine platform; the planing and mining mechanism is connected with a lifting hydraulic oil cylinder and a pitching oil cylinder; the lifting hydraulic oil cylinder and the pitching oil cylinder are fixed on the main machine platform; a material receiving shovel mechanism is hinged to the front lower part of the main machine platform; the material receiving shovel mechanism is connected with a material shovel lifting oil cylinder; the material shovel lifting oil cylinder is fixed on the main machine platform; and a screening and transporting mechanism is connected to the material receiving shovel mechanism.

Owner:LIAONING HANSHI MACHINERY MFG CO LTD

A kind of calcium carbonate carbon sphere is applied to the technology of lf steelmaking

Owner:北京璞域环保科技有限公司

A repairing process for the heating coil of the steel claw straightening machine for aluminum electrolysis

ActiveCN106216934BConducive to cost reduction and efficiency increaseAvoid damageCoil arrangementsFoundation engineeringElectrolysisRoom temperature

The invention discloses a repairing process for a heating coil of a steel claw straightening machine for aluminum electrolysis. The process comprises the steps that (1) the heating coil is dismounted; (2) the heating coil is repaired; (3) a mold is manufactured; (4) a coil foundation is manufactured; (5) the middle of the heating coil is constructed; (6) the interior of the heating coil is constructed; and (7) the constructed heating coil is installed after being maintained at the room temperature to be dried, after the coil is heated and dried, pig iron is taken out, and equipment can be put on production when the coil has no abnormal condition. The repairing process has the beneficial effects that the consumed time is short, the total cost is low, and cost decreasing and benefit increasing are facilitated for enterprises. By the adoption of the made-to-order mold manufactured according to the contraction ratio of steel claws, damage to the coil from the deformed steel claws is prevented.

Owner:GANSU DONGXING ALUMINUM

A kind of high flexure-resistant composite Portland cement and its preparation method

The invention belongs to the field of building materials, and in particular relates to a high-bending composite Portland cement and a preparation method thereof. The high-bending composite Portland cement is made of the following raw materials in parts by weight: 35-65 parts of Portland cement Clinker, 17.5‑40 parts calcined clay, 10‑22.5 parts limestone, 1.5‑5 parts gypsum. The invention provides a concrete core raw material starting from cement itself, on the basis of ensuring high cement compressive strength, the folding ratio is increased, the cement flexural strength is improved, and ordinary Portland cement clinker, calcined A high-bending composite Portland cement prepared with clay and low-grade limestone as main raw materials and a preparation method with the characteristics of simple process and suitable for industrial production.

Owner:SINOMA INT ENG +1

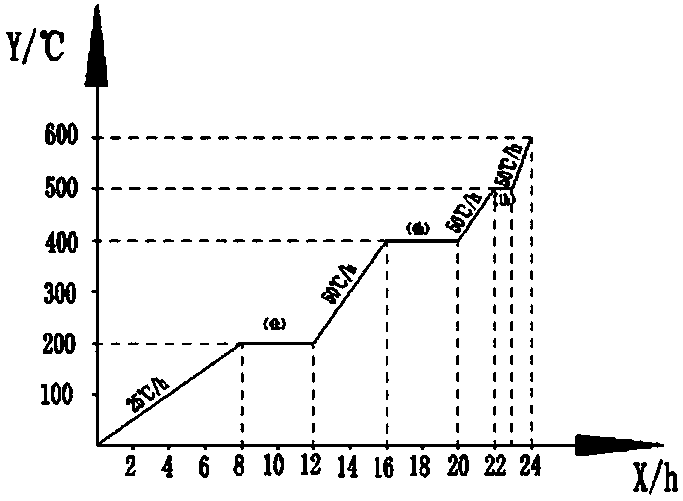

A kind of drying method of lithium ion battery cell

ActiveCN105865159BSmall amount of deformationConducive to cost reduction and efficiency increaseDrying using combination processesVacuum pumpingProcess engineering

The invention discloses a lithium ion battery core drying method. The lithium ion battery core drying method comprises the following steps of: (1) putting a lithium ion battery core in a closed system, and carrying out vacuum pumping, wherein the time taken is recorded as h; (2) heating, inflating and blasting the system simultaneously; carrying out heat preservation and pressure maintaining after reaching the setting temperature and vacuum degree; and continuously blasting in the whole process, wherein the time taken is recorded as h1, and a medium used for inflation and blasting is a non-oxide gas; and (3) maintaining the temperature of the system to be 90-110 DEG C, carrying out vacuum pumping till the vacuum degree is below 100Pa, and carrying out pressure maintaining, wherein the time taken in the whole process is recorded as h2, and h, h1 and h2 meet conditions shown in the (I). The lithium ion battery core drying method is simple in technology, improves drying efficiency, reduces the time taken for drying and the deformation of a battery core diaphragm in a drying process, facilitates realization of cost reduction, benefit increasing and product quality improvement for battery production enterprises and is suitable for large-scale popularization and application.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com