Capsule lubricant for drilling fluid, preparation method thereof, water-based drilling fluid and application

A technology of encapsulated lubricants and water-based drilling fluids, applied in chemical instruments and methods, drilling compositions, etc., can solve problems affecting rheology, low effective concentration, and large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

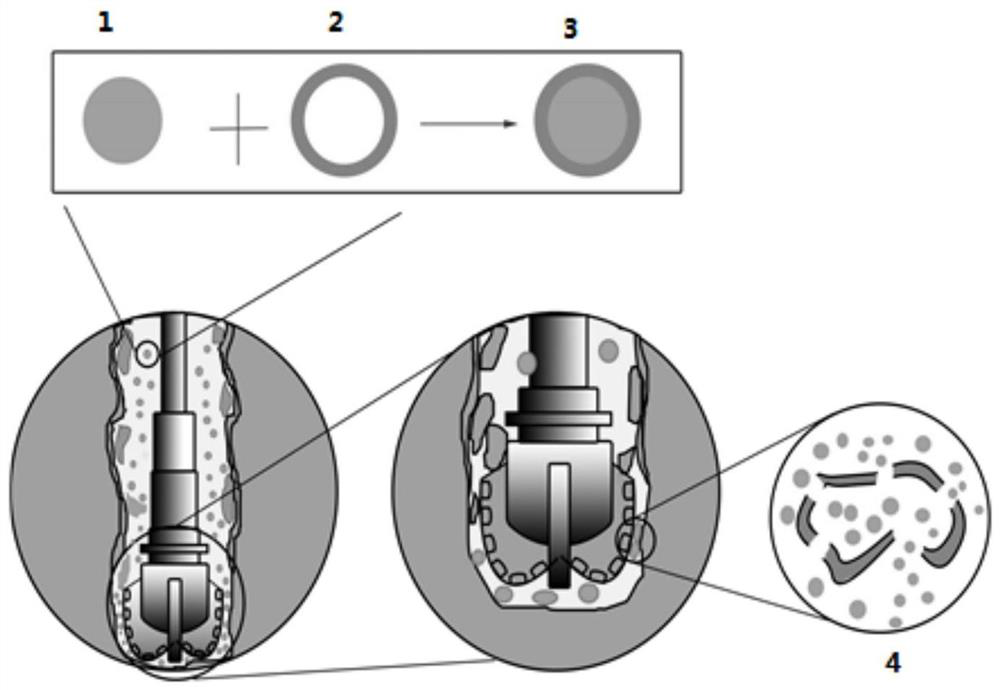

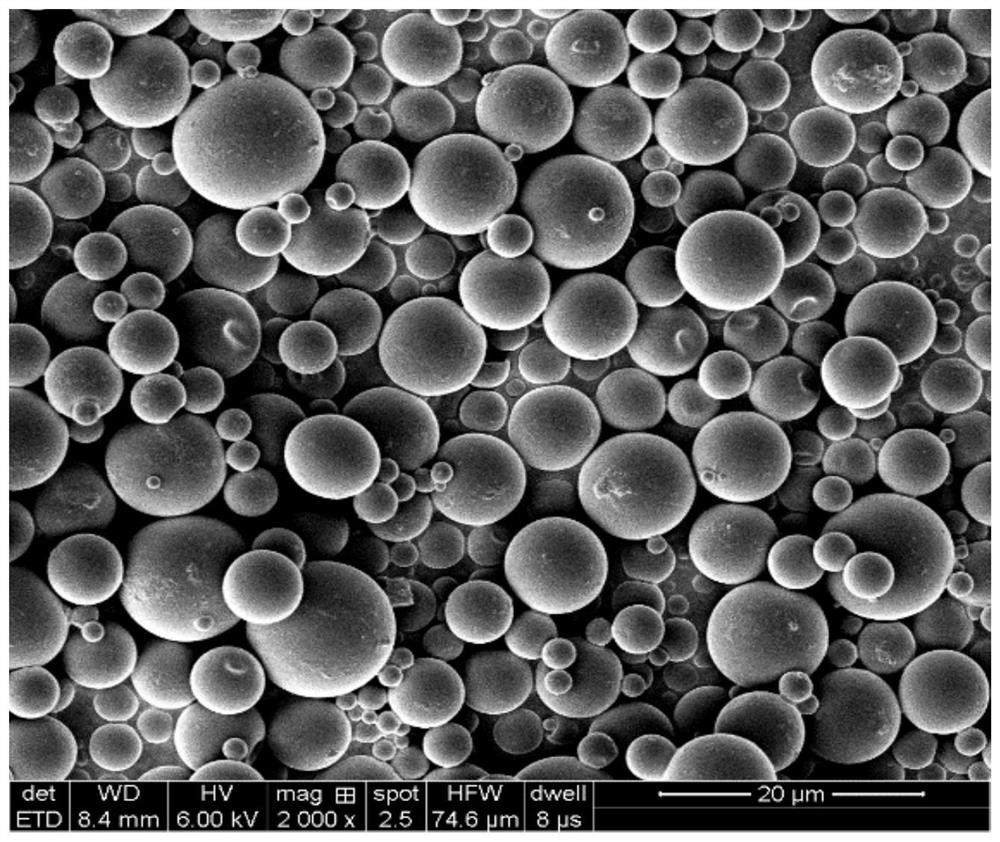

[0072] This example is to illustrate the encapsulated lubricant prepared by the phase separation method of the present invention.

[0073] (1) Prepare the wall component solution: prepare an acetic acid solution with a mass concentration of 1%, measure 200mL of the acetic acid solution and place it in a beaker, add 5.00g of chitosan, and stir it at a high speed of 3000r / min for 20min at a temperature of 50°C. Set for 1h, a clear and transparent wall component solution was obtained.

[0074] (2) Preparation of oil-in-water emulsion: Add 1.4 g of compound emulsifier (sorbitan monooleate (Span80) and polyoxyethylene octylphenol ether-10 (OP-10) to 200 mL of deionized water, weight The ratio is 1:1.5), and the HLB of the compound emulsifier is 13. Under stirring conditions, add 7.00g of lubricating oil base oil (palm oil) dropwise to the beaker; the temperature is 50°C, and the mixture is stirred at 3000r / min for 10min to obtain oil-in-water emulsion.

[0075] (3) The temperatur...

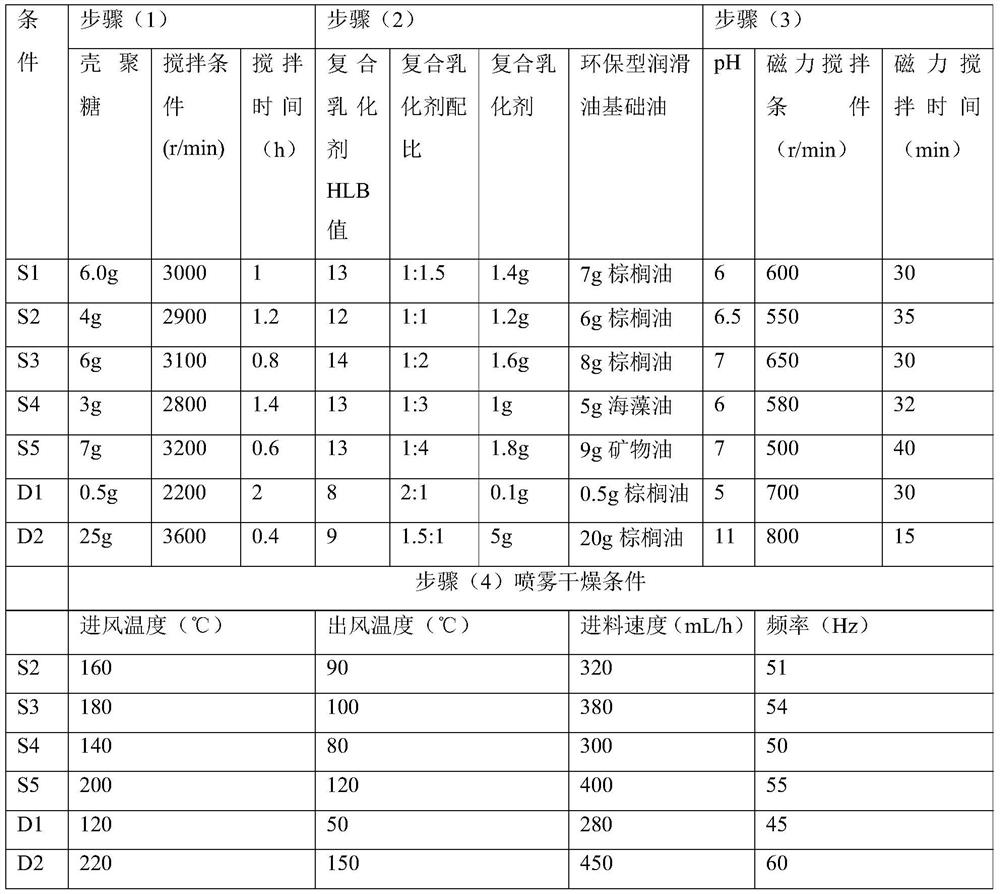

Embodiment 2-5

[0091] Prepare encapsulated lubricant according to the same conditions as in Example 1, the difference is: each component, component dosage and conditions are different, specifically as shown in Table 1, wherein, for the components not listed in Table 1 , component consumption and conditions are then considered to be the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com