A kind of high-efficiency composite defoamer for oil well cement and preparation method thereof

A technology of oil well cement and defoamer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of easy delamination, deposition, low cost performance, dangerous goods, etc., and achieve good compatibility and compatibility Capacitance, simple manufacturing process, and the effect of improving cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

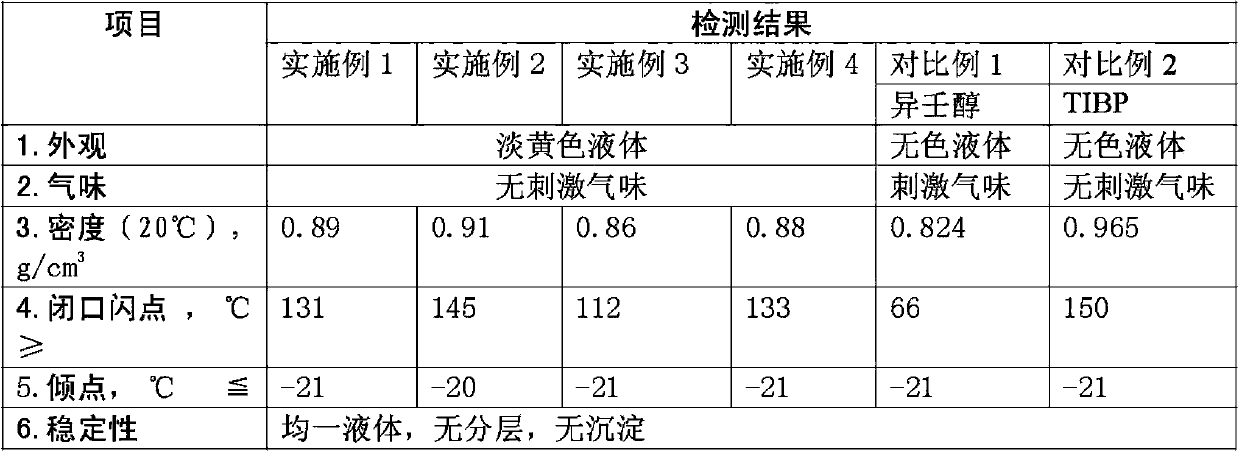

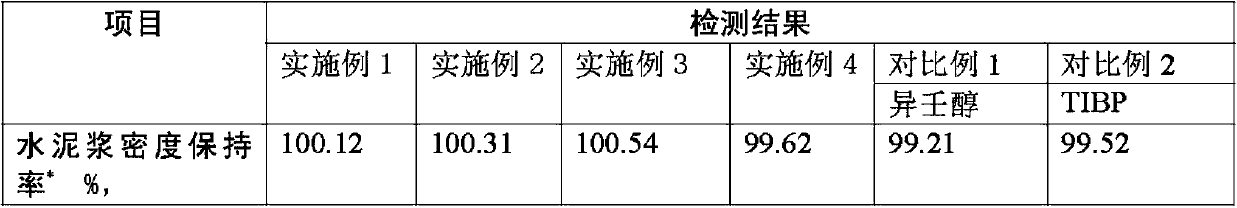

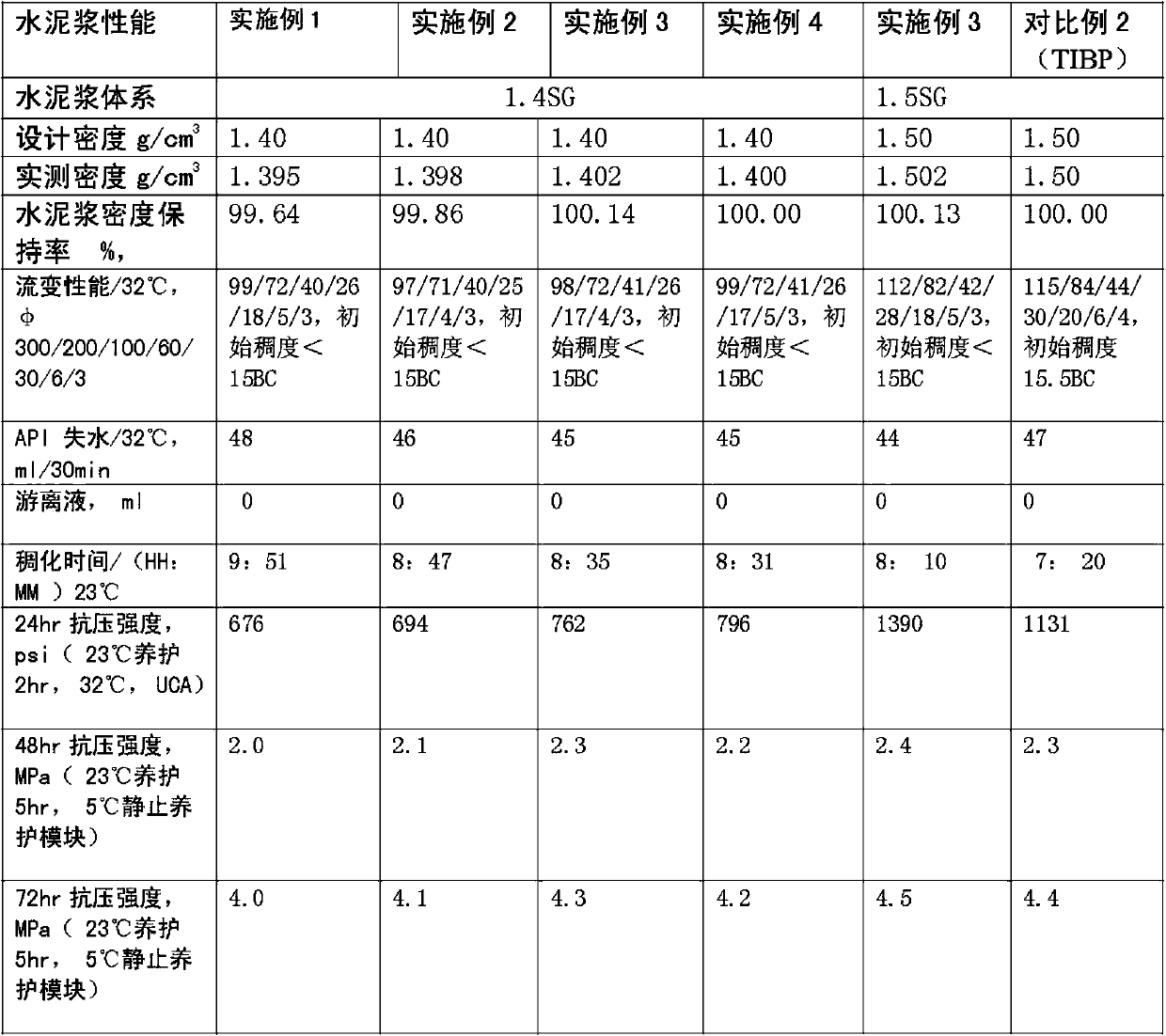

Examples

Embodiment 1

[0027] 450kg15# white oil, 450kg polyether monostearate, 85.0kg diisobutyl phthalate, 15.0kg defoaming auxiliary components (polyether PPE, TIBP are mixed at a mass ratio of 0.5:0.5).

Embodiment 2

[0029] 340kg26# white oil, 550kg ethylene glycol monooleate, 100kg diisononyl phthalate, 10.0kg defoaming auxiliary components (polyether GPE, TIBP mixed at a mass ratio of 0.25:0.75) .

Embodiment 3

[0031] 550kg5# white oil, 405.0kg2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 50kg diisobutyl phthalate, 5.0kg defoaming auxiliary components (polyether PPE , TIBP is prepared by mixing at a mass ratio of 0.1:0.9).

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com