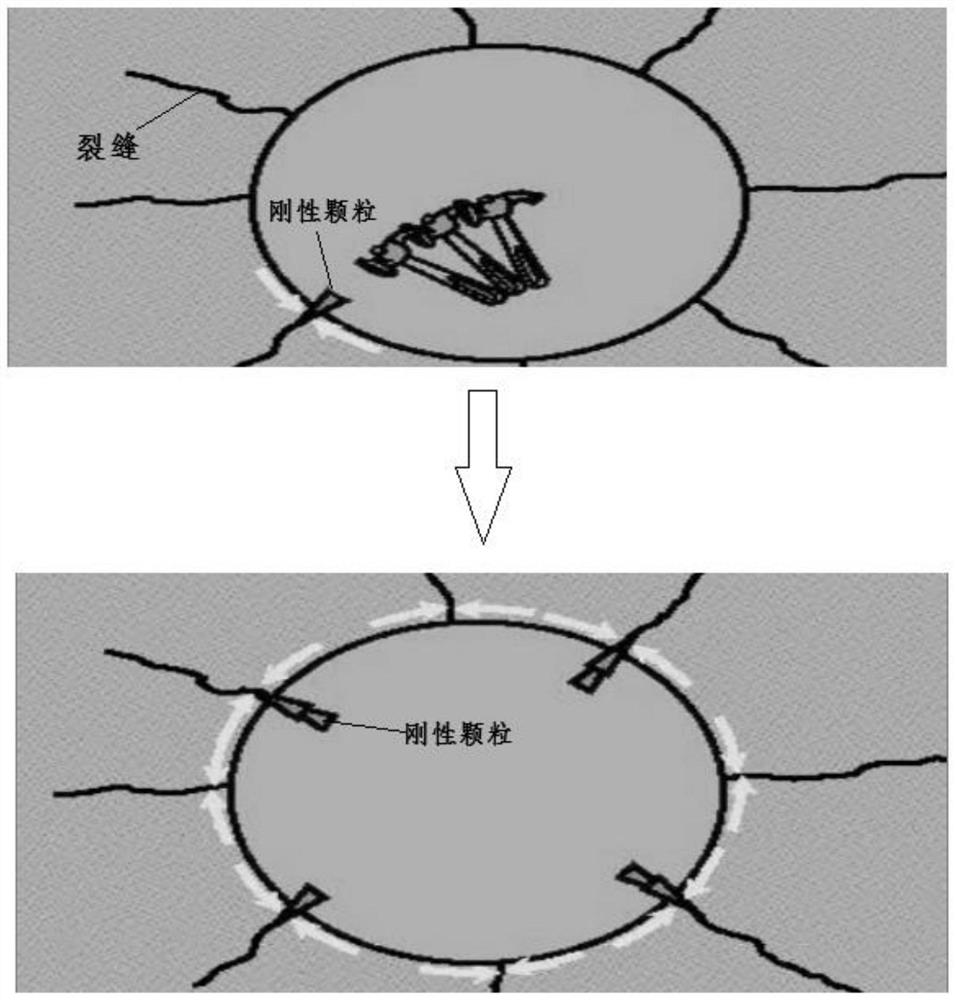

Micro-nano rigid resin anti-collapse blocking agent

A plugging agent, micro-nano technology, applied in the field of micro-nano rigid resin anti-slump plugging agent, can solve problems such as limited effect, achieve excellent leakage prevention, improve well wall, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

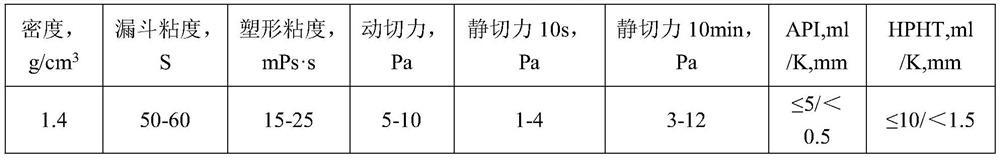

Method used

Image

Examples

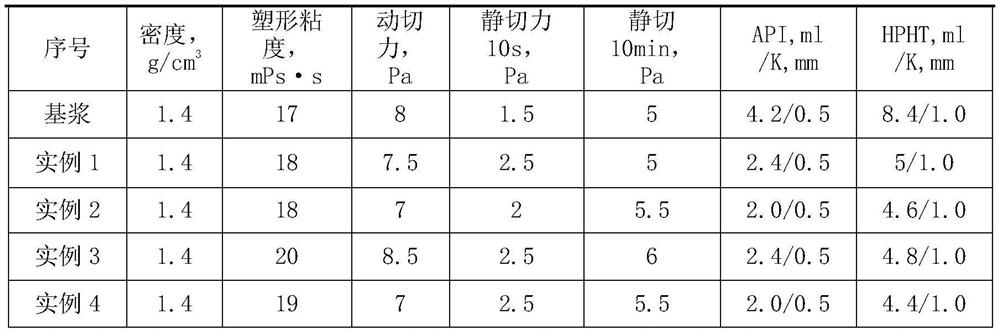

Embodiment 1

[0021] Components and mass ratio of a micro-nano rigid resin anti-slump plugging agent: 50% rigid resin particles, 25% brucite fibers, 15% calcite powder, 10% stearic acid amide; the rigid resin particles are thermoplastic acrylic , the particle ratio (mass ratio) is as follows: rigid resin particles (2500 mesh): rigid resin particles (1500 mesh): rigid resin particles (800 mesh) = 5:3:2. The anti-slump plugging agent product can be obtained after all components are mixed uniformly.

Embodiment 2

[0023] Components and mass ratio of a micro-nano rigid resin anti-slump plugging agent: 60% rigid resin particles, 20% brucite fibers, 10% calcite powder, 10% stearic acid amide; the rigid resin particles are thermoplastic acrylic , the gradation ratio is as follows: rigid resin particles (2500 mesh): rigid resin particles (1500 mesh): rigid resin particles (800 mesh) = 5:3:2. The anti-slump plugging agent product can be obtained after all components are mixed uniformly.

Embodiment 3

[0025] Components and mass ratio of a micro-nano rigid resin anti-slump plugging agent: 55% rigid resin particles, 25% brucite fibers, 10% calcite powder, 10% stearic acid amide; the rigid resin particles are thermoplastic acrylic , the gradation ratio is as follows: rigid resin particles (2500 mesh): rigid resin particles (1500 mesh): rigid resin particles (800 mesh) = 5:3:2; mineral fiber is brucite fiber; surface treatment agent is stearin acid amide. The anti-slump plugging agent product can be obtained after the components are mixed evenly;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com