A repairing process for the heating coil of the steel claw straightening machine for aluminum electrolysis

A technology of heating coils and aluminum electrolysis, applied in coil devices, induction heating, infrastructure engineering, etc., can solve problems such as high procurement costs, long time-consuming repair and re-build induction coils, and difficulty in reducing costs and increasing efficiency for enterprises. The overall cost is low, the time is less, and the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

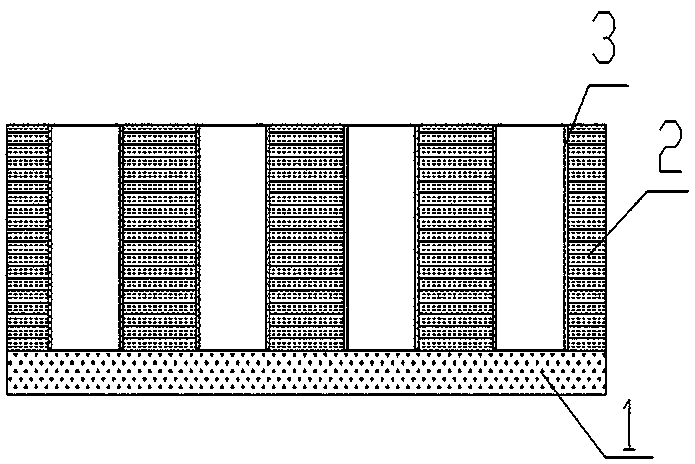

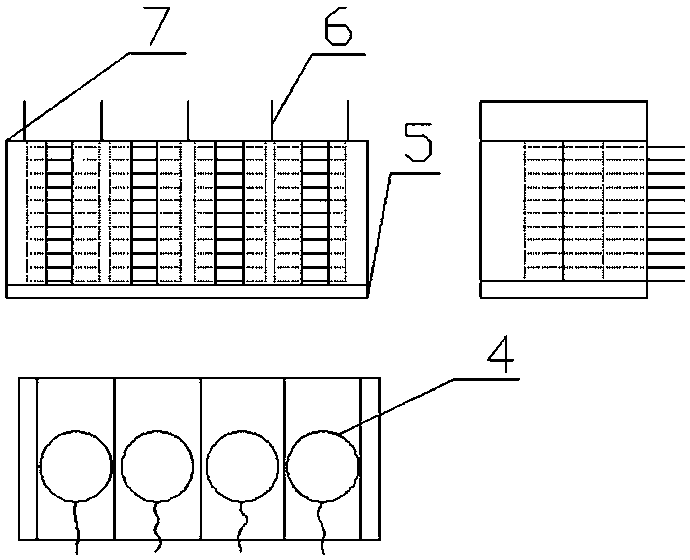

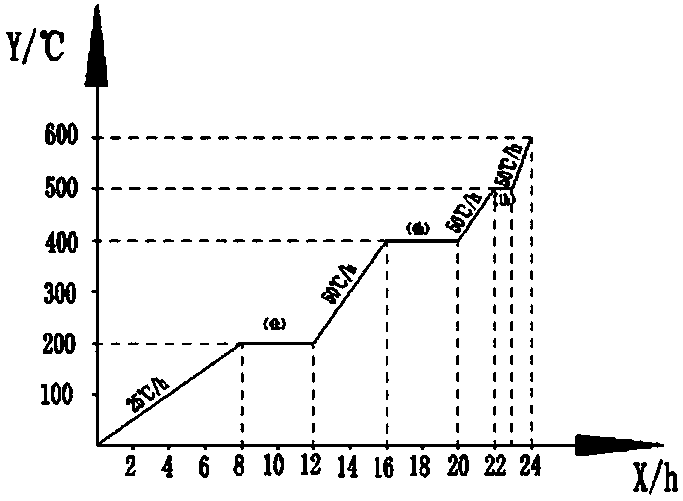

[0015] The heating coil repair process of the steel claw straightening machine for aluminum electrolysis includes 7 steps: induction coil removal, coil repair, mold making, coil foundation making, coil middle making, coil internal masonry and heating coil drying.

[0016] 1. Induction coil removal

[0017] In the process of removing the outer and inner masonry materials of the heating coil, first use a small hand hammer to clean the inner masonry materials, and the action should be light to avoid damage to the heating coil. When cleaning the masonry between and outside the heating coils, use chisel to clean up gradually.

[0018] 2. Heating coil

[0019] After cleaning all the masonry materials attached to the heating coils, check the integrity of the coils. If the coil is damaged and leaks, it needs to be welded and repaired. After the welding is completed, brush with high-temperature insulating paint and dry.

[0020] 3. Mold making

[0021] The premise of mold making is to count the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com