Production system for preparing tin dioxide by gasification

A production system, tin dioxide technology, applied in the direction of tin oxide, etc., can solve the problems of complex production equipment, serious environmental pollution, heat loss, etc., and achieve the effect of good product quality, simple production system and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

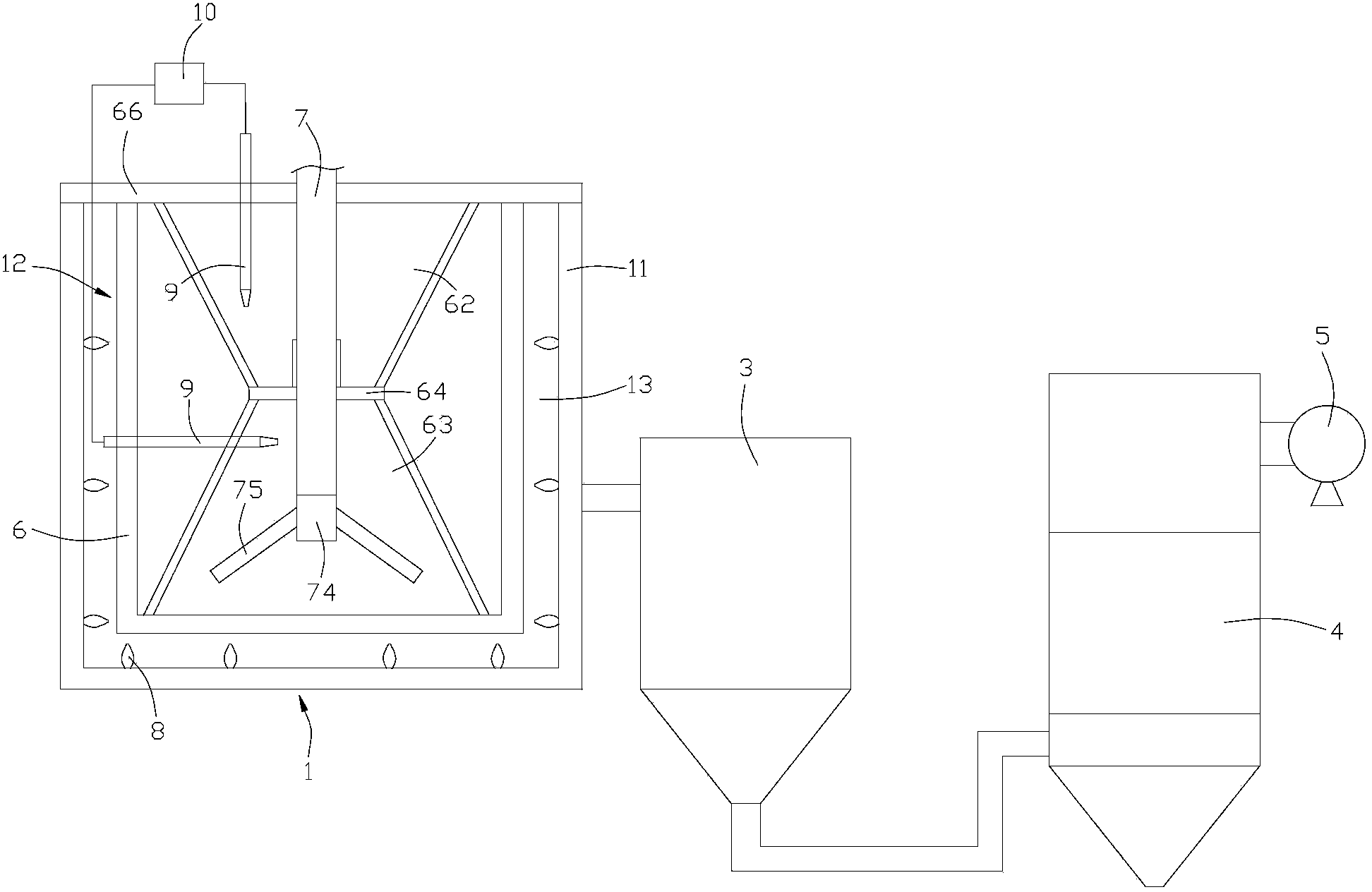

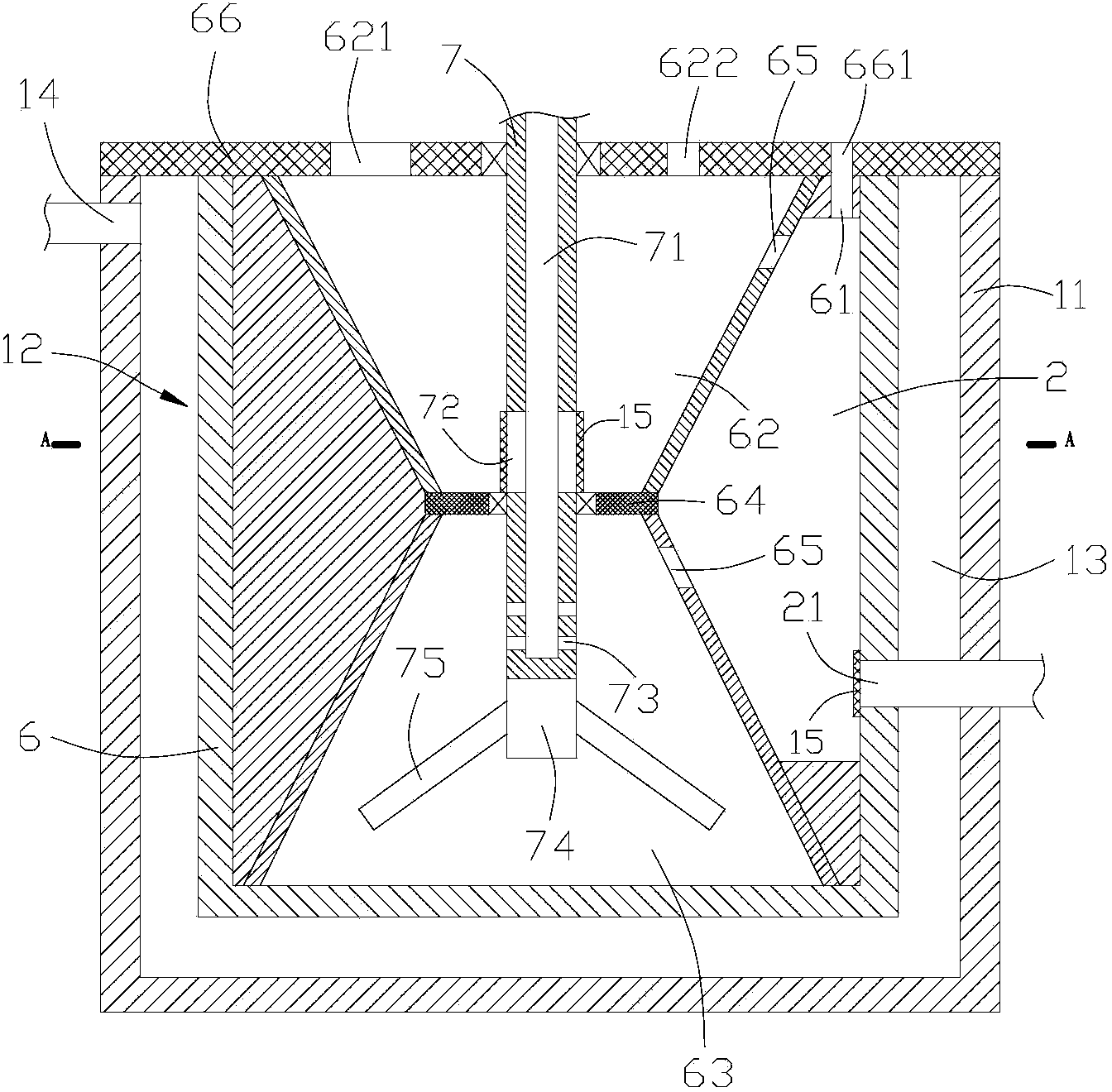

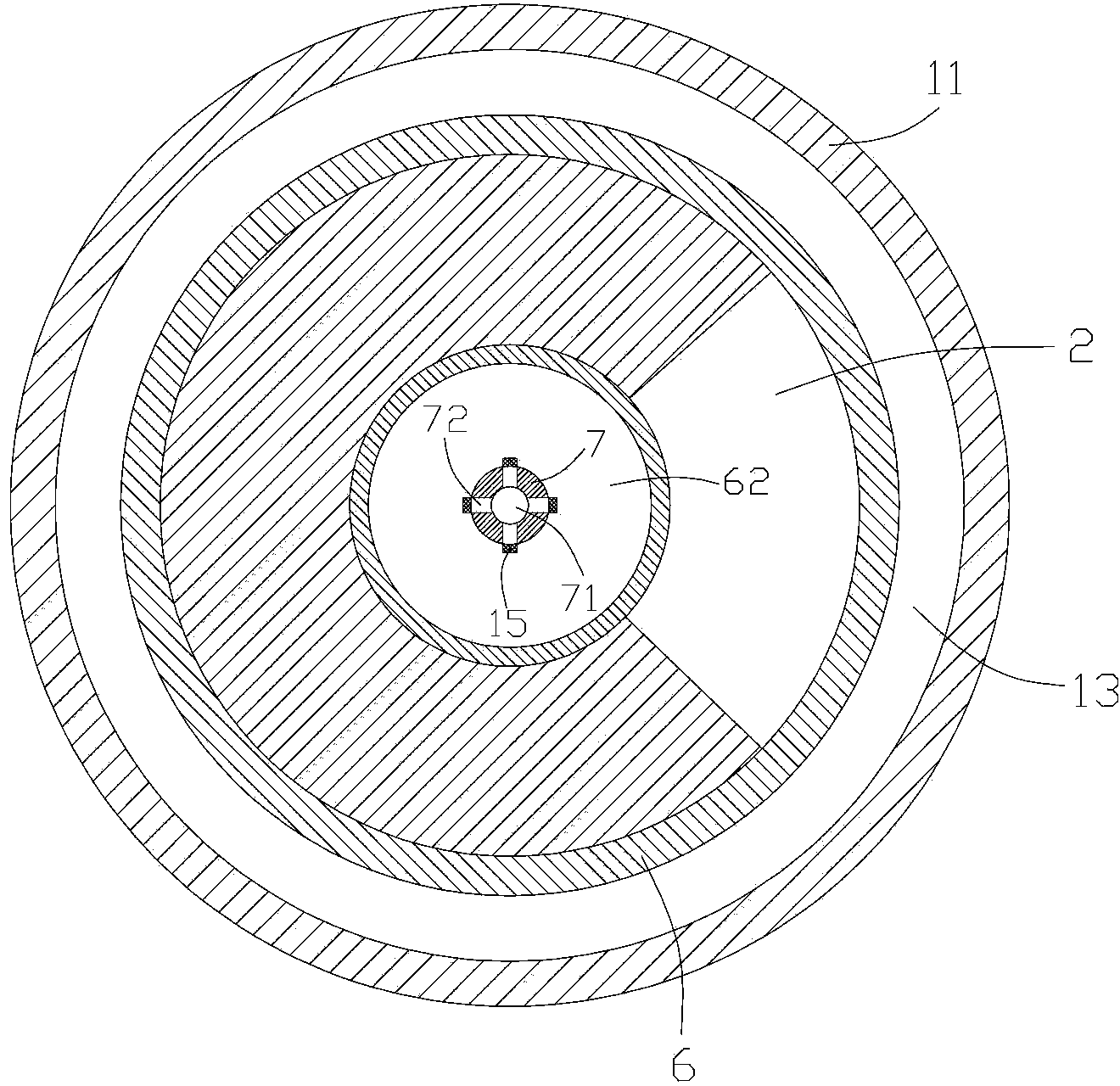

[0016] Combine below figure 1 , figure 2 and image 3 The present invention is described in further detail:

[0017] The production system of the present invention comprises a tin ingot melting, an oxidation integrated furnace 1 and a secondary oxidation chamber 2 connected to the integrated furnace to re-oxidize the oxide discharged from the integrated furnace, the secondary oxidation chamber 2 and the settling cooling cylinder 3 Connected, the tin dioxide discharged from the cooling cylinder is collected by the bag filter 4, the dust collector is provided with an exhaust fan 5, and the secondary oxidation chamber is arranged in the heat conduction body 6, and there is a secondary oxidation chamber on the body. The connected gas inlet 61, the secondary oxidation chamber communicates with the upper part of the sedimentation cooling cylinder 3 through the outlet 21 arranged on one side, and the lower part of the sedimentation cooling cylinder communicates with the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com