Preparation system of raw material salt in combined alkali production

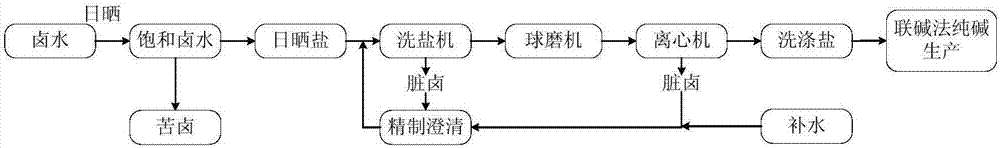

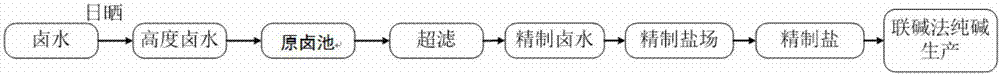

A technology of combined soda production and preparation system, which is applied in the field of raw material salt preparation system in combined soda production, can solve the problems of increasing waste sludge volume, complicated process, fluctuation of raw material salt quality, etc., achieves reduction of investment cost, simplification of production system, reduction of The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

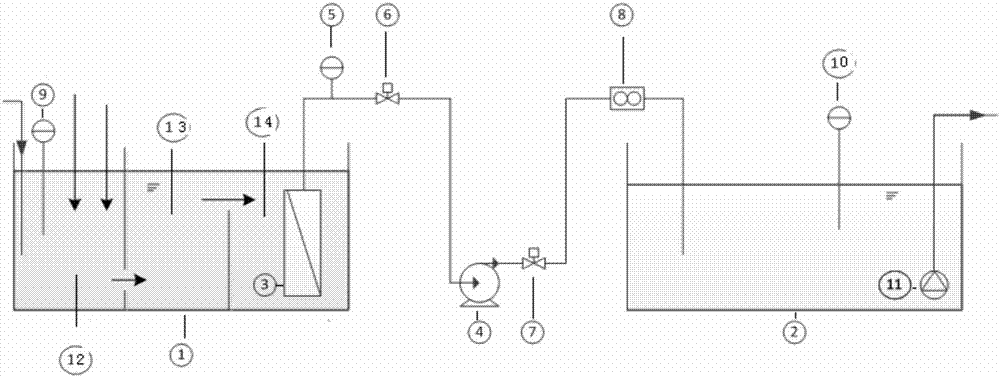

[0030] In order to make those skilled in the art better understand the technical solution of the present invention, Figure 2-3 It shows a preparation system of raw material salt in combined alkali production, and the specific operation process is as follows:

[0031] A system for preparing raw salt in combined soda production, comprising a raw brine pool 1 filled with raw brine, an ultrafiltration membrane module 3, a refined brine pool 2, and a combined alkali production system; the raw brine pool is equipped with a , the reaction zone 12 of magnesium ion, the sedimentation slag removal zone 13 that is used for the sedimentation of waste residue and the refinement zone 14 that is placed with described ultrafiltration membrane assembly; Detection; said precipitation and slag removal zone 13 communicates with the bottom of said reaction zone 12, and said refining zone 14 communicates with the top of said precipitation and slag removal zone 13; said refining zone 14 communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com