Down filling system for doll production

A technology for dolls and dolls, applied in the field of down filling, which can solve problems such as complex structure, flying down material, and inconvenient discharge of down material, and achieve the effects of simplifying the production system, reducing flying down material, and reducing production investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

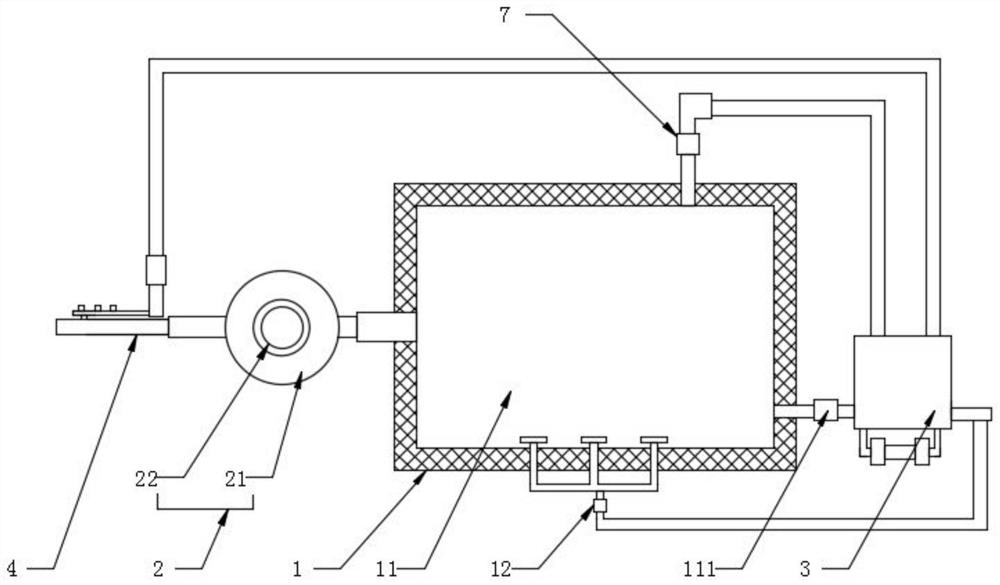

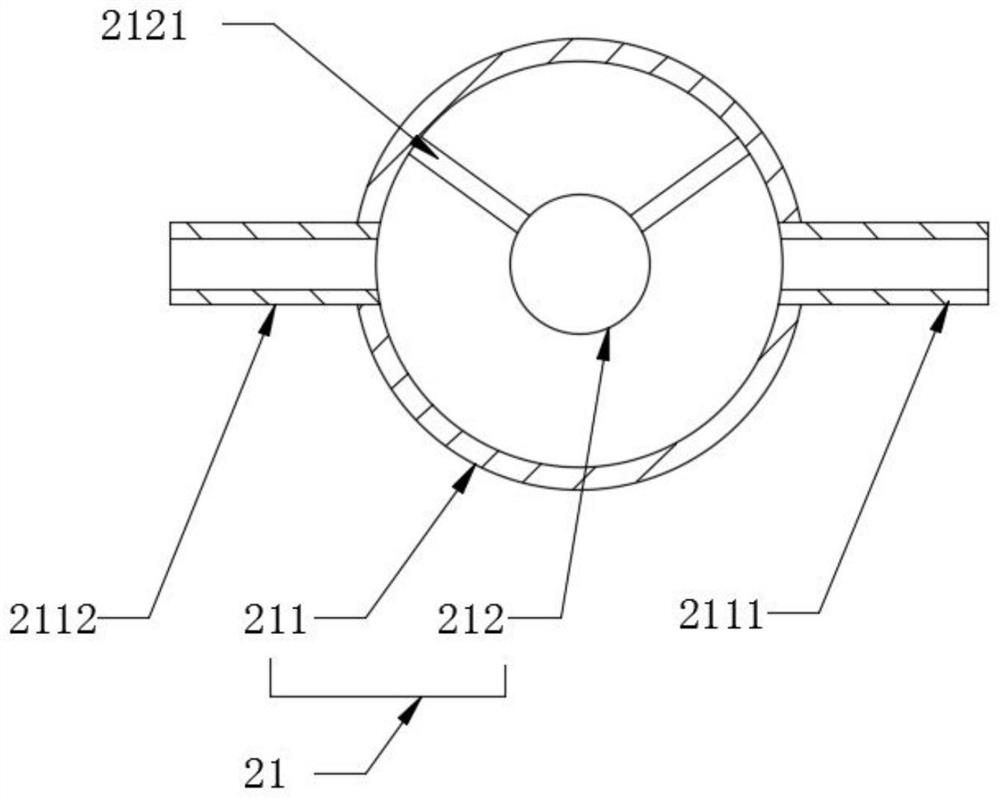

[0036] see Figure 1-5 , the down filling system for the production of doll dolls, including a down filling part 1, a pulse down filling part 2, a vacuum pulse air supply part 3 and a down down tube 4, and the down filling part 1 includes a down filling cavity 11 and a down filling cavity 11 and The external air valve 12 and the velvet chamber 11 are used to accommodate the velvet. The vacuum pulse supply part 3 includes a vacuum pump 31 and a vacuum box 32. The vacuum box 32 is provided with a negative pressure chamber 321 and a positive pressure chamber 322. The vacuum pump 31 The negative pressure chamber 321 of the air inlet shell communicates, and the air outlet communicates with the positive pressure chamber 322, the air valve 12 communicates with the positive pressure chamber 322 provided on the vacuum box 32, and the positive pressure in the positive pressure chamber 322 pushes the air valve 12 to the Sheng The fleece cavity 11 is inflated, the airflow hits the fleece ...

Embodiment 2

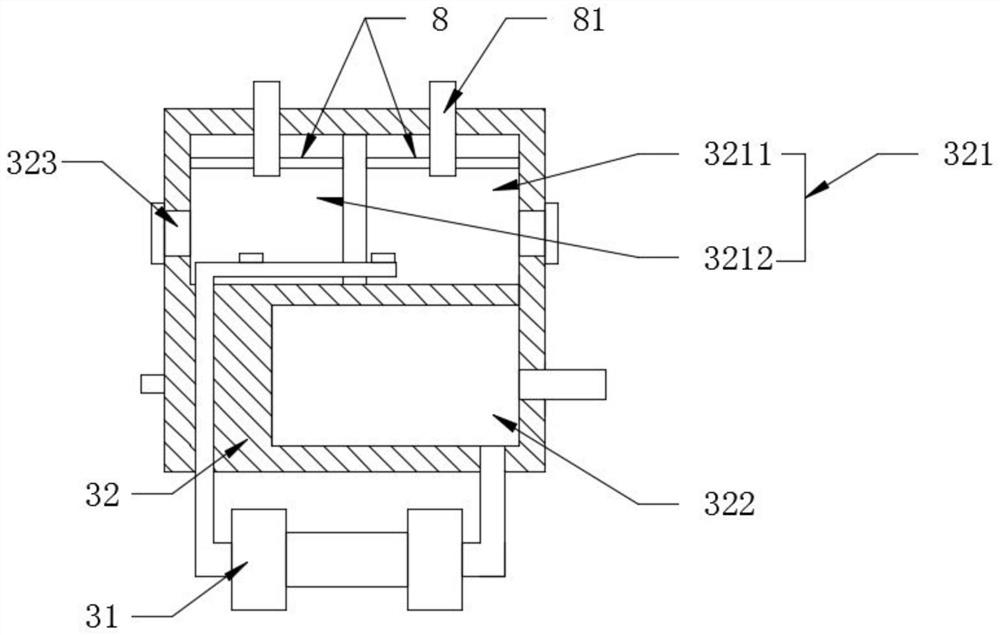

[0038] see image 3 and Figure 5 , the difference from Embodiment 1 is that the negative pressure chamber 321 is divided into a first negative pressure down filling chamber 3211 and a second negative pressure down filling chamber 3212 which are isolated from each other, and the first negative pressure down filling chamber 3211 and the second negative pressure down filling chamber 3211 are separated from each other. The down filling cavity 3212 is fixedly provided with a ventilating net plate 8, and the ventilating net plate 8 plays a role of filtering, and the middle part of the two ventilating net plates 8 is provided with a velvet tube 81 connected to the air inlet of the vacuum pump 31, and the velvet is discharged. The outside of the tube 4 is provided with a down suction tube 5, and one end of the down suction tube 5 is connected to the first negative pressure down filling cavity 3211 through the pulse valve 6, and the first negative pressure down filling cavity 3211 and...

Embodiment 3

[0040] see figure 1 and 3 The difference with Embodiment 1 and 2 is that the intake valve 111 communicates with the positive pressure chamber 322 through the pipeline, and the second negative pressure down filling chamber 3212 communicates with the down filling chamber 11 through the solenoid valve 7, thus, when it is necessary to When the cashmere material in the cashmere cavity 11 is removed, the solenoid valve 7 and the air intake valve 111 are opened, the positive pressure chamber 322 delivers gas to the cashmere cavity 11, and the second negative pressure cashmere cavity 3212 utilizes negative pressure to absorb the gas, thereby The cashmere in the cashmere chamber 11 can be completely accommodated in the second negative pressure cashmere chamber 3212, and the gas serving as the conveying medium is in a closed cycle state, thus the residual cashmere in the cashmere chamber 11 can be completely removed, The sealing cover 323 corresponding to the first negative pressure do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com