Close-range thin coal layer simultaneous mining and parallel transporting method

A thin coal seam, short-distance technology, applied in ground mining, mining equipment, earthwork drilling and mining, etc., can solve the problems of difficult tunneling support, long mining cycle, low output, etc., to improve mine output and production efficiency, reduce The effect of excavation engineering quantity and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

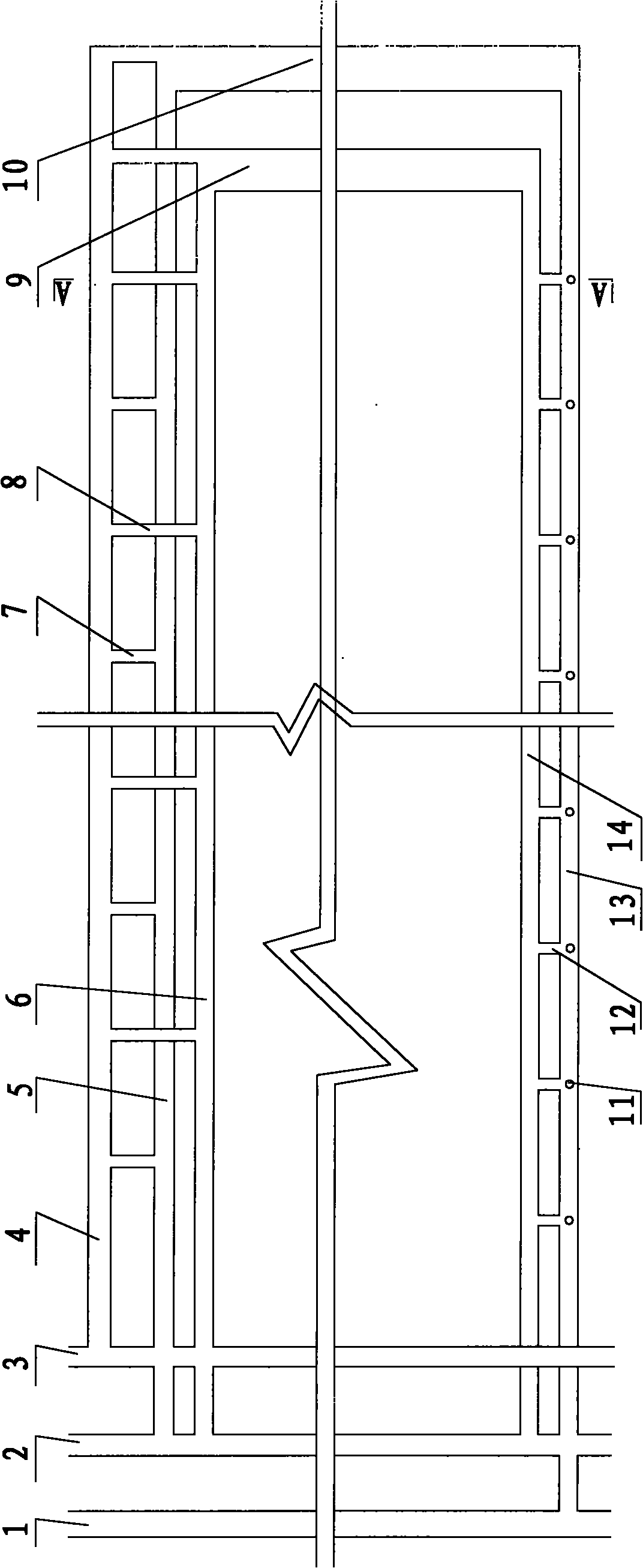

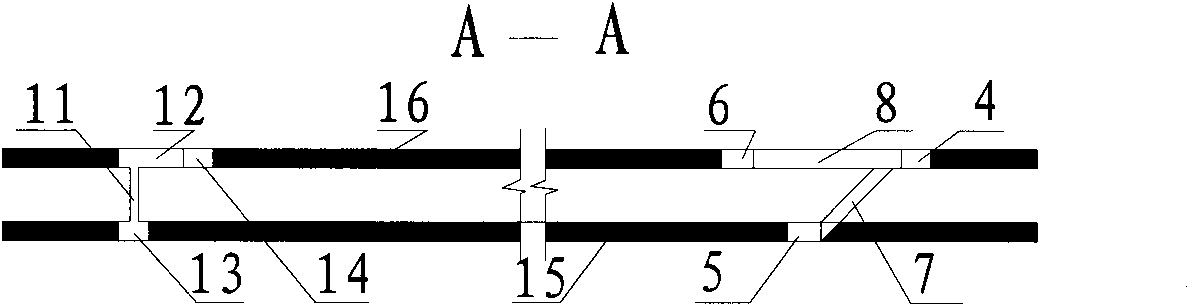

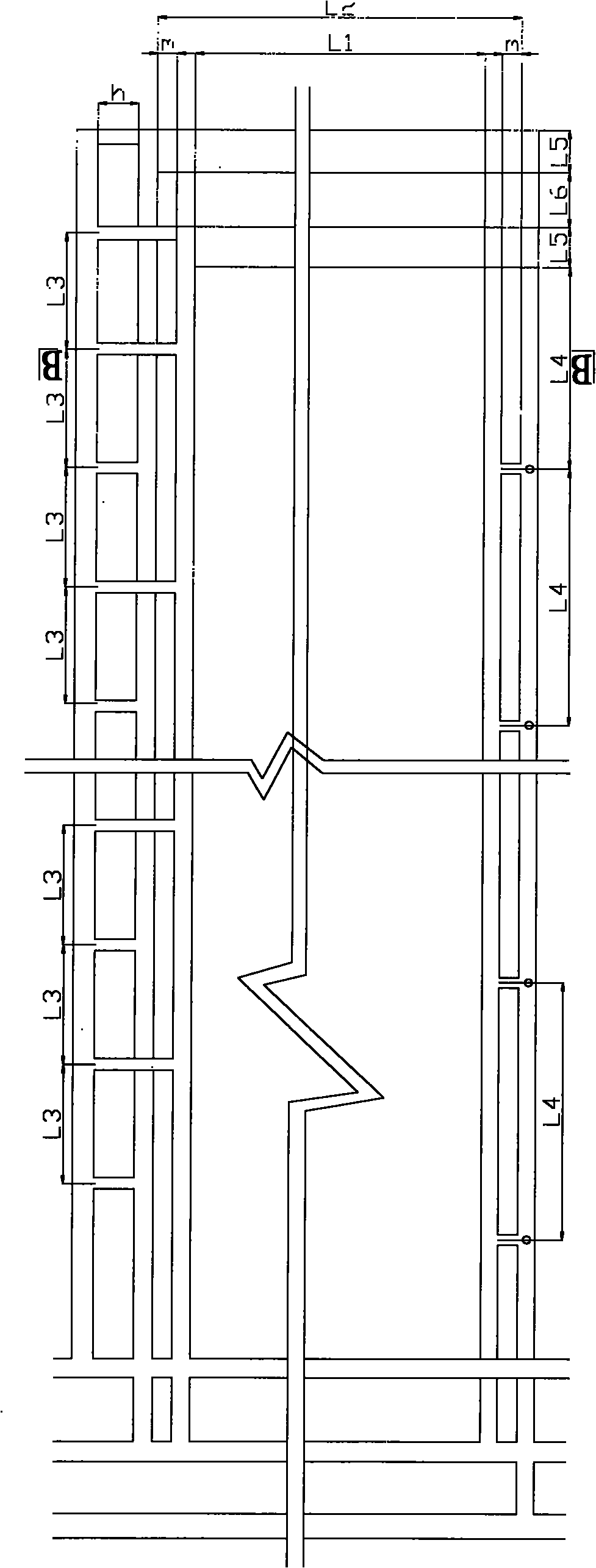

[0032] Such as figure 1 with figure 2 Shown:

[0033] According to the design department's design, three concentrated lanes are arranged along the coal seam or its roof and floor, namely centralized transportation lane 1, concentrated track lane 2, and concentrated return air lane 3, which are used as the main transportation, ventilation and pedestrians in the mining area;

[0034] Excavating the lower transport channel 13 in the lower coal seam, connecting the concentrated transportation lane 1, the concentrated track lane 2 and the lower cutout 10; excavating the lower track trough 5 in the lower coal seam, connecting the concentrated track lane 2, the concentrated return air lane 3 and the lower cutout 10 ;

[0035] In the excavation of the upper coal seam, the transport channel 14 is connected to the concentrated track roadway 2 and the upper cutout 9; in the upper coal seam excavation, the upper track track trough 6 is connected to the concentrated track roadway 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com