Outburst prevention method for close-distance coal seam group area of middling coal group

A short-distance, coal seam group technology, applied in the direction of earthwork drilling, gas discharge, safety devices, etc., can solve the problems of inaccurate positioning of drilling, complex geological conditions, high cost, etc., so as to improve the mining rate and safety production efficiency , Alleviate the connection tension and save the cost of gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

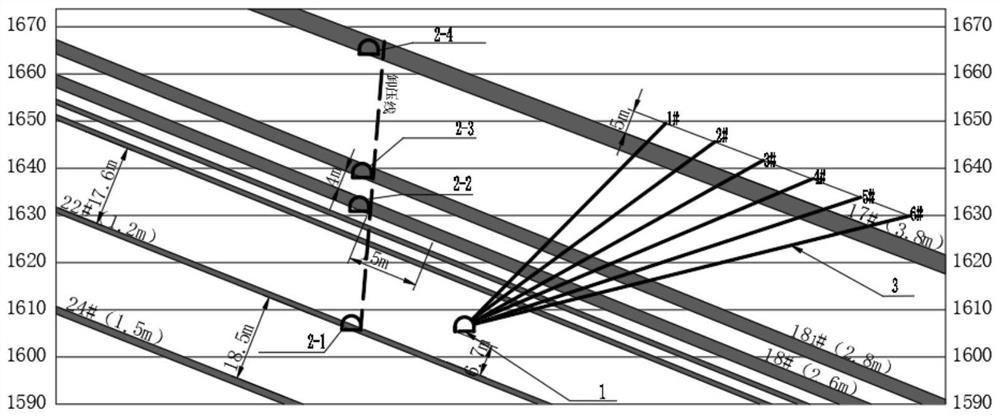

[0023] refer to figure 1 In the figure, 2-1 is the 112206 transportation lane, 2-2 is the 111806 transportation lane, 2-3 is the 111806 transportation lane, and 2-4 is the 111706 transportation lane. The construction conditions are limited, the cost is high, the treatment period is long, the single entry of comprehensive excavation is low, the drilling cannot be accurately positioned and the ordinary drilling cannot be accurately positioned when the gas control is carried out in areas with soft and high gas pressure. The invention adopts a regional outburst prevention method for short-distance coal seam groups in the middle coal formation. The method includes: constructing a gas drainage roadway 1 and arranging boreholes 3 to carry out regional pre-extraction for more than one coal seam at the same time. A gas drainage lane 1 can be used as a gas control lane for several mining faces at the same time, and can also be used as a high level lane.

[0024] Further, the method fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com