The ramp layout method applied to the stope of upward layered filling mining method

A technology of filling mining method and layout method, which is applied in the direction of filling, ground mining, mining equipment, etc., and can solve the problems of complicated excavation and slag discharge procedures, high excavation-mining ratio, and non-conformity to waste-free mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

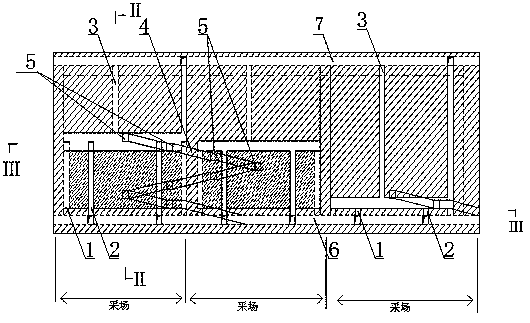

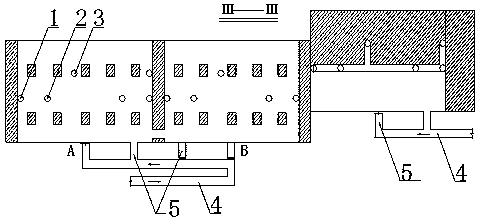

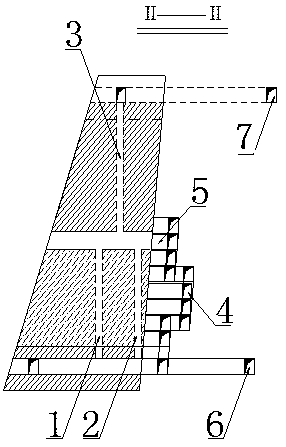

[0017] The following is based on Figure 1 to Figure 3 The specific embodiment of the present invention is further described:

[0018] see Figure 1 to Figure 3 , figure 1 There are 3 stopes in . This embodiment provides a ramp layout method applied to the stope of the upward layered filling mining method, including:

[0019] (1) When using the upward layered filling mining method to return to the ore body, on one side of the stope close to the ore body boundary or the mining boundary 5 to 10 meters away, the switchback ramp 4 is dug upward from the lower horizontal middle roadway 6, The slope of the ramp 4 is less than 20%, and it is connected with each stratum of the stope by a short connecting road 5; a scraper is used for slag removal.

[0020] (2) The ramp 4 is constructed section by section with the rise of the layered mining of the stope until it penetrates the upper horizontal middle roadway 7; the ramp 4 is used as one of the safety passages of the stope and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com