Method for constructing layer connection roadways by top slicing and cemented filling mining process

A technology of cemented filling and construction methods, which is applied in the direction of fillings, mining equipment, mining equipment, etc., can solve the problems of difficult selection of opening positions, difficult and complicated layout of layered connecting roads, etc., so as to solve the difficult and complicated layout and reduce the driving support Good cost, safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A construction method for a layered communication road of a downward layered cementation and filling mining method, comprising the following steps:

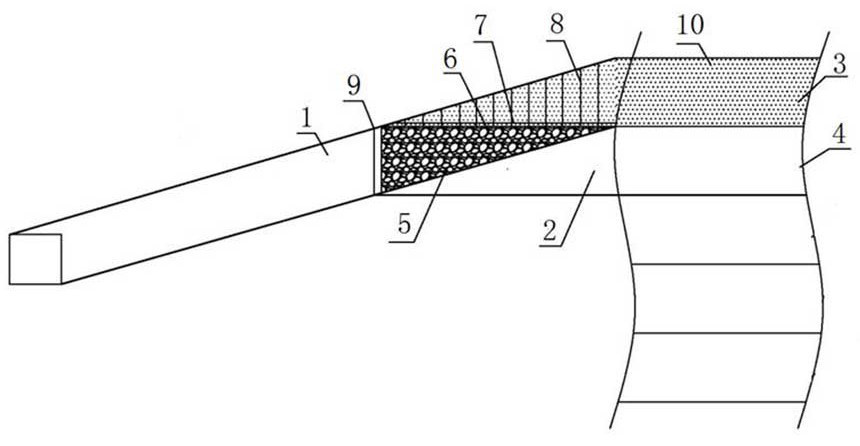

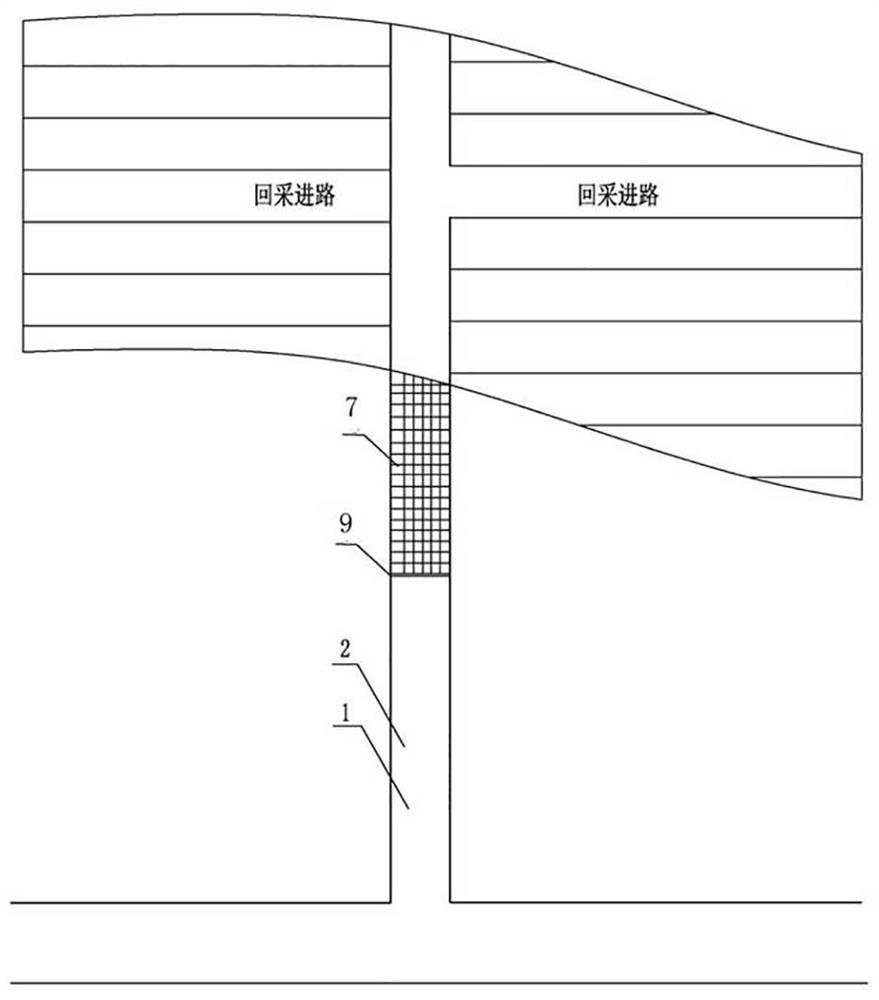

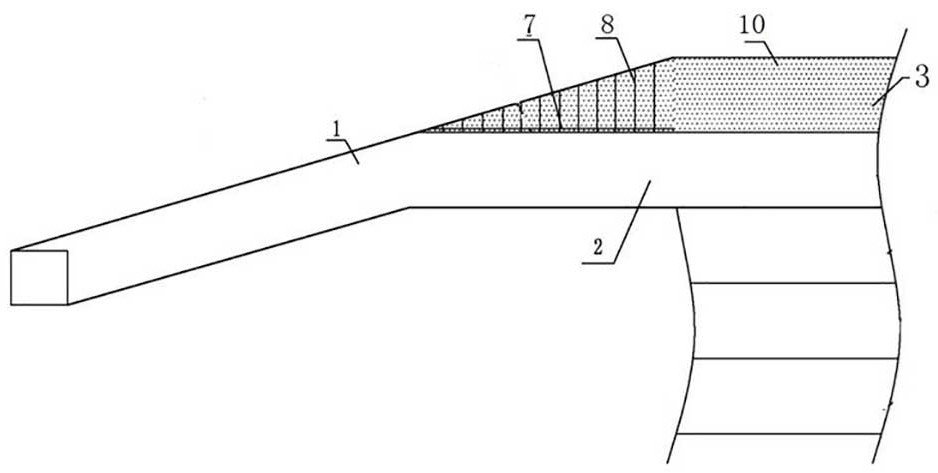

[0032] Step a: After the ore body 3 of the previous layer is mined and before the goaf of the layer is filled, waste rocks are padded from the position of the ore body to the bottom of the layer connection road 1 of the previous layer. A layered layered communication road 2 at the floor level, and the top of the waste rock is paved to form a waste rock layer 5;

[0033] Step b: Lay an isolation layer 6 on the waste rock layer 5, and seal the contact position between the waste rock layer 5 and the two walls of the layered connecting road 1 of the previous layer;

[0034] Step c: laying the bottom steel mesh 7 on the isolation layer 6, and the bottom steel mesh 7 is connected with the hanging steel bars 8 vertically suspended to the roof of the layered communication road;

[0035] Step d: Build a slab wall 9 at the level of...

Embodiment 2

[0041] On the basis of Example 1, in step b, the isolation layer 6 is formed of plastic cloth.

Embodiment 3

[0043] On the basis of Example 1, in step b, the isolation layer 6 is formed of woven cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com