Multi-layer long-wall mining roadway arrangement method for extremely-thick coal seam

A roadway layout and coal seam technology, applied in tunnels, ground mining, mining equipment, etc., can solve the problems of large amount of roadway excavation, low efficiency, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Taking a certain mine as an example to introduce a method for arranging roadways for multi-layered longwall mining in extremely thick coal seams according to the present invention, the specific steps are as follows:

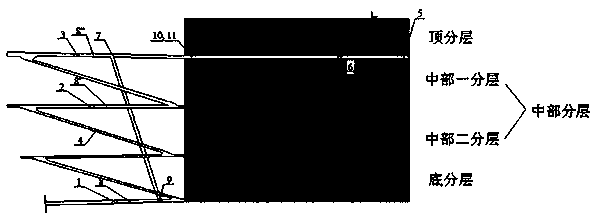

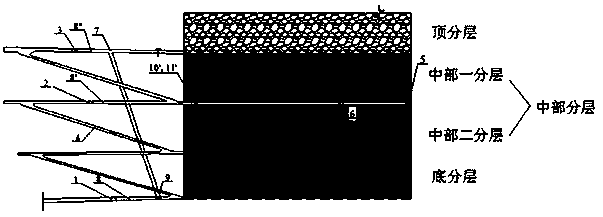

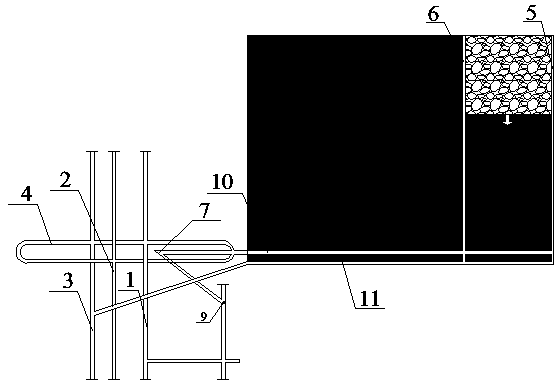

[0023] Step 1: According to geological data, the burial depth of a thick coal seam in a certain mine is 312m, and the average coal thickness is 80m. It is a horizontal coal seam with stable occurrence and can be mined in the whole area. Such as image 3 As shown, in the initial mining area, according to the mining technical conditions, the coal seam is divided into 4 layers according to the thickness from top to bottom, the upper 20 m is the top layer, and the middle 40 m is divided into two layers, namely the middle layer , the middle layer continues to be divided into middle layer 1 and middle layer 2 according to the elevation every 20m, and the bottom 20 m is the bottom layer; each layer is divided into 3 sections;

[0024] Step 2: Excavate the auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com