Drift type coal mining filling method

A technology of approach and stope, which is applied in the direction of filling, mining equipment, earthwork drilling and mining, etc., and can solve the problems of wasted filling production cost, high total cost of coal mining, complex underground coal mining system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

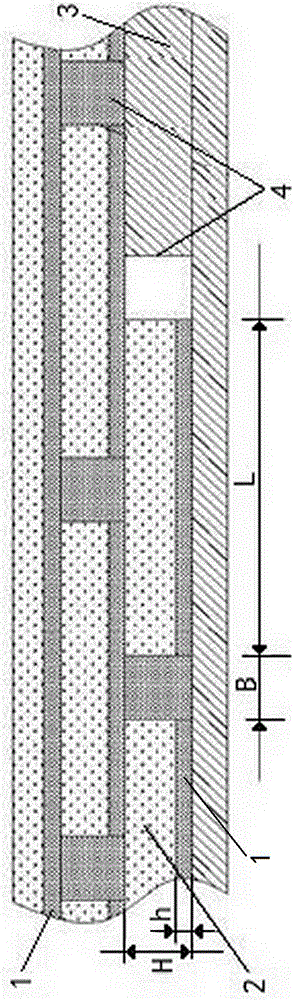

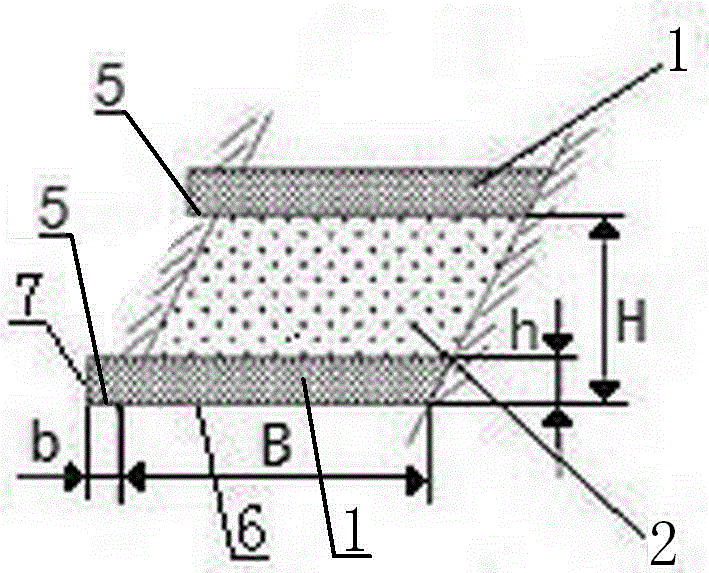

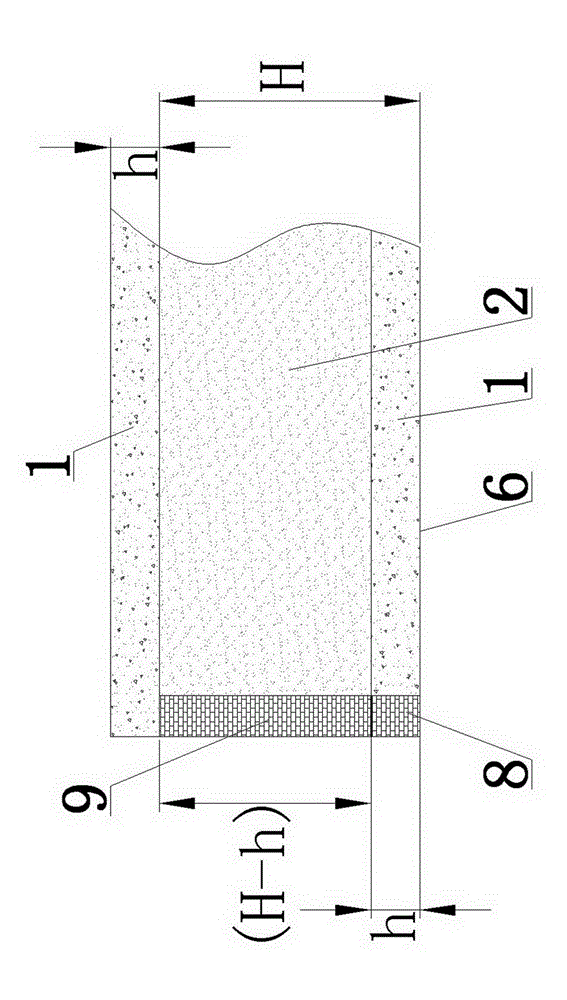

[0022]An approach-type coal mining filling method, the specific implementation steps are: ① After the mining machinery has harvested the raw coal in the stope of each approach, arrange the coal mining machinery including the mining machinery and The facilities in the field are all withdrawn from the access stope, and the access stope is naturally excavated into a filling roadway by mining machinery; ② The filling roadway is trimmed into a filling roadway with a height of H and a width of B, such as figure 1 , figure 2 , image 3 As shown, the bottom surface 6 of the filled roadway is leveled, and continuous grooves 7 are cut and dug along the direction of the filled roadway on the coal seam roof of the lower side of each filled roadway, as shown in figure 2 As shown, the height of the trench 7 is h, and the depth of the coal seam roof embedded in the lower side of the filled roadway is b, and the groove wall surface 5 at the bottom of the trench 7 is flush with the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com