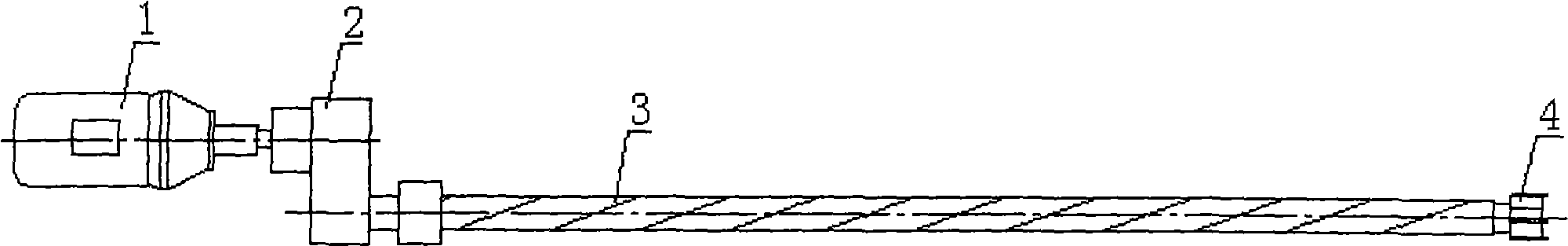

Toothed chain type method and apparatus for cutting stone

A tooth-chain and chain-type technology, applied in the field of engineering machinery and equipment, can solve problems such as difficult mining of shaped stones, inability to cut stones, difficulty in speeding up excavation, etc., to avoid rock formation damage and collapse, simple structure, Ease of use for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

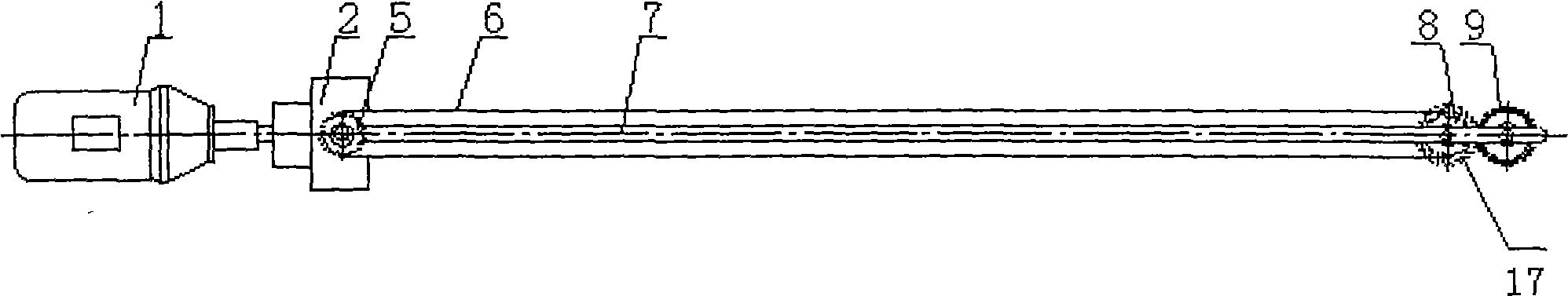

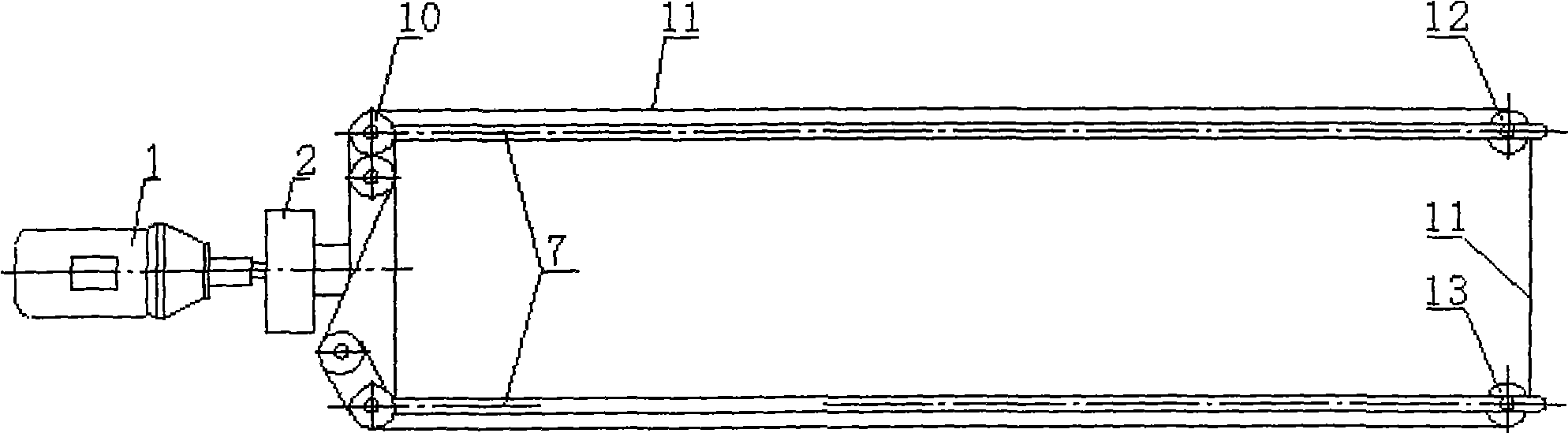

Method used

Image

Examples

Embodiment

[0036] The first step is to turn on the power supply of the drilling rig, on a certain surface of the rock mountain 16, draw a suitable dimension line according to the size of the marble to be exploited, and drill the four corners vertically to the rock mountain 16 until the required depth ; The second step is to turn on the power supply of the toothed chain saw machine, and further expand the hole into a cross groove with the hole drilled by the drilling machine; the third step is to respectively install pulleys on the front ends of the double tappets of the depth saw machine Cut the diamond rope 11, put it on the hole that has been opened into a cross groove, start the power supply, like this, the diamond rope 11 moves on the pulley rail, and is slowly pushed forward by the mechanical power to cut in depth. When the cutting is completed, the rock mountain 16 After one side, withdraw the tappet 7, and then cut the other side until the four sides of top, bottom, left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com