Superhigh-water material filled working face gangue pumping gob-side entry non-pillar mining method

A technology of backfill work and mining method, which is applied in the fields of backfill, ground mining, mining equipment, etc., to achieve the effect of reducing the intensity of mining pressure, solving the tension of excavation and replacement, and reducing the degree of stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

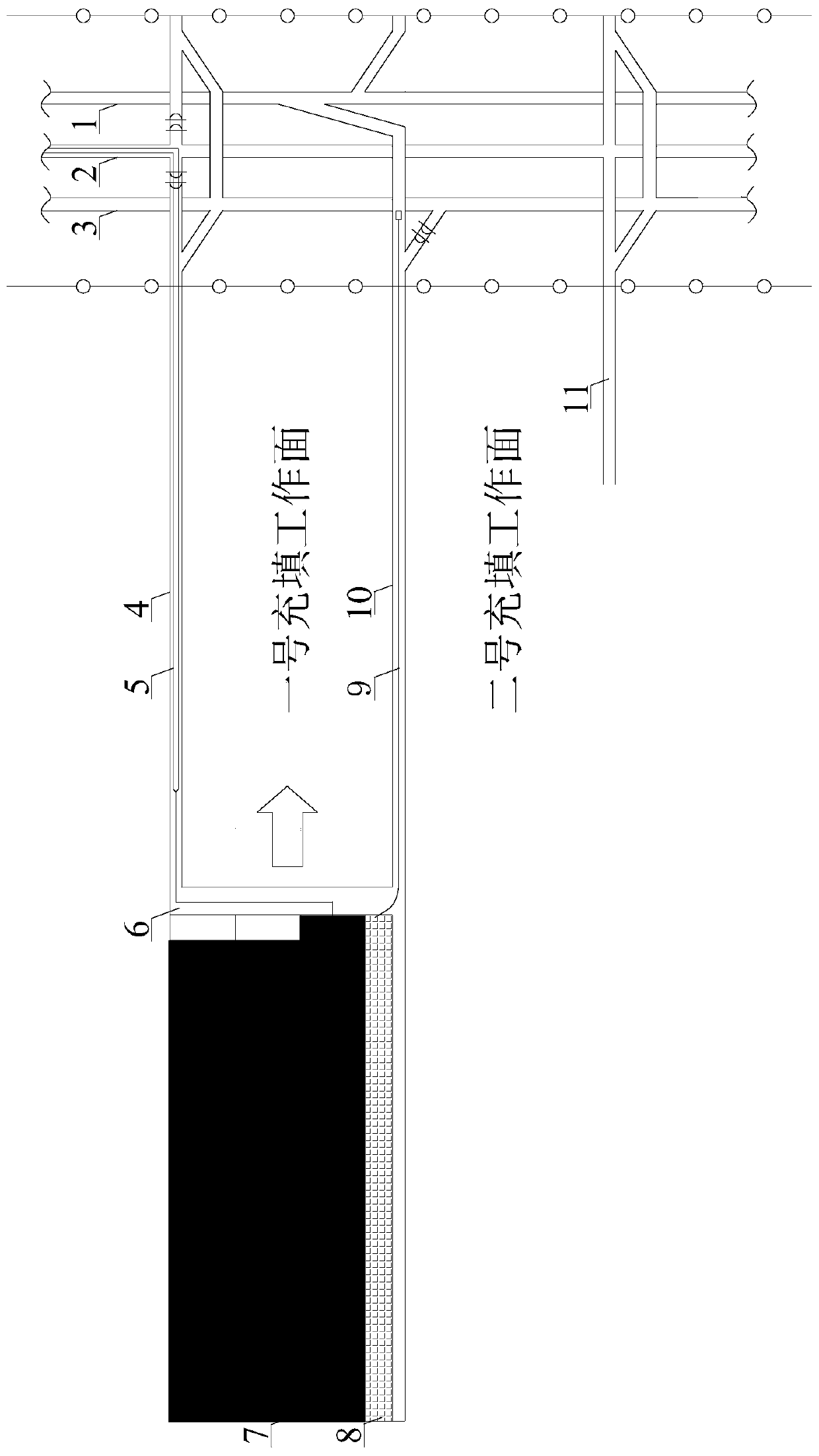

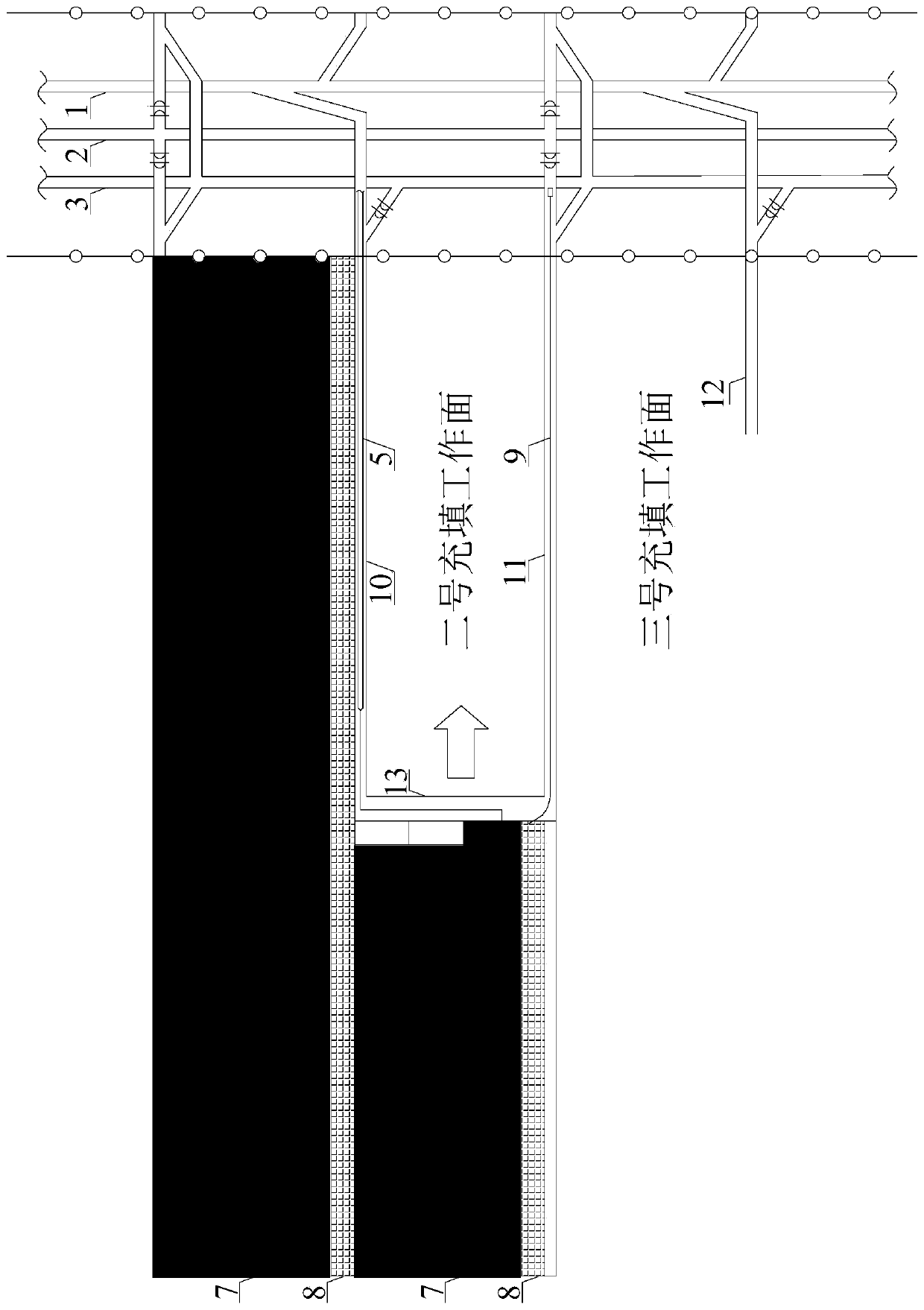

[0021] Such as figure 1 , figure 2 As shown, a coal pillar-free mining method for gangue pumping and retaining lanes in the working face filled with ultra-high water materials includes the following steps:

[0022] a. Establish an ultra-high water material filling pump station in the mine industrial square, and equip a complete ultra-high water material filling system to ensure the continuous filling of ultra-high water material 7;

[0023] b. Establish mine gangue pumping and filling system under the mine. The raw coal mined at the working face is sorted underground, and the sorted coal is transported to the surface. Go to the underground gangue treatment chamber, mix with super high water material and cement material after crushing to make pumping gangue filling body 8, and reach the side of the gob mining roadway behind the work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com