Gob-side entry retaining work mould base

An empty entry retaining and operation technology, applied in the direction of mine roof supports, pillars/supports, fillings, etc., can solve the problems of poor integrity of the formwork, damage to equipment, spillage of paste, etc., to achieve safe operation, improve the degree of mechanization, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

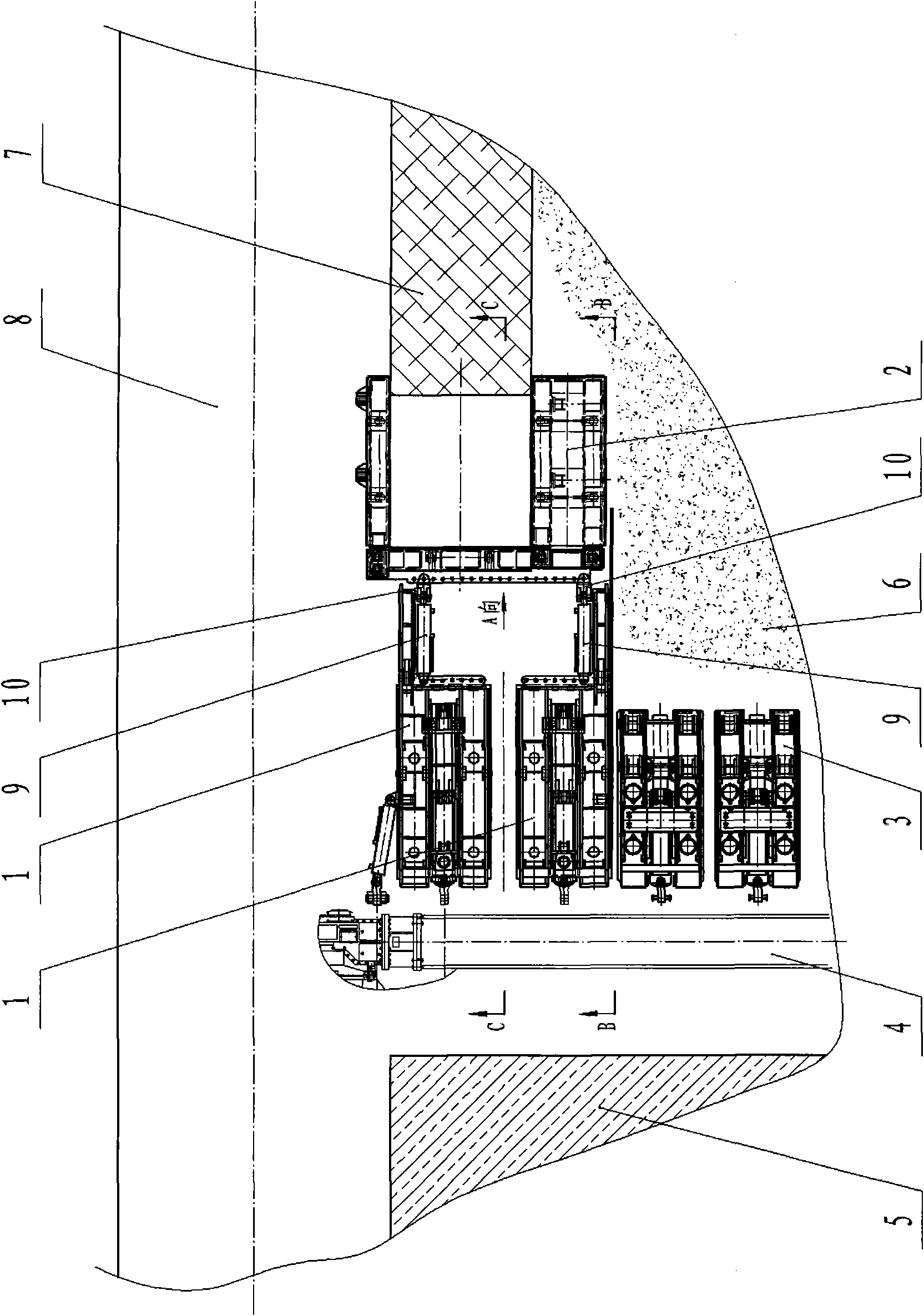

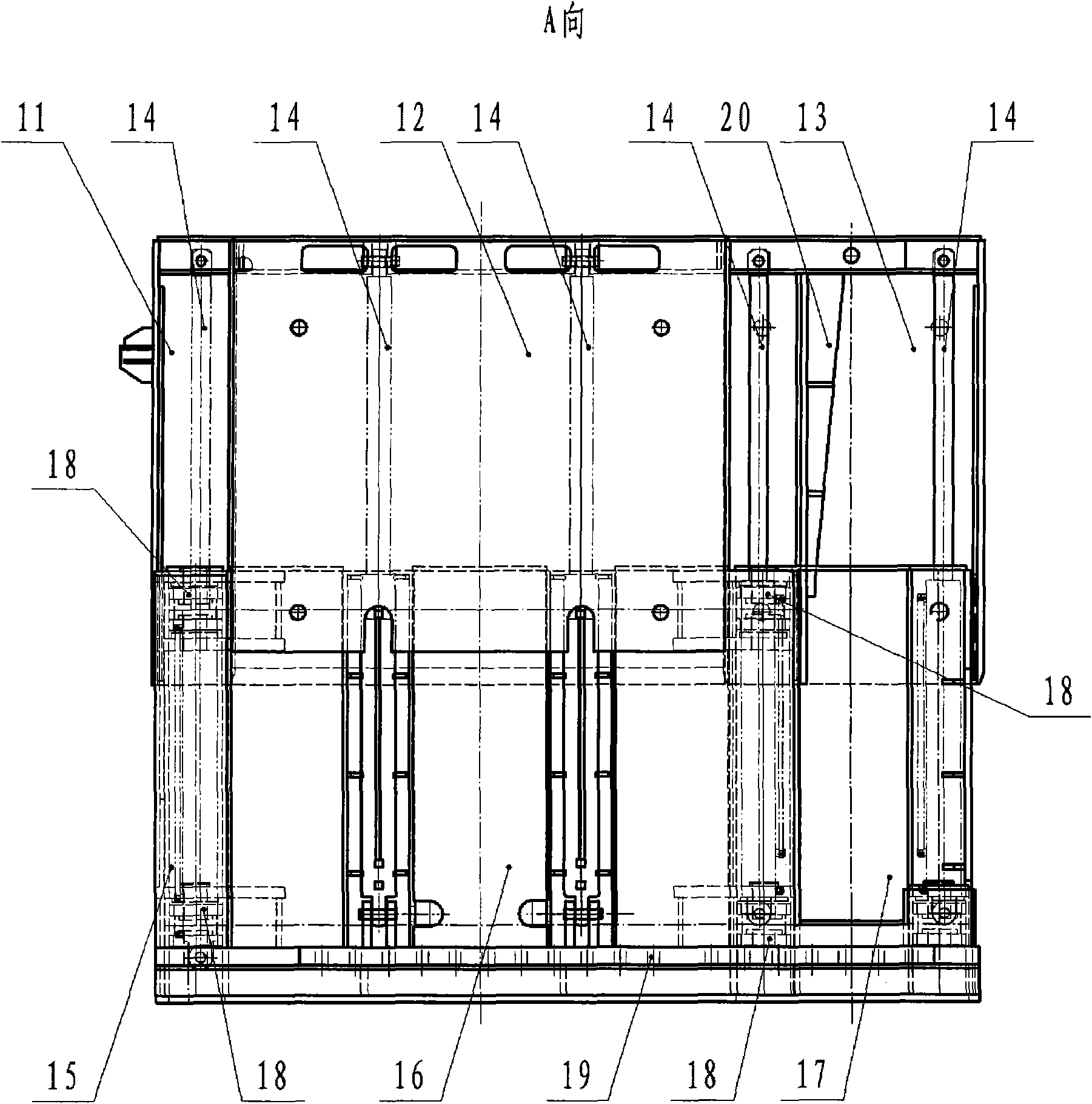

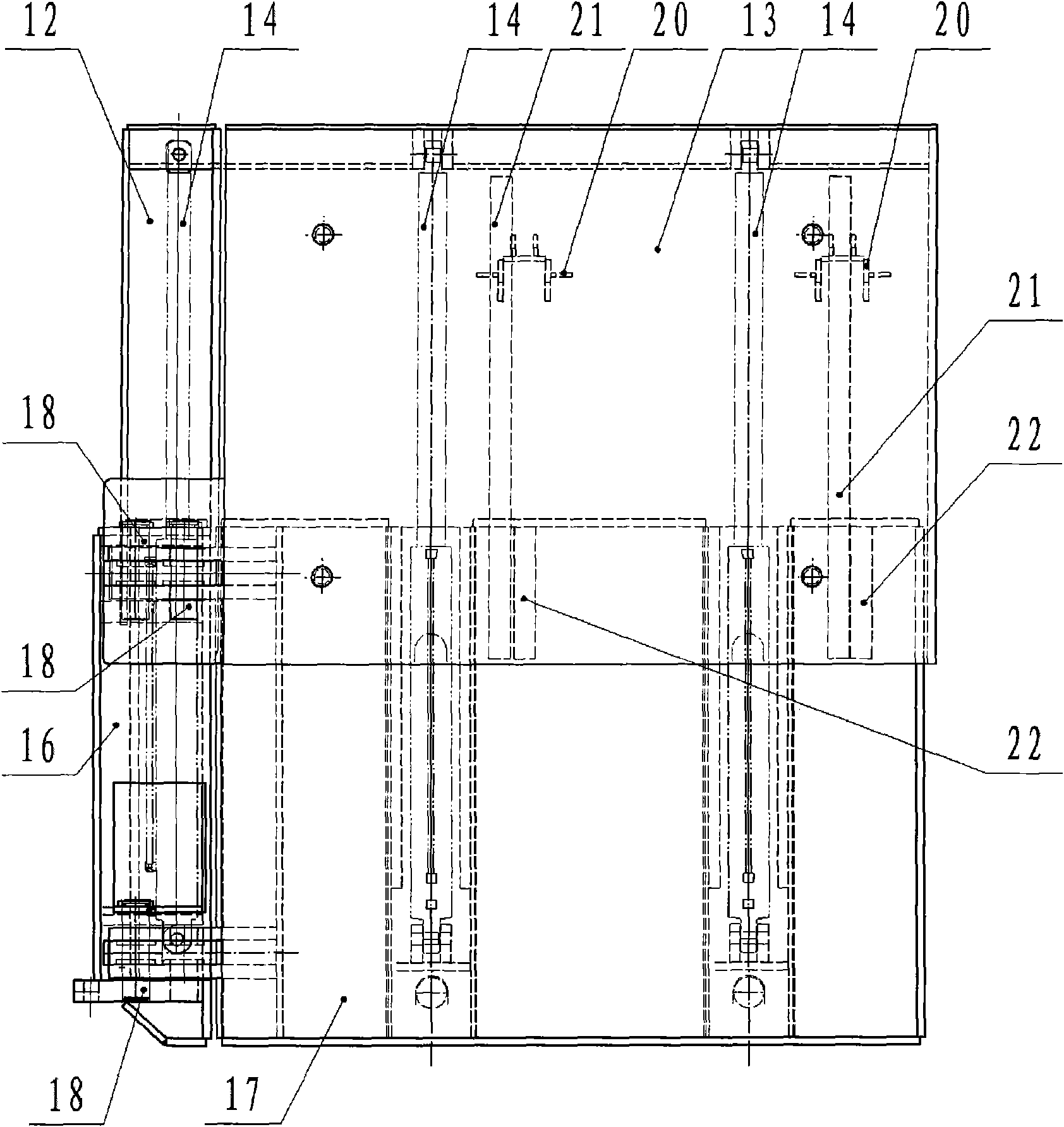

[0027] according to Figure 1~2 The specific structure of the present invention will be described in detail.

[0028] The gob-side entry retaining formwork works together with the conveyor 4 laid along the working face and the hydraulic support 3 of the common working face, and can be arranged at the nose or tail of the conveyor 4 or in front of the filling wall 7 . It can be set to include one or more baffle brackets 1 and a set of filling mold boxes 2 according to actual needs. The base 25 of the baffle bracket 1 is connected to the connecting plate on the front lower mold box 16 of the filling mold box 2 through the hydraulic cylinder 9 and the connector 10, and the baffle bracket 1 is connected to the upper baffle on the side rear of the goaf 6 The plate 30 and the lower baffle plate 31 extend between the outside of the filling formwork box 2 and the goaf 6 , and the overlapping length with the filling formwork box 2 is not less than one moving step of the baffle plate su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com