Coiled tubing hanger

A tubing hanger and tubing technology, which is used in wellbore/well components, earth-moving drilling, etc., can solve problems such as the failure of the downhole safety valve to close normally, the obstruction of the downhole safety valve, and the potential safety hazards, and is conducive to popularization and implementation. The effect of ensuring safety and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

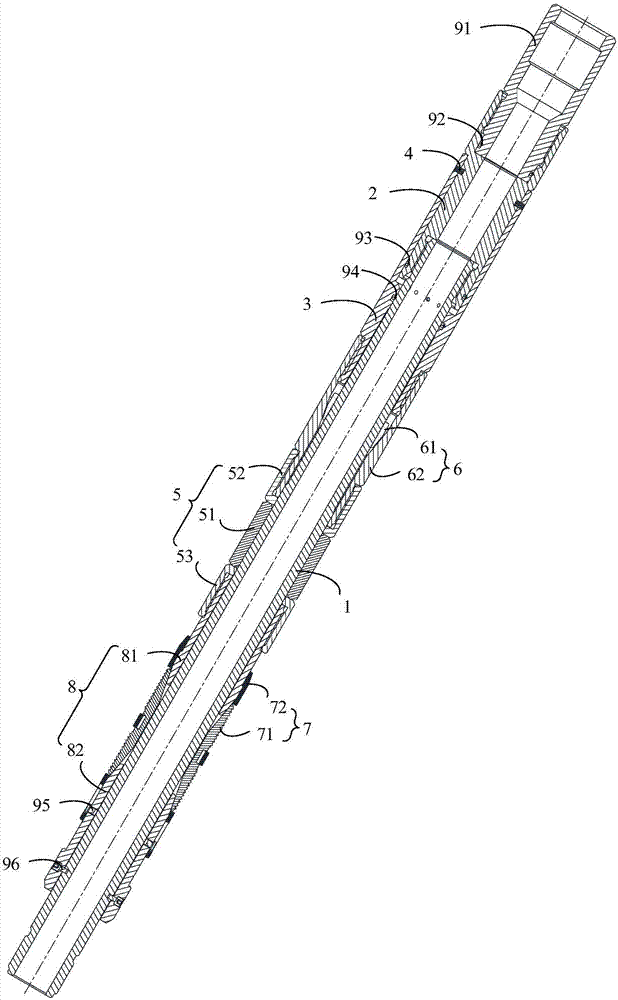

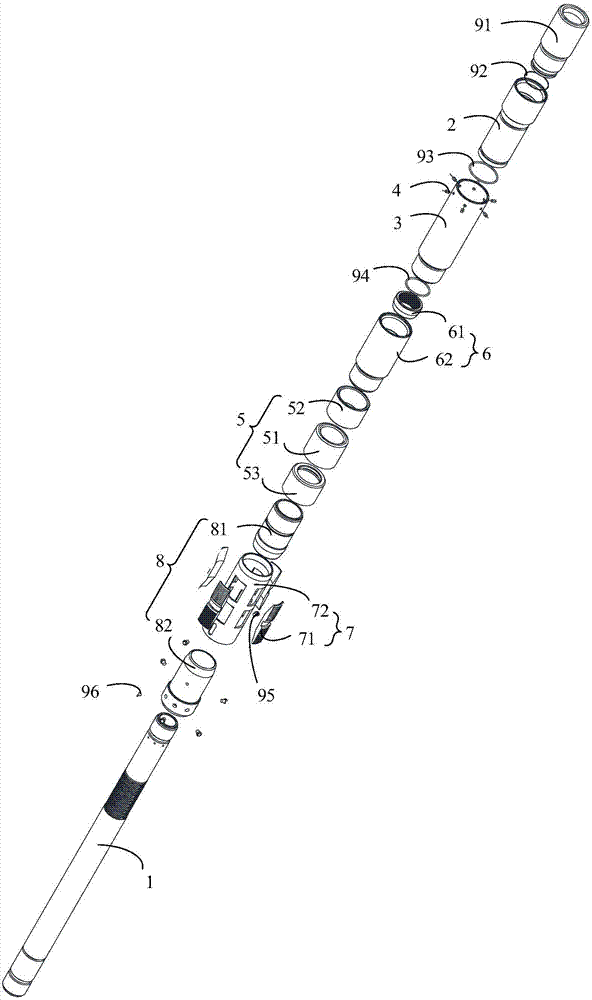

[0029] Such as figure 1 and figure 2 As shown, the embodiment of the present invention proposes a coiled tubing hanger, including a mandrel 1, an upper joint 2, a piston 3, a rubber cartridge assembly 5, a locking assembly 6, a tubing clamping assembly 7 and a slip opening guide assembly 8 . The mandrel 1 is provided with a pressure transmission hole, and the upper joint 2 is sleeved on the outer wall of the mandrel 1 and connected with the mandrel 1 . The piston 3 is sleeved on the outside of the mandrel 1 , and the piston 3 is connected to the upper joint 2 through the first shear pin 4 . A cavity is formed between the piston 3, the upper joint 2 and the mandrel 1, and the cavity communicates with the pressure transmission hole. The rubber cartridge assembly 5 is sleeved on the outer wall of the mandrel 1 for sealing the coiled tubing. The locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com