Mine recyclable steel cylinder packing pier column and construction method thereof and method for gob-side entry retaining

An empty entry retaining and steel cylinder technology, which is used in mining equipment, earthwork drilling, pillars/supports, etc., can solve the problems of low support cost, high support cost, and difficulty in recycling, and achieves less production interference and faster construction. Fast, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

[0031] 1. Mining recyclable steel cylinder sand filling pier:

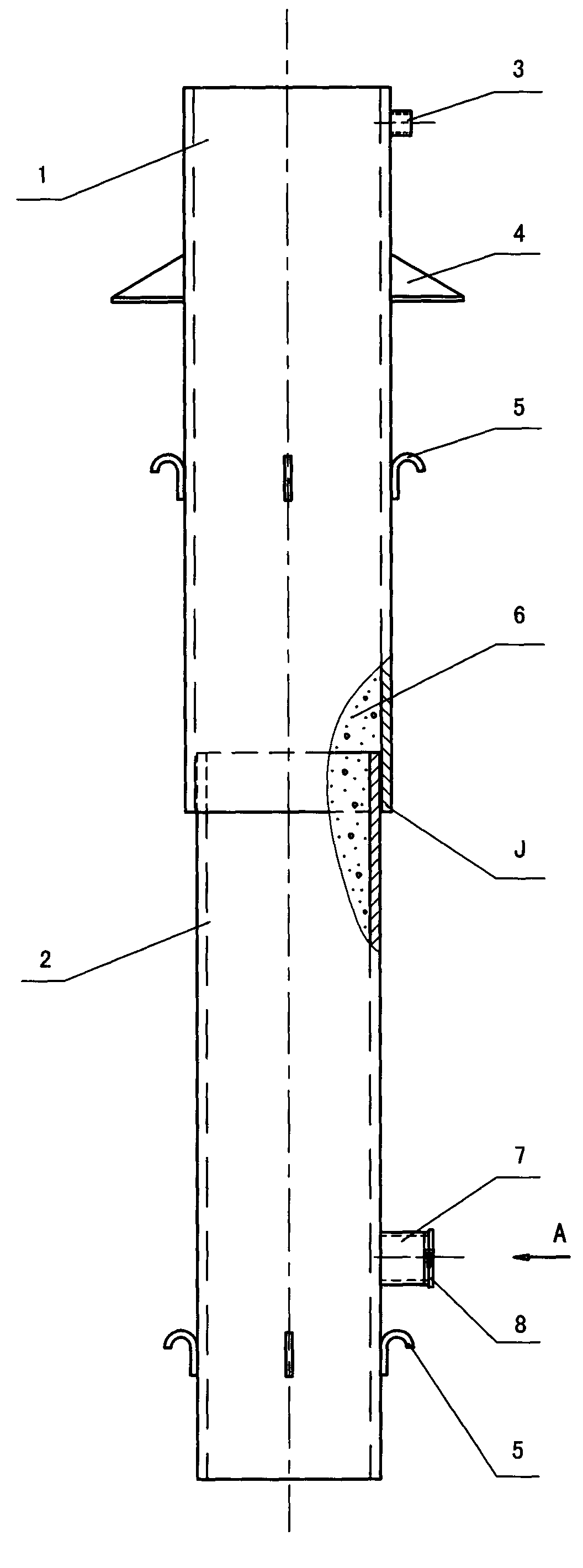

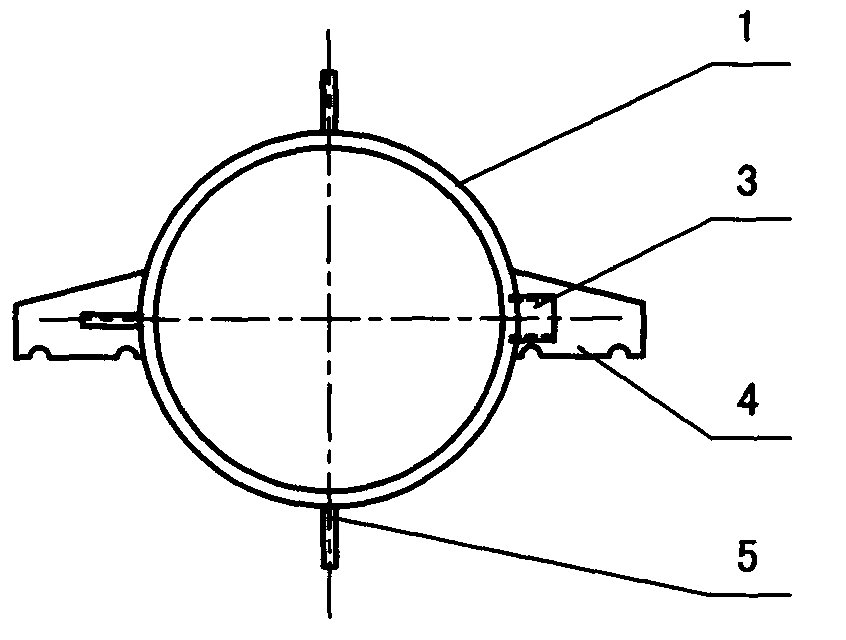

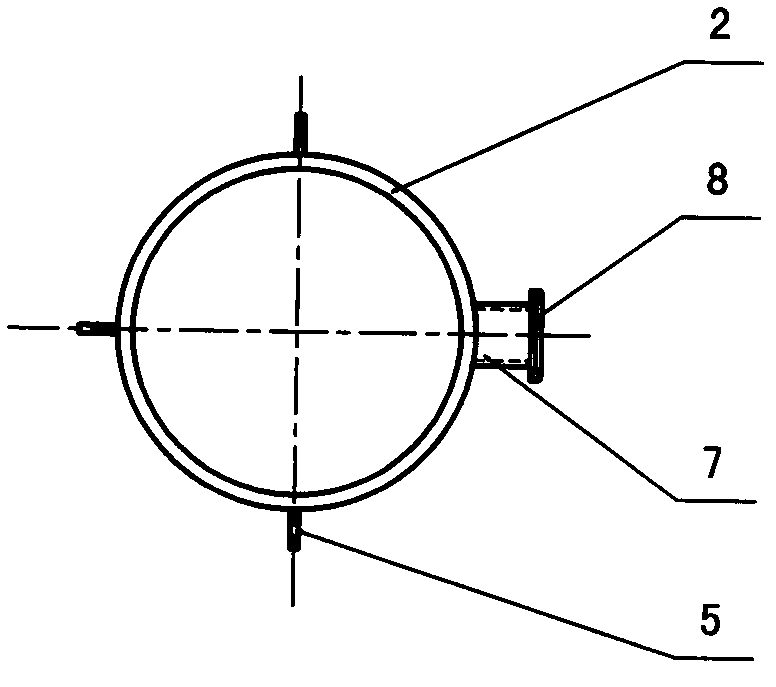

[0032] exist Figure 1~4 Shown in the present invention is the structure of the mine recyclable steel cylinder packing pier, that is, the steel cylinder sandstone packing pier. It consists of a steel cylinder mold constituting the outer wall of the pier column, and sand and gravel filler 6 filled in the steel cylinder mold.

[0033] The steel cylinder mold is a pull-type adjustable height circular steel cylinder mold; it consists of two circular steel cylinders, the upper steel cylinder 1 and the lower steel cylinder 2. There is a filling port 3 on the top of the upper steel cylinder 1 of the steel cylinder mold, that is, on the outer wall near the top; on both sides of the upper outer wall of the upper steel cylinder, there are supports for single hydraulic props or other supporting devices when supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com