Down-hole fluid heater for non-conventional energy

An unconventional heater technology, applied in the direction of production fluid, wellbore/well components, isolation devices, etc., can solve the problems of large fluid pressure loss, poor heater outlet sealing effect, low heating rate, etc., to reduce pressure loss , Improve the sealing effect of the outlet and the effect of increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

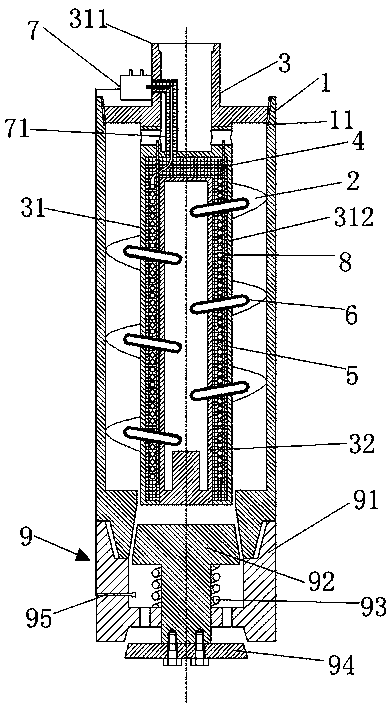

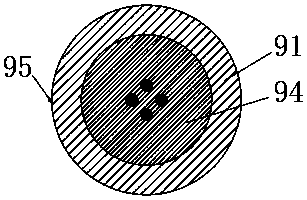

[0024] see figure 1 As shown, a downhole fluid electric heater for unconventional energy includes a shell 1, a continuous spiral baffle 2, a central tube 3, an insulating layer 4, an eddy current coil 5, a high-temperature heat pipe 6, a junction box 7, and a cooling rod 8 in one-way valve 9;

[0025] The upper part of the housing 1 is provided with a tapered internal thread, which is used to connect with the outer central pipe 31 and plays a sealing role; 31 joints are sealed.

[0026] The lower part of the housing 1 is provided with a tapered external thread for connecting with the one-way valve 9; the lower part of the housing 1 is provided with a tapered hole for cooperating with the upper valve body 92 to seal the outlet of the heater to prevent backflow of downhole fluid.

[0027] The continuous spiral baffle 2 and the central pipe 3 are welded as a whole, and the continuous spiral baffle 2 is welded as a whole by a single baffle. By splitting the continuous spiral ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com