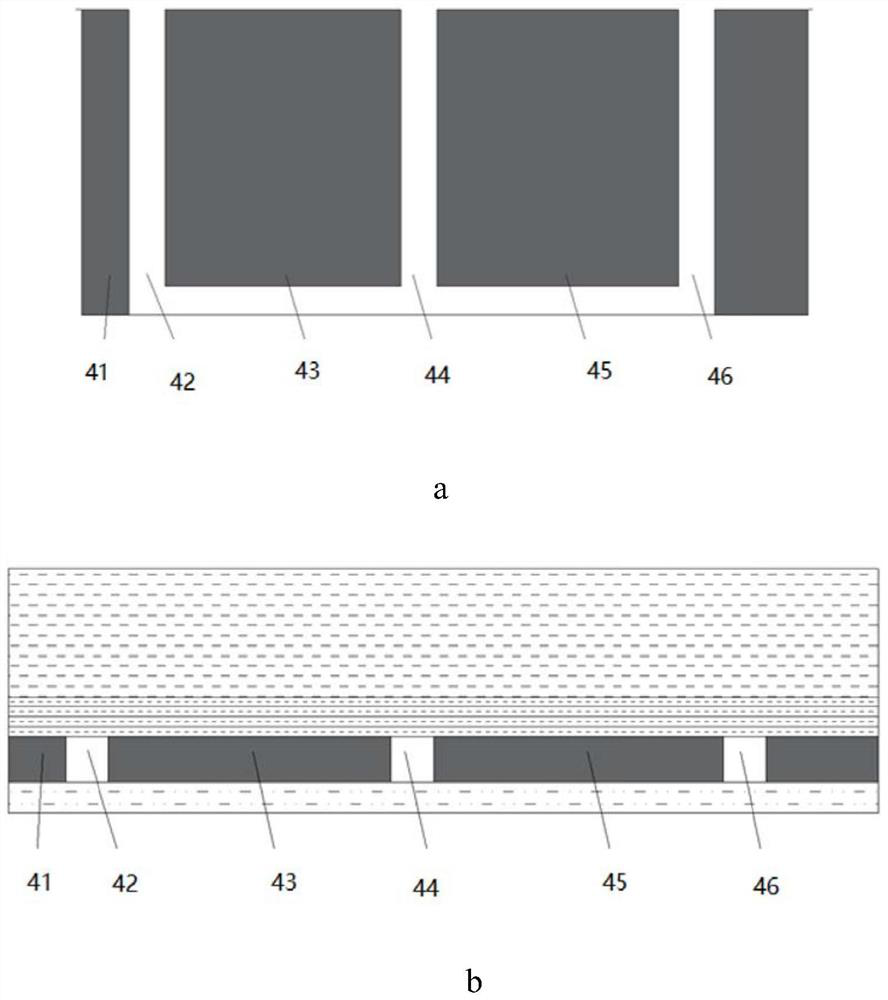

Thick coal seam confined concrete pillar roof cutting roadway forming coal pillar-free mining method

A technology that constrains concrete and mining methods. It is applied in earth cube drilling, pillars/supports, ground mining, etc., and can solve problems such as complex management systems, difficult material transportation, and low strength of filling walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

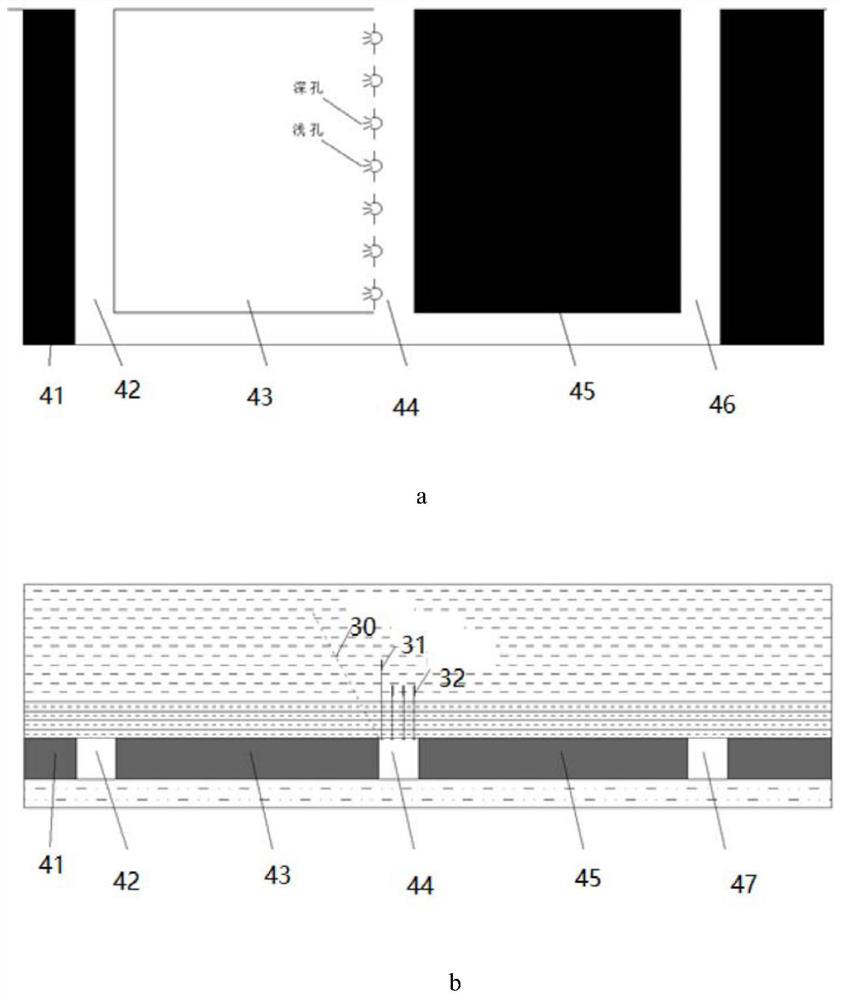

[0069] (1) Engineering conditions:

[0070] Inner Mongolia Shanbula Coal Mine 36203 Working Face Elevation The ground elevation is generally between +1254~+1327, the working face elevation is between +1105~+1125m, the vertical depth of the coal seam from the ground is 149~202m, and the ground is a typical erosive hill The landform corresponds to the dense natural forest on the surface. It is located in the Yuanjialiang area. There are no old kilns or other buildings. According to the requirements of the local government, the residents in the area of the mine field have been relocated as a whole, so the ground buildings have no impact on the mining; this area The thickness of the inner coal seam is 3.8m, the lowest is 3.2m, and the average thickness is 3.5m; the inclination length of the working face is 175.5m (1# cutout 61.5m, 2# cutout 43.9m, 3# cutout 65.1m), and the inclination angle is 0-3° , the mineable length is 1752m (the distance between 1# incision and 2# incision ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com