A method of layered paste filling the coal pillar of the stop production line in the residual mining area of the re-mined extra-thick coal seam

A technology of extra-thick coal seam and paste filling, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of affecting the safe production of coal pillars and increasing the tendency of spontaneous combustion, so as to reduce the tunneling rate, reduce waste, prevent Effects of security incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

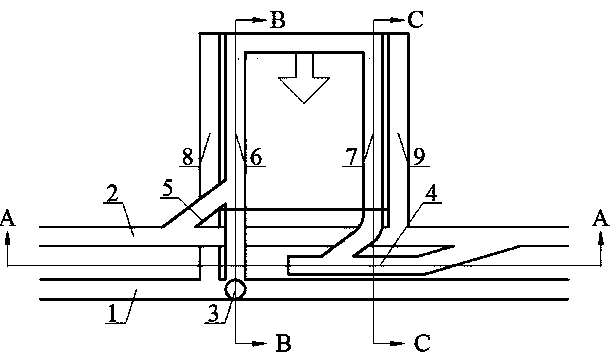

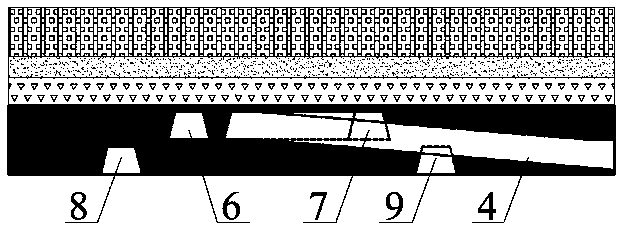

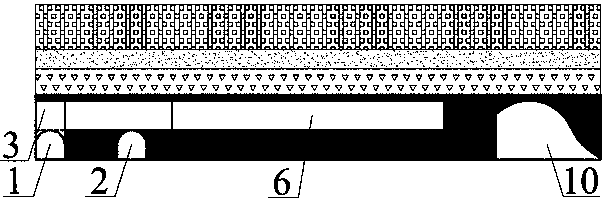

[0041] Such as figure 1 As shown, the average thickness of the coal seam in a certain mine is 8.35m, and the average inclination angle of the coal seam is 3°. According to the thickness of the coal seam, the coal pillar of the extra-thick coal seam shutdown line is divided into two layers, which are respectively recorded as Ⅰ, Ⅱ, and No. Ⅰ layered coal seam from bottom to top The thickness is 4.5m, and the thickness of No. Ⅱ layered coal seam is 3.85m.

[0042] Figure 2~Figure 4 yes figure 1 The cross-sectional diagram in the figure further illustrates the layout of the re-mining roadway.

[0043] The volume of accumulated water and the amount of gas accumulated in the goaf 10 of the original working face were detected. In order to prevent water inrush accidents in the mining roadway, the goaf of the original working face should be drained; in order to prevent gas outburst and coal seam spontaneous combustion, nitrogen and flame retardant should be injected into the goaf o...

Embodiment 2

[0051] Such as Figure 5 As shown, the average thickness of a coal seam in a certain mine is 13.76m, and the average inclination angle of the coal seam is 3°. According to the degree of the coal seam, the coal pillar of the extra-thick coal seam shutdown line is divided into 3 layers, which are respectively recorded as Ⅰ, Ⅱ, Ⅲ, and Ⅰ from bottom to top. The thickness of the seam coal seam is 5m, the thickness of the No. 2 seam is 5m, and the thickness of the No. 3 seam is 3.76m. The layered roadway is arranged in an internal staggered manner as a whole, the internal stagger distance between No. 3 layer and No. 1 layer is about 8-10m, and the internal stagger distance between No. 2 layer and No. 1 layer is about 3-5m. The order of recovery is layered recovery from top to bottom, and other steps are the same as in the previous embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com