Thin coal seam coal-pillar-free advancing type coal mining method

A coal mining method and technology without coal pillars, applied in ground mining, mining equipment, earth drilling and mining, etc., can solve the problems of difficult mining and low efficiency, achieve simple layout, high production efficiency, and improve the recovery rate of coal resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The number of mining layers in this embodiment is 1;

[0076] According to the ventilation system of the mining area and the layout of the mining area, select the location of the first mining face.

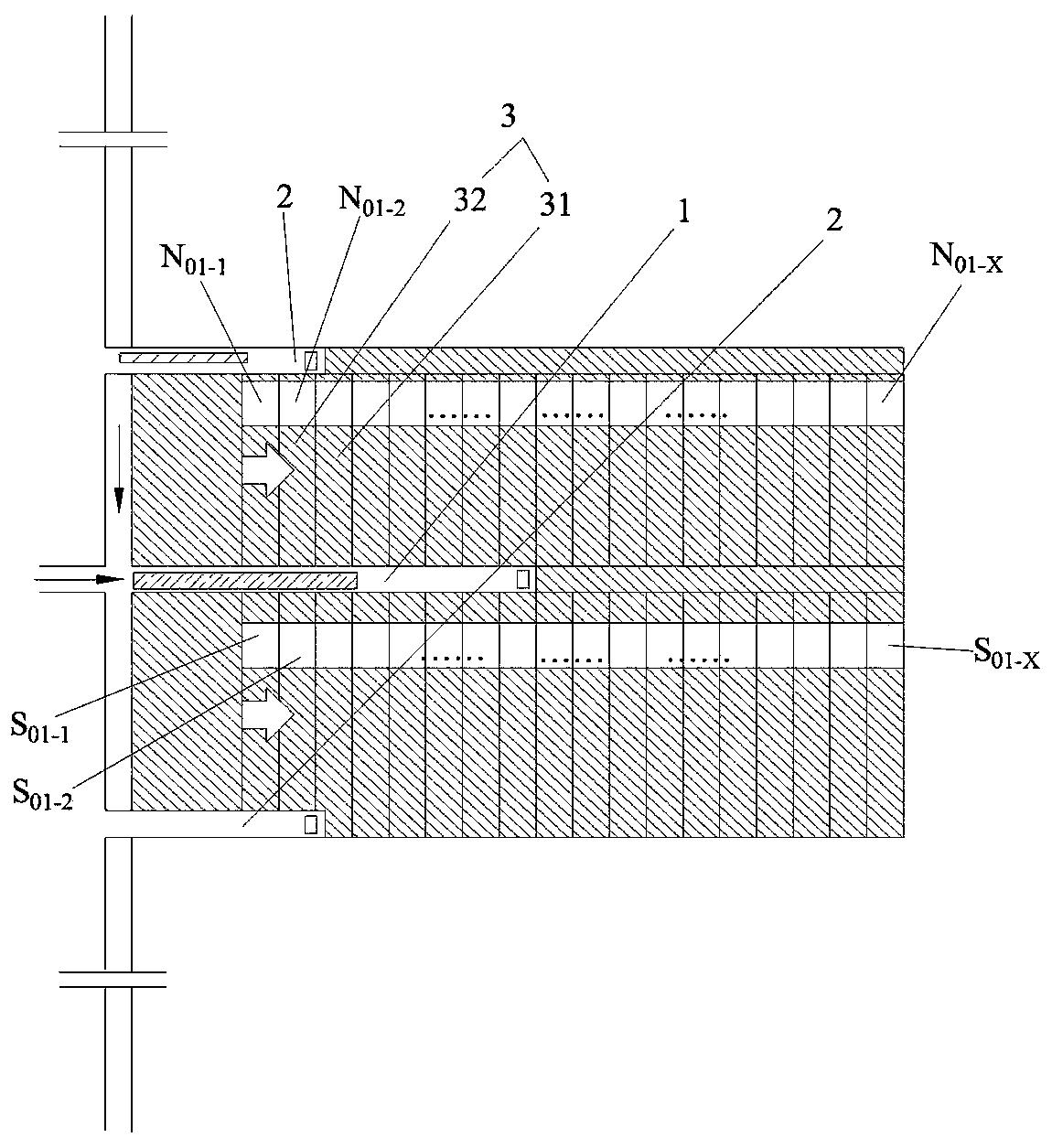

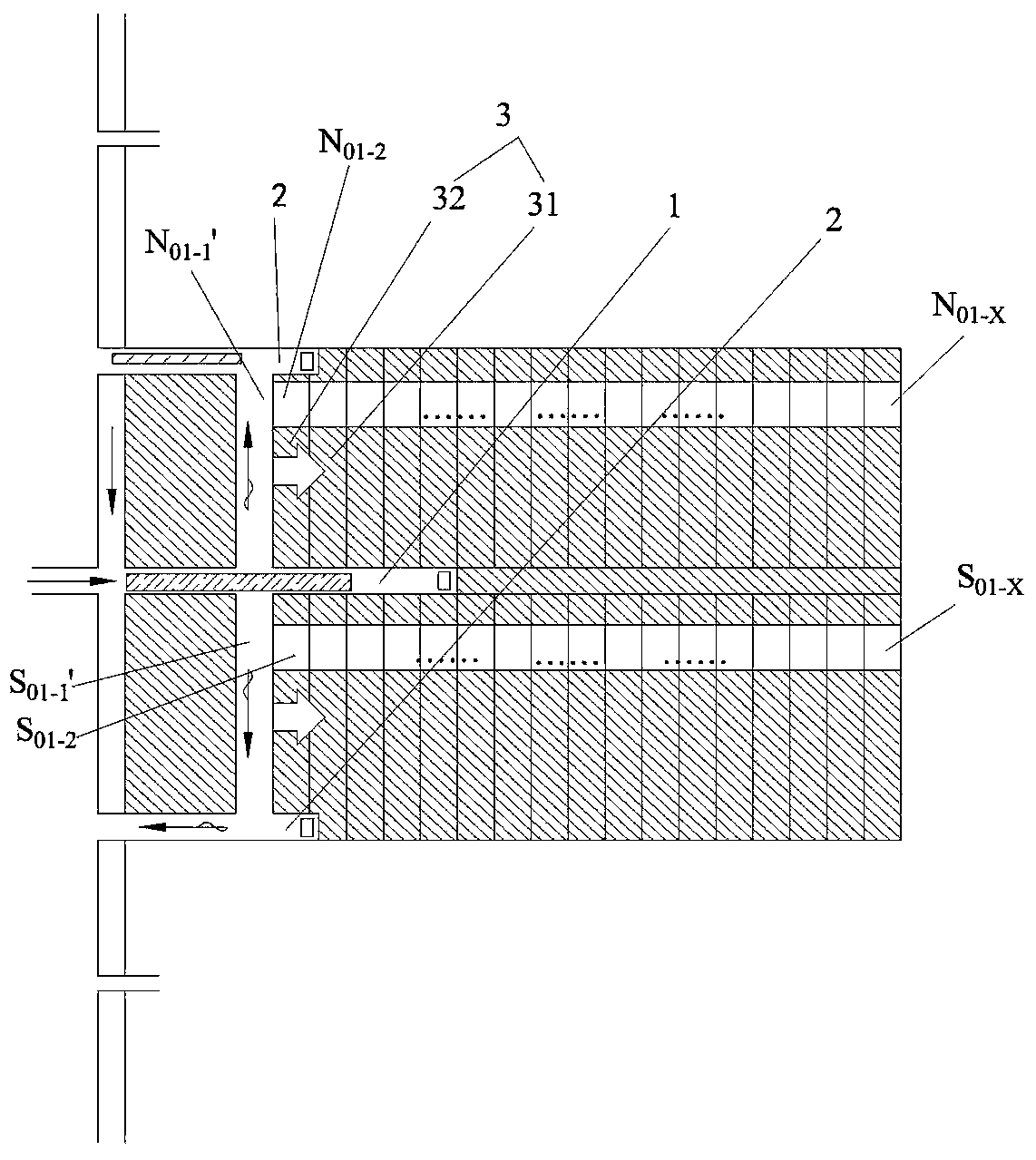

[0077] Arrange the roadheader to advance the main roadway at the opening of the main machine roadway of the coal mining machine; arrange the roadheader to advance the two auxiliary roadways at the opening of the solid waste slurry transportation roadway. figure 1 The leftmost end of , and with the mining of working area 3, the main roadway and auxiliary roadway are gradually excavated.

[0078] Further, local ventilators are used to ventilate the roadway during excavation.

[0079] Further, the protective coal pillar of the main roadway in the mining area is 25m, and the width of the working area is set to 3m. In view of the fact that the diffusion ventilation length is not greater than 5m, the auxiliary roadway is not more than 5m ahead of the working area being mined;

...

Embodiment 2

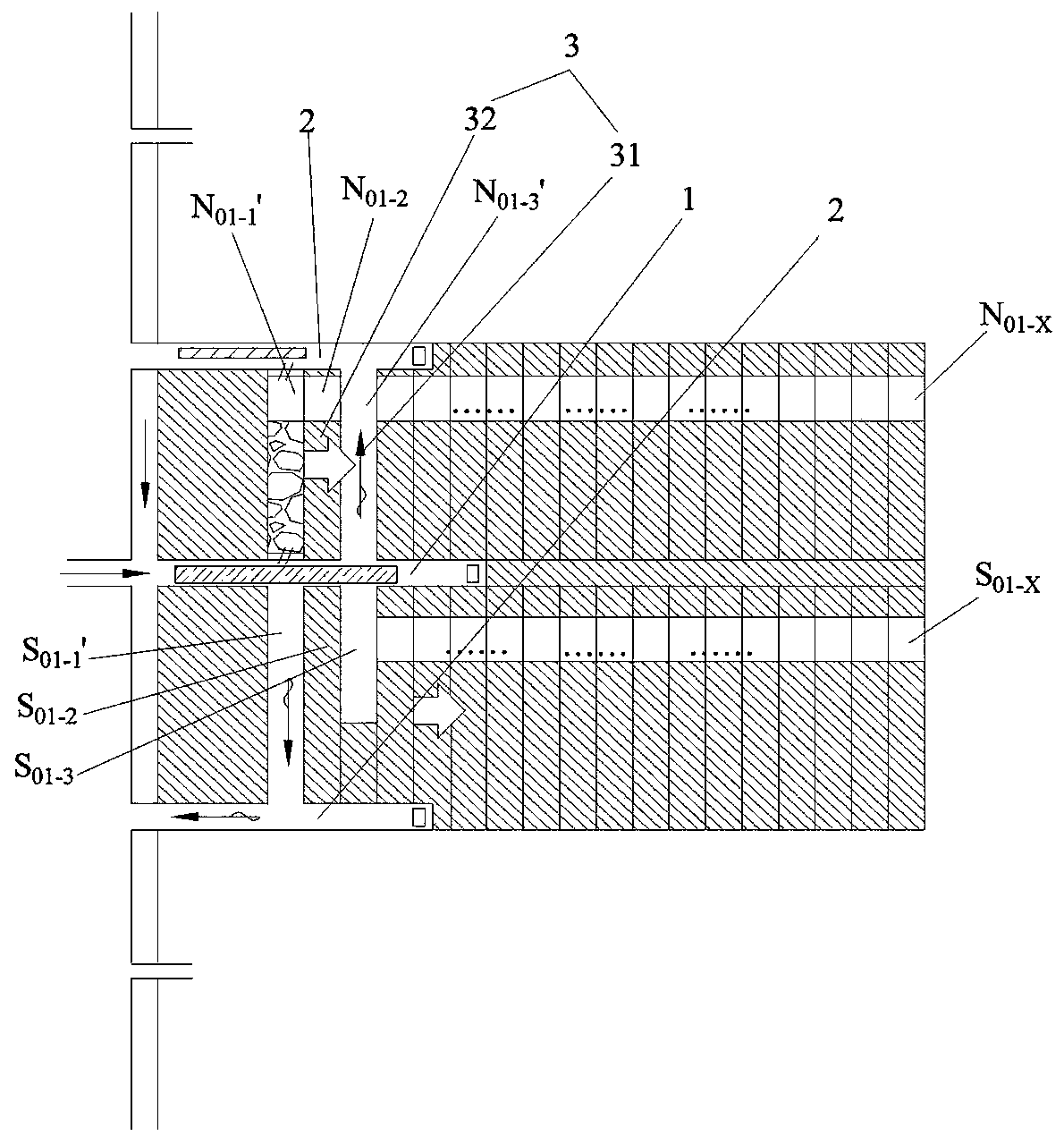

[0108] The inclination angle of the coal seam is 8~10°, the average thickness of the first coal layer (the upper mining layer) is 1.1m, the average thickness of the second coal layer (the lower mining layer) is 0.8m, and the argillaceous sandstone with an average thickness of 1.2m is between the two coal layers;

[0109] The difference with Embodiment 1 is that the coal mine area is divided into two mining layers, such as Figure 7 As shown, and the mining layer of the lower layer is preferentially mined;

[0110] When mining the lower mining layer, it is necessary to fill all odd-numbered and even-numbered working areas with non-polluting solid waste; the schematic diagram of the completion of the mining of the lower mining layer is shown Figure 8 shown.

[0111] After the mining of the lower mining layer is completed, repair the main roadway and auxiliary roadway of the lower mining layer:

[0112] Withdraw the equipment in the main roadway and auxiliary roadway of the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com