A coal mining method for pre-mining layered and broken top coal in the middle of extra thick coal seam

A technology of extra-thick coal seam and coal mining method, which is applied in special mining, ground mining, earthwork drilling and mining, etc. It can solve the problems of frequent relocation, high cost of filling materials, and low work efficiency, so as to reduce layered mining The effect of reducing the number of times, reducing the tunneling rate, and improving the resource recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

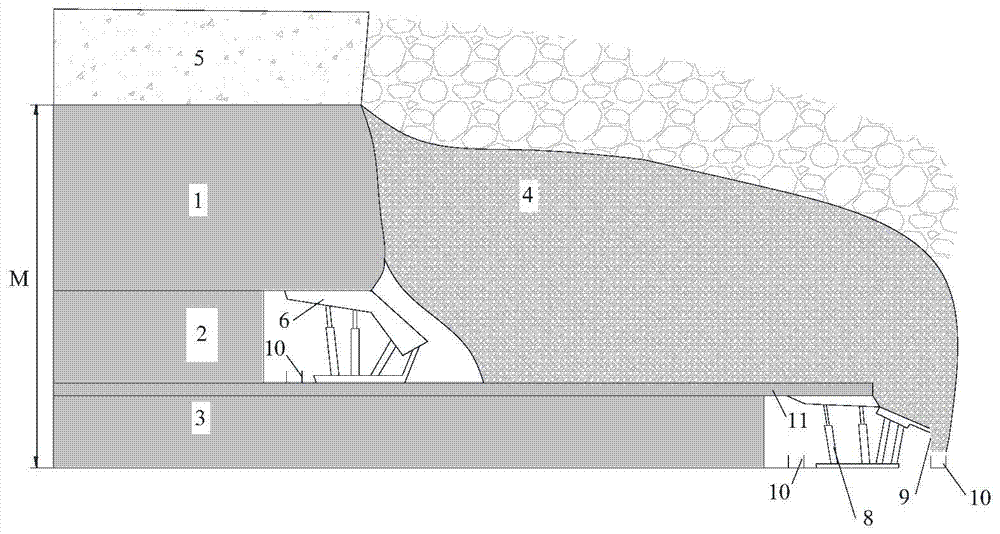

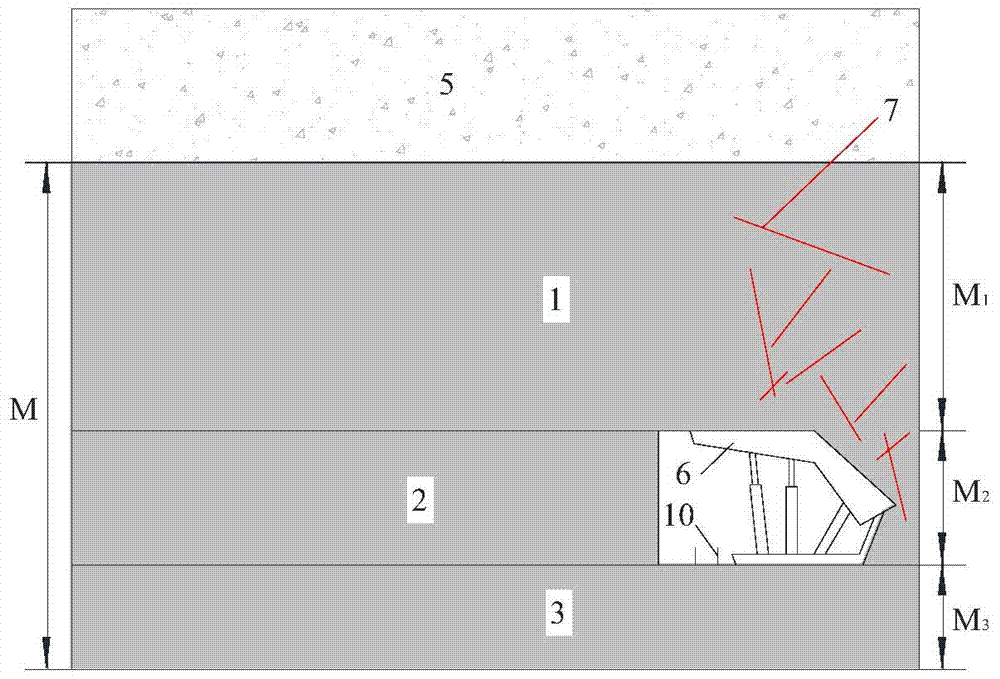

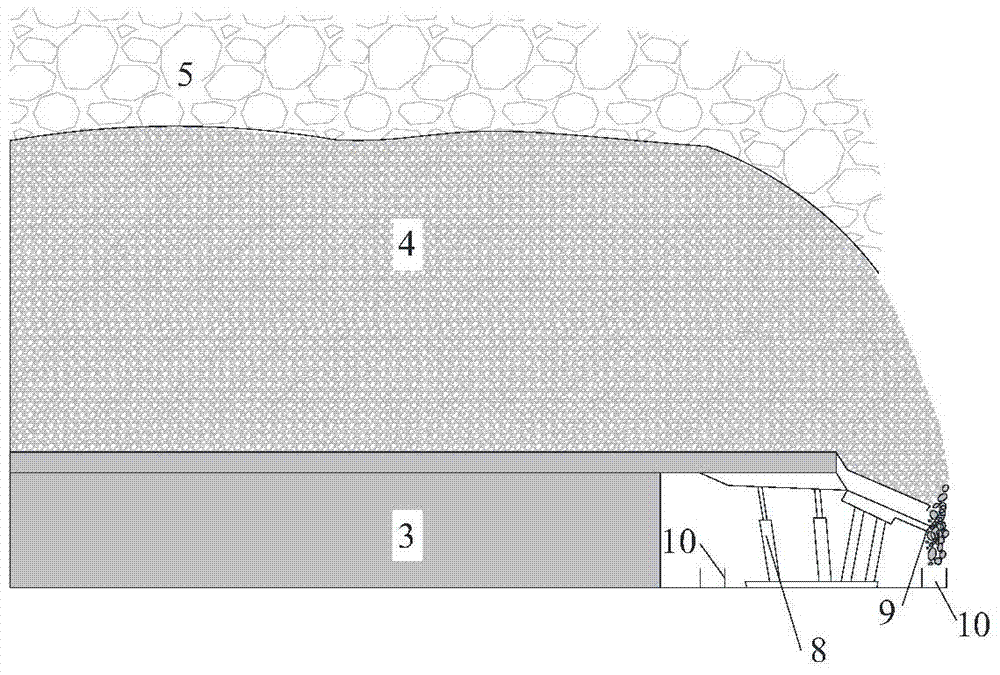

[0020] refer to figure 1 , 2 , 3 The embodiment of the present invention is described, a kind of coal mining method of pre-mining layered broken top coal in the middle of an extra-thick coal seam divides the coal seam with a thickness of M into the upper coal body 1 of the coal seam, and the thickness is M 1 ; Coal body 2 in the middle of the coal seam, the thickness is M 2 ; Coal body 3 in the lower part of the coal seam, the thickness is M 3 . Firstly, the coal body 2 in the middle of the coal seam is arranged to arrange a longwall working face with a mining height of 3-7m, and the working face is equipped with fully mechanized mining or large mining height equipment for recovery, and the fully mechanized mining hydraulic support 6 is selected according to the situation to carry out the recovery of the coal body 2 in the middle of the coal seam. The mined coal body is transported out of the working face by the scraper conveyor 10, and advances with the working face, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com