A method of layered mining of extremely thick coal seams

A technology of layered mining and coal seam, applied in the field of safe and efficient mining of huge thick coal seams, can solve the problems of complex filling process, complex roadway layout, no mining method, etc., achieve simple roadway layout system, reduce roadway excavation rate and production cost, Economically significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

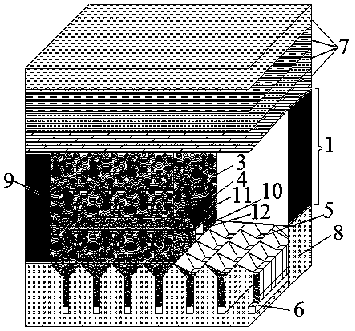

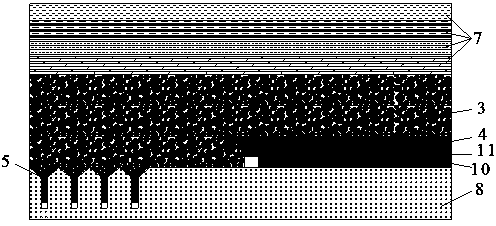

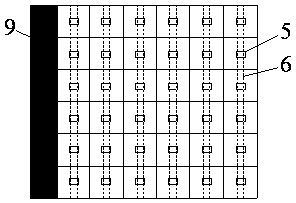

[0023] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0024] Such as Figure 1 to Figure 6 As shown, a section working face of a certain mine is selected to mine a huge thick coal seam, and the specific implementation method is as follows:

[0025] The first step is to divide the layers: according to the relevant regulations, the huge thick coal seam 1 is divided into several layers 2 according to the fully mechanized top-coal caving mining process. Considering the broken expansion of the reserved layer 4, it is required that the reserved layer 4 of each layer can be filled completely The stratum 2 goaf. In this embodiment, the huge thick coal seam is 72m thick, and its residual disintegration coefficient is 1.2, according to h=M / (K-1) (wherein h is the required top-coal thickness for filling the goaf, and M is the machine mining height, which is 4m , K is the residual disintegration coefficient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com