A method for retaining entry along the gob in fully mechanized caving face in high-gas three-soft and extremely unstable coal seam

A technology for fully mechanized caving face and working face, which is applied to ground mining, earthwork drilling, shaft equipment, etc., can solve the problems of low wall strength, tight mining continuity, and large investment in equipment and systems, so as to improve the recovery rate of coal resources. , Relieve the tension of succession, and the effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

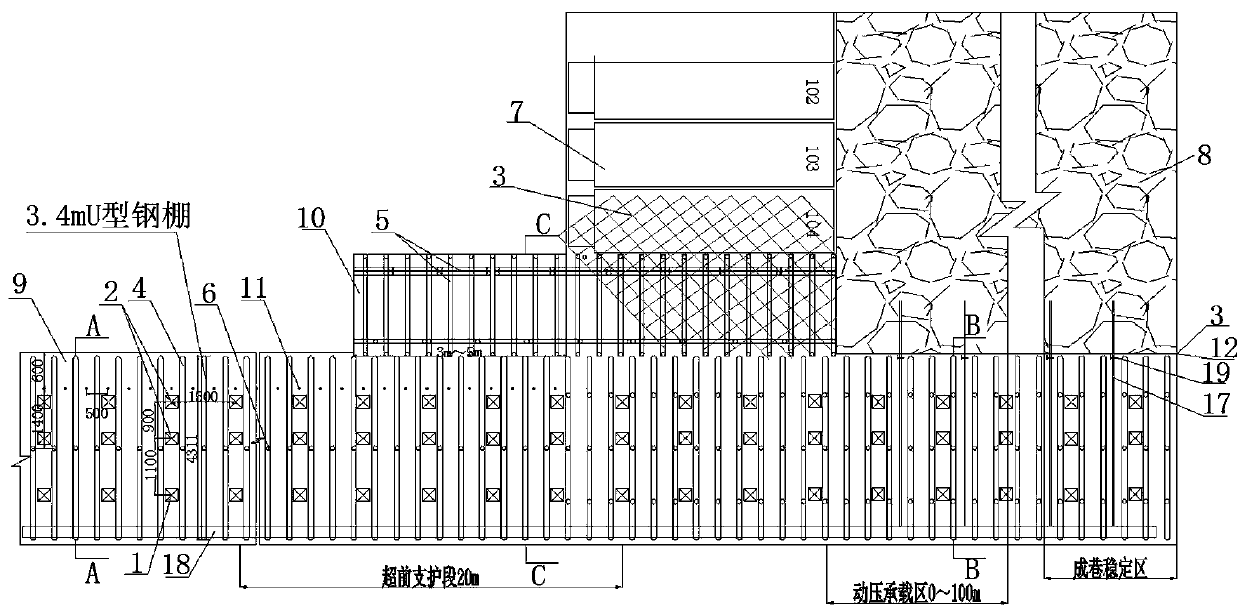

[0075] Such as figure 1 , 2 , 3, 4, 5, 6, 11, 12, 13 and 14, a kind of high gas three soft extremely unstable coal seam fully mechanized caving face method for retaining entry along the gob, comprising the following steps:

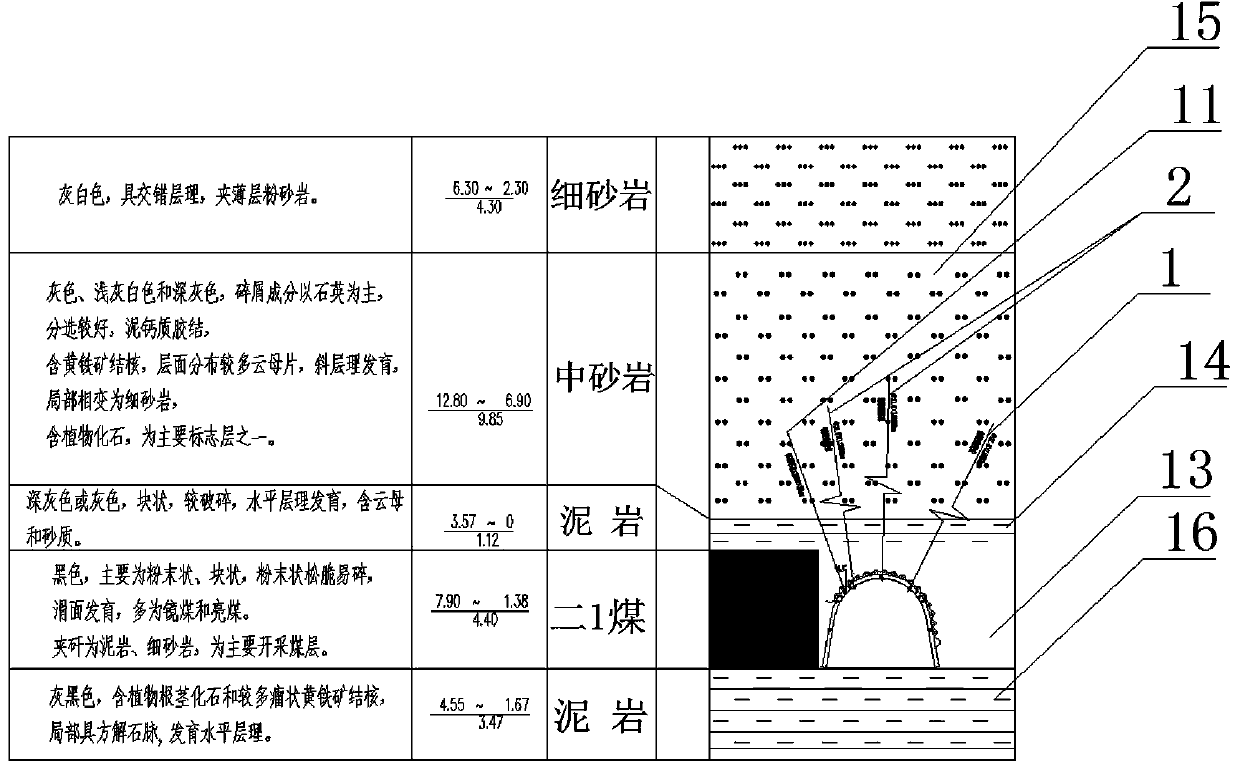

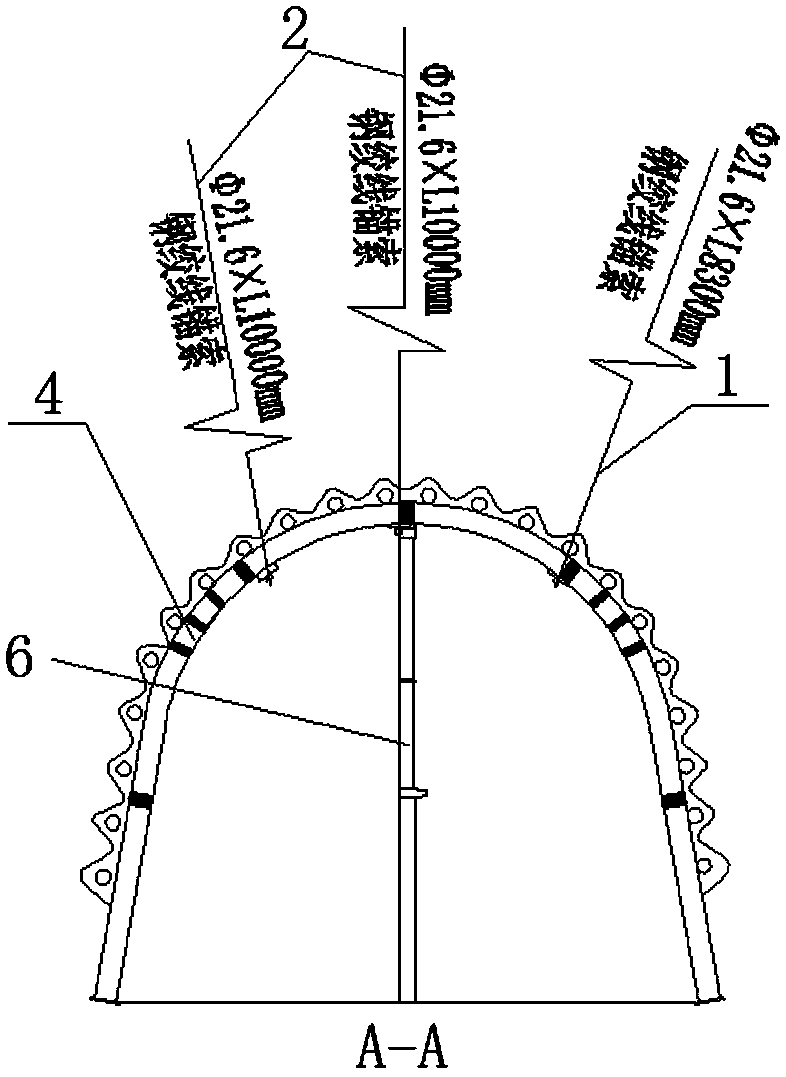

[0076] (1) if figure 2 As shown, the soft roof 14 of the roadway supported by the original one-time U-shaped steel frame shed is supported by two rows of constant resistance anchor cables 2, and the constant resistance anchor cables 2 are installed on the soft roof 14 of the roadway near the goaf 8 side, and the constant resistance anchor cable 2 is perpendicular to the roadway soft roof 14, and the constant resistance anchor cable 2 anchors the soft roof 14 on the hard roof 15 above the soft roof 14;

[0077] (2) if figure 2 As shown, the cutting hole 11 is constructed on the roof of the goaf 8 side roadway 50m ahead of the working face and directional pre-splitting blasting is carried out, and the effective anchorage range of the constant resistance...

Embodiment 2

[0099] Such as Figure 7 , 8 Shown in , 9, 10, 11, 12, 13 and 14, a kind of high gas three soft extremely unstable coal seam fully mechanized caving face method for retaining entry along the gob, comprising the following steps:

[0100] (a) if Figure 8 As shown, the soft roof 14 of the roadway supported by the original one-time anchor net cable is reinforced by two rows of constant resistance anchor cables 2, and the constant resistance anchor cables 2 are installed on the side of the soft roof 14 of the roadway near the goaf 8 , and the constant resistance anchor cable 2 is perpendicular to the roadway soft roof 14, and the constant resistance anchor cable 2 anchors the soft roof 14 on the hard roof 15 above the soft roof 14;

[0101] (b) if Figure 8 As shown, the cutting hole 11 is constructed on the roof of the goaf 8 side roadway 50m ahead of the working face and directional pre-splitting blasting is carried out, and the effective anchorage range of the constant resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com