Method for supporting retained gob-side entry of blasting-mining working faces of small-area thin seam

A technology of working face and coal seam blasting, which is applied in the field of gobside entry support in small-area thin coal seam blast mining face, and can solve the problems of scientific support methods and safety hazards in blast mining face without small area thin coal seam, etc. To achieve the effect of preventing natural ignition and harmful gas from entering the working face, maintaining stability and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] combined with Figures 1 to 3 The specific embodiment of the present invention is described further:

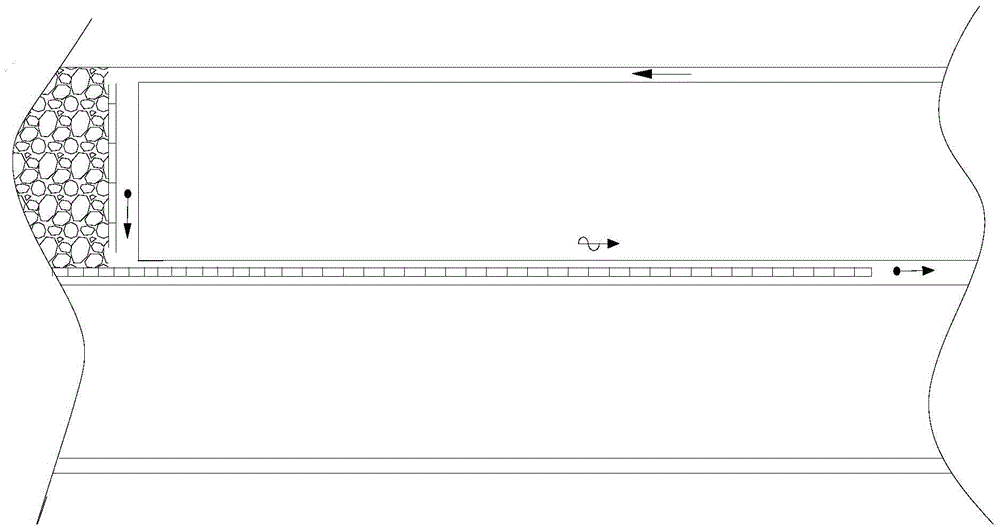

[0037] The scheme design of the pulling working face is as follows: figure 1 shown.

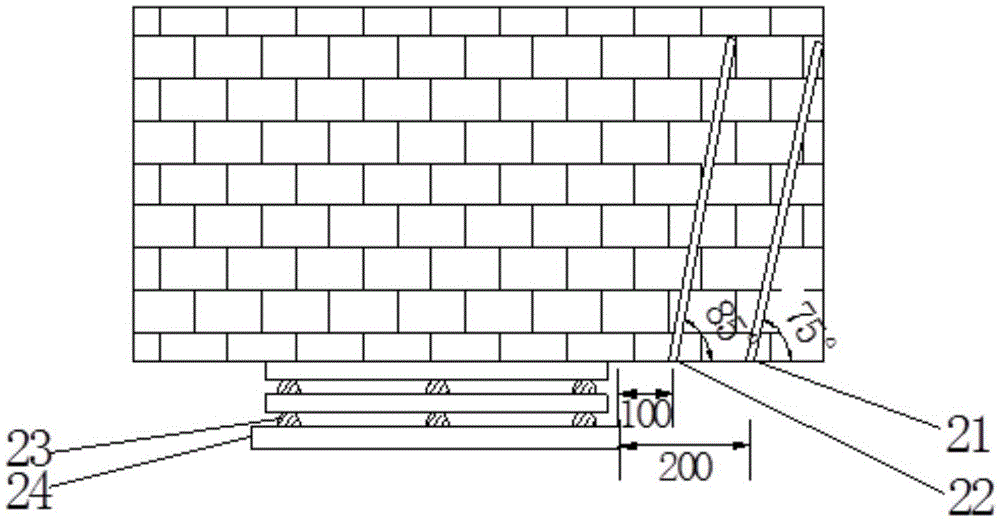

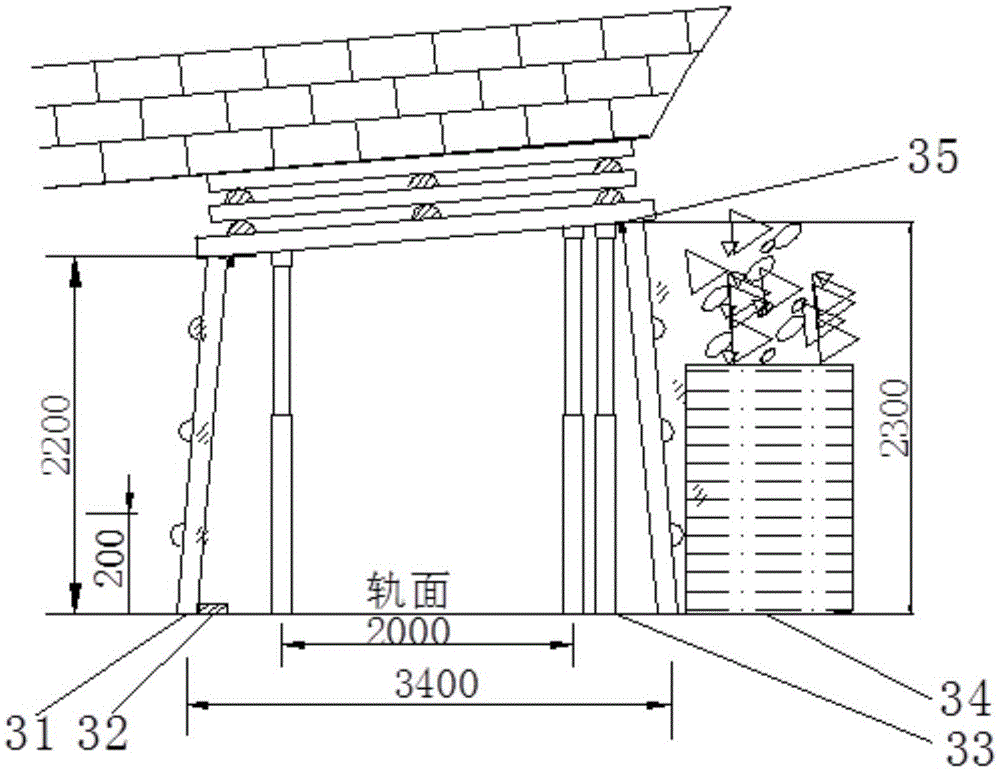

[0038] Support schemes such as figure 2 image 3 As shown, the process is: supplementary bolting 20m ahead of the working face, the row spacing is 1.0m, four bolts in each row, and the bolt specification is Φ22×2000mm; the method of advancing the coal wall is used to erect the shed, and the I-shaped steel shed The coal wall distance of the advanced working face shall not exceed 4m.

[0039] Before the shed is advanced, the gangue on the floor of the shed area is cleaned manually with a pick, and the cleaned gangue is manually transferred to the original belt conveyor transportation system to be transported to the ground. Safety. Before installing the beam, first check the section width of the roadway according to the center line, and measure the height of the roadway. If it doe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com