Comprehensive coal-mining process by using long wall mining method

A fully mechanized mining face and longwall technology, applied in ground mining, earth square drilling, underground mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The longwall coal mining method of the present invention is suitable for mining medium-thick coal seams with stable coal seams, hard roofs, simple geological structures, no faults or few faults, and gentle inclinations; it can also be selected according to the height that is convenient for mining, about 2.5m to 3.5m, Thick coal seams are mined in layers. Adopt the single-trend longwall working face full subsidence method for mining.

[0022] The fully mechanized mining face adopts super-long layout, and its face length is arranged according to the length of two traditional fully mechanized mining faces, that is, the length of the super long fully mechanized mining face can be set at 300m-1000m, and its optimal value is 360m-610m.

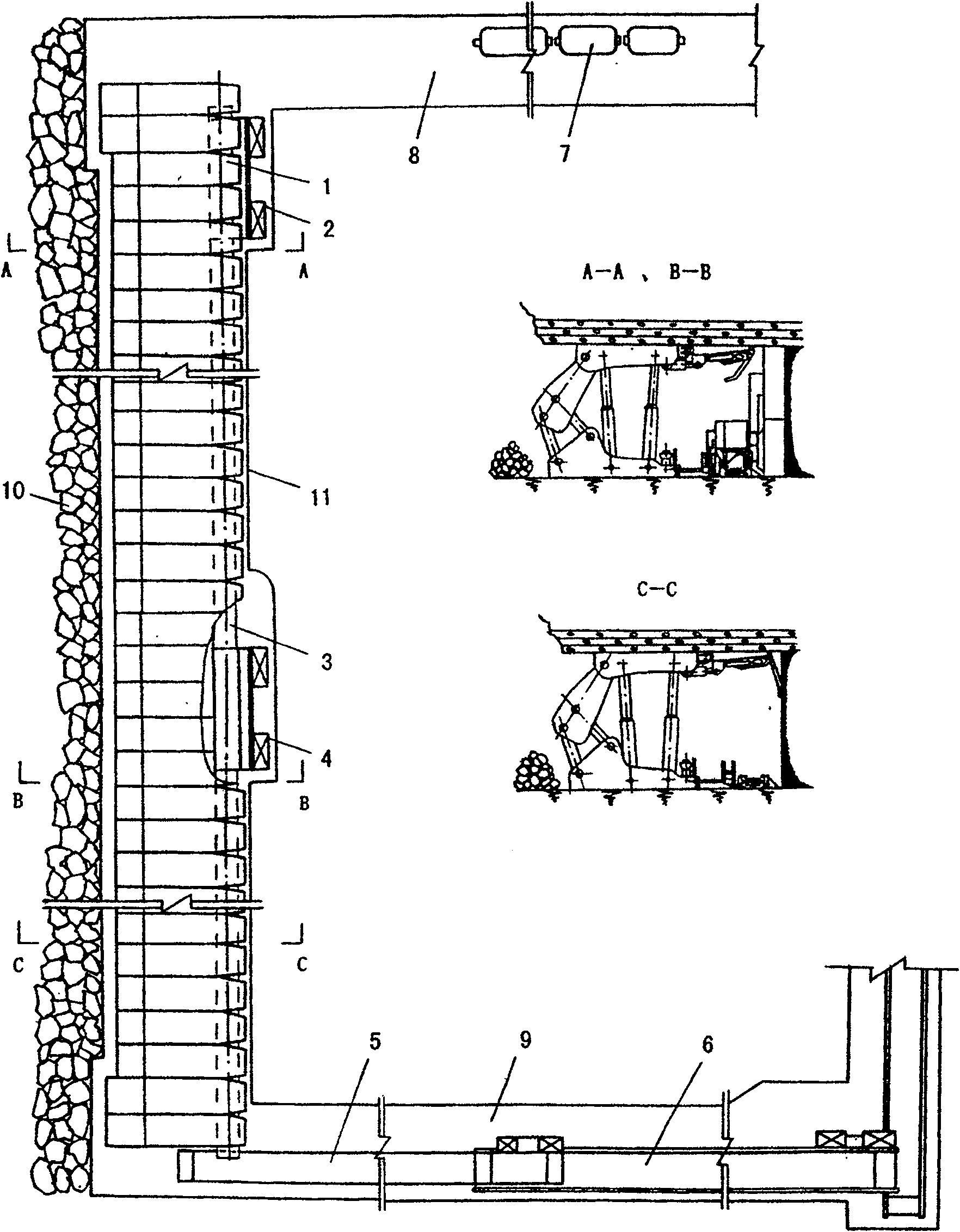

[0023] exist figure 1 Shown in the fully mechanized mining process of the present invention, the layout of fully mechanized mining equipment in the longwall mining face. On the longwall fully mechanized mining face, the hydraulic support 1 ...

Embodiment 2

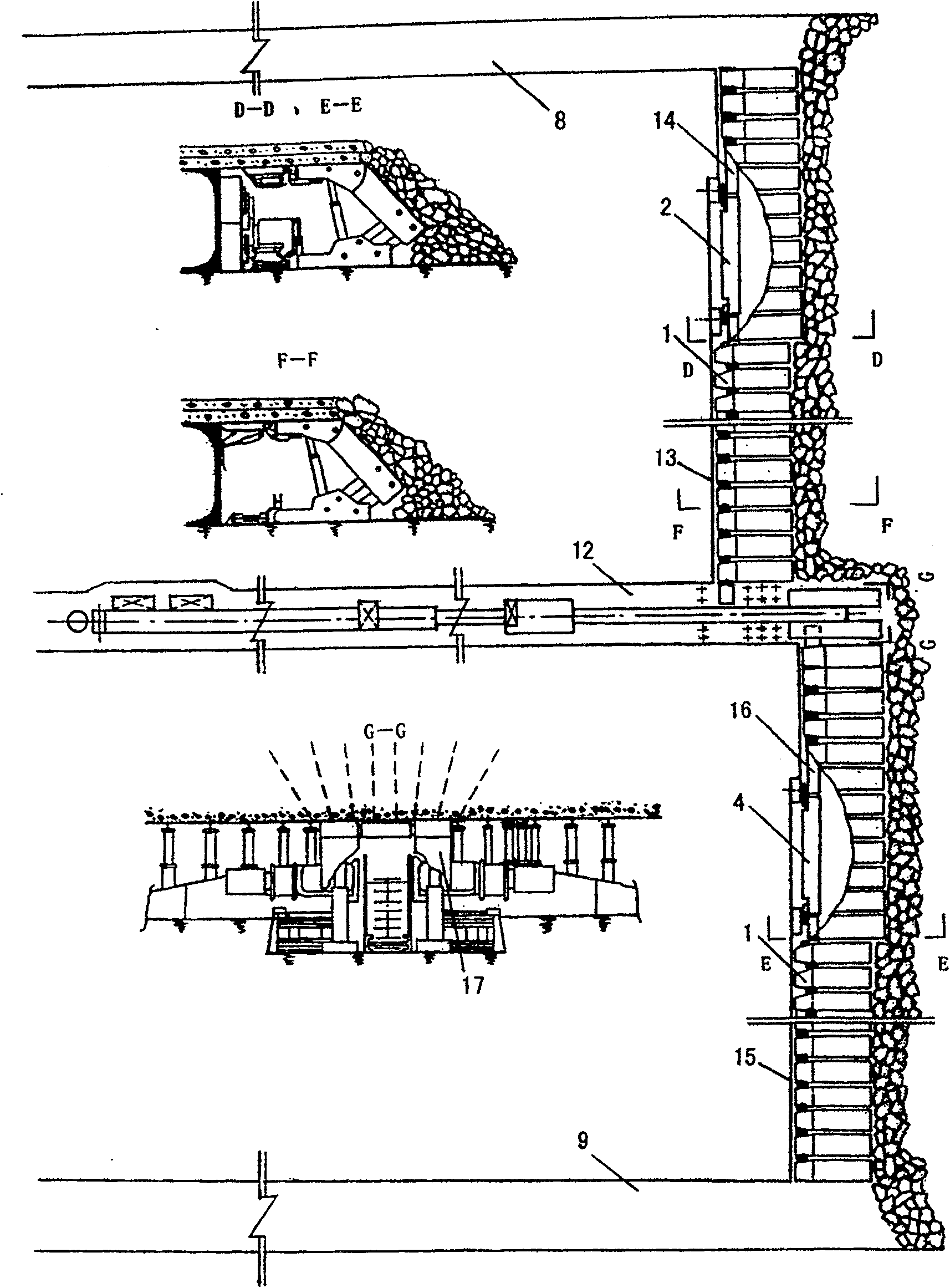

[0028] exist figure 2 Shown in the fully mechanized mining process of the present invention is the layout of the fully mechanized mining equipment in the direction of the longwall pair pulling back mining face. Arrange a middle lane 12 in the middle of the super-long fully mechanized mining face as a transport lane, and install a bridge loader 5, a retractable belt conveyor 6, a self-moving end support 17, and the like. The fully mechanized mining face is divided into the upper half working face 13 and the lower half working face 15 by the middle roadway 12, and a working face scraper conveyor 14, 16 is respectively arranged to transport the raw coal to the middle roadway. Reprinter 5, such as figure 2 As shown in the G-G cross-sectional view in the figure, a fully mechanized mining face with opposite pull is formed. The upper and lower troughs 8 and 9 are used as rail transportation or auxiliary transportation lanes, and at the same time as return air lanes; the middle la...

Embodiment 3、4

[0032] According to the layout and implementation of the fully-mechanized mining equipment in Embodiments 1 and 2, the longwall coal mining method of the present invention is used in the longwall fully-mechanized mining face in the direction of the thick coal seam inclined layered caving method mining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com